You want your equipment to work without leaks or breakdowns. Picking the right y&f hydraulic seal kits helps you keep your excavator running smoothly. Not every hydraulic seal kit will fit your machine, so you need to check for size and material. The right kit stops oil leaks and keeps dirt out. When you choose y&f hydraulic seal kits, you protect your investment. A good hydraulic seal kit gives your equipment a longer life and better performance. Always match the kit to your needs.

Key Takeaways

Always check that the hydraulic seal kit matches your equipment’s model and part number. This helps stop leaks and damage. If you do not have part numbers, measure the seal sizes carefully. This makes sure the kit fits just right. Pick seal materials like NBR, FKM, or PTFE. Choose them based on your machine’s heat, pressure, and fluid needs. This helps the seals last longer. Use Y&F hydraulic seal kits to stop leaks and lower repair costs. They also help your equipment work well. Think about custom kits for special machines or hard jobs. This gives you the best fit and performance.

Y&F Hydraulic Seal Kits Overview

What Are Hydraulic Seal Kits?

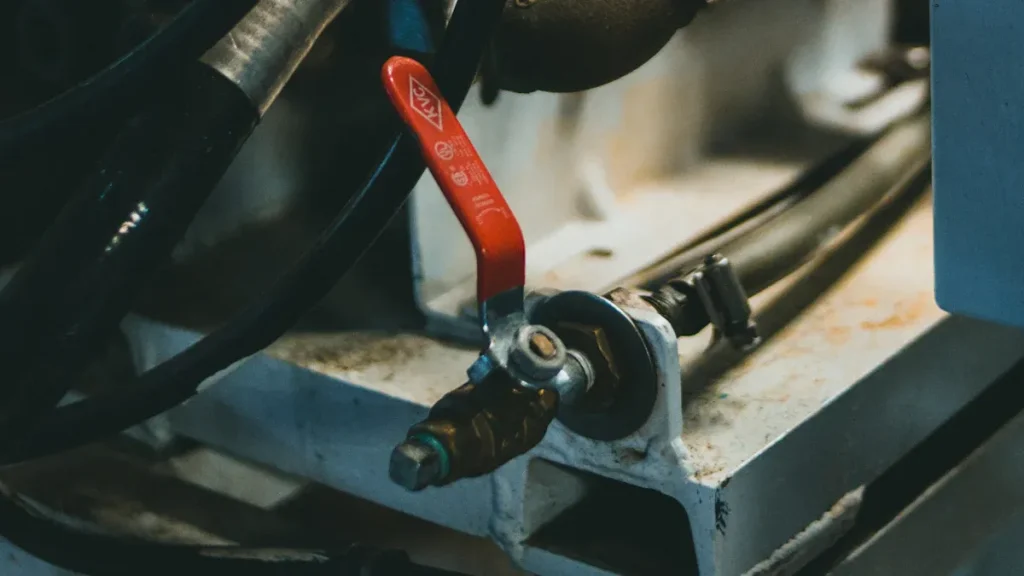

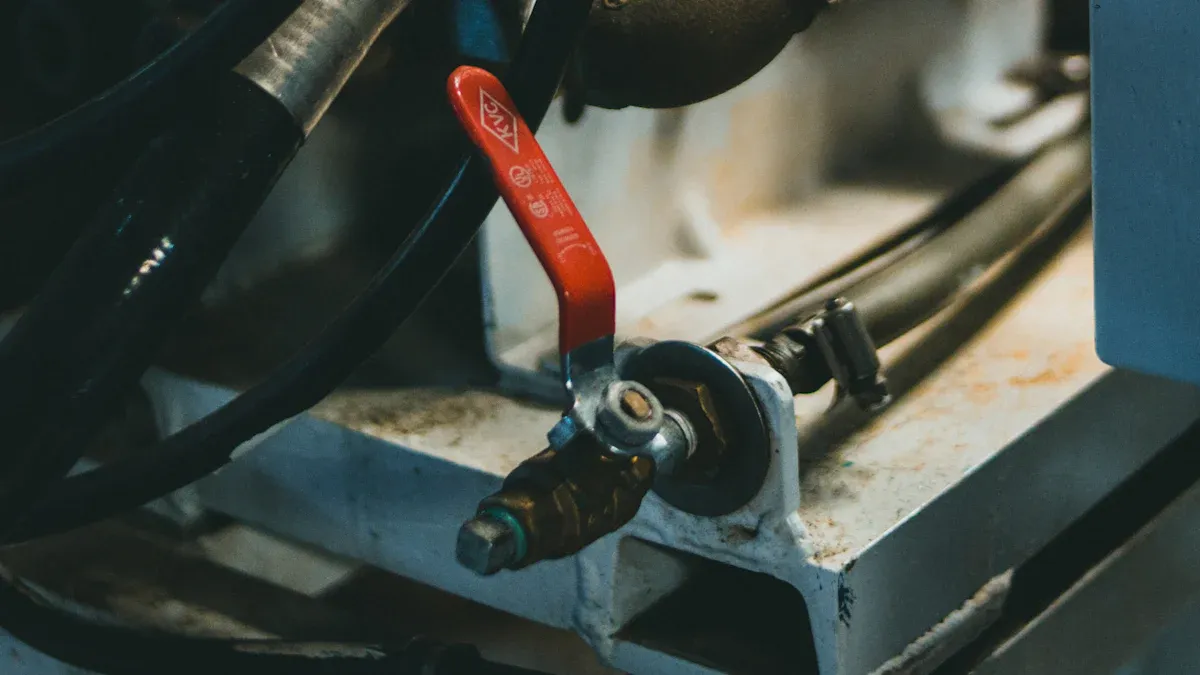

A hydraulic seal kit helps your equipment work without leaks. The kit has many seals that go inside hydraulic cylinders. These seals keep oil inside and stop dirt from getting in. When you put in a hydraulic seal kit, you protect the moving parts. This also helps your equipment last longer.

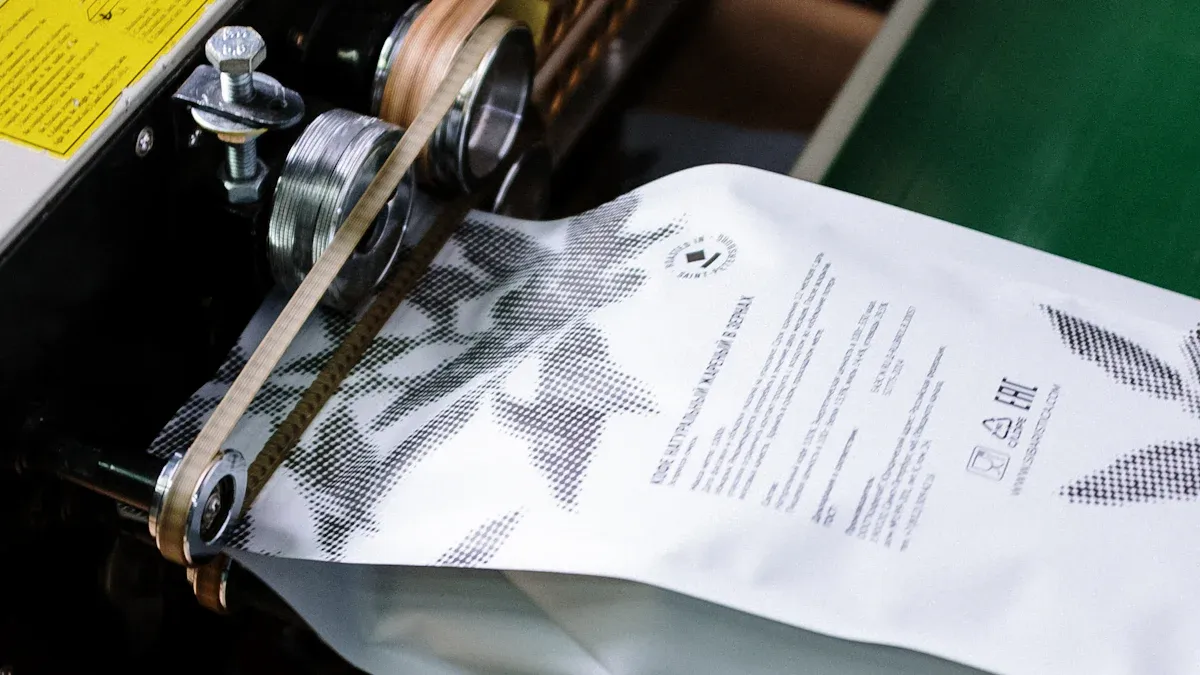

Hydraulic cylinder seals come in many shapes and sizes. Some seals go around the rod. Others go inside the cylinder. You need the right hydraulic seal kit for your machine. If you use the wrong kit, you might get leaks or damage. Y&F hydraulic seal kits work in many machines. You can find them in construction, heavy industry, food, and medical machines.

Here are some ways people use y&f hydraulic seal kits:

Construction machines like excavators, loaders, and bulldozers

Heavy industry, such as hydraulic presses and steel machines

Oil and gas machines, like high-pressure valves and drilling tools

Aerospace systems, such as aircraft landing gear and controls

Food and medical machines, where clean and safe seals are needed

Key Features of YNF Machinery Kits

YNF Machinery makes each hydraulic seal kit with care. The seals fit well and last a long time. The company uses strong materials for every kit. These materials help the seals work under high pressure and tough jobs. You can trust YNF Machinery kits to stop leaks and keep your equipment safe.

Each kit has all the hydraulic cylinder seals your machine needs. The seals match the size and shape of your equipment. YNF Machinery checks every kit before sending it out. You get a kit that meets high standards. You also get help if you have questions about your hydraulic seal kit.

Tip: Always check your equipment model before you order a kit. This helps you pick the right hydraulic cylinder seals and avoid problems later.

Hydraulic Seal Selection Process

Picking the right hydraulic seal kit helps your machine work well. You need to follow steps to make sure the seals fit. Here is a simple guide for choosing a kit from YNF Machinery.

Identify Equipment and Application

First, find out what equipment you have and what job it does. Look at the part, like the cylinder, pump, valve, or motor. Write down the maker and model number. This helps you get the right kit.

Tip: Always look for the part number on your kit or part. If you cannot find it, ask your supplier or check your manual.

Many people make mistakes here. Some choose the wrong part or forget the part number. Others do not match the kit to the job, which can cause leaks. Always match the kit to the job, like boom, arm, or bucket cylinder. This helps you avoid problems later.

Measure Seal Dimensions

If you do not have the part number, you must measure the seals. Use a caliper or tool to check shaft size, bore size, seal width, and groove size. Write down each size. Good measurements help the kit fit well.

Here is a checklist for measuring:

Shaft diameter

Bore diameter

Seal width

Groove dimensions

Stroke length

Check the old seals too. Compare their size and shape with the new ones. This helps you see any differences before you put in the new kit. If you skip this, you might get leaks.

Note: Measuring piston and rod size is very important. Even a small mistake can make the seal fail.

Check Compatibility and Specifications

After measuring, check if the kit matches your machine and fluid. Look at the seal types, like rod seals, piston seals, wipers, and O-rings. Each seal must fit the piston and rod.

Check what the seals are made of. Common materials are nitrile, PTFE, polyurethane, and Viton. The material must handle the pressure, heat, and job. Some seals work better with certain oils or in hot places.

Decide if you want an OEM kit or aftermarket kit. OEM kits come from the maker. Aftermarket kits can be just as good and may cost less. Make sure the aftermarket kit matches all needs.

Before you finish, do a test fit. Put the seals on the piston and in the grooves to check size. If you see a problem, ask your supplier for help.

Alert: Never forget to check pressure and temperature ratings. Using the wrong kit can make the seals wear out fast or break.

Step-by-Step Summary Table

Step | What to Do | Why It Matters |

|---|---|---|

1 | Identify equipment and application | Makes sure you pick the right kit |

2 | Check part numbers | Checks if it fits |

3 | Measure seal dimensions | Helps the kit fit right |

4 | Inspect old seals | Lets you see differences |

5 | Check seal types and materials | Matches seals to the job |

6 | Decide on OEM or aftermarket | Balances price and quality |

7 | Review pressure and temperature ratings | Stops early failure |

8 | Test fit before final assembly | Checks size and fit |

If you follow these steps, you will pick the right hydraulic seal kit. This keeps your equipment safe and working well.

Types of Seals in Y&F Kits

Rod Seals and Piston Seals

You will find that rod seals and piston seals are the main parts of hydraulic cylinder seals. These seals keep oil inside the cylinder and stop leaks. Rod seals sit at the opening where the rod moves in and out. They block fluid from escaping the cylinder. Piston seals fit around the piston inside the cylinder. They keep pressure on both sides of the piston and help the cylinder move smoothly.

Y&F kits use strong materials for these seals. You may see elastomers like FKM, NBR, and EPDM. Polyurethane and PTFE are also common. Some piston seals use composite materials such as bronze-filled PTFE. These materials give you chemical resistance, low friction, and long life. Rod seals often use FKM rubber and polyurethane U-cup designs. Piston seals can be made from PTFE or other composites. These choices help the seals handle high pressure and tough jobs.

Note: The right materials in rod seals and piston seals help your hydraulic cylinder seals last longer and work better.

Wipers and O-Rings

Wipers, also called scrapers, play a big role in keeping your hydraulic cylinder seals clean. They sit at the end of the cylinder and wipe dirt or dust off the rod as it moves. This keeps the inside of the cylinder free from harmful particles. Clean seals mean fewer leaks and less damage.

O-rings are another important part of hydraulic cylinder seals. You use them for static sealing. Their round shape helps them fit tightly and stop oil or gas from leaking out. O-rings work with rod seals and piston seals to keep the system tight. Together, these seals protect your equipment and keep pressure steady.

Here is a quick list of what each seal does:

Rod seals: Stop oil from leaking out of the cylinder.

Piston seals: Keep pressure on both sides of the piston.

Wipers: Remove dirt and dust from the rod.

O-rings: Seal joints and prevent leaks.

You need all these types of hydraulic cylinder seals to keep your equipment running well. Each seal has a special job. When you use the right seals, you get better performance and longer life for your hydraulic cylinders.

Materials for High-Quality Hydraulic Seal Kits

NBR, PTFE, FKM, and More

When you pick a good hydraulic seal kit, you should know what the seals are made of. The right material helps your equipment last longer and work better. There are three main materials in these kits: NBR, PTFE, and FKM. Each one is good for different jobs because of its special features.

Here is a table that shows how they are different:

Material | Physical Properties | Chemical Properties | Application Highlights |

|---|---|---|---|

NBR (Nitrile) | Strong and flexible at normal temperatures | Works with many oils, not expensive | Used for most hydraulic seals, works in normal heat |

FKM (Fluorocarbon) | Handles high heat, stays strong | Great with tough chemicals, good for hard fluids | Good for tough places, high heat hydraulic systems |

PTFE (Polytetrafluoroethylene) | Slippery, keeps its shape, low friction | Stays safe with strong chemicals, works with many fluids | Best for fast parts, very hot or chemical-heavy jobs |

NBR is strong and bends well when it is not too hot or cold. You can use it with many oils and fluids. FKM is good if your machine gets very hot or uses strong chemicals. It lasts longer in hard places. PTFE is slippery and keeps its shape. It is best for fast-moving parts or when you use strong chemicals.

Material Selection for Performance

You need to match your hydraulic seal kit to your machine’s needs. Think about how hot it gets, what fluids you use, and how fast the parts move. If your machine works in normal places, NBR is a good choice. If it gets very hot or uses strong chemicals, FKM is better. PTFE is best for fast or tough jobs.

The right material helps your piston and rod seals last longer. You will have less damage and fewer leaks. Picking the right kit keeps your machine safe and working well. Always check what the seals are made of before you buy. This easy step helps you avoid problems and keeps your equipment strong.

Tip: If you do not know which material to pick, ask your supplier for help. They can help you choose the best hydraulic seal kit for your job.

Benefits of YNF Machinery Hydraulic Cylinder Seal Kits

Leak Prevention and Durability

When you use YNF Machinery hydraulic cylinder seals, you protect your equipment from leaks. These seals fit tightly and keep oil inside the cylinder. You do not have to worry about dirt or dust getting in. The design of these seals helps your machine work in tough places. You can trust them to handle high pressure and heavy loads.

High-quality hydraulic seal kits from YNF Machinery use strong materials. These materials help the seals last longer, even when your equipment works every day. You will notice fewer leaks and less wear on your machine. The seals keep their shape and strength, so you do not have to replace them often. This means your equipment stays in good shape for a long time.

Tip: Good seals mean less time fixing leaks and more time using your equipment.

Cost-Effectiveness and Global Support

You save money when you choose high-quality hydraulic seal kits. These kits lower your maintenance costs because you do not need to replace seals as often. You also spend less on oil, since the seals stop leaks and keep oil inside the cylinder. Your equipment runs longer without problems, so you avoid costly downtime.

Here are some ways these kits help you save:

You replace the whole kit at once, which saves on labor and repair time.

The seals use premium materials, so they last longer and work better.

You lose less oil, which lowers your operating costs.

Your equipment works longer, so you get more value from your investment.

Even if the kit costs more at first, you save money over time because you do not have to fix leaks or stop work as often.

YNF Machinery gives you support wherever you are. You can get help with choosing the right hydraulic cylinder seals for your machine. The company ships worldwide, so you always have access to high-quality hydraulic seal kits. If you have questions, you can contact their team for fast answers.

Note: Effective sealing and strong support help you keep your equipment running smoothly, no matter where you work.

Custom Hydraulic Seal Kit Solutions

When to Choose Custom Kits

You may find that standard kits do not always fit your equipment. In these cases, custom hydraulic seal kits give you the best results. You should think about custom hydraulic seal kits if you work with special machines or face tough working conditions. These kits help you solve problems that standard kits cannot fix.

Here are some situations where you should choose custom hydraulic seal kits:

Your equipment uses non-standard cylinder sizes.

You need a perfect fit for unique or older machines.

Your job site has extreme temperatures or high pressure.

You want to improve performance in demanding environments.

Standard kits do not meet your specific application needs.

Custom hydraulic seal kits offer both standard and custom sizes. You get a kit that matches your machine exactly. This means less downtime and better protection for your equipment. Custom hydraulic sealing solutions help you keep your machines running strong, even in the toughest jobs.

How to Order from YNF Machinery

Ordering custom hydraulic seal kits from YNF Machinery is simple. First, you contact the YNF Machinery team with your equipment details. You should provide the model, part numbers, and any special requirements. The team will help you choose the right kit for your needs.

Follow these steps to order your custom hydraulic seal kits:

Gather your equipment information, such as model and cylinder size.

Contact YNF Machinery by email, phone, or WhatsApp.

Share your details and explain what you need in your kit.

The team will confirm your order and suggest the best kit.

YNF Machinery will prepare your custom hydraulic seal kits and ship them to you.

You can trust YNF Machinery to deliver a kit that fits your machine and meets your needs. The company supports you from start to finish, making sure you get the right kit every time.

Common Mistakes in Hydraulic Seal Kit Selection

Overlooking Compatibility

Not all hydraulic seal kits are the same. Some people pick a kit that does not fit their equipment. This can cause leaks or damage. You must check the size and type of each seal before buying. If you skip this, your machine may break down more often. You will also spend more time fixing it.

Always make sure the seal kit matches your machine’s model and cylinder type. Doing this helps you avoid repairs and keeps your equipment working longer.

Here are problems you might have if you do not check compatibility:

Seals that do not fit can make oil leak out.

Using the wrong kit means you fix things more often.

Your equipment might stop during important work.

You will spend more time and money on repairs.

You can stop these problems by reading your equipment’s manual. Use the right part number and ask your supplier for help. When the kit fits, you have less downtime and better maintenance.

Ignoring Material Requirements

Picking the wrong material for your hydraulic seals can make them fail early. Every job is different. Some seals need to handle high pressure. Others must work in hot places or with strong chemicals. If you do not think about this, your seals will wear out fast.

Always look at how your equipment works. Think about pressure, heat, and what fluid you use. Pick materials like PTFE, FKM, or NBR if you need strong or chemical-resistant seals. These materials help your seals last longer and need less fixing.

Not all materials can handle wear and rubbing.

Some seals break in very hot or cold weather.

The wrong material can cause leaks and more repairs.

Tip: Ask your supplier which material is best for your job. This helps you stop seal failure and keeps your maintenance on schedule.

Choosing the right material and checking compatibility helps you stop leaks. You will have less downtime and easier maintenance. Your hydraulic system will stay strong and work well.

You can pick the best Y&F hydraulic seal kit by doing these things:

Find out which hydraulic part you have and look for its model number.

Make sure the kit’s part number matches your machine.

If you need to, measure the seals to check their size.

Look at what kind of seal it is and what it’s made from.

Choose if you want an OEM kit or an aftermarket kit.

Check your old seals and compare them to the new ones.

Look at your system’s ratings to make sure everything fits.

Try the kit on your machine before you finish putting it together.

A good kit helps your equipment last longer and work better. The right kit is made from tough materials and keeps out dust. It also stands up to high pressure. You can ask YNF Machinery for help if you need it. Save this guide or show it to your coworkers.

FAQ

What is a hydraulic seal kit used for?

A hydraulic seal kit keeps oil inside your machine’s cylinder. It stops leaks and blocks dirt. You use it to help your equipment work better and last longer.

How do I know which seal kit fits my equipment?

Check your equipment’s model number and part number. Measure the old seals if you cannot find the numbers. You can also ask YNF Machinery for help.

Can I install a hydraulic seal kit by myself?

Yes, you can install a seal kit if you have basic tools and follow the instructions. If you feel unsure, ask a professional for help.

How often should I replace hydraulic seals?

Replace seals when you see leaks, hear strange noises, or notice slow movement. Many people check seals during regular maintenance to avoid problems.

What materials are best for hydraulic seals?

NBR works well for most jobs. FKM handles high heat. PTFE is good for fast-moving parts. Pick the material that matches your machine’s needs.