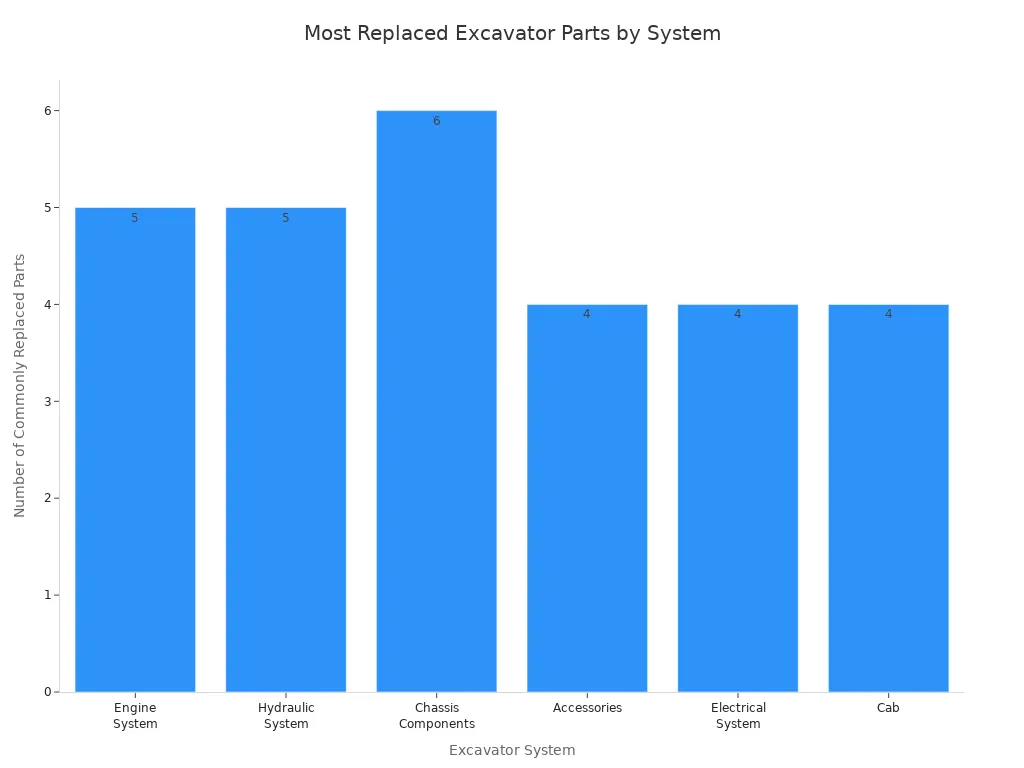

You should keep these top 10 excavator repaire parts in stock for 2025: hydraulic filters, bucket teeth, track chains, air filters, belts, seals, hoses, fuel filters, undercarriage parts, and hydraulic seals. Having genuine excavator repaire parts keeps your machine safe and saves money. It also helps you avoid long downtime when your machine is not working. Data shows that better part storage helped 59% of operations spend less on surprise repairs last year. The table below shows the most replaced excavator repaire parts and when to change them:

|

Excavator System |

Commonly Replaced Parts |

Replacement Indicators / Maintenance Frequency |

Supporting Data / Statistics |

|---|---|---|---|

|

Engine System |

Oil, piston rings, crankshafts, fuel nozzle, filters |

Change oil every 250-500 hours. Listen for strange sounds, shaking, or less power. |

Failure rate is about 80% with hydraulic system. Dirty oil causes a 5-10% pressure drop. |

|

Hydraulic System |

Hydraulic oil, filters, seals, cylinders, pumps |

Change oil every 2000-3000 hours. Clean filters every 1000 hours. Look for oil leaks or pressure drops over 10%. |

Hydraulic pressure is 300-350 bar. Seal leaks cause problems. |

|

Chassis Components |

Tracks, pins, bushings, rollers, idlers, shock absorption system |

Check track wear every 500-1000 hours. Replace if wear is over 30% or if there are cracks. |

Good track tension lowers failure by 15%. If shock absorption drops over 15%, replace it. |

|

Accessories |

Bucket, arm, breaker, grab |

Check for wear every 500 hours. Replace if there are cracks or wear over 20%. |

Strong alloys make parts last 20% longer. Loose parts make work slower. |

|

Electrical System |

Electric control box, sensors, instrument panel, wiring |

Calibrate sensors every 1000 hours. Check for old wires and big changes in voltage or temperature (±10%). |

Calibration makes response 5-8% faster. Problems cause alarms and wrong data. |

|

Cab |

Seats, air conditioning, seat belts, instruments |

Check safety gear often. Check air conditioning every three months. |

Good design makes operators less tired by 15-20%. Parts last 5-7 years. |

Tip: Pick OEM excavator repaire parts to make your machine more reliable and help your top 10 parts last longer. This helps you avoid big repair bills and keeps your excavator working well.

Key Takeaways

-

Always have the top 10 excavator repair parts ready. This helps you avoid long waits and expensive fixes. Check parts like filters, bucket teeth, track chains, hoses, and seals often. This lets you find problems early. Use real OEM parts for a better fit and longer use. This also keeps your machine’s warranty safe. Follow the maker’s schedule to change filters, belts, and seals on time. Keep your parts organized and look at them every month. This helps you be ready and spend less on sudden repairs.

Hydraulic Filters

Function

Hydraulic filters keep the hydraulic system safe. They catch dirt and metal pieces before they reach important parts. Clean filters help the machine work well. This means better performance and fewer problems. Dirty filters can lower pressure and slow the excavator. You might hear odd sounds or see leaks if filters get blocked. Always use the right filter for your machine to keep it safe and working well.

Replacement Tips

Check your hydraulic filters often. Most brands say to change them every 1,000 hours. Some machines need new filters after only 250 hours. This is true if you work in dusty or rough places. Watch for these signs that filters need changing:

-

The machine loses power or moves slowly.

-

The flow rate drops or pressure goes down.

-

You hear strange sounds or see leaks.

Tip: Always read your excavator’s service manual for the right schedule. Changing filters at the wrong time can cost a lot to fix.

Here is a simple guide for filter care:

|

Service Interval |

Hydraulic Filter Maintenance |

|---|---|

|

250 hours |

Change hydraulic filter element |

|

1,000 hours |

Replace hydraulic filters (general recommendation) |

|

2,000 hours |

Change hydraulic oil and filter |

Keeping extra filters in stock helps you avoid delays. You can keep your excavator ready for work when you have the right parts.

Bucket Teeth

Wear and Replacement

Bucket teeth help your excavator break hard ground and move heavy stuff. These teeth get hit hard and scraped a lot as you work. The tips of the teeth get the most damage first. If the teeth are not strong enough, they might bend or change shape. When digging deeper, teeth rub against rocks and concrete. This makes deep scratches and wears them down.

Some things that wear out teeth are:

-

Hitting hard things

-

Rubbing on rough stuff like rock or concrete

-

Bad material or no heat treatment

If teeth get dull, chipped, or cracked, digging gets harder. Your excavator will use more fuel and work slower. Check the teeth often. Change them if you see deep lines, broken tips, or if they do not cut well. Teeth made from strong alloy steel or tungsten carbide last longer. They help your machine work better.

Tip: Look at your bucket teeth after every shift. This is very important if you dig in rocky or rough places. Changing teeth early stops bigger problems and keeps your excavator working.

Compatibility

It is important to pick the right bucket teeth for your excavator. Not every tooth fits every bucket or machine. You must match the size, shape, and how the teeth attach to your equipment. Wrong teeth can make digging bad and might hurt your bucket.

Manufacturers make different teeth for different jobs. Some teeth are for normal digging. Others are for rock or frozen ground. Always check your operator’s manual or ask your parts supplier before buying new teeth. This helps you get the right teeth and the best results for your work.

Note: Keep extra sets of the right bucket teeth in your stock. This helps you change them fast and avoid waiting when you need new ones.

Track Chains

Maintenance

Track chains play a key role in your excavator’s movement and stability. You need to keep them in top shape to avoid costly repairs and downtime. Start by cleaning your tracks after every use. Remove rocks, mud, and plants that can get stuck between the links and track pads. This simple step helps prevent extra wear.

Check your tracks often for cuts, tears, or signs of heavy wear. Look at the rollers and idlers, and make sure you lubricate them well. Proper lubrication keeps the chain moving smoothly and reduces friction. You should not worry about over-lubricating—more is better than less.

Always adjust track tension to match the manufacturer’s guidelines. If the chain is too loose, it may jump teeth. If it is too tight, it can cause damage. Make sure the sprockets line up correctly in both the axial and angular planes. Poor alignment puts stress on the chain and shortens its life.

Tip: Train your operators to avoid sharp turns, spinning, and high speeds on hard surfaces. These actions wear out the track pads and chains much faster.

Choose the right track pads for your job and terrain. The correct pattern helps your tracks last longer and gives you better traction.

Stocking Advice

You should keep extra track chains and track pads in your parts inventory. This helps you replace worn parts quickly and keeps your excavator working. Stocking the right parts means you do not have to wait for deliveries when something breaks.

Inspect your inventory often. Check for missing or damaged parts. Keep a record of how often you replace track chains and track pads. This helps you plan your orders and avoid running out.

Note: Always buy genuine parts from trusted suppliers. Quality parts last longer and fit your machine better.

A good stocking plan saves you time and money. It keeps your excavator ready for any job.

Air Filters

Importance

Clean air filters help your excavator’s engine work well. They stop dust and dirt from getting inside the engine. If you use your machine in dusty places, filters can clog faster. When you wait too long to change filters, dust can get into the engine. This can wear out parts, lower power, and use more fuel. You might have to pay more for repairs and fix breakdowns more often.

If you do not take care of air filters, the engine can get too hot or stop working. Checking and changing filters on time saves money and helps your equipment last longer.

Good air filters let air move the right way. This helps the engine burn fuel better and keeps the excavator running smoothly. You will not have to pay for big repairs and your work will stay on track.

Replacement Schedule

You need to follow a simple plan to care for air filters. Most people say you can clean the outer filter up to six times before getting a new one. After 1,000 hours, change both the outer and inner filters at the same time. If you work where it is very dusty, check and change filters more often.

-

Use compressed air to clean the outer filter, but do not get too close or you might break it.

-

Never clean the inner filter. If you see dust or damage, put in a new one right away.

-

Always look for clogs or worn spots when you check your machine.

Tip: Always follow the rules from your machine’s maker. Change your plan if you see more dust or tough work at your job.

Changing filters on a schedule keeps your engine safe and your excavator ready to work.

Belts

Common Issues

Belts play a vital role in your excavator’s performance. You rely on them to drive fans, alternators, and hydraulic pumps. Over time, belts can crack, fray, or stretch. Heat, dust, and vibration speed up this wear. If you hear squealing or see slipping, you may have a worn belt. A loose belt can cause poor power delivery. A broken belt can stop your machine and lead to costly downtime.

You should check belts for signs of damage during every inspection. Look for glazing, missing chunks, or uneven wear. If you see any of these problems, replace the belt right away. Ignoring these signs can lead to sudden breakdowns. You can avoid bigger repairs by acting early.

Tip: Always follow the maintenance schedule in your operator’s manual. Early detection of belt issues keeps your excavator running smoothly.

Stocking Tips

Keeping the right belts in stock helps you avoid long delays. Construction-grade belts use reinforced cords and special rubber compounds. These features help them last longer in tough conditions. When you stock multiple types of belts, you can handle repairs faster. You do not have to wait for parts to arrive.

Here are some ways stocking belts improves repair turnaround times:

-

Reinforced belts last longer and reduce downtime.

-

A good stocking program means you always have critical belts on hand.

-

Expert support helps you pick the right belt and set up a maintenance plan.

-

Bulk orders and partner programs give you in-stock guarantees and easier scheduling.

-

These steps help you fix your excavator quickly and avoid unexpected failures.

You should keep a record of which belts you use most often. Review your inventory every month. Replace any belts that show signs of aging or damage. Work with trusted suppliers to get genuine parts. This approach keeps your machine ready for work and reduces emergency repairs.

Seals

Types

Excavators use different seals to protect important parts. Each seal has a special job. Here are the main types you should know:

-

Hydraulic seals keep fluid inside pumps and cylinders. They work under high pressure and move a lot.

-

O-rings are small but do a big job. They seal joints and connections. You need the right material for heat and chemicals.

-

Gaskets seal flat places like flanges and joints. They stop leaks of fluids and gases.

-

Dust seals keep dirt and dust away from moving parts. This helps your machine last longer.

The table below shows where each seal goes and why they might fail:

|

Seal Type |

Application Area |

Common Failure Causes / Notes |

|---|---|---|

|

Hydraulic Seals |

Hydraulic cylinders, pumps |

Fail from lots of use, old age, or bad assembly |

|

O-Rings |

Sealing interfaces, bucket connections |

Get old, handled wrong, or damaged by chemicals |

|

Dust-proof Rings |

Hydraulic cylinders, external protection |

Let in dust or get oil mixed in |

|

End Cover Seals |

Cylinder ends |

Lose pressure or leak |

|

Piston Seals |

Inside cylinders |

Work with end cover seals to keep pressure |

|

Gaskets |

Engines, gearboxes, valves |

Leak fluids if old or not fitted right |

|

Dust Seals |

External components |

Dirt and debris can cause problems |

Tip: Check seals often to find wear early. This helps stop leaks and keeps your excavator safe.

Replacement

Change seals before they break. Bad seals can leak and lower hydraulic pressure. This can cause problems and stop your excavator. Replacing seals on time keeps pressure up and stops leaks. Your machine will run better and safer.

Look for leaks, low pressure, or slow movement. These signs mean seals may be worn out. Change them right away if you see these problems. Waiting too long can make repairs cost more and take longer.

Changing seals on time also stops boom drift. It keeps your hydraulic system working well. You will have fewer breakdowns and finish work on time. Always use the right seals and follow the maintenance plan.

Note: Clean fluid and good assembly help seals last longer. Good habits save money and protect your excavator.

Hoses

Inspection

You need to inspect hoses on your excavator often. Hoses carry hydraulic fluid under high pressure. If a hose fails, your machine can stop working. You can prevent most hose problems by following a regular inspection schedule:

-

Check hoses every day. Look for cracks, leaks, or bulges.

-

Inspect hydraulic hoses each week. Focus on signs of wear, damage, or leaks. Replace any hose that looks bad.

-

Every month, check the whole hydraulic system. Listen for strange noises or feel for vibrations. These can mean a hose is about to fail.

You should know the main reasons hoses fail. The table below shows common causes and how you can prevent them:

|

Cause |

Description |

Preventative Measures |

|---|---|---|

|

Heat Aging |

High temperatures make hoses hard and cracked. |

Move hoses away from heat. Use heat shields. |

|

Abrasion |

Hoses rub against parts or other hoses and wear out. |

Reroute hoses. Add covers or shields. |

|

Site Damage |

Sharp objects like rebar or concrete cut or tear hoses. |

Use shields or covers to protect hoses. |

|

Hydraulic Contamination |

Dirty fluid with sharp bits damages the inside of hoses. |

Keep fluid clean. Watch hose condition. |

|

Wear and Tear |

Hoses wear out from pressure cycles, not just hours of use. |

Inspect often. Replace hoses that show any failure. |

Tip: Early detection of hose problems helps you avoid costly breakdowns and keeps your excavator running.

Replacement

You should replace hoses before they break. Waiting too long can cause leaks or sudden failures. Always use the right type and size of hose for your machine. Check the fittings and clamps when you install a new hose. Tighten them to the correct level.

When you see any of these signs, replace the hose right away:

-

Cracks or splits on the surface

-

Leaks at the ends or along the hose

-

Bulges or soft spots

-

Worn or frayed covers

Keep spare hoses in your parts stock. Store them in a cool, dry place away from sunlight. This helps them last longer. Use only genuine hoses from trusted suppliers. Quality hoses fit better and last longer.

Note: A good replacement plan reduces downtime and keeps your excavator safe and productive.

Fuel Filters

Role

Fuel filters keep dirt and water out of your engine. Clean fuel helps the engine work well. This stops damage to important parts like injectors. Good filters that meet OEM standards give the best protection. If dirt gets in, the engine may start hard or lose power. Sometimes, the engine might misfire or stop working. These problems can make you stop working and cost a lot to fix.

A good fuel filter keeps your engine safe and helps it last longer. Always check your owner’s manual for the right filter. Using the correct filter helps your excavator work its best.

Maintenance

You need to change fuel filters often to keep things running well. Most filters need changing every 500 to 1,000 hours. If you work in dusty or rough places, change them more often. Bad fuel means you should check filters sooner.

Look for these signs that your filter needs help: Hard starting, engine misfiring, or loss of power. If you see any of these, change the filter right away. Regular care stops dirt from building up. This keeps your engine strong and helps it last longer. Clean filters stop damage to injectors and lower engine wear.

Tip: Always follow the schedule in your owner’s manual. Regular service saves fuel and money on repairs.

|

Operating Condition |

Recommended Replacement Interval |

|---|---|

|

Normal |

1,000 hours |

|

Harsh/Dusty |

500 hours |

|

Poor Fuel Quality |

500 hours or sooner |

Taking care of fuel filters keeps your excavator working well and protects your machine.

Undercarriage Parts

Wear Points

The undercarriage has many parts that wear out fast. You need to watch rollers, idlers, sprockets, and track pads. These parts get hit by rocks and dirt all the time. Heavy loads and rough ground make them wear out even faster. Dirt and rocks rub against these parts and cause deep marks. Over time, this makes the parts wear unevenly. If you do not check often, you might miss broken or missing parts. Oil leaks from rollers or idlers mean the seals are bad. Leaks can cause big problems and cost a lot to fix.

Bad driving habits make parts wear out faster. Driving backward fast, turning sharply, or working on slopes without balance can make parts wear out three times faster. If tracks slip more than 5%, you will spend more on repairs and fuel. If you do not clean mud and dirt after each shift, your machine can break down sooner. Training operators to check parts and use good habits helps stop these problems. Finding issues early lets you fix them before they get worse.

Tip: Check your undercarriage often and use good habits. This helps your parts last longer and keeps your machine working.

Stocking Essentials

You should always keep extra undercarriage parts in your stock. These parts are rollers, idlers, sprockets, and track pads. Having spares lets you fix your machine fast when something breaks. This stops long waits and keeps your excavator working. The undercarriage costs a lot to fix if you wait too long. Stocking the right parts saves money and protects your machine.

Here is a quick table to help you know what to keep in stock:

|

Component |

Replacement Indicator |

Stocking Advice |

|---|---|---|

|

Rollers |

Oil leaks, flat spots |

Keep at least 2 spares |

|

Idlers |

Excessive play, noise |

Stock 1-2 per machine |

|

Sprockets |

Worn teeth, sharp edges |

Replace in sets, stock extras |

|

Track Pads |

Cracks, missing bolts |

Keep several on hand |

Check your stock every month. Replace any old or damaged parts. Always buy real parts for the best fit and longest life. This helps you avoid big repair bills and keeps your excavator ready for work.

Hydraulic Seals

Function

Hydraulic seals are very important for your excavator. These seals keep hydraulic fluid inside the system. They stop leaks and help your machine work well. When you use the right seals, your excavator keeps strong pressure. This means your machine has steady power. Piston seals and O-rings make sure fluid does not escape. This helps your excavator stay powerful.

Good seals also protect your equipment from damage. They stop fluid from leaking and keep dirt out. This makes your machine last longer and keeps it safe for workers. Each seal has its own job. For example, piston seals keep fluid from moving past the piston. This holds pressure in the cylinder. O-rings seal joints and connections. They stop leaks in important places. Dust seals keep dirt and debris out of moving parts.

Tip: Check your hydraulic seals often. If you find wear or damage early, you can stop leaks and save money on repairs.

Replacement

You must pick the right hydraulic seals for your excavator. The seal material is very important. Different materials work better with heat, pressure, or chemicals. Here is a simple guide:

|

Material |

Temperature Range |

Pressure Rating |

Best Use Case |

|---|---|---|---|

|

NBR (Nitrile) |

-40°C to +120°C |

Medium |

General hydraulic systems, mineral oil use |

|

Viton (FKM) |

-20°C to +200°C |

High |

High-temp, chemical resistance, hydraulic breakers |

|

Polyurethane |

-30°C to +100°C |

High |

Rod seals, wipers, dusty or high-pressure jobs |

|

PTFE (Teflon) |

-200°C to +260°C |

Very High |

Piston seals, extreme pressure, harsh conditions |

|

EPDM |

-50°C to +130°C |

Medium |

Cold weather, water-based fluids |

When you change seals, match the material to your job. Use Viton for high heat or chemicals. Use EPDM for cold weather. Always follow what your machine’s maker says. Keep extra seals in a clean, dry place so they stay good.

Note: Using the right seal and material stops leaks, keeps pressure, and helps your excavator work its best.

Excavator Repair Parts Inventory

Stocking Strategy

You need a good plan to manage your excavator repaire parts. First, look at your Bills of Materials (BoMs) to find the most important parts. This helps you avoid having too many or too few parts. Sort your stock by machine, how often you use it, or by type. This makes it easy to find what you need fast.

Here are some simple ways to keep your inventory correct and ready:

-

Use a tracking system, like CMMS software, to see where parts are and how they are used.

-

Set up reorder points with alerts so you do not run out or have too much.

-

Count your parts often with cycle counts and spot checks.

-

Keep broken or old excavator repaire parts in a separate place so no one uses them by mistake.

-

Remove parts you do not use to save space and cut down on waste.

Tip: Keep spare parts in a spot that is easy to get to. This helps you fix your excavator faster and keeps it working.

Good suppliers help you get new, used, or rebuilt excavator parts quickly. Trusted suppliers give better prices and help you find rare parts. They also offer warranties and help after you buy, which keeps your machine working well.

Cost-Effectiveness

Using real excavator repaire parts saves money over time. Fake parts might cost less, but they can break your machine. For example, a fake fuel injector once caused a $10,000 engine repair. Real parts make your machine more reliable and stop breakdowns. They also help you keep your warranty and insurance.

You can save money by:

-

Picking good aftermarket parts that meet OEM standards.

-

Working with suppliers who give bulk deals and fast shipping.

-

Using data to plan when to order parts so you do not have to rush.

|

Benefit |

How It Helps Your Work |

|---|---|

|

Genuine Parts |

Fewer breakdowns, longer machine life |

|

Strong Supplier Relationships |

Lower costs, faster repairs |

|

Automated Inventory Systems |

Less waste, better accuracy |

Note: Buying the right excavator parts and working with good suppliers protects your business and keeps your excavator ready for any job.

If you keep these 10 repair parts in stock, your excavator will work well and not have long delays. Checking parts often and buying from trusted suppliers helps you save money. Using inventory software makes it easier to track what you have. Always use real parts to keep your machine safe and keep your warranty. Try to learn about new digital tools for maintenance. Check important parts often to catch problems early. Doing these things keeps your excavator working and helps your business stay ahead.

FAQ

How often should you check your excavator parts inventory?

You should check your parts inventory every month. This helps you spot missing or damaged items early. Regular checks keep your excavator ready for work and prevent long delays.

Can you use aftermarket parts instead of OEM parts?

You can use aftermarket parts if they meet OEM standards. Always check quality and fit before buying. OEM parts offer better reliability and protect your machine’s warranty.

What is the best way to store spare excavator parts?

Store spare parts in a clean, dry place. Keep them away from sunlight and moisture. Use labeled bins or shelves for easy access. This protects parts from damage and saves time during repairs.

How do you know when to replace hydraulic hoses?

Look for cracks, leaks, or bulges on hoses. If you see any of these signs, replace the hose right away. Regular inspections help you catch problems before they cause breakdowns.

Why is it important to use genuine filters and seals?

Genuine filters and seals fit your machine perfectly. They protect your engine and hydraulic system from dirt and leaks. Using real parts helps your excavator last longer and work better.