Choosing the right Bobcat mini excavator parts is crucial for ensuring your machine’s optimal performance and longevity. You face challenges when selecting parts for specific applications. A well-informed decision can enhance your mini excavator’s efficiency and lifespan. This guide will help you navigate the complexities of part selection. Whether you need components for a Bobcat compact track loader or other models, understanding your needs is essential. When you buy parts, consider their compatibility and quality to maximize your investment.

Key Takeaways

Understand your excavator’s application to select the right parts for optimal performance, whether for construction, landscaping, or agriculture.

Choose between rubber and steel tracks based on your work environment; rubber tracks are ideal for soft terrains, while steel tracks excel in rugged conditions.

Evaluate the durability and material quality of parts to ensure they withstand heavy-duty tasks and reduce the frequency of replacements.

Ensure compatibility of new parts with your existing equipment to avoid operational issues and maintain efficiency.

Consult experts and manufacturers for tailored advice and utilize online tools to assist in selecting the right parts.

Establish a regular maintenance schedule to inspect and service your excavator, preventing costly repairs and extending its lifespan.

Select high-quality parts from trusted suppliers like YNF Machinery to maximize your investment and enhance your machine’s performance.

Identifying Your Excavator’s Application

Understanding the specific application of your compact excavator is crucial for selecting the right parts. Different tasks require different components, and knowing your machine’s intended use will guide you in making informed decisions.

Understanding Different Use Cases

Construction and Demolition

In construction and demolition, compact excavators play a vital role. You need robust parts that can withstand heavy-duty operations. For example, Bobcat E50 rubber tracks are ideal for these environments. They offer maximum performance and durability, providing excellent grip on various terrains. When working on construction sites, ensure your mini excavator is equipped with parts designed for tough conditions.

Landscaping and Agriculture

Landscaping and agriculture require a different set of parts. Here, the focus shifts to versatility and precision. Compact excavators used in these fields often need attachments that allow for delicate handling of soil and plants. Consider using non-marking treads if you work on surfaces where leaving marks is undesirable, such as decorative driveways or sports courts. These treads ensure your work remains clean and professional.

Matching Parts to Specific Tasks

Heavy-Duty vs. Light-Duty Applications

When matching parts to tasks, consider whether your application is heavy-duty or light-duty. Heavy-duty applications demand parts that can handle significant stress and wear. For instance, rubber tracks designed for heavy-duty use provide the necessary support and durability. In contrast, light-duty applications might benefit from lighter, more flexible parts that offer ease of movement and efficiency.

Choosing the right parts for your compact excavator involves understanding your specific application. Whether you’re in construction, landscaping, or agriculture, selecting components that match your tasks ensures optimal performance. For reliable and high-quality parts, consider YNF Machinery as your preferred supplier. They offer a wide range of options tailored to meet your needs.

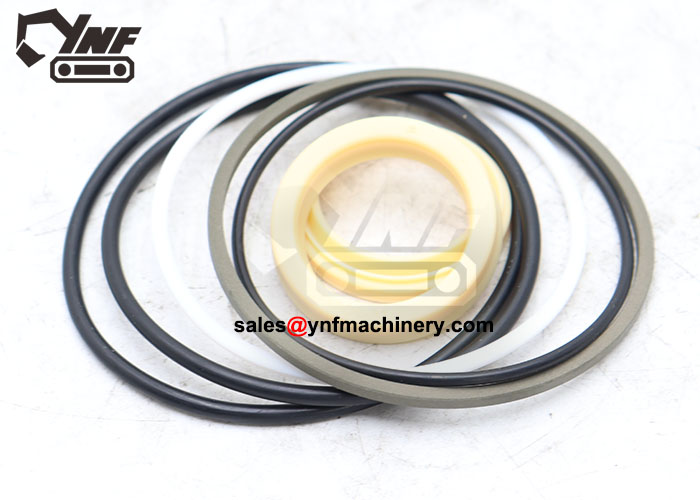

Types of Bobcat Mini Excavator Parts

Understanding the various parts available for your Bobcat mini excavator is essential for optimizing its performance. Each component plays a crucial role in ensuring your machine operates efficiently and effectively. Let’s explore some key parts and their significance.

Right Tracks for Your Mini Excavator

Selecting the right tracks for your mini excavator is vital. Tracks influence your machine’s traction, stability, and overall performance. You have two primary options: rubber and steel tracks.

Rubber vs. Steel Tracks

Rubber tracks offer flexibility and are ideal for soft terrains like grass or dirt. They minimize ground disturbance, making them perfect for landscaping and agricultural tasks. Steel tracks, on the other hand, provide durability and strength, suitable for rugged environments like construction and demolition sites. Consider your work environment when choosing between these track types.

Choosing the Right Tread Pattern

Choosing the right tread pattern enhances your compact excavator’s efficiency. Different patterns cater to specific terrains and tasks. For instance, a zigzag pattern might offer better grip on loose soil, while a block pattern provides stability on hard surfaces. Evaluate your operational needs to select the most suitable tread pattern.

Arms and Attachments

The attachments of compact excavators significantly expand their functionality. By selecting the appropriate arms and attachments, you can tailor your machine to meet diverse job requirements.

Standard vs. Extended Arms

Standard arms offer a balance between reach and power, suitable for general tasks. Extended arms provide additional reach, ideal for deep digging or reaching over obstacles. Your choice depends on the specific demands of your projects.

Popular Attachments and Their Uses

Bobcat offers a wide range of attachments, enhancing your compact excavator’s attachment capabilities. Popular options include buckets for digging, augers for drilling, and grapples for handling materials. These attachments eliminate the need for multiple machines, saving you time and money. Choose attachments based on the tasks you frequently encounter.

For high-quality Bobcat mini excavator parts, consider YNF Machinery as your preferred supplier. They offer a comprehensive selection tailored to meet your specific needs, ensuring your machine performs at its best.

Key Considerations for Selecting Parts

When selecting parts for your compact excavator, you must consider several key factors to ensure optimal performance and longevity. These considerations will guide you in making informed decisions that enhance your machine’s efficiency.

Durability and Material

Evaluating Material Quality

You should prioritize material quality when choosing parts for your compact excavator. High-quality materials ensure durability and withstand the rigors of heavy-duty tasks. Randy Riesland, a seasoned Bobcat Service Technician, emphasizes the importance of selecting parts made from robust materials. He notes that durable components reduce the frequency of replacements, saving you time and money in the long run. Look for parts that meet or exceed industry standards to guarantee reliability.

Weather and Terrain Considerations

Consider the weather and terrain where your compact excavator operates. Different environments demand specific parts to maintain performance. For instance, if you work in muddy or wet conditions, opt for tracks designed to handle such terrains. These tracks provide better traction and prevent slippage, ensuring safety and efficiency. In contrast, dry and rocky terrains may require more rugged tracks to withstand wear and tear. By matching parts to your work environment, you enhance your machine’s functionality.

Compatibility with Existing Equipment

Ensuring Fit and Functionality

Ensuring that new parts fit seamlessly with your existing equipment is crucial. Incompatible parts can lead to operational issues and reduced efficiency. Before purchasing, verify that the parts match your compact excavator’s specifications. This step prevents potential problems and ensures smooth operation. Randy Riesland advises consulting your machine’s manual or a professional to confirm compatibility, which helps avoid costly mistakes.

Checking Manufacturer Specifications

Always check the manufacturer’s specifications when selecting parts. These guidelines provide essential information about the right tracks, attachments, and other components suitable for your compact excavator. Adhering to these specifications ensures that the parts function correctly and maintain the machine’s integrity. By following the manufacturer’s recommendations, you safeguard your investment and prolong your equipment’s lifespan.

For high-quality bobcat mini excavator parts, consider YNF Machinery as your preferred supplier. They offer a wide range of options tailored to meet your specific needs, ensuring your machine performs at its best.

Consulting Experts and Manufacturers

When selecting parts for your compact excavator, consulting experts and manufacturers can provide invaluable guidance. Their insights help you make informed decisions, ensuring your machine operates at its best.

Importance of Professional Advice

When to Seek Expert Consultation

You should seek expert consultation when you face uncertainty in choosing the right parts for your compact excavator. Experts possess in-depth knowledge of Bobcat machinery and track applications. They can offer tailored advice based on your specific needs and work environment. For instance, if you’re unsure about the best tracks for your Bobcat compact track loader, an expert can guide you in selecting the most suitable option.

Questions to Ask Your Dealer

When consulting with your dealer, prepare a list of questions to maximize the value of the interaction. Consider asking:

What are the best parts for my specific model?

How do these parts enhance my compact excavator’s performance?

Are there any maintenance tips for prolonging the lifespan of these parts?

These questions help you gather essential information, ensuring you make the right purchase decisions.

Manufacturer Support and Resources

Utilizing Online Tools and Guides

Manufacturers often provide online tools and guides to assist you in selecting the right parts. These resources offer detailed specifications and compatibility information, helping you make informed choices. By leveraging these tools, you can ensure that the parts you buy fit seamlessly with your compact excavator.

Accessing Customer Service

Accessing customer service is crucial when you need additional support. Manufacturers like YNF Machinery offer comprehensive customer service to address your queries and concerns. Their team can provide expert advice, ensuring you select the best parts for your needs. Whether you require assistance with installation or have questions about part compatibility, their support team is ready to help.

For high-quality Bobcat mini excavator parts, consider YNF Machinery as your preferred supplier. They offer a wide range of options tailored to meet your specific needs, ensuring your machine performs at its best.

Maintenance Tips for Longevity and Performance

Maintaining your compact excavator ensures its longevity and optimal performance. Regular upkeep prevents unexpected breakdowns and extends the life of your machine. Here are some essential maintenance tips to keep your equipment in top shape.

Regular Inspection and Servicing

Routine inspections and servicing are vital for identifying potential issues before they become major problems. By staying proactive, you can avoid costly repairs and downtime.

Creating a Maintenance Schedule

Develop a maintenance schedule tailored to your compact excavator’s usage and environment. Regularly check components like tracks, hydraulic systems, and engine parts. A well-planned schedule helps you stay organized and ensures that no aspect of maintenance is overlooked. Consider setting reminders for routine checks and servicing to keep your machine running smoothly.

Common Signs of Wear and Tear

Recognizing signs of wear and tear early can save you from extensive repairs. Look for cracks or fraying on tracks, unusual noises from the engine, or hydraulic leaks. These indicators suggest that parts may need replacement or repair. Addressing these issues promptly maintains your compact excavator’s efficiency and prevents further damage.

Proper Storage and Handling

Proper storage and handling of your compact excavator play a crucial role in preserving its condition. By following best practices, you can protect your investment and ensure its readiness for future tasks.

Best Practices for Storage

Store your compact excavator in a dry, sheltered area to protect it from harsh weather conditions. Moisture and extreme temperatures can cause rust and damage to components like tracks and engines. If indoor storage isn’t available, consider using covers to shield your machine from the elements. Regularly clean your equipment before storage to remove dirt and debris that could cause corrosion.

Handling Tips to Prevent Damage

Handle your compact excavator with care to prevent unnecessary wear and tear. Avoid overloading the machine or operating it on unsuitable terrains. Use the right tracks for the specific environment to enhance stability and performance. Proper handling reduces the risk of accidents and prolongs the life of your equipment.

For high-quality parts and expert advice on maintaining your compact excavator, consider YNF Machinery as your preferred supplier. They offer a wide range of options tailored to meet your specific needs, ensuring your machine performs at its best.

Selecting the right bobcat mini excavator parts is crucial for maintaining your machine’s efficiency and longevity. This guide emphasizes the importance of consulting experts and adhering to regular maintenance schedules. By investing in quality parts, you ensure that your equipment operates smoothly, reducing downtime and repair costs. High-quality tracks and components enhance the performance of your bobcat compact track loader, providing reliability in various applications. When you buy from trusted suppliers like YNF Machinery, you gain access to durable parts that maximize your investment’s value over time.

FAQ

What are the most important factors to consider when selecting Bobcat mini excavator parts?

When choosing parts for your Bobcat mini excavator, focus on compatibility, durability, and the specific application. Ensure the parts fit your model and meet the demands of your work environment. High-quality materials enhance longevity and performance.

How do I determine the right tracks for my mini excavator?

Consider the terrain and tasks you frequently encounter. Rubber tracks suit soft terrains like grass, while steel tracks excel in rugged environments. Evaluate tread patterns based on your operational needs for optimal traction and stability.

Can I use aftermarket parts for my Bobcat mini excavator?

Yes, you can use aftermarket parts. However, ensure they meet or exceed OEM standards for quality and compatibility. Aftermarket options often provide cost-effective solutions without compromising performance.

Where can I find manuals for parts, service, and maintenance?

You can order parts, service, and operation manuals from your local dealer or the official Bobcat Shop. These resources offer valuable guidance for maintaining and servicing your equipment.

How often should I inspect and service my mini excavator?

Regular inspections and servicing are crucial. Create a maintenance schedule based on your machine’s usage and environment. Routine checks help identify potential issues early, preventing costly repairs and downtime.

What are common signs that parts need replacement?

Look for cracks or fraying on tracks, unusual engine noises, or hydraulic leaks. These signs indicate wear and tear, suggesting parts may need replacement. Addressing these issues promptly maintains efficiency.

How can I ensure new parts fit my existing equipment?

Verify compatibility by consulting your machine’s manual or a professional. Ensuring parts match your excavator’s specifications prevents operational issues and ensures smooth functionality.

What questions should I ask my dealer when purchasing parts?

Ask about the best parts for your model, how they enhance performance, and maintenance tips for prolonging lifespan. These questions help you make informed decisions and maximize your investment.

How can I access customer support for part selection and installation?

Manufacturers like YNF Machinery offer comprehensive customer service. Their team provides expert advice on part selection and installation, ensuring you choose the best options for your needs.

Why should I choose YNF Machinery as my preferred supplier?

YNF Machinery offers a wide range of high-quality Bobcat mini excavator parts tailored to meet your specific needs. Their commitment to quality and customer satisfaction ensures your machine performs at its best.