Excavator track shoes are an important part of the excavator undercarriage. They are found under the machine. They hold up the heavy equipment and help it move on different surfaces. Good track shoes excavator picks give you better grip and keep your excavator steady. When you pick the right track shoes, you get these good things:

You spread out the excavator’s weight so it does not sink on soft ground.

You hold onto slippery or steep ground for safer use.

You protect the ground and your machine from getting hurt.

You move with more control and use less energy.

Stronger track shoes last longer and need less fixing, which helps your excavator work better and saves you money.

Key Takeaways

Excavator track shoes hold up the machine’s weight. They help it move safely on many surfaces. Picking the right track shoes gives better grip and balance. It also keeps the machine and ground safe. Steel track shoes last a long time. They are good for rough ground. Rubber shoes are quieter. They protect soft surfaces. There are different track shoe types for each job. Single grouser is for hard ground. Double grouser is for mixed surfaces. Triple grouser is for soft or bumpy soil. Check and care for track shoes often. This stops damage, saves money, and keeps your excavator working well.

Excavator Track Shoes

What Are Track Shoes

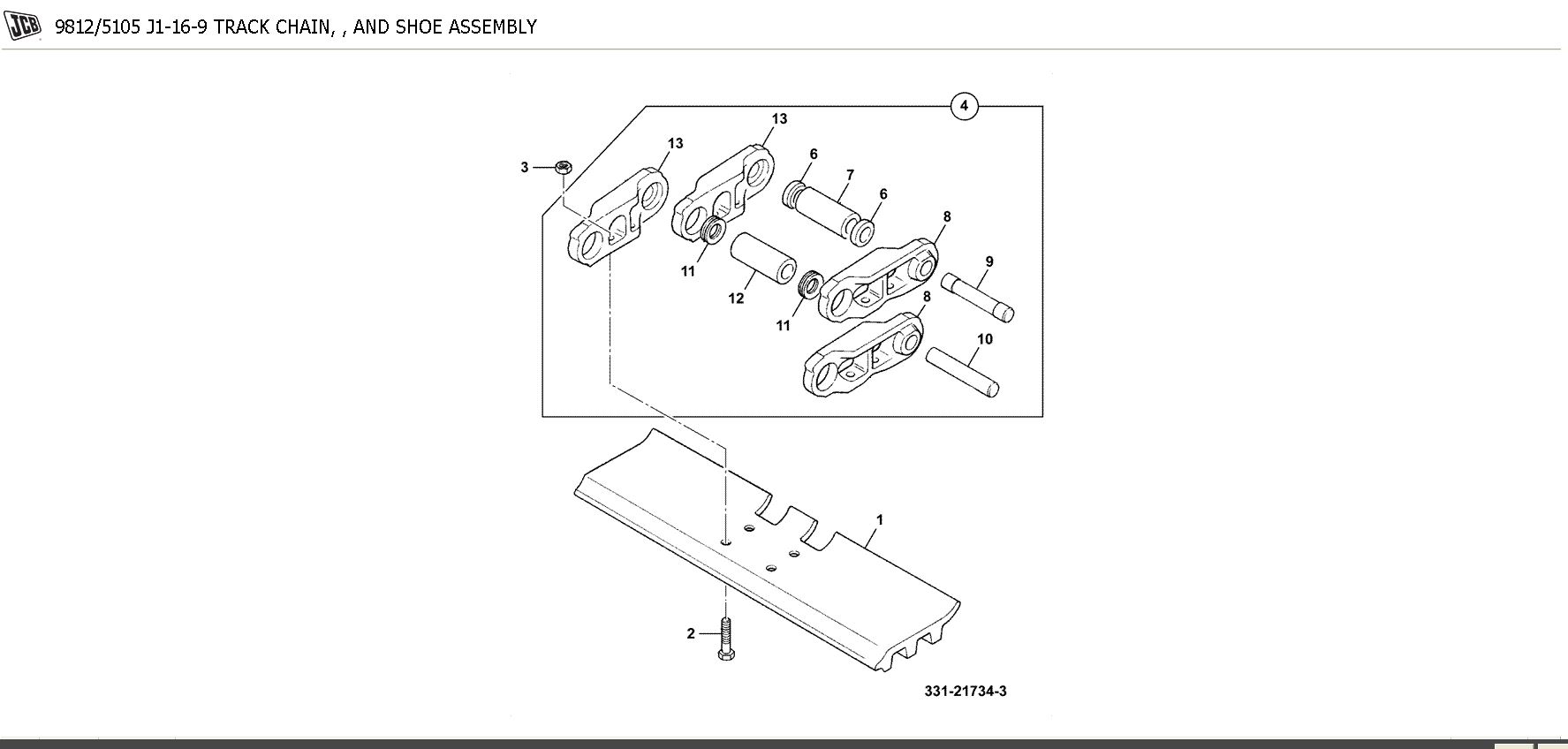

Track shoes are strong, flat plates at the bottom of excavator tracks. They connect to link assemblies and make a belt around the undercarriage. These plates hold up the excavator’s weight and help it move on many surfaces. When you look at a track shoes excavator, you see these plates touching the ground.

Manufacturers use tough materials for track shoes. The most common are steel and rubber. Each one has its own good points:

Steel track shoes last a long time. They work well on rough, rocky, or muddy ground. They give great grip and do not wear out fast.

Rubber track shoes are lighter and quieter. They protect paved roads, soak up bumps, and make the ride smoother. You can use them in cities or on soft dirt when you do not want to hurt the ground.

Here is a table that shows the main good things about each material:

Material | Advantages |

|---|---|

Steel | Very strong and hard to wear out; lasts a long time; great grip on rocks or hard dirt; easy to clean; helps keep the machine steady in tough places |

Rubber | Soaks up bumps and shakes; smoother and quieter; makes the driver less tired; gentle on roads and soft ground; good for soft dirt, mud, and cities; does not hurt the ground or make much noise |

You can pick steel or rubber depending on your job site and work. Some track shoes have rubber pads you can bolt or clip on. This gives you more ways to install them and helps them last longer.

Function in Excavator Tracks

Track shoes are very important for how excavator tracks work. They do more than just hold up the machine. You need them for grip, balance, and to protect the ground. When the excavator moves, the track shoes grab the ground and spread out the weight. This stops the excavator from sinking in soft dirt or tipping on bumpy ground.

Track shoes connect to other undercarriage parts. Here is how the main parts work together:

Component | Role and Interaction with Track Shoe and Undercarriage Parts |

|---|---|

Track Shoes | Help the machine float, grip, and protect the link assembly; attach to link assemblies; hold up the machine; act as a rail for moving; help push dirt; some have special shapes or holes for better use. |

Link Assemblies | Moved by sprockets and final drive; hold up the machine; act as a rail for the machine; track shoes attach here. |

Sprockets | Move power from the engine to link assemblies; make the tracks move. |

Idlers | Guide the track in and out of rollers; sometimes hold up the machine; control how tight or loose the track is. |

Track Rollers | Hold up and guide the machine on the track. |

Carrier Rollers | Hold up and guide the machine on the track; help keep the track tight. |

Your excavator works better when track shoes spread out the weight. This design makes the undercarriage last longer and wear out less. Some track shoes have treads or holes that clean themselves. These keep dirt from piling up, so you get good grip even in mud or sand.

Track shoes also soak up bumps and shakes. This keeps the inside parts safe and makes your job more comfortable. When you pick the right track shoes excavator, you get better balance, lower the chance of tipping, and make sure your machine can do hard work.

Tip: Check your track shoes often for damage or wear. Good track shoes help your excavator tracks work well and stay safe.

Importance

Traction and Stability

Excavators need good traction and stability to work safely. Track shoes help a lot with this. The tread pattern on your track shoes affects how well your machine grips the ground. Different patterns help your tracks move in mud, snow, rocks, or on pavement. Here are some ways tread patterns help:

Rubber track tread patterns change how much grip you get. More friction means your tracks hold better.

Lugs on the tracks dig into soft ground. More lugs give you more grip.

Grooves and spaces in the tread push away water, mud, or ice. This keeps your tracks clean and gripping well.

Block tread patterns cover more ground. This helps you stay steady on hard surfaces and feel less shaking.

C-lug and zig-zag patterns help you move on soft or slippery ground.

The right track shoes help your excavator move better. Your machine can climb hills, turn, and work on bumpy ground without slipping. This keeps you and your machine safe. If you use old or wrong track shoes, you lose grip and control. Your excavator might slip or tip, which is dangerous.

You can see how each track shoe type works best on certain ground:

Track Shoe Type | Terrain Suitability | Impact on Stability and Traction |

|---|---|---|

Single Grouser | Rough, muddy, uneven terrain | Gives the most grip, great for tough ground |

Double Grouser | Mixed surfaces (gravel, clay, compacted soil) | Balances grip and turning |

Triple Grouser | Firm ground | Makes you stable with less grip |

Swamp Shoes | Soft, swampy, wetland areas | Spreads weight, stops sinking, helps on soft ground |

Rubber Shoes | Urban, indoor environments | Quieter, protects floors, good for gentle surfaces |

Picking the right track shoes gives you the best grip and balance for your job.

Weight Distribution

Track shoes do more than just help you grip the ground. They also spread out your excavator’s weight. This stops your machine from sinking in soft dirt or sand. Wide track shoes help your tracks float on loose ground. This makes your excavator easier to control and keeps it from getting stuck.

If your track shoes wear out or do not fit right, you can have problems with weight. Here is what can happen:

Extra stress on sprockets, bushings, and rollers

Loose pins and shoe parts

Shorter life for track joints

Broken shoes and tracks

Undercarriage parts can break

These problems can make your machine line up wrong and move harder. Your excavator may break down sooner. Keeping your track shoes in good shape helps your excavator run well and last longer.

Ground Protection

You want to protect the ground when you work, especially in cities or on soft dirt. Track shoes help by spreading your excavator’s weight over a bigger area. This lowers ground pressure and stops deep ruts or holes.

Wider track shoes work best on soft or sandy ground. They keep your excavator from sinking and hurting the soil. If you work in places like parks or city streets, rubber track shoes or bolt-on rubber pads are smart. These pads soak up bumps and protect the ground from scratches or dents.

Here is a table that shows how different track pad types protect the ground:

Track Pad Type | Advantages | Disadvantages | Ground Protection Suitability |

|---|---|---|---|

Bolt-on Pads | Strong, fit well | Harder to put on | Best for gentle ground (rubber pads) |

Chain-on Pads | Good on rough ground | Needs more care, wears out faster | Not as good for soft surfaces |

Clip-on Pads | Easy to put on, flexible | Wears out faster, not as tight | Good for many jobs, less for gentle ground |

Material Type | Advantages | Disadvantages | Ground Protection Suitability |

|---|---|---|---|

Rubber | Soaks up bumps, protects ground, quiet | Wears out faster in tough jobs | Best for gentle places |

Polyurethane | Tough, lasts long, bends well | Costs more, not as soft as rubber | Good, but not as gentle as rubber |

Steel | Very strong | Can hurt the ground | Not for gentle ground |

When you pick the right track shoes, you protect your machine and the ground. This lets you work in more places and keeps people happy. Good ground protection also means less cleanup and fixing after the job.

Note: Always check your track shoes for damage. Changing them on time keeps your excavator safe, helps you move better, and protects the ground.

Track Shoes Excavator Types

Single Grouser

Single grouser track shoes have one raised bar across each shoe. You get the highest traction with these shoes, especially on tough ground. They dig deep into soil or rock, which helps your excavator push and pull heavy loads. You can choose from moderate-service, extreme-service, or super-extreme types. Moderate-service shoes work well in places with less impact. Extreme-service and super-extreme shoes last longer in harsh conditions.

You should use single grouser shoes when you need strong grip and deep penetration.

These shoes fit best for bulldozing, rock drilling, or working on rough terrain.

They do not turn as easily, so you may find maneuvering harder.

Double Grouser

Double grouser track shoes have two bars on each shoe. This design gives you a balance between grip and movement. You get excellent traction on hard and rocky ground, which helps reduce slipping. These shoes work well for road construction and mining where you need both stability and some maneuverability.

Double grouser track shoes wear out faster because more of the shoe touches the ground.

You may notice lower fuel efficiency compared to other types.

They work best on firm, solid ground but not as well in mud or soft soil.

Triple Grouser

Triple grouser track shoes have three bars. You get the best maneuverability with these shoes. They spread the weight of your machine, which helps prevent sinking into soft ground. You should use triple grouser track shoes on mud, loose soil, or uneven terrain. These shoes help your excavator stay stable and move smoothly over rough areas.

Triple grouser track shoes work well for construction sites, farms, and quarries.

They give you good traction and control on hills or rocky ground.

You can use them for loaders, haul trucks, and bulldozers that need to move over many types of surfaces.

Here is a table to help you compare the three types:

Grouser Type | Traction Level | Maneuverability | Best Terrain |

|---|---|---|---|

Single Grouser | Highest | Lower | Tough, rocky, or muddy |

Double Grouser | Moderate | Balanced | Hard, rocky, or solid |

Triple Grouser | Good on soft ground | Highest | Mud, loose soil, uneven |

Rubber vs. Steel

You can choose between rubber and metal track shoes for your excavator. Rubber tracks give you a smoother, quieter ride. They protect delicate surfaces like pavement or lawns. You can move faster and turn more easily with rubber tracks, but they wear out faster and do not grip as well on mud or rocks.

Metal track shoes, often called steel tracks, last much longer. They give you better traction on rough, rocky, or muddy ground. You may notice more vibration and noise with metal track shoes, but they handle tough jobs and heavy loads better. Steel tracks cost more at first, but you replace them less often.

Feature | Rubber Tracks | Steel Tracks (Metal Track Shoes) |

|---|---|---|

Durability | Shorter lifespan | Longer lifespan |

Traction | Lower on mud and rocks | Superior on rough terrain |

Surface Impact | Gentle on delicate surfaces | Can damage soft or paved ground |

Operator Comfort | Smoother, quieter ride | More vibration and noise |

Maintenance | More frequent replacement | Easier to repair, less frequent |

Tip: Pick the right track shoes for your job site. The right choice helps your excavator last longer and work better.

Choosing Track Shoes

Job Site Conditions

You need to look closely at your job site before picking track shoes. Every work environment brings its own challenges. Start by checking for sharp objects, spills, or uneven ground. Construction sites often have debris and moving machines. Farms may have bumpy fields and chemicals. Think about the weather, too. Wet or muddy ground needs shoes that grip well and resist slipping. If you work in extreme heat or cold, choose shoes that handle those temperatures. Some sites have electrical hazards, so you may need special shoes for safety. Always pick shoes that fit well and feel comfortable. Good support helps you avoid foot pain and injuries.

Tip: The right track shoes help you stay safe and work longer without problems.

Here’s a checklist for job site conditions:

Check for sharp objects or spills.

Look for uneven or soft ground.

Think about weather and temperature.

Watch for chemicals or water.

Check for electrical hazards.

Pick shoes with good grip for the surface.

Make sure the shoes fit well and feel comfortable.

Machine Requirements

Your excavator has its own needs. Always match track shoes to your machine’s size and type. Check the manufacturer’s guide for the right shoe width and type. Make sure the shoes fit with the rollers, idlers, and sprockets. Track tension matters, too. If the tracks are too loose or tight, they wear out faster. Use strong bolts and high-quality steel for long life. Good fit and strong parts keep your heavy equipment running safely.

Specification Aspect | Details |

|---|---|

OEM Specification | Use shoes made for your machine’s brand and model. |

Track Shoe Width & Type | Pick the right width and grouser type for your job. |

Fitment | Make sure shoes fit well with all undercarriage parts. |

Track Tension | Keep tracks tight enough for smooth movement. |

Material Quality | Choose high-grade steel for strength and wear resistance. |

Shoe Width and Design

Shoe width changes how your excavator moves. Wide track shoes spread weight over a bigger area. This helps you float on soft or muddy ground and keeps you from sinking. Narrow shoes put more pressure on the ground. You get better grip on hard surfaces and can turn more easily in tight spots. If you use shoes that are too wide, you may have trouble turning and wear out parts faster. If shoes are too narrow, you might sink in soft soil. Always pick the narrowest shoe that still gives you enough support and grip for your job.

Note: For soft ground, use wider shoes with single grousers. For rocky or hard ground, choose narrower shoes for better traction.

Choosing the right track shoes improves your machine’s performance and helps the undercarriage last longer. You save money and avoid breakdowns by matching shoes to your job and machine.

Track Shoe Replacement

Signs of Wear

You need to know what to look for when replacing track shoes. Spotting problems early helps you avoid bigger repairs. Here are the most common signs of excessive wear and tear:

Cracked, broken, or loose track shoes

Loss of traction or worn traction bars

Wear on the leading and trailing edges of the shoes

Uneven wear patterns, like side wear from misalignment

Track tension issues, such as tracks that are too tight or too loose

Cracking or fraying in rubber tracks

Corrosion or metal fatigue in steel tracks

Missing shoes or loose bolts

Tip: Regular maintenance and inspection help you catch these problems before they get worse.

When to Replace

You should plan for track shoe replacement when you see thinning, cracks, or a loss of traction. If you notice any of the signs above, do not wait. Early detection prevents damage to your undercarriage and keeps your excavator safe. Most track shoes last between 2,000 and 3,000 hours, but rough terrain or heavy loads can shorten this time.

Component | Recommended Replacement Interval (hours) | Replacement Triggers |

|---|---|---|

Track Shoes | 2,000 to 3,000 | Thinning, cracks, loss of grip |

If you replace worn track shoes on time, you avoid costly repairs and reduce downtime. You also protect other parts, like rollers and sprockets, from extra stress.

Maintenance Tips

You can make your track shoes last longer with good habits. Follow these steps:

Clean the undercarriage after each use to remove mud and rocks.

Check and adjust track tension often. Use the manufacturer’s guide for best results.

Inspect both tracks for similar tension and wear.

Lubricate moving parts, such as pins and bushings, to prevent rust.

Rotate tracks if you work in one direction or on slopes.

Operate smoothly. Avoid sharp turns and dragging the bucket.

Note: Good care and early action save you money and keep your excavator working its best.

Track shoes are very important for your excavator’s safety and how well it works. Picking the right track shoes and taking care of them helps your machine last longer. Your excavator will also work better.

If you check your track shoes often, you can find problems early. This means you fix things before they get worse. You will have less time when your machine is not working. Your job site will be safer, too.

Taking care of your track shoes saves money on repairs. It also helps your equipment last longer.

Remember: If you keep your excavator in good shape, your projects go smoothly and your team stays safe.

FAQ

How often should you inspect excavator track shoes?

You should check your track shoes before each workday. Look for cracks, loose bolts, or worn treads. Early checks help you spot problems and keep your machine safe.

Can you mix rubber and steel track shoes on one excavator?

You should not mix rubber and steel track shoes. Mixing them can cause uneven wear and damage your undercarriage. Always use the same type on both tracks for best results.

What happens if you use the wrong track shoe width?

If you use shoes that are too wide, your excavator may have trouble turning. Shoes that are too narrow can cause your machine to sink in soft ground. Always match the width to your job site.

How do you clean excavator track shoes?

Use a pressure washer or stiff brush to remove mud, rocks, and debris. Clean after each use to prevent buildup. This helps your track shoes last longer and keeps your excavator running smoothly.