You want to change your chinese mini excavator hydraulic pump so your machine works well again. Problems like dirt, broken seals, and air in the system can make the pump stop working. Look at the table below to see the main reasons pumps fail:

Cause of Failure | Description |

|---|---|

Contamination in the Pump | Water, dust, and dirt can make the pump too hot and rusty. |

Failing Seals | Leaky seals cause fluid to escape and make the pump work badly. |

Overpressure and Overloading | Too much pressure can break the pump. |

Air in Pump and in Fluid | Air makes the pump work less well and can hurt it. |

Low Oil, Incorrect Oil, or Too Much Oil | Wrong oil amounts can make the pump too hot and cause trouble. |

You will likely spend between $1,500 and $4,000 for parts and labor. The price changes if the pump is bigger or made by a different company. Labor costs can be different if the job is harder.

Pick the right pump and follow each step. Making sure the pump fits and is put in right helps your mini excavator work safely and well. If you know some basic mechanics, you can do this job.

Key Takeaways

Look for signs that the hydraulic pump is failing, like leaks, getting too hot, or losing power. Fixing these problems early can stop more damage from happening.

Pick the correct hydraulic pump by making sure it fits your excavator model. Check that the flow rate and pressure are right for your machine.

Get your workspace ready with all the tools and safety gear you need. This helps make the replacement easy and keeps you safe from harm.

Replace the pump by following each step, like disconnecting lines, moving fittings, and letting air out of the system.

Take care of your hydraulic system often by looking for leaks, changing the fluid, and cleaning the filters. This will help your new pump last longer.

When to Replace Your Hydraulic Pump

Signs of Pump Failure

Watch for signs that your hydraulic pump is failing. If you see hydraulic fluid leaking, the pump might have a broken seal or an inside problem. Less power or pressure can make your excavator slow or weak. Overheating is another warning sign. If the pump gets too hot, it can hurt seals and lower fluid quality.

Here are the most common symptoms you might notice:

Hydraulic fluid leaks near the pump or hoses

Less power or pressure when you use the machine

The pump or hydraulic fluid gets too hot

If you ignore these signs, your excavator may work slowly or feel weak. Inside leaks and dirt can make things worse. Seals that are not put in right may cause more damage and even make the machine unsafe. Some people find rust or dirt in the hydraulic system, which can make the excavator work badly. A bad case seal in the pump can cause leaks inside that you cannot see.

Tip: If your excavator cannot lift well or the bucket feels weak, check the hydraulic pump first.

Diagnosing Issues

You can use easy checks and tools to find problems with your chinese mini excavator hydraulic pump. Start by looking for leaks you can see or listen for banging and knocking sounds. These sounds often mean air is trapped in the system, which can make it get too hot.

Pressure testing helps you know if the pump works right. If the hydraulic parts feel weak, like the boom or dozer blade cannot lift together, you may have a pressure problem. Sometimes, the boom drops when you lift the arm or bucket. If the bucket tilt feels weak and gives in when you push it into the ground, the pump may not give enough pressure.

Here is a table showing common diagnostic signs and what they mean:

Diagnostic Sign | Implication |

|---|---|

Visible or Internal Leaks | Leaks make the machine work worse and lower fluid pressure. |

Banging and Knocking Sounds | Air in the system causes overheating and cavitation. |

Increase in Temperature | Pressure drop makes fluid hotter, hurting seals and fluid quality. |

Weak Final Drive Motor | Low fluid pressure makes the motor lose power. |

If you see heat building up near the relief valve, you may have a problem with the pump or a leaking part. Pressure readings can help you know if the pump is the problem. Good readings mean the pump works, but weak performance means there is a problem.

Choosing a Chinese Mini Excavator Hydraulic Pump

Pump Types

Mini excavators use three main hydraulic pump types. Each type works in its own way and has special features.

Gear Pump: This pump moves fluid with gears. It is simple and costs less. Sometimes, friction can make it less efficient.

Piston Pump: This pump uses pistons that move back and forth. It gives strong pressure and has valves to stop fluid from going backward. Heavy-duty machines often use piston pumps for better power.

Vane Pump: This pump is small and uses vanes that adjust to move fluid. Vane pumps are reliable and run smoothly.

Check which pump type your chinese mini excavator hydraulic pump uses before you buy a new one.

Compatibility Tips

Picking the right pump means checking a few things. You want the pump to fit and work well.

Make sure the pump fits your excavator model.

Check the flow rate and pressure. The pump must match your machine’s needs.

Buy pumps from trusted companies. Good pumps last longer and work better.

Look at the warranty and support. Good support helps if you have problems.

Think about how long the pump will last and if it is easy to fix.

Look at the pump’s details. The table below shows what to check:

Specification | Details |

|---|---|

Flow Rate | Must match your excavator’s fluid needs (e.g., 50 L/min) |

Displacement | Affects efficiency and energy use |

Power Source | Check voltage requirements |

Size and Weight | Should fit your excavator’s design |

Operating Pressure | High-pressure pumps handle tough jobs |

Material Quality | Cast iron and steel last longer |

Be careful of fake parts. These use bad materials and may not fit right. You might see rough or uneven edges. If the price is very low, it could be fake. Using fake pumps can cancel your warranty and cause safety risks.

Where to Buy

You can buy a chinese mini excavator hydraulic pump from YNF Machinery. YNF Machinery sells pumps for many excavator models. Check the warranty before you buy. Some warranties only cover the frame, while others include the hydraulic pump and electronics. Ask about support and replacement choices.

Supplier | Warranty Terms |

|---|---|

YNF Machinery | Ask about coverage for hydraulic pump and electronics |

Preparation Steps

Tools and Materials

Get your tools and materials before you start. This helps you work faster and safer. You need basic hand tools and some special things.

Tool or Material | Purpose |

|---|---|

Wrenches (metric/standard) | Loosen and tighten bolts |

Screwdrivers | Remove covers and panels |

Hydraulic fluid | Fill the system after replacement |

Safety glasses | Protect your eyes |

Gloves | Shield your hands |

Steel-toe boots | Guard your feet |

Spill mats/absorbents | Catch drips and spills |

Waste oil container | Store old hydraulic fluid |

Clean rags | Wipe surfaces and hands |

Tip: Use a waste oil container and spill mats. This keeps your work area clean and safe.

Safety Setup

Safety matters when you work with hydraulic systems. You must protect yourself and the environment. Do these things before you start:

Wear safety glasses, gloves, and steel-toe boots.

Put on a hard hat if you work near heavy parts.

Check your area for obstacles and hazards.

Learn how your mini excavator works.

Look at all controls and mirrors before you start.

Use seat belts if you move the machine.

Get training on how to use the machine and what to do in emergencies.

Think about the environment too. Hydraulic oil is hazardous waste. Use spill mats or absorbent materials to catch drips. Put old oil in a waste container. Take used oil and the old pump to a recycling center or collection point.

Note: Clean the hydraulic system often. Test the oil every 300 to 500 hours. This helps your excavator run well.

Replace Hydraulic Pump

Disconnect Hydraulic Lines

Start by turning off your mini excavator and making sure the hydraulic system is not pressurized. Use wrenches to loosen the bolts on the hydraulic lines connected to the pump. Place spill mats under the connections to catch any fluid that drips out. Remove each line slowly to avoid sudden leaks. If you find a connection that will not come loose, use a penetrating oil and wait a few minutes before trying again.

Check each line for damage. Look for cracks or worn spots. Damaged lines can cause leaks after you install the new pump. Most leaks happen because of loose or damaged fittings, failed seals, or broken lines. If you see any problems, replace the parts before you continue.

Tip: Mark each hydraulic line with tape or tags. This helps you reconnect them to the correct spot later.

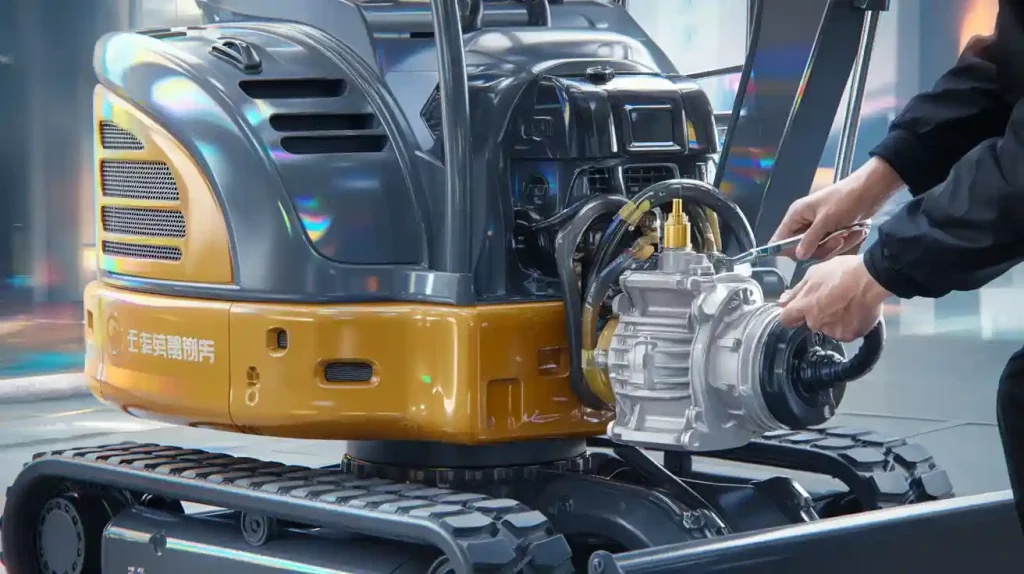

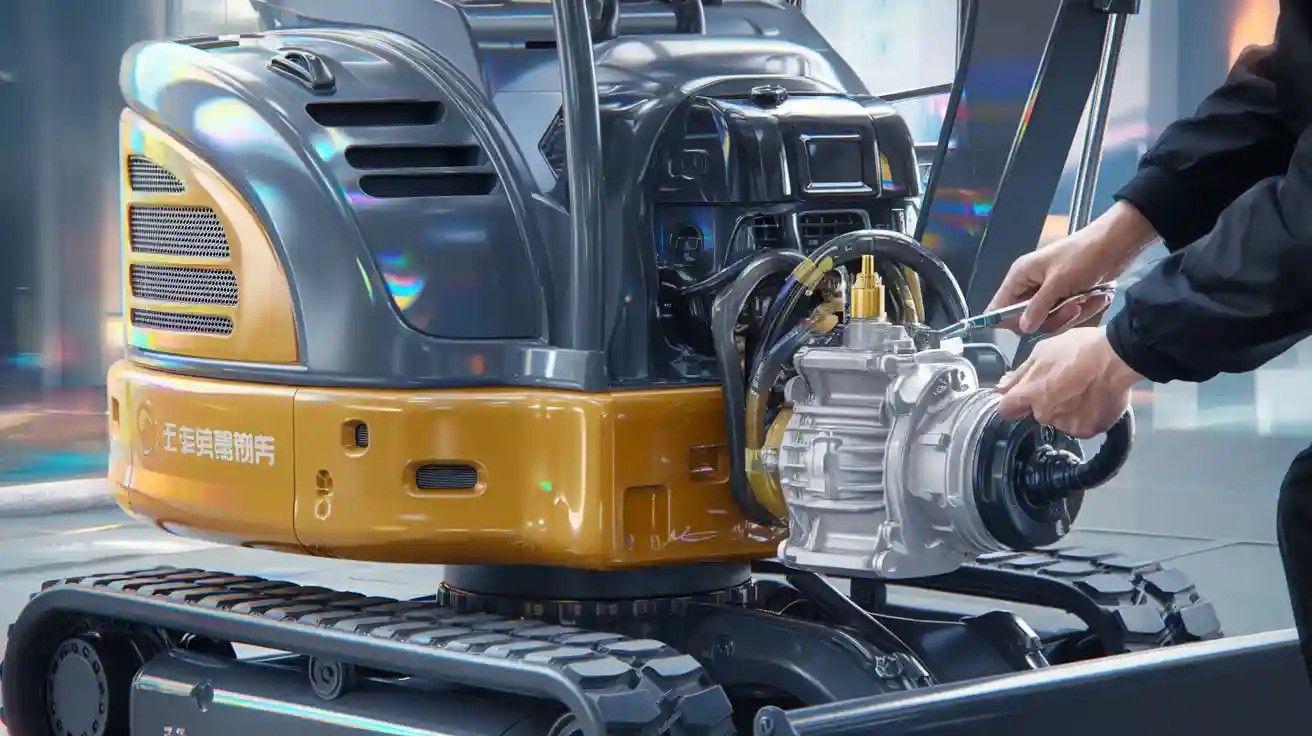

Transfer Fittings

After you disconnect the lines, remove the old pump from your chinese mini excavator hydraulic pump system. Set the pump on a clean surface. You need to transfer all necessary fittings from the old pump to the new one. Pay special attention to intake fittings, as these control how fluid enters the pump.

Use clean rags to wipe each fitting. Inspect the seals and threads. If you see any damage, replace the fitting or seal. Good seals prevent leaks and keep the system working well. Move each fitting one at a time to avoid mixing them up.

Note: Take photos of the old pump before you remove the fittings. This makes it easier to match each fitting to its correct spot on the new pump.

Install New Pump

Place the new pump into the mounting area. Line up the bolt holes with the frame of your mini excavator. Use the correct bolts and tighten them with a wrench. Make sure the pump sits flat and does not move. Securely bolting the pump keeps it from vibrating or shifting during use.

Connect each fitting and hydraulic line to the new pump. Tighten each connection by hand first, then use a wrench to finish. Do not over-tighten, as this can damage the threads or crush the seals. Check that every line matches the tag or tape you used earlier.

Alert: If you skip tightening a fitting, you may see leaks when you start the system. Always double-check each connection.

Reconnect and Bleed System

After you install the new chinese mini excavator hydraulic pump, fill the hydraulic tank with fresh fluid. Use the type recommended by your excavator’s manual. Do not reuse old fluid, as it may contain dirt or air.

Bleed the hydraulic system to remove trapped air. Air in the system can cause slow operation and damage parts. You can use manual or automatic bleeding methods:

Step | Description |

|---|---|

Step 3 | Bleed the hydraulic system to remove trapped air, ensuring smooth operation. |

Method 1 | Manual Bleeding: Open the bleeder valve or hydraulic lines to release air manually, ideal for older excavators. |

Method 2 | Automatic Bleeding: Activate the built-in automatic system for modern excavators. |

Step 4 | Check hydraulic oil quality after bleeding; ensure it is clean and free of contaminants. |

Step 5 | Test the system after bleeding and oil inspection to ensure smooth operation and identify any remaining air. |

If you skip bleeding, air stays in the system. This leads to slow operation, more wear, and expensive repairs. Always check the oil after bleeding. Make sure it looks clean and does not have bubbles.

Incomplete bleeding leaves air in the system and causes problems.

Air-contaminated systems run slower and wear out faster.

Skipping this step can lead to major repair costs.

Test your excavator after you finish. Move the boom, bucket, and tracks. Listen for strange sounds and watch for leaks. If you see any problems, stop and check the connections.

Tip: YNF Machinery offers support if you have trouble with your hydraulic pump installation. Contact them for advice or replacement parts.

Test and Troubleshoot

System Check

After you install the new chinese mini excavator hydraulic pump, you need to check if everything works as it should. Start by turning on the excavator and letting it idle for a few minutes. Watch the hydraulic fluid level and look for leaks around the pump and hoses. Move the boom, bucket, and tracks slowly. Listen for any strange sounds, such as knocking or hissing. These sounds can mean air is trapped or a connection is loose.

Check the speed of the tracks and the digging force. A good hydraulic pump sends high-pressure oil to the boom and travel motor. This helps your excavator dig with more power and move faster. If the pump works well, you will see smooth movement and strong lifting. The hydraulic system’s efficiency controls how quickly your machine cycles and how much work it can do in less time.

Tip: If you notice slow movement or weak digging, stop and inspect the pump and connections before using the excavator for heavy work.

Common Issues

Sometimes, problems appear even after you install a new pump. Use these steps to find and fix common issues:

Look for leaks or worn parts near the pump.

Check the hydraulic fluid level. Make sure it matches the manufacturer’s guide.

Inspect the filters. Dirty or clogged filters slow down fluid flow.

Measure the pressure at the pump’s inlet and outlet with a gauge.

Watch the fluid temperature. High heat can mean a problem.

Listen for odd sounds when the system runs.

Check for air in the hydraulic circuit. Bleed the system if needed.

Write down what you see and measure. This helps if you need expert help later.

Issue | What to Check | Solution |

|---|---|---|

Leaks | Fittings, hoses, seals | Tighten or replace parts |

Weak power | Fluid level, pressure, filters | Add fluid, clean filters |

Overheating | Fluid temperature, pump area | Cool down, check airflow |

Noisy operation | Air in system, loose parts | Bleed air, tighten bolts |

Pump performance affects how well your excavator works. If the pump does not send enough pressure, the tracks move slowly and digging force drops. Factors like pump displacement, valve design, and fluid type change how much power your machine gets. When you optimize these, you get better speed and stronger digging.

If you still have trouble after these checks, contact YNF Machinery for support. They can help you solve pump problems and offer replacement parts.

You can change your chinese mini excavator hydraulic pump if you follow each step. Make sure the pump fits your machine. Move all fittings from the old pump to the new one. Bleed the system to get rid of air. Doing regular maintenance helps your pump work longer:

Look at the pump and parts for leaks or damage.

Change hydraulic fluid often and use the correct type.

Clean filters and check seals for problems.

Test pressure and follow the maker’s schedule.

If you hear loud sounds, see slow movement, or notice hot fluid, ask an expert for help. YNF Machinery can give you good parts and advice.

FAQ

How do you know if the new hydraulic pump fits your mini excavator?

Check your excavator’s model number and compare it with the pump’s specifications. Look at the flow rate, pressure, and size. Ask YNF Machinery for help if you feel unsure.

Can you install a hydraulic pump without professional help?

You can install the pump if you have basic mechanical skills and follow safety steps. Read your excavator’s manual. Use the right tools. Contact YNF Machinery for support if you need advice.

What should you do with old hydraulic fluid and the removed pump?

Put old fluid in a waste oil container. Take the fluid and pump to a recycling center. Do not pour oil on the ground. YNF Machinery can guide you on safe disposal.

How often should you check your hydraulic pump after replacement?

Check the pump every month for leaks, noise, or weak power. Look at the fluid level and quality. Clean filters often. YNF Machinery recommends regular checks to keep your excavator working well.

Where can you buy a reliable hydraulic pump for your Chinese mini excavator?

You can buy a reliable hydraulic pump from YNF Machinery. They offer pumps that fit many excavator models. Ask about warranty and support before you order.