Replacing worn-out or damaged top race excavator parts on your Top Race excavator is essential to keep it running efficiently and safely. Over time, components face wear and tear from heavy use, which can lead to unexpected breakdowns or reduced performance. By addressing these issues promptly, you prevent costly repairs and extend the lifespan of your equipment. High-quality replacement parts ensure durability and reliability, even under tough conditions. This guide empowers you, as a beginner, to take control of your excavator’s maintenance and keep it operating at its best.

Key Takeaways

Regularly inspect your excavator for signs of wear and damage to prevent costly repairs and downtime.

Use the right tools and safety gear to ensure a safe and efficient part replacement process.

Choose high-quality replacement parts from reputable suppliers like YNF Machinery to enhance durability and performance.

Create a maintenance schedule based on manufacturer guidelines to keep your excavator in optimal condition.

Properly clean and lubricate your excavator after each use to minimize wear and extend the lifespan of its components.

Avoid common mistakes such as skipping inspections and using low-quality parts to maintain your excavator’s reliability.

Consider budget-friendly options like aftermarket parts and bulk purchases to manage costs without sacrificing quality.

Identifying Worn-Out or Damaged Top Race Excavator Parts

Keeping your Top Race excavator in top condition requires regular attention to its components. Identifying worn-out or damaged parts early can save you from costly repairs and downtime. This section will help you recognize the signs of wear and ensure your excavator operates efficiently.

Visual Signs of Wear and Tear

Inspecting your excavator visually is one of the simplest ways to detect issues. Look for cracks, dents, or deformities on key components like the bucket, tracks, and hydraulic hoses. Pay close attention to excavator attachments such as bucket teeth, cutting edges, and wear plates. These parts endure constant friction and impact during operation, making them prone to visible damage.

Rust or corrosion on metal parts is another red flag. It weakens the structural integrity of components, increasing the risk of failure. Hydraulic systems may show signs of oil leaks, which often indicate worn seals or damaged hoses. Regularly checking for these visual cues ensures you catch problems before they escalate.

Performance Issues to Watch For

Changes in your excavator’s performance often signal underlying issues. If you notice reduced digging efficiency, it may be time to replace worn bucket teeth or cutting edges. Sluggish or jerky movements in the hydraulic system could point to failing seals or bearings. Unusual noises, such as grinding or squeaking, often indicate excessive wear in moving parts.

Pay attention to the engine’s performance as well. Difficulty starting, reduced power, or increased fuel consumption may suggest problems with critical engine components. Addressing these issues promptly helps maintain your excavator’s peak efficiency.

Regular Inspection Tips

Routine inspections are essential for identifying potential problems early. Create a checklist to ensure you examine all critical areas of your excavator. Include components like tracks, hydraulic hoses, engine parts, and attachments. Perform these inspections before and after each use to monitor wear levels and spot damage.

Follow the manufacturer’s guidelines for maintenance intervals. For example, excavator spare parts like seals and bearings should be replaced based on usage intensity and operating conditions. Keeping a log of inspections and replacements helps you track the condition of your equipment over time.

“Timely replacement of worn parts not only preserves your excavator’s performance but also prevents excessive damage to other components.”

By staying vigilant and proactive, you can extend the lifespan of your excavator and avoid unexpected breakdowns. This guide equips you, as a beginner, with the knowledge to identify and address wear effectively.

Tools and Preparation for Replacing Top Race Excavator Parts

Replacing parts on your Top Race excavator requires the right tools, safety measures, and a well-prepared workspace. Proper preparation ensures a smoother process and reduces the risk of errors or accidents. This section provides a clear guide to help you get started.

Essential Tools for the Job

Having the correct tools is crucial for replacing excavator parts effectively. Using improper tools can damage components or lead to incomplete repairs. Below is a list of essential tools you should have on hand:

Wrenches and Sockets: These are necessary for loosening and tightening bolts and nuts. Ensure you have a variety of sizes to match different components.

Screwdrivers: Both flathead and Phillips screwdrivers are useful for removing smaller screws on panels or attachments.

Pliers: Use pliers for gripping, bending, or cutting wires and small parts.

Hydraulic Hose Tools: Specialized tools like hose crimpers and cutters are essential for working on hydraulic systems.

Torque Wrench: This tool ensures bolts are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening.

Rubber Mallet: A mallet helps with gently tapping parts into place without causing damage.

Seal Puller and Installer: These tools are vital for replacing seals in hydraulic cylinders or other components.

Investing in high-quality tools ensures durability and precision. Tools designed for heavy-duty use are better suited for excavator maintenance tasks.

Safety Gear to Ensure Protection

Safety should always be your top priority when working on heavy machinery. Wearing the right protective gear minimizes the risk of injuries. Equip yourself with the following:

Safety Gloves: Protect your hands from sharp edges, hot surfaces, and chemical exposure.

Safety Glasses or Goggles: Shield your eyes from debris, dust, or hydraulic fluid splashes.

Steel-Toe Boots: These boots provide protection against heavy objects that might accidentally fall.

Hard Hat: A hard hat protects your head from potential impacts in the work area.

Hearing Protection: If you’re working in a noisy environment, earplugs or earmuffs can prevent hearing damage.

High-Visibility Vest: This ensures you remain visible to others in the workspace, especially in low-light conditions.

Wearing the appropriate safety gear not only protects you but also allows you to focus on the task without unnecessary distractions.

Preparing Your Work Area

A well-organized workspace is essential for efficient and safe part replacement. Follow these steps to prepare your area:

Clear the Space: Remove any unnecessary tools, debris, or obstacles from the area. A clutter-free workspace reduces the risk of tripping or misplacing tools.

Stabilize the Excavator: Park the excavator on a flat, stable surface. Engage the parking brake and use wheel chocks to prevent movement.

Lay Out Tools and Parts: Arrange your tools and replacement parts within easy reach. Use a tool organizer or tray to keep everything in order.

Ensure Proper Lighting: Good lighting helps you see small details and avoid mistakes. Use portable work lights if needed.

Disconnect Power Sources: Turn off the excavator and disconnect the battery to prevent accidental starts during the replacement process.

Follow Manufacturer Guidelines: Refer to the user manual for specific instructions on disassembly and reassembly. This ensures you follow the correct procedures.

“Preparation is the foundation of successful maintenance. A well-prepared workspace saves time and prevents costly errors.”

By gathering the right tools, wearing proper safety gear, and organizing your work area, you set yourself up for a smooth and efficient replacement process. This guide equips you with the knowledge to handle the task confidently and safely.

Step-by-Step Guide to Replacing Top Race Excavator Parts

Replacing parts on your Top Race excavator may seem challenging, but with the right approach, you can handle it confidently. This step-by-step guide simplifies the process, ensuring you can maintain your equipment effectively.

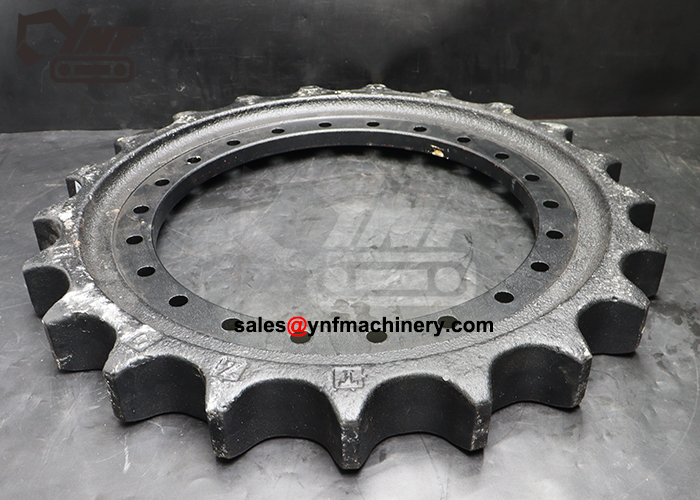

Replacing Tracks

Tracks endure constant stress during operation, making them one of the most frequently replaced components. Worn or damaged tracks can reduce stability and digging efficiency. Follow these steps to replace them:

Inspect the Tracks: Check for cracks, tears, or excessive wear. If the tracks appear loose or uneven, it’s time for a replacement.

Lift the Excavator: Use a jack or lifting equipment to raise the excavator. Ensure it is stable and secure before proceeding.

Remove the Old Tracks: Loosen the tensioner bolt to release tension. Slide the old tracks off the sprockets and rollers.

Install the New Tracks: Align the new tracks with the sprockets and rollers. Slide them into place, ensuring proper alignment.

Adjust Tension: Tighten the tensioner bolt until the tracks are snug but not overly tight. Proper tension prevents premature wear.

Test the Tracks: Lower the excavator and test the movement. Ensure the tracks move smoothly without slipping or binding.

“Replacing tracks promptly ensures your excavator remains stable and efficient during operation.”

Regularly inspect your tracks to avoid unexpected downtime. Proper maintenance extends their lifespan and improves overall performance.

Replacing Buckets

Buckets play a critical role in digging and material handling. Over time, bucket teeth, cutting edges, and wear plates experience significant wear. Replacing these parts restores digging efficiency. Here’s how to replace a bucket:

Detach the Bucket: Remove the pins or bolts securing the bucket to the arm. Use a hammer or mallet if the pins are stuck.

Inspect the Bucket: Check for cracks, dents, or worn teeth. Replace the entire bucket if the damage is extensive.

Replace Bucket Teeth: Remove worn teeth using a wrench or pliers. Attach new teeth by securing them with pins or bolts.

Install the New Bucket: Align the bucket with the arm. Insert the pins or bolts and secure them tightly.

Test the Attachment: Operate the excavator to ensure the bucket moves freely and securely.

“Bucket teeth and cutting edges are vital for efficient digging. Regular replacement keeps your excavator performing at its best.”

Inspect your bucket after each use. Prompt replacement of worn parts prevents further damage to the attachment.

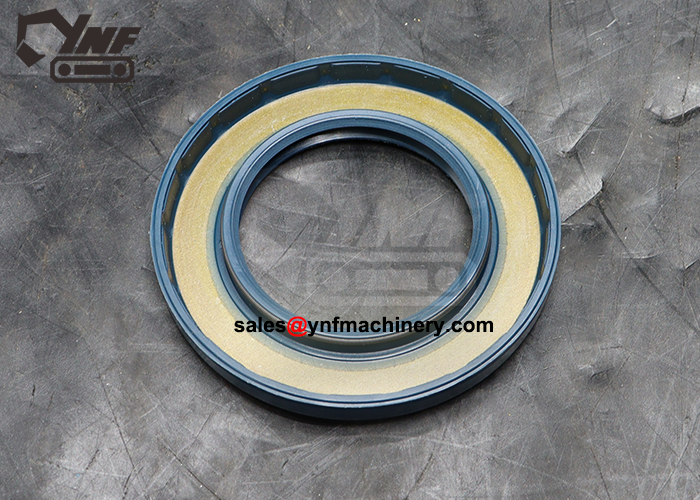

Replacing Hydraulic Components with YNF Machinery’s Hydraulic Cylinder Seal Kits

Hydraulic systems power your excavator’s movements. Leaks or reduced performance often indicate worn seals. YNF Machinery’s Hydraulic Cylinder Seal Kits provide a reliable solution for replacing these components. Follow these steps:

Identify the Problem: Look for oil leaks or sluggish hydraulic movements. These signs often point to worn seals.

Disassemble the Cylinder: Remove the cylinder from the excavator. Use a wrench to loosen the bolts and carefully detach it.

Remove the Old Seals: Use a seal puller to extract the worn seals. Clean the cylinder thoroughly to remove debris or oil residue.

Install New Seals: Select the correct seals from the kit. Align them properly and press them into place using a seal installer.

Reassemble the Cylinder: Reattach the cylinder to the excavator. Tighten the bolts securely to prevent leaks.

Test the System: Operate the hydraulic system to ensure smooth and leak-free performance.

“High-quality seal kits, like those from YNF Machinery, ensure durability and prevent future leaks.”

Regular maintenance of hydraulic components enhances efficiency and reduces the risk of costly repairs. YNF Machinery’s kits offer a dependable solution for maintaining your excavator.

Sourcing High-Quality Top Race Excavator Parts

Finding reliable replacement parts for your Top Race excavator is essential to maintain its performance and longevity. High-quality parts ensure your equipment operates efficiently, reduces downtime, and withstands the demands of heavy use. This section will guide you on why YNF Machinery stands out, how to verify part quality, and ways to find budget-friendly options.

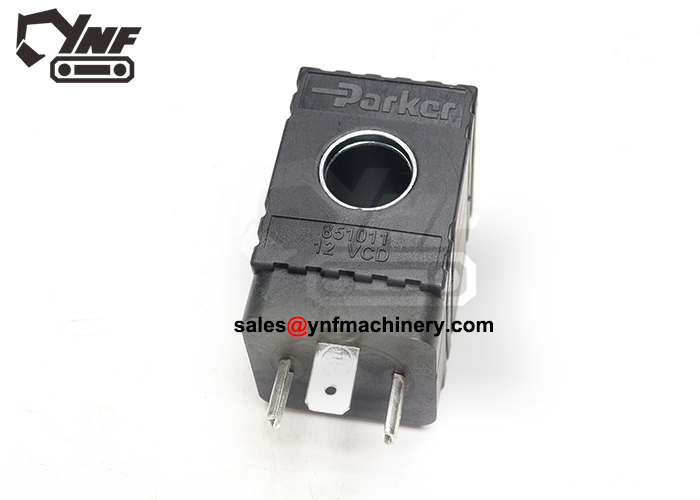

Why Choose YNF Machinery for Excavator Engine Parts and Couplings

YNF Machinery has built a reputation as a trusted supplier of excavator parts for over 35 years. Their products are designed to meet the rigorous demands of construction, mining, and infrastructure projects. Choosing YNF Machinery ensures you receive parts that deliver durability, efficiency, and safety.

Durability: YNF Machinery’s parts, such as excavator engine parts and couplings, are crafted from high-grade materials. These components can endure extreme conditions, reducing the risk of breakdowns.

Efficiency: Their parts are engineered to optimize performance. For example, their hydraulic pump couplings ensure smooth power transmission, enhancing the overall functionality of your excavator.

Safety: High-quality parts minimize the chances of equipment failure, ensuring a safer working environment.

“Investing in quality parts like those from YNF Machinery helps you avoid frequent replacements and costly repairs.”

Additionally, YNF Machinery offers both OEM and aftermarket options, giving you flexibility without compromising on quality. Their competitive pricing and low minimum order quantities make them an excellent choice for businesses of all sizes.

Tips for Verifying Part Quality

Ensuring the quality of replacement parts is crucial for maintaining your excavator’s reliability. Follow these tips to verify the quality of the parts you purchase:

Check Material Specifications: High-quality parts are made from durable materials like reinforced steel or high-grade rubber. Verify the material details provided by the supplier.

Inspect Manufacturing Standards: Look for parts that meet or exceed OEM standards. This ensures compatibility and performance.

Examine Product Certifications: Reputable suppliers provide certifications or quality assurance documents. These validate the part’s compliance with industry standards.

Read Customer Reviews: Feedback from other users can provide insights into the part’s performance and durability.

Consult the Supplier: Reliable suppliers like YNF Machinery offer expert support. They can help you confirm compatibility based on your excavator’s model and specifications.

“Quality parts not only enhance performance but also extend the lifespan of your excavator.”

By taking these steps, you can confidently select parts that meet your needs and avoid substandard products.

Budget-Friendly Options for Replacement Parts

Maintaining your excavator doesn’t have to break the bank. You can find cost-effective solutions without sacrificing quality by following these strategies:

Choose Aftermarket Parts: YNF Machinery offers high-quality aftermarket options that meet OEM standards. These parts provide excellent performance at a lower cost.

Buy in Bulk: Purchasing frequently used parts, like seals or couplings, in bulk can reduce costs. YNF Machinery’s low minimum order quantities make this approach feasible.

Look for Promotions: Keep an eye out for discounts or special offers from reputable suppliers. These deals can help you save money on essential parts.

Prioritize Essential Replacements: Focus on replacing critical components first, such as hydraulic seals or engine parts. Addressing these areas prevents further damage and reduces long-term expenses.

“Budget-friendly options, when chosen wisely, maintain your excavator’s performance while keeping costs under control.”

By sourcing parts strategically, you can balance quality and affordability, ensuring your excavator remains a valuable asset for your projects.

Maintenance Tips to Extend the Lifespan of Top Race Excavator Parts

Proper maintenance plays a vital role in ensuring your Top Race excavator operates efficiently and lasts longer. By following these practical tips, you can minimize wear and tear, reduce unexpected breakdowns, and maximize the return on your investment.

Regular Cleaning and Lubrication

Keeping your excavator clean is one of the simplest yet most effective ways to maintain its parts. Dirt, mud, and debris can accumulate on critical components, leading to corrosion and reduced performance. After each use, clean the excavator thoroughly, paying close attention to areas like the undercarriage, hydraulic hoses, and attachments. Use a pressure washer or a soft brush to remove stubborn grime without damaging the surface.

Lubrication is equally important. Moving parts, such as pins, bushings, and joints, require regular lubrication to reduce friction and prevent premature wear. Use high-quality grease recommended by the manufacturer. Apply it generously but avoid over-lubricating, as excess grease can attract dirt. A well-lubricated machine operates smoothly and efficiently, extending the lifespan of its components.

“Regular cleaning helped remove dirt, mud, and debris, reducing the chances of corrosion and preserving the structural integrity of our excavator.” – Cleaning Crew Member

Proper Storage Practices

Storing your excavator correctly protects it from environmental damage and ensures it remains in optimal condition when not in use. Always park the machine on a flat, stable surface. Engage the parking brake and lower all attachments to the ground for added stability. If possible, store the excavator indoors to shield it from harsh weather conditions like rain, snow, or extreme heat.

When indoor storage isn’t an option, use a heavy-duty cover to protect the machine. Ensure the cover fits snugly and provides adequate ventilation to prevent moisture buildup, which can lead to rust. Before storing the excavator for an extended period, clean it thoroughly, lubricate all moving parts, and disconnect the battery to avoid drainage.

“Proper storage practices ensured our excavator remained free from corrosion and operational for extended periods.” – Maintenance Manager

Scheduling Routine Maintenance with YNF Machinery’s Support

Routine maintenance is the cornerstone of keeping your excavator in top shape. Create a maintenance schedule based on the manufacturer’s recommendations and the intensity of use. Include tasks like inspecting hydraulic systems, checking engine oil levels, and replacing worn-out parts. Regular inspections help you identify potential issues early, preventing costly repairs and downtime.

YNF Machinery offers comprehensive support to simplify your maintenance routine. Their high-quality replacement parts, such as hydraulic cylinder seal kits and engine components, ensure your excavator operates reliably. By partnering with YNF Machinery, you gain access to expert advice, fast shipping, and durable parts that meet or exceed OEM standards.

“Timely replacement of spare parts helped minimize the risk of unexpected breakdowns and downtime, ensuring uninterrupted operation on the job site.” – Equipment Operator

A well-maintained excavator not only performs better but also lasts longer. By cleaning and lubricating regularly, storing it properly, and scheduling routine maintenance with trusted suppliers like YNF Machinery, you can extend the lifespan of your Top Race excavator parts and keep your machine running smoothly.

Common Mistakes to Avoid When Replacing Top Race Excavator Parts

Replacing parts on your Top Race excavator can seem straightforward, but common mistakes often lead to inefficiencies, higher costs, or even equipment damage. Avoiding these pitfalls ensures a smoother process and keeps your excavator running at its best. This guide highlights the most frequent errors and how you can prevent them.

Skipping Inspections

Skipping inspections is one of the most critical mistakes you can make. Regular inspections help you identify worn or damaged parts before they cause significant issues. Without these checks, small problems can escalate into costly repairs or unexpected downtime.

Why Inspections Matter: Inspections allow you to catch early signs of wear, such as cracks, leaks, or unusual noises. For example, a minor hydraulic leak can quickly worsen if left unaddressed, leading to system failure.

How to Avoid This Mistake: Create a routine inspection schedule. Check components like tracks, hydraulic hoses, and engine parts before and after each use. Use a checklist to ensure you don’t overlook any critical areas.

“Neglecting inspections often results in expensive repairs and reduced equipment lifespan. Proactive checks save time and money.”

By prioritizing inspections, you maintain your excavator’s performance and prevent avoidable breakdowns.

Using Incorrect Tools

Using the wrong tools for part replacement can damage components and compromise the repair process. It also increases the risk of injury, as improper tools may slip or fail under pressure.

Common Issues with Incorrect Tools: A mismatched wrench can strip bolts, while a standard screwdriver may not provide the precision needed for delicate parts. Hydraulic systems, in particular, require specialized tools like seal pullers and hose crimpers.

How to Avoid This Mistake: Invest in a complete set of high-quality tools designed for heavy machinery. Ensure you have essentials like torque wrenches, pliers, and hydraulic-specific tools. Refer to the manufacturer’s guide to confirm the required tools for each task.

“The right tools not only make the job easier but also ensure the integrity of your excavator’s components.”

Equipping yourself with proper tools guarantees safer and more efficient part replacements.

Buying Low-Quality Parts

Opting for low-quality parts might save money upfront, but it often leads to frequent failures, higher maintenance costs, and reduced machine performance. Poor-quality parts wear out faster and may not meet the specifications required for your excavator.

Impact of Low-Quality Parts: Substandard parts can cause frequent breakdowns, leading to extended downtime. For instance, low-grade hydraulic seals may fail under pressure, resulting in leaks and system inefficiencies.

How to Avoid This Mistake: Always choose high-quality parts from reputable suppliers like YNF Machinery. Their parts meet or exceed OEM standards, ensuring durability and reliability. While high-quality parts may cost more initially, they reduce long-term expenses by minimizing replacements and repairs.

“Investing in quality parts ensures your excavator operates efficiently and avoids unnecessary downtime.”

By selecting reliable components, you enhance your excavator’s performance and extend its lifespan.

Avoiding these common mistakes helps you maintain your Top Race excavator effectively. Regular inspections, proper tools, and high-quality parts are essential for smooth operations and long-term reliability. Following this guide ensures you replace parts with confidence and keep your equipment in peak condition.

Maintaining your Top Race excavator requires consistent attention to identifying, sourcing, and replacing worn-out parts. This ensures optimal performance, longevity, and safety. Regular maintenance helps you catch minor issues early, preventing costly breakdowns and extending the life of your equipment. High-quality replacement parts, like those from YNF Machinery, provide durability and reliability, keeping your excavator running efficiently. Follow this guide to confidently manage your excavator’s upkeep. Prioritize routine care and timely replacements to maximize your machine’s effectiveness and minimize downtime.

FAQ

What are the most common parts that need replacement on a Top Race excavator?

The most frequently replaced parts include tracks, bucket teeth, hydraulic seals, and batteries. Tracks and bucket teeth endure constant wear from digging and moving materials, while hydraulic seals can degrade over time due to pressure and fluid exposure. Battery replacement is also common, especially if the excavator shows signs of starting issues or reduced power.

Tip: Regular inspections help you identify these parts’ wear early, preventing unexpected breakdowns.

How do I know when it’s time to replace a part?

You should replace a part when you notice visible damage, performance issues, or unusual noises. For example, cracks in tracks, oil leaks from hydraulic systems, or reduced digging efficiency signal the need for replacement. Always consult your user manual for specific guidelines on part lifespan and maintenance schedules.

Can I replace parts on my Top Race excavator myself?

Yes, many parts can be replaced with basic tools and preparation. Tracks, buckets, and hydraulic seals are examples of components you can handle with the right guidance. However, for complex repairs like engine overhauls, consider consulting a professional to ensure proper installation and safety.

Why is it important to use high-quality replacement parts?

High-quality parts ensure durability, efficiency, and safety. For instance, premium hydraulic seals prevent leaks and maintain optimal pressure, while durable tracks improve stability and performance. Using substandard parts increases the risk of frequent failures, higher maintenance costs, and reduced machine lifespan.

Pro Tip: Trusted suppliers like YNF Machinery provide parts that meet or exceed OEM standards, ensuring reliability.

How do I choose the right replacement parts for my excavator?

Start by identifying your excavator’s model and the specific part you need. Check the part number in your user manual or consult the supplier for compatibility. Reputable suppliers like YNF Machinery offer expert support to help you select the correct parts for your machine.

What tools do I need for replacing excavator parts?

Essential tools include wrenches, screwdrivers, pliers, a torque wrench, and hydraulic-specific tools like seal pullers. A rubber mallet and a tool organizer can also make the process smoother. Investing in high-quality tools ensures precision and reduces the risk of damaging components.

How often should I inspect my excavator for worn parts?

Inspect your excavator before and after each use. Focus on critical areas like tracks, hydraulic hoses, and attachments. Regular inspections help you catch early signs of wear, such as cracks, leaks, or loose components, ensuring timely replacements and uninterrupted operation.

Can I find budget-friendly options for replacement parts?

Yes, you can find cost-effective solutions without compromising quality. Aftermarket parts from reliable suppliers like YNF Machinery offer excellent performance at a lower cost. Buying in bulk or looking for promotions can also help you save money on essential replacements.

What should I do if my excavator’s battery needs replacement?

If your excavator struggles to start or shows reduced power, it might be time for a battery replacement. Disconnect the old battery carefully, ensuring all connections are secure when installing the new one. Always choose a battery compatible with your excavator’s specifications for optimal performance.

How can I extend the lifespan of my excavator parts?

Regular maintenance is key. Clean your excavator after each use to remove dirt and debris. Lubricate moving parts to reduce friction and wear. Store the machine properly to protect it from harsh weather. Scheduling routine maintenance with trusted suppliers like YNF Machinery ensures your excavator stays in top condition.