You want your excavator to work well and last a long time. Safety is the most important thing when you fix heavy equipment. Always use the right service manual before you start any repairs. Clean tools and a neat workspace help stop damage to daewoo excavator engine parts. This guide helps operators, mechanics, and DIYers who want their excavator to work well.

Key Takeaways

Always read the service manual before you start repairs. Wear the right safety gear to protect yourself and your excavator.

Look for warning signs like odd sounds, smoke, or leaks early. This helps stop bigger engine problems from happening.

Check part numbers closely before you buy anything. Get real or good parts from trusted places like YNF Machinery. This helps prevent damage.

Get your workspace ready by finding the right tools. Clean the area and park the excavator on flat ground. This makes your work safe and steady.

Follow each step to take out old parts and put in new ones. Test the machine after to make sure it works well and lasts longer.

Identify Engine Parts

Spot Failure Signs

It is important to know when your excavator engine parts are not working right. Watch for warning signs before you try to fix anything. Some signs are:

Strange sounds from the engine, like knocking or rattling.

The excavator loses power or moves slowly when you use it.

Smoke comes out of the exhaust, especially blue or black smoke.

Oil leaks or puddles show up under the excavator.

The engine gets too hot or warning lights turn on.

Tip: If you see any of these signs, stop using the excavator right away. Acting early can stop bigger problems and save you money.

Check the engine and other parts as soon as you notice a problem. Use a flashlight to look for cracks, worn hoses, or loose parts. Listen for new sounds from the engine when it is running. These steps help you find which daewoo excavator engine parts need to be replaced.

Confirm Part Numbers

You need to make sure you have the right part numbers before you buy new excavator parts. Every part in the excavator engine has its own number. This number helps you get the correct part and avoid mistakes.

Here are the steps to check part numbers:

Get your excavator’s service manual. The manual has all the part numbers for your machine.

Take out the old part and look for a number stamped or printed on it.

Check if the number on the old part matches the one in the manual.

Write down the numbers before you order new daewoo excavator engine parts.

Step | Action | Why It Matters |

|---|---|---|

1 | Check the manual | Makes sure you have the right info |

2 | Look at old part | Checks for an exact match |

3 | Match the numbers | Stops you from ordering the wrong part |

4 | Write down numbers | Helps when you order or ask for help |

Always check the numbers twice. Using the wrong part can hurt the excavator engine or make you need more repairs later.

Gather Tools and Parts

You need to get your tools and daewoo excavator engine parts before you start. This helps you work faster and make fewer mistakes.

Tools Checklist

You must use the right tools to change daewoo excavator engine parts. Daewoo and Doosan say you should use special wrenches and kits. These tools help you take off and put on parts safely. They stop you from breaking anything. Here is a table that shows the tools you need:

Tool Name | Description | Price (USD) | Notes |

|---|---|---|---|

Special Change Cylinder Head Wrench | Used for cylinder head replacement | 160.00 | Suitable for all brands |

Exchange Cylinder Seal Kit Tool Wrench | For exchanging cylinder seals | 339.00 | Must buy |

Special Wrench for Excavator Repair Hydraulic Cylinder | Universal wrench for hydraulic cylinder repair | 239.99 | Compatible with many brands |

You also need simple hand tools, gloves, and safety glasses. Look in your service manual to see if you need other tools for your excavator.

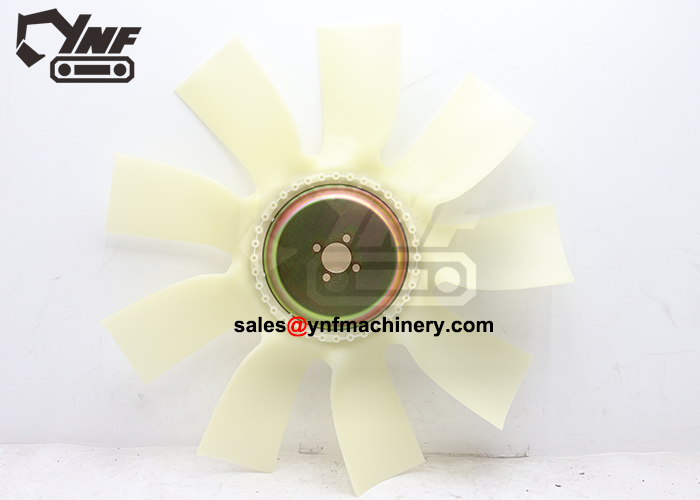

Find Genuine or Quality Parts

You should use real or good aftermarket daewoo excavator engine parts. Bad parts can break your machine and cost more money. The best way is to buy your daewoo excavator engine parts from YNF Machinery. They sell parts that fit and work well. Always check if the parts match your model and part numbers before you buy them.

Tip: If you buy from YNF Machinery, you will not get fake or bad parts.

Review Service Manual

You need to read your service manual before you fix anything. The manual tells you what to do step by step. It also gives you safety tips and shows the right part numbers. You will see how tight to make bolts. Reading the manual helps you do the job right and stay safe.

Note: Keep your manual close while you work. Look at it often so you do every step the right way.

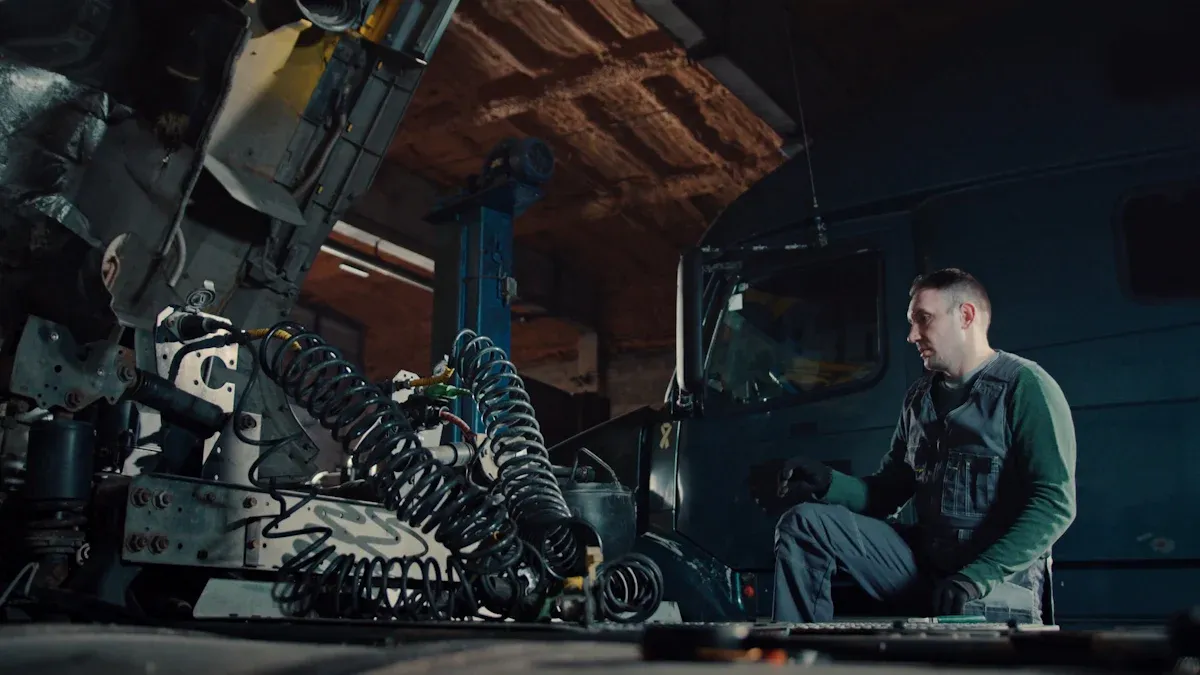

Step-by-Step Guide: Preparation

Before you start working on your excavator, you need to follow this step-by-step guide. These steps help you stay safe and keep your machine in good shape. You will find this guide useful for any parts and repair guide or replacement job.

Park on Level Ground

Always park your excavator on hard, level ground. This step keeps the machine stable and stops it from moving or tipping over. You should check that the brakes work and safety pins are in place. Use blocks if needed to keep the excavator from rolling.

Park the excavator on a flat surface.

Set the brakes and use safety pins.

Place blocks under the tracks if the ground is not even.

Tip: Stable parking prevents accidents and protects you and your equipment.

Disconnect Battery

You must disconnect the battery before you touch any engine parts. This step stops electrical shocks and keeps you safe. Remove the negative cable first. This action cuts off power and lowers the risk of sparks or short circuits.

Turn off the engine.

Find the battery and remove the negative cable.

Keep the cable away from the battery post.

Never work on the engine or wiring with the battery connected. This simple step can prevent serious injuries.

Drain Engine Fluids

Draining engine fluids is a key part of this step-by-step guide. You need to remove old oil, coolant, and fuel before you start repairs. This step keeps the work area clean and stops spills. Wait until the engine cools down before you open the radiator cap. Hot coolant can burn your skin.

Let the engine cool down.

Place a pan under the drain plugs.

Open the plugs and let fluids drain out.

Dispose of fluids safely.

Always wear gloves and safety glasses when you handle engine fluids.

Ensure Clean Work Area

A clean work area helps you avoid contamination of engine parts. Dirt and dust can damage new parts during replacement. Sweep the floor and wipe down your tools. Keep all parts organized on a clean table.

Clean the workspace before you start.

Use clean rags to wipe tools and parts.

Keep fluids and old parts away from new ones.

Cleanliness is important for every step in this guide. It helps your excavator run better after repairs.

By following this step-by-step guide, you make sure your excavator is ready for safe and effective repairs. You protect yourself and your machine. You also set up a smooth process for the next steps in your parts and repair guide.

Remove Old Daewoo Excavator Engine Parts

Access Engine Compartment

You need to open the engine compartment before you start removing any parts. Use the release lever or latch to unlock the cover. Lift the hood slowly and secure it with the safety prop. Make sure you have enough light to see all the parts inside. Check for any wires or hoses that might block your way. Move them aside carefully.

Tip: Always wear gloves and safety glasses when you work near the engine compartment.

Loosen Bolts Evenly

You must loosen bolts in the right order. The service manual shows you the correct sequence, especially for cylinder head bolts. Loosen each bolt a little at a time. Do not remove one bolt all the way before loosening the others. This method prevents damage to the engine block and keeps the parts from warping.

Here is a simple process you can follow:

Find the bolts that hold the part in place.

Use the right wrench for each bolt.

Turn each bolt a quarter turn.

Move to the next bolt and repeat.

Continue until all bolts are loose.

Step | Action | Reason |

|---|---|---|

1 | Find bolts | Locate all fasteners |

2 | Use correct wrench | Prevents stripping |

3 | Loosen in stages | Avoids stress on engine |

4 | Repeat for each bolt | Keeps parts safe |

Loosening bolts evenly helps you avoid cracks and other damage.

Inspect and Remove Components

You need to inspect each part as you remove it. Look for signs of wear, rust, or cracks. Check seals and gaskets for leaks. If you see any broken or worn pieces, make a note. Remove each component slowly and keep track of where it goes. Place small parts like nuts and washers in a tray so you do not lose them.

Take out the part gently.

Look for damage or wear.

Set each part on a clean surface.

Write down any problems you find.

Careful inspection helps you spot issues before you install new parts.

Handle Old Parts Safely

You must handle old parts with care. Some parts may have oil or coolant on them. Wear gloves to protect your hands. Place old parts in a container or on a clean rag. Do not mix old and new parts. Dispose of damaged or worn parts according to local rules. If you plan to reuse any part, clean it before storage.

Use a container for old parts.

Keep old and new parts separate.

Clean reusable parts before storing.

Follow safety rules for disposal.

Safe handling keeps your workspace clean and protects the environment.

Check Compatibility

Compare Old and New Parts

You need to check that your new Daewoo excavator engine parts match the old ones before you install them. Lay both parts side by side on a clean table. Look at the size, shape, and color. Check for any small differences. Even a small change can cause problems later.

Look at the bolt holes and mounting points. They should line up exactly.

Check the length and width of each part. Use a ruler or caliper for accuracy.

Inspect the surface finish. The new part should not have extra bumps or rough spots.

Compare the labels or part numbers. They must match what you wrote down earlier.

Tip: If you see any difference, do not install the new part. Contact YNF Machinery for help. They can help you find the correct Daewoo excavator engine parts for your machine.

Match Specs and Fit

You must make sure the new part fits and works with your excavator. Use the manufacturer’s guidelines to check the specifications. This step helps you avoid damage and keeps your machine running well.

Follow these steps to verify specs and fit:

Match the engine’s output to the hydraulic pump model. For example, if you use a Cummins engine, check that it works with the T5V140DT hydraulic pump.

Check the engine mounting points and crankshaft alignment. The new part must fit exactly in the same place as the old one.

Measure the hydraulic pump coupling and shaft dimensions. They must match to avoid misalignment.

Read both the Cummins and Daewoo service manuals. These books show you which parts and specs are compatible.

Use an adapter plate if the mounting points do not line up. This plate helps you fit the new part safely.

Ask a professional to make the adapter plate if needed. This step keeps your machine strong and safe.

Always double-check specs before you install any part. Careful checks save you time and money. If you have questions, YNF Machinery can help you find the right fit for your Daewoo excavator.

Install New Engine Parts

Align and Position

You need to place each new part in the correct spot before you start the installation. Take your time and check the alignment. Use your hands to guide the part into place. Make sure the bolt holes line up with the engine block. If you feel resistance, stop and check for dirt or debris. Clean the area again if needed. A good fit helps prevent leaks and damage later.

Tip: Lay out all parts on a clean table before you begin. This step helps you see if anything is missing.

Some parts, like gaskets or seals, need a thin layer of oil before you install them. This step helps them seat properly. Always follow the service manual for special instructions. If you use a part from YNF Machinery, check the packaging for extra tips.

Torque to Spec

You must tighten bolts to the correct torque. Use a torque wrench for this step. The service manual gives you the right numbers. Start with the bolts in the center and work outward. Tighten each bolt a little at a time. This method keeps pressure even and stops warping.

Here is a simple process:

Place the bolt in the hole.

Turn it by hand until snug.

Set your torque wrench to the number in the manual.

Tighten each bolt in the correct order.

Step | Action | Why It Matters |

|---|---|---|

1 | Hand-tighten bolts | Prevents cross-threading |

2 | Use torque wrench | Ensures proper tightness |

3 | Follow sequence | Avoids stress on parts |

If you skip this step, the replacement may fail. Always double-check your work.

Reconnect Systems

After you finish installing the new parts, you need to reconnect hydraulic hoses, wires, and other systems. Check each connection for dirt or damage. Push hoses onto their fittings until you hear a click or feel them lock in place. Secure wires with clips or ties. Look at the manual to see if you missed anything.

Note: Take your time with this step. A loose hose or wire can cause leaks or engine problems.

Once you finish, review your work area. Remove tools and old parts. Your careful installation helps your excavator run smoothly and safely.

Step-by-Step Guide: Final Drive Replacement

Replacing the final drive on your excavator is a big job. You need to follow each step in this guide to keep yourself and your machine safe. The final drive moves the tracks and helps your excavator work on tough ground. If you see leaks, hear grinding noises, or notice the track does not move, you may need a final drive replacement.

Safety Precautions

Start with safety. Let the engine cool before you touch any final drive parts. Hot metal can burn your skin. Wear gloves, safety glasses, and steel-toed boots. Always use the parking brake and block the tracks. Never work under the excavator unless you support it with strong stands. Tell someone you are working on the final drive so they can help if you need it.

Tip: Safety comes first. Take your time and check each step in the guide.

Use Proper Lifting Equipment

You must use the right tools to lift the final drive. The final drive is heavy and awkward. Use a crane, hoist, or jack that can hold the weight. Attach lifting straps to the final drive at the marked points. Never try to lift the final drive by hand. If you drop it, you can get hurt or damage the part.

Check the weight of the final drive in your manual.

Use lifting equipment that matches or exceeds this weight.

Secure the final drive before you move it.

Follow Model-Specific Steps

Each excavator has its own steps for final drive replacement. Always read your service manual before you start. Here is a simple guide you can follow:

Remove the track from the final drive. This step gives you space to work.

Disconnect hydraulic hoses from the final drive. Plug the hoses to stop leaks.

Unbolt and remove the old final drive. Use your lifting equipment for this step.

Line up the new final drive with the mounting holes.

Bolt the new final drive in place. Tighten bolts to the correct torque.

Reconnect hydraulic hoses to the final drive.

Reinstall the track and check for proper fit.

Note: If you need new parts, YNF Machinery can supply the right final drive for your excavator.

After you finish, test the excavator final drive. Watch for leaks and listen for strange sounds. This guide helps you finish the job safely and correctly.

Test and Inspect Excavator

Refill Fluids

Before you test your excavator, fill up all the fluids. Use clean oil, coolant, and hydraulic fluid that match your manual. Pour each fluid slowly so you do not spill. Check the levels with dipsticks or sight glasses. Make sure you use the right gear oil for the final drive. If you see dirt in the fluid, stop and clean it up. Always use new fluids after you change engine or final drive parts. This step helps your excavator work well and keeps the final drive safe.

Tip: YNF Machinery has good fluids and parts for your excavator. Using the right products helps your final drive and engine last longer.

Start and Monitor Engine

Start the engine and let it run for a few minutes. Watch the gauges for oil pressure, coolant heat, and hydraulic fluid. Listen for odd sounds from the engine or final drive. If you hear banging or knocking, turn off the engine and check the parts. Look at the exhaust for smoke. Blue or black smoke means you should check the engine again. Make sure the final drive moves the tracks without problems. If the excavator feels slow or weak, check the hydraulic fluid and final drive for trouble.

System | What to Watch For | What It Means |

|---|---|---|

Engine | Strange sounds | Possible damage |

Final drive | Grinding or slow tracks | Needs checking |

Hydraulic | Low pressure | Leak or blockage |

Check for Leaks or Issues

After you start the engine and move the excavator, look for leaks or other problems. Some common issues after changing engine or final drive parts are:

Leaks around the final drive or hydraulic hoses.

Odd noises from the final drive, like banging or knocking.

The final drive or hydraulic pump gets too hot.

Seals break and hydraulic fluid leaks from the final drive.

The excavator moves slowly, which can mean leaks or low fluid.

Signs of wear or damage on the final drive, which may mean you need a new one.

If you find any of these problems, stop the machine and fix them first. Always check the final drive and hydraulic system after every repair. Careful checks help you avoid bigger problems and keep your excavator working well.

Note: If you need help or new parts, contact YNF Machinery. They give good support and have quality final drive parts for your excavator.

Maintenance After Replacement

Change Oil and Filters

You need to change the oil and filters after you finish replacing engine parts. Fresh oil helps your excavator run smoothly. Clean filters keep dirt out of the engine and the final drive. Use the oil type listed in your service manual. Replace the oil filter and the hydraulic filter. Check the final drive for old oil and drain it if needed. Pour new oil into the final drive until it reaches the correct level. YNF Machinery offers quality filters and oil for your excavator.

Tip: Always use clean tools when you change oil and filters. Dirty tools can cause problems in the final drive.

Inspect After 50 Hours

After you run your excavator for 50 hours, inspect all the new parts. Look at the final drive for leaks or strange noises. Check the bolts on the final drive and engine to make sure they are tight. Examine the hydraulic hoses for cracks or leaks. Use a flashlight to see inside the final drive area. If you find any problems, fix them right away. YNF Machinery can help you get the right parts if you need replacements.

Inspection Item | What to Check | Action Needed |

|---|---|---|

Final drive oil | Level and color | Top up or change |

Bolts | Tightness | Re-torque if loose |

Hydraulic hoses | Leaks or cracks | Replace if damaged |

Ongoing Care Tips

Regular maintenance keeps your excavator working well. Check the final drive oil every week. Listen for new sounds from the final drive when you operate the machine. Clean the final drive area to remove dirt and debris. Grease the fittings on the final drive as shown in your manual. Watch for leaks around the final drive and fix them quickly. If you need help or new parts, contact YNF Machinery for support.

Note: Good maintenance helps your final drive last longer and keeps your excavator safe.

You have an easy guide to change Daewoo excavator engine parts. Always read your service manual and use safe steps. Check your work after you finish each step. Do regular maintenance and look at your machine often. If you find a hard problem, ask an expert for help. Pick YNF Machinery for good parts. Taking care of your excavator keeps it strong and ready to work.

FAQ

How do you find the correct Daewoo excavator engine part number?

First, check your service manual for the part number. Next, look at the old part for a number on it. Write this number down before you order new parts. YNF Machinery can help you find the right part if you need help.

What safety gear should you wear when replacing engine parts?

You should wear gloves, safety glasses, and steel-toed boots. Always use clean tools and keep your work area neat. Safety gear keeps you safe from burns, cuts, and other injuries.

Can you use aftermarket parts for Daewoo excavators?

It is best to use real or good aftermarket parts. YNF Machinery sells parts you can trust. Bad parts can break your excavator and cost more money.

How often should you check the final drive after replacement?

Check the final drive after you use it for 50 hours. Look for leaks, loose bolts, or strange sounds. Checking often helps you find problems early and keeps your excavator working well.

Where can you buy quality Daewoo excavator engine parts?

You can get quality Daewoo excavator engine parts from YNF Machinery. They have real and good aftermarket parts. Always check the part numbers before you buy anything.