A flexible rubber coupling joins pipes and seals pipe joints in plumbing. You can use a plumbing rubber coupling to fix leaks. You can also use it to join pipes that do not match up. Many people pick flexible rubber couplings for fast repairs. They can also join pipes made from different things.

You save time because it is easy to install.

You spend less money than with other hard pipe joining ways.

You can use them in houses and in city water systems.

Key Takeaways

Flexible rubber couplings let you connect pipes fast and easy. This saves you time and hard work when fixing pipes. These couplings make tight seals that do not leak. This keeps your plumbing safe and working well. Flexible couplings take in movement and shaking. They help protect pipes from breaking and lower noise. You can use flexible rubber couplings with many pipe types. This makes them useful for homes and factories. Checking couplings often can help them last longer. It also keeps your plumbing system working great.

Flexible Rubber Coupling Overview

What Is a Flexible Rubber Coupling

A flexible rubber coupling connects two pipes in plumbing. This small pipe piece helps you join pipes fast. It lets you make your pipeline longer. When you add a pipe coupling, fluid moves better. You can fix leaks or join pipes that do not match up. Flexible couplings work for repairs and new plumbing jobs.

Flexible rubber couplings are special because they absorb shaking. They also fix pipes that do not line up. You can use them where pipes move or shift. These couplings handle pipes that are not straight. This keeps your plumbing working well. They also resist chemicals, so they last longer. You can pressurize and depressurize the pipes many times. The coupling does not wear out quickly.

Tip: You can use flexible rubber couplings for sewer lines and cast iron pipes. They help you make joints that do not leak or rot.

Key Features and Materials

Flexible couplings have many good features for plumbing:

You get joints that do not leak and stop water damage.

You can install them easily, even if pipes are not lined up.

You get protection from chemicals and bad weather.

You can use them in homes and big buildings.

The materials in a flexible rubber coupling matter a lot. Here is a table with the most common materials:

Material Type | Description |

|---|---|

Natural Rubber | Used in flexible couplings, giving stretch and strength. |

Synthetic Rubber | Mixed with natural rubber to make it bend and resist chemicals. |

PVC | Strong material, fights chemicals, sunlight, and sewer gases, so it lasts long. |

You find flexible couplings made from these materials for strength and bending. Rubber gives stretch, and synthetic blends protect against chemicals. PVC makes the coupling strong, so you can use it in tough places.

You use flexible couplings for many plumbing jobs, like joining sewer and cast iron pipes.

You get joints that do not leak or rot.

You keep your plumbing safe from chemicals and weather.

How Flexible Couplings Work

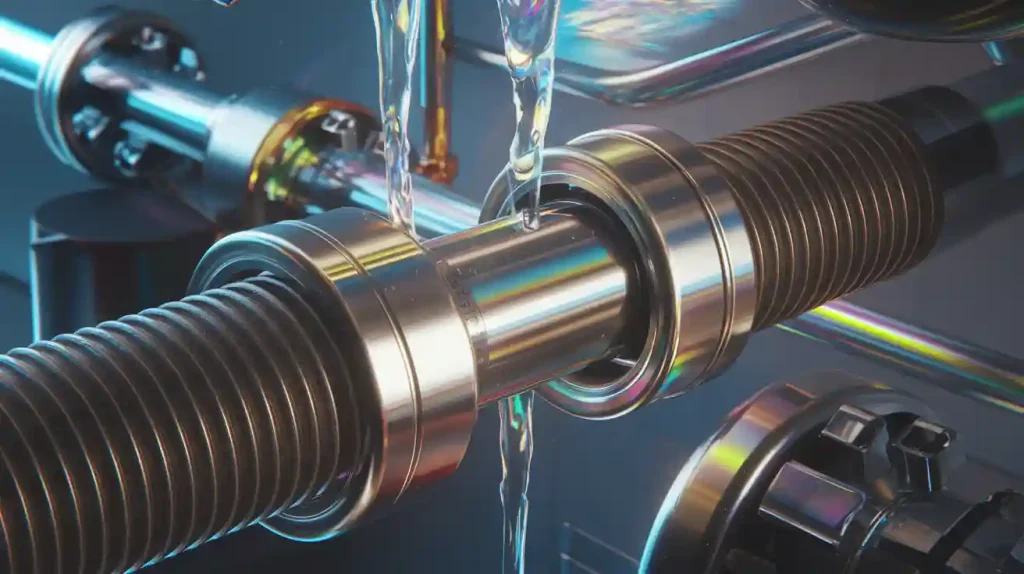

Pipe Connection and Sealing

When you use flexible couplings, you make strong connections between pipes. You can join pipes made from different materials, such as PVC or cast iron. The flexible rubber coupling fits over the ends of the pipes. You then tighten stainless steel clamps around the coupling. These clamps press the rubber against the pipe surface. This creates a watertight seal that stops leaks.

You can see how the sealing process works in the table below:

Component | Description |

|---|---|

Cast-A-Dapter | A rubber adapter that provides flexible, watertight sealing of pipes into treatment tanks. |

Installation Steps | Pipes are installed through the adapter, aligned, and secured with stainless steel clamps. |

Pressure Resistance | Seals to +13 psi in straight alignment and +10 psi at 7 degrees deflection. |

You get a tight seal when you use heavy duty rubber couplings and clamps. You can disconnect the pipes easily for maintenance. Sometimes, you may find that hose clamps do not always give a perfect seal. You need to check the tightness and make sure the clamp fits well. If you see leaks, you may need to adjust or replace the clamp.

Flexible couplings help you with quick repairs. You do not need special tools. You can fix leaks or join pipes that do not line up. You save time and keep your plumbing safe.

Tip: Always check the clamp after installation. A loose clamp can cause leaks. Tighten the clamp until the coupling feels secure.

Absorbing Movement and Vibration

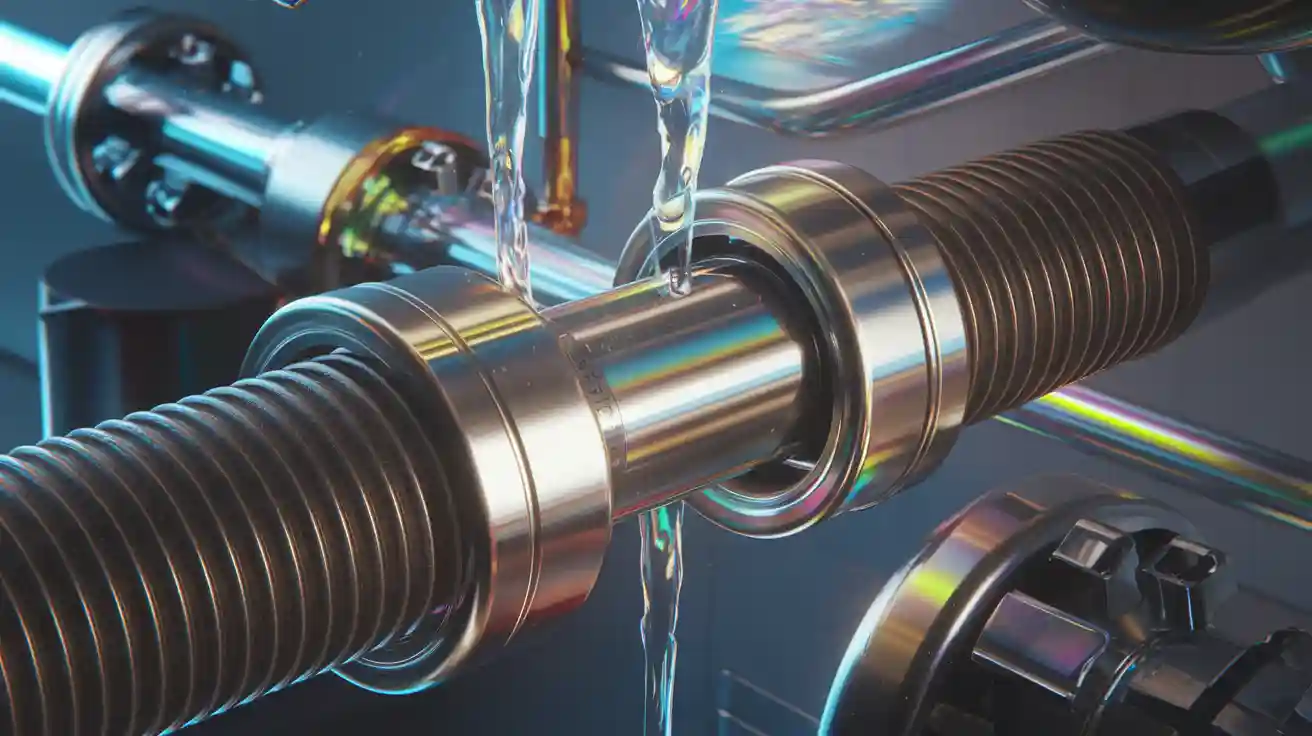

Flexible couplings do more than just seal pipes. You also use them to absorb movement and vibration in your plumbing system. Pipes can move because of temperature changes or shifting ground. Pumps and compressors can cause vibrations. If you use rigid connections, these forces can damage your pipes.

Flexible couplings act as buffers. They absorb and dissipate vibrations so the stress does not reach the pipes. You protect your plumbing from buckling or separation. You also reduce noise in your system. The flexible materials in the coupling isolate vibrations and noise, making your home or building quieter.

Here are some ways flexible couplings help with movement and vibration:

The sleeve bends to handle angular misalignment. You do not need to worry about leaks.

The sleeve stretches or compresses to fix lateral misalignment. Pipes stay aligned.

Some couplings adjust to length changes, so you keep a strong seal even if pipes move.

The connector absorbs vibrations from pumps and compressors. You extend the life of your pipes.

You prevent noise from traveling through the plumbing system.

You get reliable performance when you use flexible couplings for attaching pipes. You can handle misalignment, movement, and vibration. You keep your plumbing safe and quiet.

Note: If you want to protect your plumbing from damage, choose a pipe coupling that absorbs vibration and movement. You can use flexible couplings for both repairs and new installations.

Plumbing Rubber Coupling Benefits

Leak Prevention

You want your pipes to stay dry. Flexible couplings help stop leaks. They make a strong seal between pipes. The rubber fits tightly around the pipe ends. Stainless steel clamps squeeze the coupling onto the pipe. This keeps water from leaking out.

Researchers have tested flexible couplings for leaks. The table below shows what they found:

Study | Findings |

|---|---|

Fernando and Karabelas | Used sound waves to measure pressure and checked models for accuracy. |

Li et al. | Studied how pressing and pipe angle change sealing. |

Zhou et al. | Found wedge-shaped rings close gaps and seal better. |

Chen et al. | Looked at stress changes and sealing under water pressure. |

Persson et al. and Lorenz et al. | Studied how water and rough surfaces affect rubber seals. |

Flexible couplings stop leaks better than hard connectors. They work well because they can move with the pipes. The table below shows how flexible couplings help:

Mechanism | Benefit |

|---|---|

Misalignment Compensation | Stops stress and lowers breakdowns. |

Vibration Damping & Shock Absorption | Protects parts and makes less noise. |

Enhanced Load Distribution | Lowers stress and reduces failure. |

You can trust flexible couplings to keep pipes safe. They work even when pipes move or shake.

Easy Installation and Maintenance

You save time with flexible rubber couplings. You do not need special tools or skills. The coupling slides over the pipe ends. You tighten the clamps. You can fix pipes fast, even if they do not match up. Flexible couplings fit many pipe types, so you do not worry about size.

Taking care of your coupling is easy. You should do these checks:

Look for cracks or tears in the rubber.

Check for bulges that may mean damage inside.

See if the rubber is too hard or soft from age or chemicals.

Look at flanges and hardware for rust that could cause leaks.

Experts say you should check your coupling often:

Maintenance Task | Interval |

|---|---|

Visual Inspection | Every 2,500 hours |

Bolt Torque Inspection/Recertification | Every 5,000 hours |

Complete Coupling Disassembly & Inspection | Every 10,000 hours |

You keep your plumbing working well if you follow these steps. Flexible couplings make repairs and care simple. You spend less time and money.

Applications in Plumbing

Residential and Industrial Uses

You see flexible couplings in homes and businesses a lot. These connectors help fix many plumbing problems. Here are some ways people use them:

Connecting different pipe sections and materials

Improving waste and vent connections

Making sure seals do not leak

Sometimes, you need to join a PVC pipe to a cast iron drain. A plumbing rubber coupling makes this job simple. You do not have to worry about leaks or pipes that do not match. Flexible couplings also help when you put in new sinks or toilets. They let you join pipes that do not line up right.

In factories, you use flexible couplings for no-hub cast iron and schedule 40 PVC pipes. These couplings also work with clay, concrete, and PVC pipes. You get a tight and leak-proof seal, even if pipes are not straight. Flexible couplings give strong seals, so you can trust them in hard jobs.

Municipal Water and Sewer Lines

Flexible couplings are important in city water and sewer systems. You use them to join pipes in water and wastewater lines. These couplings handle movement, misalignment, and shaking. They help stop leaks and cracks that can happen with stiff connectors.

Here are some problems flexible couplings fix in city plumbing:

Handle movement from temperature changes

Fix misalignment from ground settling

Take in vibrations from machines nearby

A pipe coupling that bends keeps your system safe when pipes move. You protect the strength of the whole network. Flexible couplings let you make fast repairs and join different pipe types. This keeps water and sewer lines working well, even when things change.

Tip: If you work with city plumbing, pick flexible couplings to control pipe movement and stop leaks.

Choosing Flexible Couplings

Sizing and Compatibility

It is important to pick the right size for your flexible couplings. The size helps the coupling fit and seal your pipes well. First, measure the pipe diameter. Make sure the coupling matches your pipe size. You also need to know what material your pipe is made of. Pipes can be PVC, copper, or steel. Each pipe material needs its own sealing method. The table below shows how sealing changes with each pipe type:

Pipe Material | Required Sealing Method |

|---|---|

PVC | Specific sealing method |

Copper | Different sealing method |

Steel | Unique sealing method |

Before you buy a plumbing product, think about other things too. The table below lists important things to check:

Factor | Description |

|---|---|

Temperature and Pressure Range | Make sure the coupling works for your system’s temperature and pressure. |

Thermal Expansion and Movement | The coupling should allow pipes to move and expand. |

Environmental Conditions | Check if the pipes will touch chemicals or sunlight. |

Dynamic System Attitude | Think about vibration and pipes not lining up. |

Cost & Lifecycle Analysis | Compare price and how long the coupling will last. |

Maintenance Needs | Plan how often you need to check or change the coupling. |

Tip: Always match the coupling size and sealing method to your pipe material. This helps your water and wastewater systems work well.

Types and Features

There are different types of flexible couplings for plumbing jobs. Some couplings work with threaded connections to help stop leaks. Other couplings absorb vibration and let pipes move a little. These features protect your pipes and keep your plumbing working.

When you shop for couplings, look for special features. Some couplings resist scratches, chemicals, water, oil, and holes. Others stay strong in hot temperatures or tough soil. The table below shows what features to look for:

Feature | Description |

|---|---|

Material | Rubber |

Reinforcement | Stainless steel bands for extra strength |

Pressure rating | 150 PSI |

Temperature rating | -30 to 140 deg F |

Applications | Good for all Schedule 40 pipe jobs |

You get better results with couplings that have strong bands and seals. Chemical resistance helps in hard places. If you want a coupling that lasts, pick one that resists sunlight and sewer gases.

Note: YNF Machinery makes flexible rubber couplings with strong features for many plumbing jobs. You can trust their products to last and work well.

Flexible rubber couplings help a lot in plumbing. They are easy to put in and stop leaks well. You also save money when you use them. These couplings work for many years in different places:

Application Type | Expected Lifespan |

|---|---|

Residential Plumbing | 15–20 years |

Commercial HVAC Systems | 10–15 years |

Industrial Piping | 5–10 years |

Underground Infrastructure | 8–12 years |

You can fix pipes fast and keep things working right. Flexible couplings help you save water and cut down on waste. If you want repairs you can trust, use flexible rubber couplings for your next job.

FAQ

What pipes can you connect with a flexible rubber coupling?

You can join PVC, cast iron, clay, and concrete pipes. Flexible couplings work with many pipe types. You do not need special tools for most connections.

How do you install a flexible rubber coupling?

Slide the coupling over the pipe ends. Tighten the stainless steel clamps with a screwdriver. Check the seal for leaks. You finish the job quickly.

Can flexible rubber couplings handle pipe movement?

Yes. The rubber absorbs vibration and movement. You protect your pipes from damage. Flexible couplings keep your plumbing safe when pipes shift or shake.

How long does a flexible rubber coupling last?

Most couplings last 10 to 20 years. You get longer life with regular checks and proper installation. Rubber and stainless steel resist wear and chemicals.

Where can you buy reliable flexible rubber couplings?

You can buy high-quality flexible rubber couplings from YNF Machinery. Their products work well for plumbing jobs and last a long time.