You might see that pump coupling rubber works as a bendable link between the motor and the pump shaft. This part helps take in shakes and lessens sudden hits. It helps the machine work well and not break down. Using pump coupling rubber makes your pump system work better and last longer.

The table below shows how pump coupling rubber helps machines work better and last longer:

Benefit | Impact on Efficiency and Lifespan |

|---|---|

Flexibility | Makes sure power moves smoothly even if parts do not line up. |

Shock Absorption | Cuts down on sudden hits, so parts do not get hurt. |

Vibration Dampening | Keeps machines safe from too much shaking, so they last longer. |

Reduced Wear and Tear | Makes it less likely for parts to break or need fixing. |

Key Takeaways

Pump coupling rubber links the motor and pump shafts. It helps power move smoothly and cuts down on shaking. This flexible material takes in shocks and vibrations. This helps keep your equipment safe and makes it last longer. Check pump coupling rubber often for cracks or damage. This keeps it working well and stops expensive repairs. Pick the right pump coupling rubber for your job. This makes things work better and keeps things quieter. Using pump coupling rubber can help you save money. It lasts a long time and does not need much care.

Pump Coupling Rubber Overview

What Is Pump Coupling Rubber

Pump coupling rubber connects the motor shaft to the pump shaft. This part is flexible and helps move power from the motor to the pump. It lets both shafts turn together, even if they are not lined up. Pump coupling rubber takes in vibrations and cuts down on noise. This helps your equipment last a long time.

When you pick pump coupling rubber, you get a part that fits many pump systems. It links the motor and pump shaft so power moves without trouble. You do not have to worry about small alignment problems or sudden shocks. The rubber can bend and stretch, so it handles these issues without breaking.

Tip: YNF Machinery has pump coupling rubber for many pump systems. Their products help lower vibration and noise.

Here is a table that lists what pump coupling rubber does in pump systems:

Function | Description |

|---|---|

Power Transmission | Connects two shafts to send power from the motor to the pump shaft. |

Misalignment Accommodation | Lets the shafts work even if they are not lined up. |

Mechanical Adaptability | Helps the shafts turn smoothly and lowers damage. |

Vibration and Noise Reduction | Cuts down on shaking and noise, so equipment lasts longer. |

Malfunction Prevention | Lowers the chance of problems from misalignment. |

Key Features

Pump coupling rubber has many features that make it good for pump systems. These features help your equipment work better and last longer.

Flexibility: The rubber bends easily. It lets the pump shaft and motor shaft move even if they are not lined up. Flexible disc packs let the shafts move in different ways.

Vibration Damping: Elastomeric couplings use rubber to take in vibrations. This keeps your pump and motor safe from shaking and noise. Rubber vibration isolators help control shaking.

No Lubrication Needed: You do not need oil or grease. Pump coupling rubber works with little care.

Cost-Effectiveness: Pump coupling rubber usually costs less than metallic couplings. You save money on the part and on repairs.

Misalignment Handling: You can have more misalignment than with metallic couplings. This makes it easier to install and lowers the risk of damage.

Low Reactionary Loads: The rubber puts less stress on bearings. This helps your pump and motor last longer.

Elastomeric Construction: Elastomeric couplings have areas with different hardness. These areas help lower noise and make the machine run smoother.

Here is a table that compares pump coupling rubber to metallic couplings:

Feature | Pump Coupling Rubber | Metallic Couplings |

|---|---|---|

Cost | Usually costs less | Costs more |

Vibration Damping | Good at stopping vibrations | Needs oil or grease |

Misalignment Handling | Allows more misalignment | Needs careful alignment |

Durability | Can be hurt by chemicals and heat | Lasts longer |

Maintenance | Needs little care | Needs oil or grease and more care |

Pump coupling rubber has some limits. High heat can make the rubber soft and weak. Chemicals can make the rubber swell or crack. If you use pump coupling rubber in tough places, check it often for damage.

Common ways pump coupling rubber can fail:

Misalignment: Check the shafts are lined up when you install and use them.

Vibration: Make sure loads are balanced to stop too much shaking.

Shock Loading: Try to avoid sudden shocks to the pump.

Chemical Attack: Make sure the rubber matches the fluids you use.

Thermal Expansion: Watch for heat changes that can hurt the rubber.

New designs use better elastomeric materials like polyurethane blends. These last longer and stand up to chemicals and heat. Some pump coupling rubber now has smart sensors. These sensors help you watch temperature, torque, and vibration. You can fix problems before they get worse.

Note: For pump coupling rubber that lasts longer and needs less care, look for ones with composite materials or smart sensors.

How Pump Coupling Works

Torque Transmission

Pump coupling rubber helps move power from the motor to the pump shaft. It grabs the force when the motor turns and passes it to the pump. This lets both shafts spin together, even if they are not lined up. Elastomeric couplings are made from rubber and plastic. They absorb shocks when moving power. This keeps noise and vibration low. You get smooth power transfer, which is important for strong jobs. If you use centrifugal pump coupling, it handles heavy loads and keeps the pump running. It stops sudden stops from happening.

Flexible couplings can handle some misalignment between shafts. The design decides how much misalignment it can take. Elastomeric couplings use a flexible part to allow for small misalignment. This keeps friction low. Always check the maximum misalignment from the manufacturer before installing.

Here are ways pump coupling rubber helps with torque transmission:

Moves power from motor to pump shaft.

Absorbs shocks to protect equipment.

Handles misalignment for easier setup.

Supports strong jobs in tough places.

Makes centrifugal pump coupling work better.

If you want your pump to work well in strong jobs, you need a coupling that can handle big forces. Centrifugal pump coupling depends on this. You get better performance and less wear on your equipment.

Tip: Always check alignment when installing. Misalignments cause more than half of failures in rotating equipment. One misaligned pump can cost thousands in repairs and lost energy each year.

Vibration Absorption

Pump coupling rubber does more than move power. It also absorbs vibration and shock. When your pump runs, it shakes and makes noise. The rubber coupling acts like a cushion and soaks up these forces. This keeps your pump and motor safe.

Lab tests show elastomeric connectors absorb vibration very well. They bend in different directions and soak up shaking better than other materials. PTFE connectors work almost as well as rubber types for vibration.

Material Type | Vibration Absorption Capability | Notes |

|---|---|---|

Elastomeric Connectors | Very good | Bends in different ways to soak up vibration. |

PTFE | Almost as good | Works nearly as well as rubber types for vibration. |

Different coupling types work in different ways. Victaulic couplings do better than flex connectors in vibration tests. Double sphere rubber couplings do not absorb as much vibration as Victaulic couplings.

Coupling Type | Performance Improvement | Test Configuration Details |

|---|---|---|

Victaulic Couplings | Better than flex connectors | Showed better vibration control than old devices. |

Double Sphere Rubber | Not as good | Compared to Victaulic couplings in vibration tests. |

Flexible couplings soak up vibration and energy. This lowers noise when working. Rigid couplings make more noise because they are solid. Cushion couplings are great at soaking up vibration and shock. The flexible part acts as a damper and turns movement into heat. This lowers vibration and shock, protects your equipment, and makes the workplace better.

If you use centrifugal pump coupling, you notice less noise and smoother work. Strong jobs make more vibration, so this feature helps a lot. Pump coupling rubber keeps your pump system quiet and safe.

Here are ways to keep your pump coupling rubber working well:

Re-lubricate every six months to stop rust and wear.

Use laser alignment tools to check for precision and stop early wear.

Take apart some parts to remove old grease and check for damage.

Always follow these steps. Good alignment stops too much vibration, early wear, energy loss, and lowers repair costs. If you use pump coupling rubber in strong jobs, regular checks help you avoid expensive repairs.

Note: YNF Machinery has pump coupling rubber that absorbs vibration and works for strong jobs. Their products help you get the most from centrifugal pump coupling.

Types of Pump Coupling

When you look at pump systems, you see different couplings. Each type has its own design and works best for certain jobs. It is important to know how each type works. This helps you pick the right one for your pump.

Jaw Type

Jaw type couplings have two metal hubs and a rubber spider. One hub goes on the motor shaft. The other hub goes on the pump shaft. The spider sits in the middle and helps move power. This design lets you handle misalignment and vibration. You do not need tools to put it in or take it out. If the spider wears out, you can change it easily.

Key Features | Applications |

|---|---|

Superior Misalignment Compensation | Industrial Pumps |

Advanced Torsional Vibration Damping | Conveyor Systems |

Innovative Fail-Safe Design | Fans and Blowers |

Tool-Free Installation and Maintenance | Industrial Machinery |

Interchangeable Spider Elements | |

Compact and Lightweight Design | |

Temperature and Chemical Resistance | |

Zero Backlash Operation | |

High Torque Density | |

Electrical Isolation |

You often see jaw type couplings in pumps, fans, and conveyors. The elastomeric coupling in jaw types helps control vibration and makes setup easy.

Tire Type

Tire type couplings use a rubber part shaped like a tire. The hubs go on the shafts, and the tire sits between them. The tire bends and stretches to take in shocks and vibration. This type works well where there is a lot of shaking or heavy loads. It helps protect your pump and motor.

Tire type couplings take in shocks and vibration, so they are good for tough jobs.

The tire works in shear, which helps lower vibration and keeps your equipment safe.

You can use tire type couplings in steel plants, mining, and other hard places.

The elastomeric coupling in tire types gives you more flexibility and less wear.

Tire couplings handle misalignment and high torque, so your machines last longer.

You see tire type couplings where pumps face strong shaking and heavy loads. The design lets you handle misalignment and keeps your system safe.

Centrifugal Pump Coupling

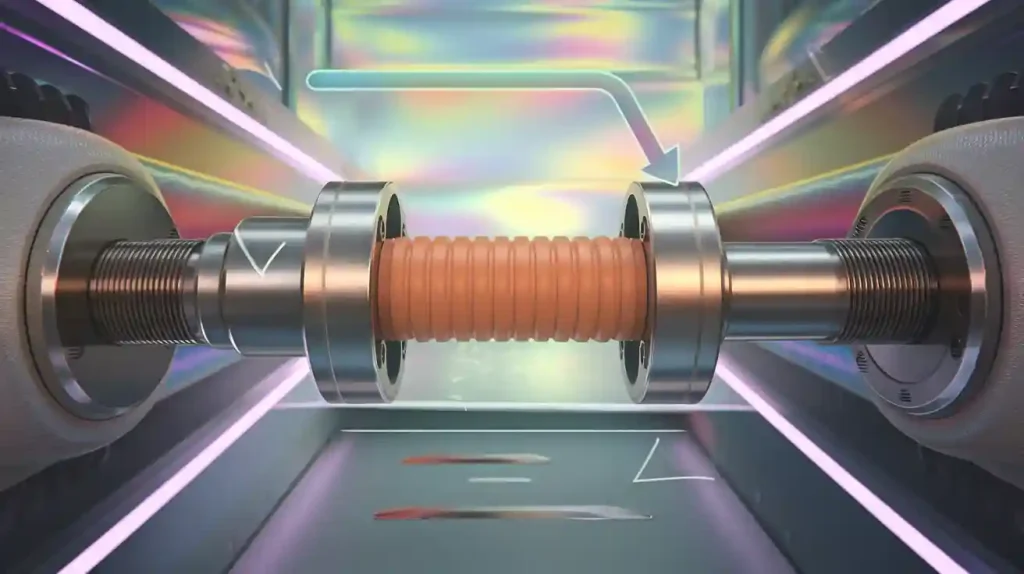

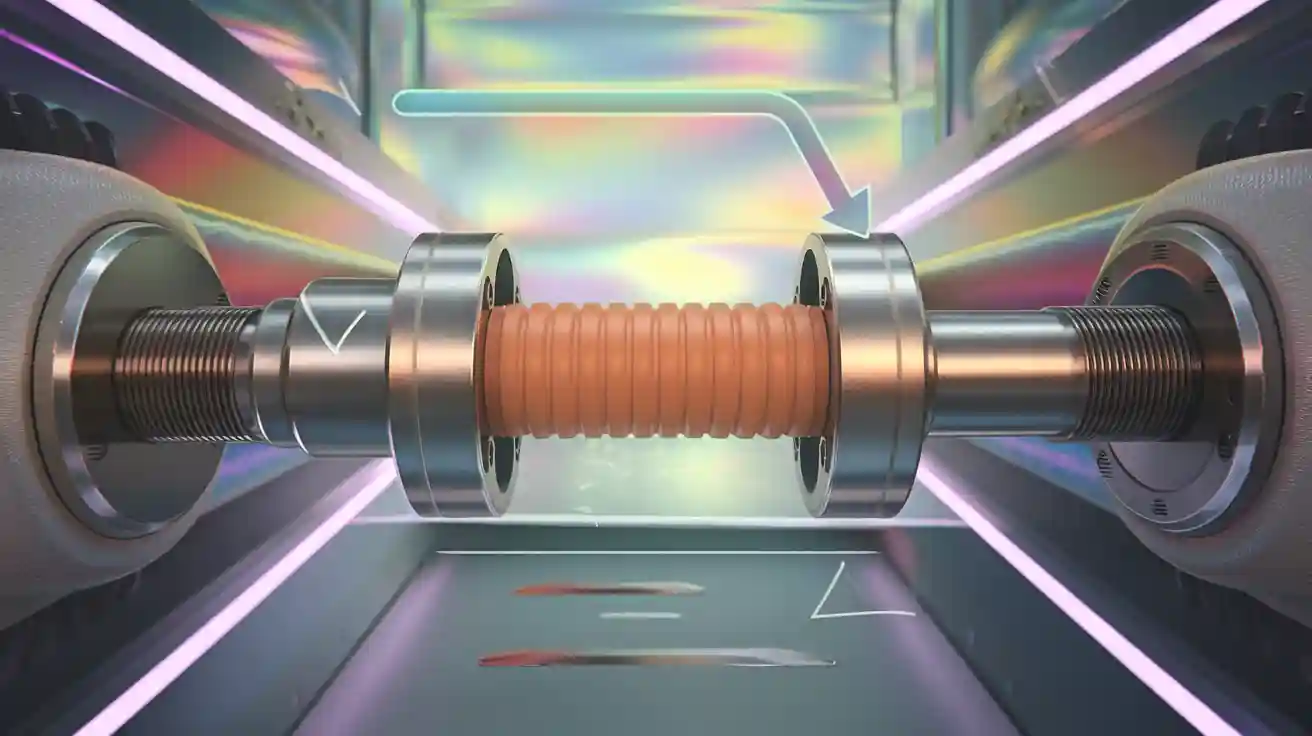

Centrifugal pump coupling is the most common type in pump systems. You use it to connect the motor shaft to the pump shaft in centrifugal pumps. It has two metal hubs and a rubber insert. The elastomeric coupling in this type helps take in vibration and shock. You get smooth power transfer and less noise.

Centrifugal pump coupling works well in water pumps, HVAC, and machines. You see it where you need strong power and low vibration. The rubber insert is easy to change, so you do not need much care. You do not need oil or grease, which saves time and money.

Centrifugal pump coupling uses elastomeric coupling to handle misalignment and vibration.

You get quick setup and easy care.

The rubber insert takes in shock and end float.

Centrifugal pump coupling does not need oil or grease.

You find this type in small and mid-sized pumps.

The design lets you change the insert if it fails.

Centrifugal pump coupling gives you strong torque and smooth work.

You use it in water pumps, industrial pumps, and HVAC.

Centrifugal pump coupling protects your equipment from damage.

It works in tough places and heavy jobs.

Centrifugal pump coupling helps you save money on repairs.

It keeps your pump system running well.

Centrifugal pump coupling is the best choice for many pumps.

It uses elastomeric coupling for vibration control.

Centrifugal pump coupling is easy to put in and take care of.

It gives you long-lasting work.

Centrifugal pump coupling is safe and reliable.

It works with many kinds of pumps.

Centrifugal pump coupling is the top pick for pump systems.

It helps you get the most from your pump.

Centrifugal pump coupling is sold by YNF Machinery.

Many industries trust centrifugal pump coupling.

It is the standard for pump systems.

Centrifugal pump coupling gives you peace of mind.

It is the answer for pump coupling needs.

Centrifugal pump coupling is the right pick for your pump.

Tip: YNF Machinery has centrifugal pump coupling and other types for your pump system. You get products that help your equipment last longer.

Applications

Water Pumps

Pump coupling rubber is used in many water pumps. It links the motor and pump shaft together. This makes power move smoothly, even if the shafts are not lined up. The rubber takes in vibration and shock. Your pump stays quiet and lasts longer. If you use water pumps at home or on a farm, you want less noise and fewer problems. Pump coupling rubber helps you get these results. YNF Machinery sells strong pump coupling rubber for water pumps. This helps your pump work better and need less fixing.

Tip: Look at your water pump coupling rubber often. Change it if you see cracks or damage. This keeps your pump working well.

Industrial Use

Many industries use pump coupling rubber. You find it in factories, car plants, ships, and building sites. Each place needs something special. You want to stop vibration, fix misalignment, and take in shock. This helps machines work well and last longer.

Industrial Sector | Operational Requirements |

|---|---|

Industrial Machinery | Lower vibration, fix misalignment, take in shock, make power move smoothly. |

Automotive Industry | Take in shock, stop damage from quick starts or stops. |

Marine and Shipping | Fix misalignment from ship movement, lower vibration. |

Construction Equipment | Take in hits and vibration, work well in tough places. |

HVAC Systems | Lower noise and vibration for good heating and cooling. |

You see pump coupling rubber in conveyor belts, mixers, and big machines. The rubber helps your equipment do hard jobs and work in rough places. YNF Machinery gives pump coupling rubber for many kinds of work. You get parts that help your machines stay strong and last long.

HVAC Systems

Pump coupling rubber helps HVAC systems work better. You want your heating and cooling to be quiet and smooth. The rubber coupling lowers vibration and noise. It also fixes misalignment, so your system does not break easily.

Contribution Type | Description |

|---|---|

Vibration Reduction | Flexible rubber couplings lower vibration, so compressors work well. |

Noise Dampening | Rubber helps stop noise, making things quieter. |

Flexibility | Rubber couplings fix misalignment, lower stress, and help things run smoothly. |

Rubber bushings give flexibility and help stop shaking, so your HVAC works better.

You hear less noise from fans and air units because the rubber stops vibration.

The strong rubber takes in shocks and keeps your system safe.

You want your HVAC to last and keep your space comfy. Pump coupling rubber helps you do this. YNF Machinery has pump coupling rubber for HVAC systems. This helps you get quiet and steady heating and cooling.

Benefits of Pump Coupling Rubber

Flexibility

You want your pump to handle movement and not break. Pump coupling rubber gives your system flexibility. The elastomeric material can bend and stretch. This helps when shafts move or shift. Your pump and motor stay connected even if not lined up.

Vibration control keeps pipes and joints safe from leaks.

Flexible couplings work in hot and cold places. They stop parts from getting loose or cracking.

Restrained flexible couplings last longer and need less care.

The elastomeric design lets the coupling take in shock loads. When the motor starts or stops, the rubber twists and softens the force. This protects your pump shaft and lowers damage risk.

The elastomeric flexible part can stretch or move in shear. It moves when a load is put on it. Torsional flexibility lets the elastomeric shear coupling lower vibration. It keeps one shaft safe from the other’s effects.

Noise Reduction

You want your pump to be quiet. Pump coupling rubber helps lower noise by soaking up vibration. The elastomeric material acts like a cushion between motor and pump. Studies show rubber isolators support the pump group. They change how the pump moves. Rubber’s stiffness helps cut down vibration.

Rubber isolators lower sound by about 2.0 dB(A) in piston pump housings.

The elastomeric coupling makes your workplace quieter and more comfortable.

The shock from the motor is less because energy is used to twist the flexible part. This cushions the pump shaft from the shock.

Longevity

You want your pump and motor to last a long time. Pump coupling rubber helps your equipment last longer. Field data shows rubber couplings can last over 40,000 hours. This happens if you pick the right type and keep it lined up. Heat, oil, and chemicals can change how long it lasts. Regular checks help a lot.

Maintenance Tip | Benefit |

|---|---|

Follow installation instructions | Stops early failure |

Minimize misalignment | Lowers wear and tear |

Size coupling correctly | Handles torque and work cycle |

Shield exposed couplings | Keeps them safe from damage |

Inspect regularly | Finds problems early |

Lubricate as recommended | Keeps coupling working well |

You save money on repairs because pump coupling rubber needs less care. It breaks down less often. The elastomeric material helps your pump and motor work well for years. YNF Machinery sells pump coupling rubber that lasts a long time.

Pump coupling rubber helps your pump system run well. It also helps your pump last longer. You should check things like misalignment and speed. Torsional stiffness and torque density are important too. These help you pick the best coupling. Experts say you should match the coupling to your job. You also need to check how it is installed. This helps lower vibration. YNF Machinery sells pump coupling rubber for many jobs. You get better results, less noise, and longer life for your equipment.

Look for flexibility and ways to control vibration.

Pick the type that fits your pump system.

Check and take care of couplings for good results.

If you choose the right pump coupling rubber, your machines stay safe and work well.

FAQ

What does pump coupling rubber do in a pump system?

Pump coupling rubber connects the motor shaft to the pump shaft. You get smooth power transfer, less vibration, and lower noise. This part helps your pump work better and last longer.

How often should you check or replace pump coupling rubber?

You should inspect pump coupling rubber every six months. Look for cracks, wear, or damage. Replace it if you see any problems. Regular checks help your pump stay safe and work well.

Can pump coupling rubber handle misalignment?

Yes, pump coupling rubber can handle small misalignments between shafts. You do not need perfect alignment. The flexible rubber absorbs movement and keeps your pump running smoothly.

Where can you buy reliable pump coupling rubber?

You can buy reliable pump coupling rubber from YNF Machinery. Their products fit many pump systems. You get strong, long-lasting couplings that help your equipment work better.

What are signs that pump coupling rubber needs replacement?

You may see cracks, swelling, or noise from your pump. Vibration may increase. If you notice these signs, you should replace the pump coupling rubber soon.