Fuel efficiency is crucial for your vehicle and excavator, and the performance of vehicle fuel pumps and excavator hydraulic pump systems plays a major role in how much fuel you use and spend. By understanding pump technology and keeping up with regular maintenance, you can save both fuel and money. Recent studies highlight how pump systems can significantly impact energy consumption:

Evidence | Description |

|---|---|

Energy Consumption | Excavators equipped with servo motor pump-control cylinders use about 65% less energy than older systems. |

Pump-Controlled System | Pump-controlled hydraulic cylinders in excavators improve energy efficiency and reduce fuel usage. |

Hybrid Excavators | Hybrid hydraulic excavators, featuring advanced hydraulic pump technology, save energy, use less fuel, cut emissions, and lower costs. |

Innovative technology also helps you maximize fuel savings:

Connected vehicles use real-time data to optimize vehicle fuel pumps and manage fuel consumption.

Artificial Intelligence predicts fuel needs for more efficient use of vehicle fuel pumps and excavator hydraulic pump systems.

Predictive analytics assist in planning fuel purchases.

Automation reduces errors and improves operational efficiency.

By learning about vehicle fuel pumps, excavator hydraulic pump systems, and the latest technology, you can make smart decisions to boost fuel efficiency and lower costs.

Key Takeaways

Taking care of vehicle fuel pumps and excavator hydraulic pumps is important. It stops problems like clogged filters. It also helps you use less fuel.

Using new pump technology, like load-sense pumps, can lower fuel use a lot. Some systems can save up to 70% of energy.

Picking the right pump for your machine is key. You need to think about fuel type and pressure needs. This helps your machine work better and saves fuel.

Using smart technology, like digital hydraulics, helps use fuel wisely. It also cuts down on pollution. This saves money and helps the environment.

Checking things like equipment condition and how much it can carry keeps things running well. It also stops fuel from being wasted.

Pump Roles in Fuel Use

Vehicle Fuel Pumps

You need vehicle fuel pumps and excavator hydraulic pump systems for your engine to work well. The fuel pump in your car does many important things. It keeps the fuel pressure steady so your car runs smoothly. It stops vapor lock by making sure fuel stays cool and under pressure. It also changes how much fuel goes to the engine when you speed up or slow down. This helps your car use fuel better.

If your fuel pump works well, your engine gets the right amount of fuel. This helps stop misfires and keeps your car from losing power. Newer fuel injection systems need pumps that give higher pressure and steady flow. If your pump cannot do this, your engine may not burn fuel right and may lose power.

Tip: Take care of your vehicle fuel pumps and excavator hydraulic pump system. This helps you avoid problems like blocked filters, dirty injectors, or broken pumps. These problems can make your car idle rough, stall, or use more fuel. Change your fuel filter every 20,000 to 30,000 miles. Use good fuel and check your fuel system often.

Here is how a good fuel pump helps your car use less fuel. High-performance pumps give the engine the right amount of fuel. This stops waste. Steady fuel pressure helps your engine work well, even when you need more power. Good pumps help your car use less fuel, which saves you money.

Excavator Hydraulic Pump

The excavator hydraulic pump is very important for your machine. You need it to give the right flow and pressure for work. The pump changes mechanical energy into hydraulic energy. This lets your machine dig, lift, and move heavy things.

The hydraulic pump makes pressurized fluid for the whole hydraulic system. This fluid lets your excavator do jobs with strength and accuracy. The pump helps your machine move smoothly and with control.

How well your excavator hydraulic pump works affects how much fuel you use. If the pump works well, your machine uses less fuel. Smart modes change engine and hydraulic power to fit digging needs. This helps save fuel. Watching machine settings lets the system change power by itself. This keeps your machine working hard but using less fuel.

Evidence Description | Impact on Fuel Usage |

|---|---|

The machine works better and does not waste power. | Lower fuel use because of better performance. |

Smart mode changes engine and hydraulic power for digging. | Fuel use is lower because power matches the job. |

Watching machine settings lets the engine change power by itself. | The machine works hard but uses less fuel. |

Bigger hydraulic parts give more digging force, so fewer moves are needed. | Less work means less fuel is used. |

You can also get benefits from new hydraulic pump designs. Hybrid excavators use special technology to save energy from the boom’s movement. This helps use less fuel and makes less pollution. Independent Metering Valve Technology and closed-center valve control systems help save fuel when the machine is not working. New machines can use up to 20% less fuel than old ones.

Note: Keep your vehicle fuel pumps and excavator hydraulic pump system in good shape. Upgrading to new technology can help you use less fuel and spend less money.

Efficiency Factors

Energy Transfer

You can make your hydraulic system work better by learning how energy moves in it. Energy moves in pumps in different ways. This depends on things like speed, displacement, pressure, temperature, and load. Each one changes how well your pump works and how much fuel you use.

Here is a table that lists the main things that affect energy transfer:

Factor | Description |

|---|---|

Speed | Changes how fast the pump moves fluid and how well it works. |

Displacement | Bigger flow rates can make the pump work better, but not always. |

Pressure | Has a big effect on how well hydraulic pumps work. |

Temperature | Changes how thick the fluid is, which affects energy movement. |

Load | Different jobs can change how well the pump works. |

If you control these things, your hydraulic system can use less fuel and work better.

System Design

How your hydraulic system is built changes how much fuel you use. If you pick designs that save energy, you can use less fuel and make less pollution. For example, proportional valve control and energy recovery systems help your excavator work smarter. These features let your machine use only the power it needs. They also fix problems like wasted energy in control valves. When you pick a good system, you get better work and save money on fuel.

Tip: Try to find machines with new hydraulic system designs. These can help you do more work and use less fuel.

Operational Variables

The way you use your equipment also changes how much fuel you use. Many things can make your pumps use more or less fuel:

Construction process: Working slowly or making mistakes uses more fuel.

Equipment condition: Leaks or dirty filters make your system work harder.

Operating methods: Fast starts and stops waste fuel.

Operating conditions: Bumpy ground or bad weather can use more fuel.

Load capacity: Heavier loads need more power and fuel.

Maintenance: Checking and cleaning your system helps it work well.

If you watch these things, you can keep your hydraulic system working well and spend less on fuel.

Excavator Hydraulic Pump Technology

Load-Sense Pumps

Load-sense pumps help your excavator use fuel better. These pumps change how much fluid moves based on what the machine needs. When you use the excavator, the pump feels the load. It changes flow and pressure to fit the job. This helps stop energy waste and keeps things working well.

Load-sensing pumps change flow for each job your excavator does.

The system matches pump output to the load, so less energy is lost.

Hydraulic variable displacement piston pumps give the right flow for every task.

The load sensing technology changes pump flow and size by itself.

The pump only uses the energy needed, so you save fuel.

You can see big changes in energy use. Some systems cut energy use by 19% to 70%. You spend less money on fuel and help the planet by making fewer emissions.

Tip: If you want your hydraulic system to use less fuel, pick machines with load-sense pumps.

Trias Hydraulic Systems

Trias hydraulic systems help you save fuel and make less pollution. The system works better because it cuts hydraulic losses and uses fuel wisely. Trias uses smart controls to make sure your excavator only uses the power it needs.

Trias hydraulic systems help you use less fuel and make fewer emissions.

You spend less on fuel because the system stops hydraulic losses.

Trias can lower fuel use by up to 26% in some excavators.

You help the planet by making less pollution from your machine.

Trias hydraulic systems keep your excavator working well. You finish jobs faster and spend less money on fuel.

Energy Recovery Solutions

Energy recovery solutions let you reuse energy that would be lost. When you move the boom or other parts, these systems save and store energy. You can use this saved energy later. This helps you save fuel and makes your hydraulic system work better.

Study Title | Fuel Consumption Reduction | Excavator Type | Key Findings |

|---|---|---|---|

Power control strategy and performance evaluation of a novel electro-hydraulic energy-saving system | 17.6% | 23-ton hydraulic excavator | Big drop in fuel use and better performance. |

Research on energy saving system of hydraulic excavator based on three-chamber accumulator | 11.42% | 21.5-ton hydraulic excavator | Energy use drops a lot by saving energy from the hydraulic system. |

You get better work and spend less on fuel. Energy recovery solutions can make your system harder to use and cost more money. Digital hydraulic technology gives smart control, but you may pay more at first.

Aspect | Details |

|---|---|

Increased Efficiency | Energy recovery solutions help your system work better and use less fuel. |

Complexity | Old hydraulic technology makes systems harder to control. |

Cost Implications | You pay more to use these energy recovery solutions. |

Digital Hydraulic Technology | Smart controls help, but you need to spend more at first. |

Note: Think about saving fuel and spending less money, but also about the higher cost and harder controls of energy recovery solutions.

Digital Hydraulics

Digital hydraulics use smart controls to make your excavator work better. Your machine and its tools talk to each other easily. The system sets hydraulic pressure and controls for every job. Hybrid systems mix old hydraulics with digital controls. You get things like automatic grading and better load control.

Digital upgrades help you set hydraulic systems for better work.

Hybrid systems give you automatic grading and better load control.

You waste less material and stay safer, even if you are new.

New excavators use engines that make less pollution and change speed.

Better fuel injection and electronic controls help you use less fuel.

You get better engine designs that use less fuel and make less pollution. These changes make your hydraulic system work better than old ones. Digital hydraulics have some problems too. You need good power management and enough strength for hard jobs. Mixing electric and hydraulic systems can be tough, especially far from power sources.

You need to balance power supply and how well things work.

Full electric systems are hard for big machines, even with better batteries.

Tip: Digital hydraulics help you do great work and save fuel, but think about the problems before you upgrade.

New hydraulic pump technology helps your excavator work better, use less fuel, and make less pollution. Pick the right hydraulic system and keep it in good shape. This makes your excavator work well and helps the environment.

Optimizing Fuel Use

Pump Selection

Picking the right pump helps you save fuel and keeps your equipment working well. You need to choose a pump that fits your machine’s needs. Here are some important things to check:

Fuel Type: Make sure the pump works with your fuel, like diesel or gasoline.

Flow Rate (Capacity): Pick a pump that matches how much fuel or hydraulic fluid your machine uses.

Pressure Requirements: Check that the pump can handle the pressure your system needs.

Viscosity: Choose a pump that works well with the thickness of your fuel.

Self-Priming Capability: Select a pump that can remove air and draw fuel easily.

Power Source: Match the pump’s power source to your equipment.

You should also think about engine size, injection pressure, and fuel quality. Pumps for bigger engines or hard jobs need to be strong and tough. If you work in rough places, pick a pump made for heavy use.

Tip: YNF Machinery has pumps for many vehicles and excavators. You can find pumps that fit your needs and help you use less fuel.

Maintenance Tips

Taking care of your pumps helps them last longer and saves fuel. You should:

Check pumps and hoses often to find leaks or damage early.

Use clean fuel and hydraulic oil to keep fluids managed.

Take care of the hydraulic system to stop breakdowns.

Do daily checks before starting your machine.

Change filters and fluids on a regular schedule.

These steps help your pump work longer and keep your machine running well.

Upgrades and Innovations

New pump technology can help you use less fuel. Hybrid excavators use both engines and electric or hydraulic parts to save energy. Some models save energy from moving parts, while others use batteries and electric motors. Advanced electro-hydraulic systems, like those in some Volvo CE models, help the engine and hydraulic flow. This can give you up to 10% better fuel efficiency and longer times between service.

Electric fuel pumps that change pressure when needed also help save fuel. Variable-displacement pumps in construction equipment can save 7% to 8% on fuel. These upgrades help you work smarter and spend less money on fuel.

Note: If you want to upgrade or change a pump, YNF Machinery has new solutions that help you use less fuel and keep your equipment working well.

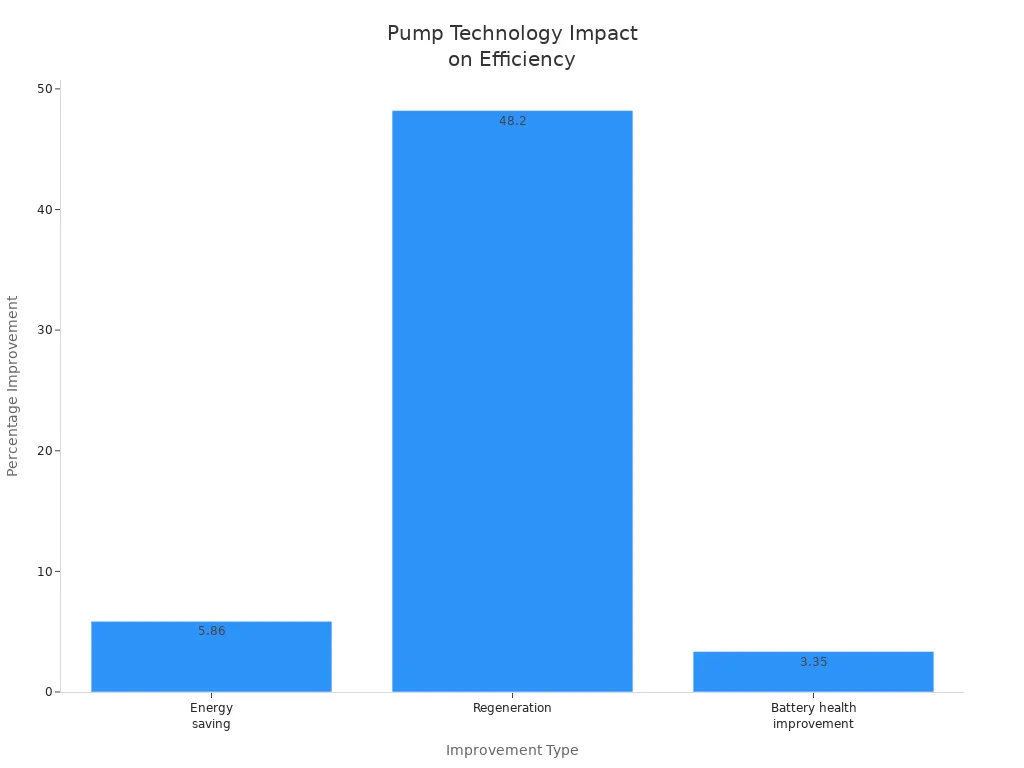

You can make your machine use less fuel. Pick the right pump for your needs. Use new technology to help save energy. Take care of your pump with regular maintenance. Modern pumps help save energy and keep batteries healthy. The chart below shows how much you can save:

Experts say you should do these things:

Check pumps every week for leaks or damage.

Clean your equipment often to keep it working well.

Wipe up spills as soon as you see them.

Look at alarms on tanks to spot problems.

Fix any issues early before they get worse.

New ideas like smart sensors and better materials help pumps last longer. These things also help pumps work better. Learn about pump technology to keep your vehicles and excavators working well.

FAQ

How do fuel pumps affect my vehicle’s fuel efficiency?

Fuel pumps send the right amount of fuel to your engine. If your pump works well, your car uses less fuel. You save money and help your engine run smoothly.

What is the best way to maintain my excavator hydraulic pump?

Check your pump and hoses often. Clean filters and use good hydraulic oil. Fix leaks quickly. These steps help your pump last longer and use less fuel.

Can new pump technology lower my fuel costs?

Yes! New pumps, like load-sense and digital hydraulics, help your machine use only the fuel it needs. You spend less on fuel and get better performance.

Where can I buy reliable pumps for my equipment?

You can find high-quality pumps at YNF Machinery. They offer pumps for vehicles and excavators. Their products help you save fuel and keep your equipment working well.

What signs show my pump needs repair or replacement?

Watch for rough idling, strange noises, or leaks. If your machine uses more fuel or loses power, your pump may need attention. Fix problems early to avoid bigger issues.