You use your excavator every day. Good equipment helps you finish work on time. It also helps you avoid costly delays. Regular maintenance keeps your excavator track motor working well. It protects the excavator undercarriage from damage. Easy maintenance tips can help you stop expensive repairs. They also help your machine last longer. Taking care of your excavator is worth it in the end.

Key Takeaways

Clean the excavator undercarriage every day. Remove things like mud, rocks, and wood. This stops damage. It saves fuel. It helps you find problems early.

Look at the track motor every day. Check for leaks. Listen for strange sounds. See if parts are loose. Finding problems early saves money. It keeps your excavator working.

Check track tension often. Adjust it when needed. Good tension makes parts last longer. It stops slipping. It helps your excavator work better.

Put grease on pins, bushings, and grease points every day. Use the grease the manual says to use. Grease lowers friction. It stops cracks. It protects hydraulic parts.

Follow the maintenance schedule from the manufacturer. Read and use the operator guidelines. Taking care of your excavator keeps it safe. It makes it last longer.

Clean the Excavator Undercarriage

Remove Debris Daily

You should clean the undercarriage every day. This helps your excavator work well. Dirt, rocks, mud, wood, and concrete chunks can pile up. These things get stuck in the tracks and other spots. If you leave debris, it can freeze or get hard. This can make rollers stop moving and bolts get loose. Extra debris makes your machine use more fuel. Cleaning the tracks stops these problems.

Tip: Use a shovel for hard stuff like rocks and wood. Pressure washers are good for dirt and loose debris. In cold weather, clean before mud and debris freeze. This keeps rollers and bolts safe.

Cleaning each day takes about ten minutes. Check the undercarriage after every shift. Look for packed mud, clay, or snow. Take out anything you see. Cleaning helps you find problems early. It keeps your excavator working well.

Common debris to look for:

Rocks

Mud and thick mud

Dirt

Wood

Concrete chunks

Trash

Sticky messes

Cleaning the tracks every day is very important. It helps you avoid expensive repairs and lost time.

Prevent Damage and Downtime

Cleaning the undercarriage keeps your excavator safe. Debris rubs on parts and wears them out faster. When you clean, you stop damage and keep parts lined up. Regular cleaning stops rollers from freezing and bolts from getting loose. This keeps your machine working right.

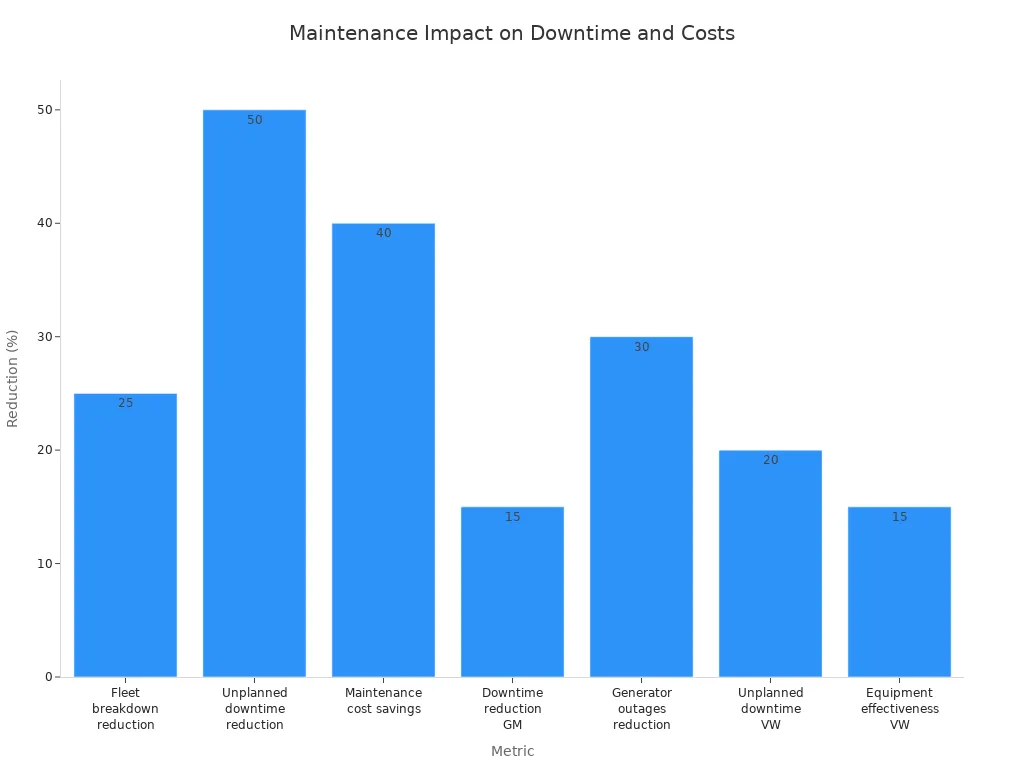

Studies show daily cleaning can lower equipment failures by 30%. Cleaning also helps you find problems before they get worse. You save money and your excavator lasts longer. Cleaning and checking the undercarriage every day is the best way to stop downtime.

Note: Cleaning the undercarriage is not just for looks. It helps with safety, saves fuel, and makes your machine last longer.

Inspect Excavator Track Motor

Check for Wear and Leaks

You should check your excavator track motor every day. Look at it before you start work. See if there are oil spots under the excavator after it sits overnight. Oil spots can mean leaks in the hydraulic or gear oil systems. Listen for strange sounds like grinding, squeaking, or knocking. These sounds can mean parts inside are worn out.

Check the fluid levels during your inspection. If the hydraulic fluid or gear oil is low, it can hurt the system. Look at hoses and fittings for cracks, bulges, or if they are loose. Wipe seals and hoses with a cloth to get rid of dirt. This makes it easier to see leaks. If you find leaks, tighten any loose parts or change broken seals and hoses right away. Watch the final drive oil levels to stop overheating and breakdowns.

Tip: Checking the whole undercarriage helps you find leaks and worn parts early. Finding problems early saves money and keeps your excavator working longer.

Key indicators of wear and leaks:

Strange noises from bearings or hydraulic pumps.

Fluid leaks under the excavator.

Cracked or loose hoses and fittings.

Worn seals or gaskets.

Low fluid levels.

Oil marks behind gears or drops on tracks.

Spot Loose or Damaged Parts

Look at the undercarriage for loose bolts, broken track shoes, or missing parts. Use your eyes to check if everything is there. If you hear odd noises, try to find where they come from. Take off covers or anything in the way to see better.

If you find loose or broken parts, stop using the excavator right away. Get repairs or new parts before you use it again. Look at the operator manual if you need help with where parts go. A full check makes sure all parts are tight and no debris is left.

Note: Checking and fixing things often stops big repairs. Look at the undercarriage every day to find problems early.

Checking the undercarriage and doing daily checks help keep your excavator track motor working well. Acting early protects your machine and stops downtime.

Maintain Track Tension

Prevent Premature Wear

You should check track tension often. If you do not, your excavator can wear out quickly. Loose tracks can slip and rub on other parts. Tracks that are too tight put extra stress on the motor and other parts. Both problems make your excavator not last as long.

Here is what the manufacturer says about track tension and its effects:

Aspect | Details |

|---|---|

Impact of Improper Track Tension | Causes more wear, stress failures, uneven wear, slippage, and shorter lifespan of motors |

Lifespan Improvement | Proper tension can improve track lifespan by up to 23% |

Manufacturer Specs | Sag should be 10-20mm; adjust tension for mud or hard ground |

Consequences of Incorrect Tension | Slippage can increase fuel use by 18% and speed up wear |

Maintenance Recommendations | Inspect and adjust tension regularly to factory specs |

Warranty Implications | Damage from bad tension may not be covered by warranty |

Keeping the right track tension saves money. It also helps your excavator last longer. Always follow the manufacturer’s rules for sag and tension.

Tip: Check track tension before you start a new job. If you see tracks slipping, check them right away. Daily checks help you find problems early.

Adjust as Needed

You can fix track tension with easy steps. Follow these to keep your excavator working well:

Look at the track adjuster and grease cylinder for dirt or damage.

Clean the grease fitting (Zerk) and make sure it works.

Add grease to the adjuster to move the front idler out and tighten the track.

To make the track looser, let grease out by loosening the fitting. Sometimes you need a pro for this.

Measure the sag between the middle roller and the track. Most machines need 15-30 mm of space.

Change the tension for the ground. Use tighter tension on hard ground and looser on soft ground.

Always wear safety gear and park on flat ground before you adjust.

Check for worn links or stretched tracks. These can stop you from adjusting more.

Check track tension at least once a month. Many people check it every day or every 50 hours. Regular checks stop slippage, lower wear, and keep your excavator safe.

Note: If the track is too tight, it can wear out faster and slow your machine. If it is too loose, it can come off and break things. Always use the operator’s manual for the right way to adjust.

Lubricate Daily

Pins and Bushings

You need to lubricate pins and bushings every day. These parts move a lot and carry heavy loads. Without enough grease, they wear out fast. Friction builds up and causes metal parts to grind against each other. This leads to cracks and even metal fatigue. You might see cracks at weld seams or near the boom. If you ignore these signs, the damage can become dangerous.

Tip: Always use the grease recommended by your manufacturer. High-quality grease protects pins and bushings from dirt, water, and heat.

Neglecting daily lubrication can cause:

More friction and faster wear on pins and bushings

Extra movement in joints, making them loose

Cracks and metal fatigue from stress

Premature failure of important parts

Higher repair costs and more downtime

Proper lubrication also helps your hydraulic system. Greased pins and bushings reduce strain on hydraulic cylinders. This keeps your excavator running smoothly and extends the life of your hydraulic components.

Grease Points

You should check and grease all critical points on your excavator every day. Important grease points include boom pins, stick pins, bucket pins, and track drives. These areas face the most stress and need extra care. If you miss daily greasing, you risk permanent damage. Repairs for these parts can cost thousands of dollars.

A simple daily routine can help:

Wipe off old grease and dirt from fittings.

Apply fresh grease until you see a small amount coming out.

Use the right pressure to avoid damaging seals.

Pay special attention to the track drive and hydraulic connections.

Note: Using high-quality grease and following the right schedule keeps your excavator safe. It also prevents metal-on-metal contact, which can destroy bearings and track motors.

Field studies show that proper lubrication greatly reduces wear and tear on track motors. Clean grease keeps out dirt and metal particles. This protects your hydraulic system and moving parts. When you keep up with daily greasing, you lower the risk of breakdowns and save money on repairs.

Grease Point | Why It Matters | How Often |

|---|---|---|

High stress, costly to fix | Daily | |

Stick Pins | Frequent movement | Daily |

Bucket Pins | Heavy loads | Daily |

Track Drives | Protects track motor & hydraulic | Daily |

Monitor Wear Patterns

Identify Misalignment

You can find misalignment by checking wear on the tracks. Look at both sides of the track links. If one side wears down more, the undercarriage may not be lined up. Inside edge wear means the track or undercarriage needs to be fixed. Sprocket misalignment can make the track come off or wear out fast. If idlers wear unevenly, there could be a misalignment problem.

Tip: Take pictures of the undercarriage and track wear every month. Compare these photos to see changes and spot misalignment early.

Checking often helps you find problems before they get worse. Watch for strange shaking or track sag that is not even. These signs can mean misalignment. If you see scalloped or uneven wear, check all undercarriage parts for alignment.

Common wear patterns and what they mean:

Too much case drain and scratches inside: Dirty oil, less power, slow track speed.

Worn gears and bearings: Loud screeching, slow movement.

Oil leaks and pressure loss: Broken seals, weak motor performance.

One track moves faster: Stuck spools or pistons, two-speed system problems.

Address Issues Early

Act quickly if you see strange track wear or misalignment. Fixing problems early saves money and keeps your excavator working. If you hear grinding or whining, stop the machine and check the drive case. Look for gear alignment problems or worn parts. Fix or replace gears if needed.

Follow these steps when you see early signs:

Check hydraulic fluid levels on flat ground. Add the right fluid if needed.

Look at the motor for damage or loose parts.

Drive the excavator and watch for steering or power problems.

Fix leaks by tightening parts or changing seals and hoses.

Clean the undercarriage to stop debris from causing more damage.

Watch speed, power, and fluid levels to catch problems early.

Note: Finding track slippage, uneven wear, or leaks early lets you fix problems before they get worse. Keeping the undercarriage clean and checking for wear helps you avoid big repairs.

A simple table helps you track common issues:

Symptom | Possible Cause | Action Needed |

|---|---|---|

Uneven track wear | Misalignment | Realign components |

Screeching noises | Worn gears/bearings | Replace parts |

Oil leaks | Damaged seals | Fix or replace seals |

Slow movement | Hydraulic issues | Check fluid levels |

Fixing problems early helps your undercarriage last longer and stops downtime. You also save a lot of money by stopping big damage.

Best Operating Practices for Excavator Maintenance

Follow Operator Guidelines

You can help your excavator work well by following the operator guidelines. Manufacturers give tips to help you get the most from your track motors. Always check track tension before you start working. The right tension, about 20-30mm sag, stops extra stress on the drive motor. It also keeps tracks from slipping off. Clean the undercarriage after each shift. This is important if you work in clay, sand, or rocky soil. Cleaning removes debris that can cause wear and tension problems.

Tip: Use only fluids and filters the manufacturer says to use. This keeps the hydraulic system safe and helps your excavator work its best.

Check the undercarriage and track motors every day. Look for wear, leaks, or misalignment. If you see uneven wear or flat spots, check alignment and tension right away. Write down your maintenance in a logbook. This helps you remember service times and find problems early.

Some best practices from manufacturers are:

Change track tension for different conditions. Use looser tension in cold weather and tighter tension in rocky places.

Do not make sharp turns or pivot. Use wide turns or three-point turns to lower stress on tracks and motors.

Follow break-in steps for new tracks. Go slow and check tension often for the first 50 hours.

Replace worn parts quickly to stop more damage.

Avoid Common Mistakes

You can stop expensive repairs by avoiding common mistakes. Many operators forget to change gear oil often. Old oil cannot protect gears and bearings. This can cause damage. Always check and change gear oil when needed.

Some operators ignore leaks in the final drive or hydraulic system. Leaks cause fluid loss and dirt inside. This can hurt seals and other parts. If you see oil spots or hear strange sounds, stop and check the machine.

Mistakes to avoid:

Not changing gear oil.

Not checking the case drain filter.

Ignoring leaks.

Using wrong track tension.

Leaving debris in tracks.

Note: Good maintenance means checking for leaks, adjusting track tension, and cleaning tracks every day. These steps help you stop breakdowns and keep your excavator working longer.

A simple table helps you remember what to check:

Task | Why It Matters |

|---|---|

Change gear oil | Stops gear damage |

Check for leaks | Prevents fluid loss |

Adjust track tension | Lowers wear |

Clean tracks | Makes tracks last longer |

By following these tips, you protect your excavator and make sure it works well on every job.

Follow Manufacturer’s Schedule

Use the Manual

Always use the operation and maintenance manual for your excavator. The manual gives you easy steps to care for your track motors and undercarriage. You will see sections like “Excavator Undercarriage Care” and “Track and Undercarriage Maintenance.” These parts show you how to check for oil leaks and inspect seals. They also tell you how to keep track tension right. The manual explains when to clean, lubricate, and inspect each part.

Tip: Look at the manual before starting a new job. Check it if you notice something strange. The manual helps you avoid mistakes and keeps your excavator working well.

There are tables in the manual that show when to do each task. Some checks are daily, others are weekly or monthly. Following these steps helps you find problems early and stop breakdowns.

Key manual sections to review:

Full undercarriage inspection

Drive motor oil leak and seal check

Track tension adjustment

Cleaning and lubrication schedules

Stay Consistent

Doing regular maintenance is the best way to protect your excavator. Regular checks stop early wear and keep your track motors working well. You can use tools like GoCodes Asset Tracking or apps like Cat Inspect. These tools let you scan a QR code to see what maintenance is needed. They help you track inspections, set reminders, and remember important tasks.

Note: Setting reminders or using a log makes it easy to remember each service. You can write down inspections or use an app for alerts.

Here is how following the schedule helps your excavator:

You check and replace parts on time to protect hydraulic systems.

You check oil levels and filters to stop failures and help your track motors last longer.

You find wear or leaks early to keep your equipment safe.

You avoid expensive repairs and keep your excavator working well.

You get help from technicians or dealers to make maintenance better.

A regular routine keeps your excavator in good shape and helps you get the most from your machine.

You get lots of good things when you use these seven tips for your excavator track motor.

Your equipment lasts longer and does not get damaged as fast.

You have less downtime and do not spend as much on repairs.

Your machine works better and does not stop as much.

You can find problems early and stop big breakdowns.

You stay safer and get more out of your money.

Taking care of your excavator track motor often can cut downtime in half and lower repair bills by almost half. Start doing these things now to keep your equipment working well for a long time.

FAQ

How often should you check excavator track motor oil levels?

You should check oil levels every day before you start work. Low oil can damage the motor and cause breakdowns. Keeping oil at the right level helps your excavator last longer.

What signs show your track motor needs repair?

Look for oil leaks, strange noises, slow movement, or uneven track wear. These signs mean you should stop and inspect your excavator. Fix problems early to avoid bigger repairs.

Tip: Write down any changes in sound or movement in your maintenance log.

Can you use any grease for excavator track motors?

You should use only the grease recommended by your manufacturer. Using the wrong grease can cause more wear and damage. High-quality grease protects moving parts from dirt and heat.

Grease Type | Use For |

|---|---|

Lithium-based | General purpose |

Molybdenum-based | Heavy loads |

Why does track tension matter for excavator motors?

Track tension affects how your excavator moves and how long the motor lasts. Loose tracks can slip off. Tight tracks wear out faster. Check and adjust tension often to keep your machine safe.

Loose tracks: More slippage, higher wear

Tight tracks: Extra stress, faster damage