Buying excavator engine parts from China can help buyers save on cost. Many people choose chinese excavators because they see a lower price compared to other markets. Some chinese excavators offer a wide range of options for both large and compact machines. China excavator engine parts factories produce parts for many types of excavators. Chinese excavators sometimes show differences in quality, so buyers need to check each product. Reliable chinese excavators often come from suppliers with a good record. Some chinese excavators may not meet every need, but buyers can find many options in China. Chinese excavators attract buyers who want to reduce cost and find many choices. Most chinese excavators can fit different brands and models. Buyers should always compare chinese excavators before making a final choice.

Key Takeaways

Buying excavator engine parts from China can save you 20% to 50% compared to other markets, helping you get more value for your money.

China offers a wide range of parts for many types of excavators, including compact and mini models, giving you many choices to fit your needs.

Quality and reliability can vary between suppliers, so always check reviews, ask for samples, and verify certifications before buying.

Clear communication with suppliers and confirming all details in writing helps avoid misunderstandings and order mistakes.

Flexible order options and fast shipping from China make it easier to manage inventory and test new parts without large commitments.

Pros of Sourcing from China

Cost Savings

Many buyers choose Chinese excavators and engine parts because of the lower price. The cost-effectiveness of sourcing from China stands out in the global market. Chinese excavators and their parts often cost 20% to 50% less than those from Western or Japanese brands. This price difference comes from lower manufacturing and labor costs, efficient supply chains, and government support. For example:

Chinese OEMs offer excavators at 20-30% lower price than premium brands like Caterpillar and Komatsu.

Mini excavators from China can be 30-50% less expensive for similar specifications.

Labor wages in China are 60-75% lower, which helps keep the price down.

These savings allow buyers to get more value for their money. Many businesses find that the price-to-performance ratio of Chinese excavators meets their needs. Lower cost does not always mean lower performance, especially when buyers select reliable suppliers. The cost-effectiveness of buying a compact excavator or buying a mini excavator from China makes it easier for small and large companies to expand their fleets.

Wide Range of Parts

China leads the world in excavator production and parts availability. Market studies show that Chinese companies hold over 70% of the domestic market share. This high output means buyers can find a wide range of parts for many types of excavators. Chinese excavators cover both large machines and compact excavators from China. Companies like Hengli have replaced many imported hydraulic components with local products, increasing parts availability.

Note: While Chinese suppliers have expanded their range of excavator engine parts, the engine segment still relies on foreign technology and partnerships. However, the variety of related parts and components continues to grow.

The growing supplier base in China supports buyers looking for specific parts or unique features. This variety helps buyers find the best deals on mini excavators and engine parts that fit their needs.

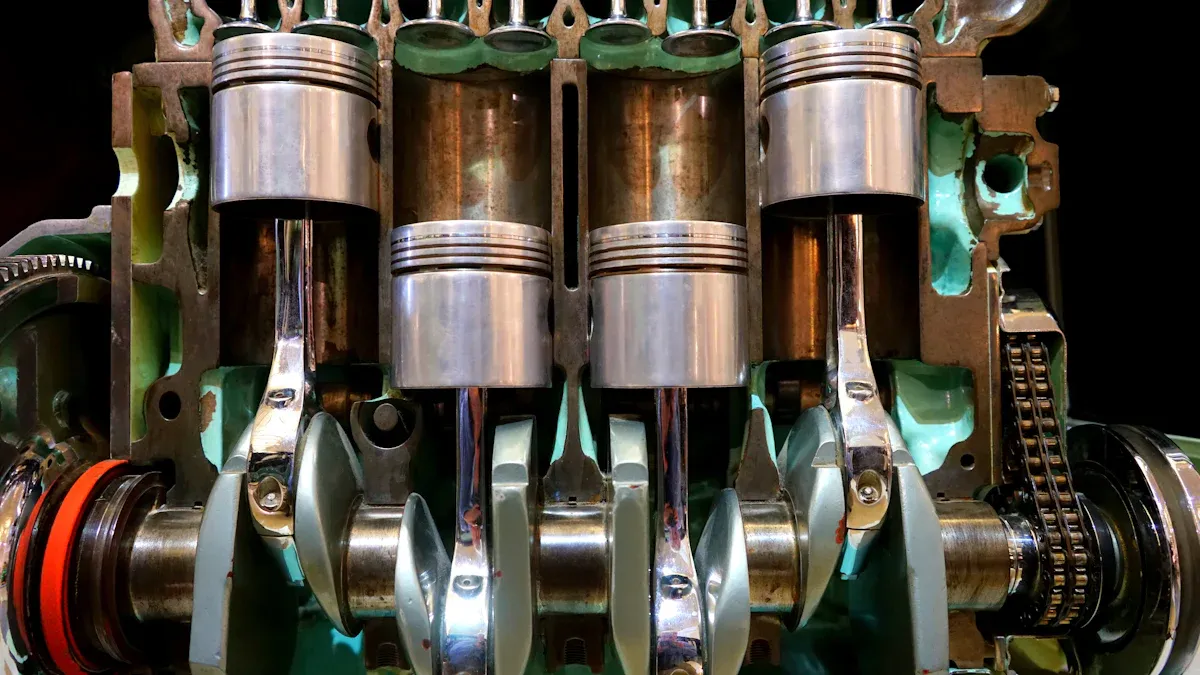

China Excavator Engine Parts Factories

China excavator engine parts factories play a key role in the global supply chain. These factories produce a wide selection of parts for different excavators. Many factories focus on both quality and value, offering products that meet international standards. The presence of many china excavator engine parts factories means buyers can compare options and choose the best value.

Factories in China often use advanced manufacturing techniques.

Many factories offer both standard and custom parts for various excavators.

Buyers can find parts for both new and older models, increasing the value of their investment.

China excavator engine parts factories help buyers maintain their machines at a lower cost. The large number of factories also encourages competition, which can lead to better price and performance.

Compact Excavators from China

Compact excavators from China have become popular worldwide. Many buyers choose these machines because of their value and cost-effectiveness. Companies like Xinyuan Heavy Industry Co., Ltd. hold a large share of the wheeled excavator market in China. Caterpillar has also increased its production capacity in China, showing the strength of the market.

Compact excavators from China offer a good price-to-performance ratio.

Buying a compact excavator or buying a mini excavator from China gives buyers access to modern features at a lower price.

Chinese excavators often include options for different job sites, making them flexible for many uses.

The value of compact excavators from China attracts buyers who want reliable performance without a high price. Many businesses find that buying a mini excavator from China helps them grow while keeping costs low.

Flexible Orders

China excavator engine parts factories support flexible orders to meet the needs of different buyers. Many suppliers offer low minimum order quantities (MOQs), sometimes as low as one piece. This flexibility helps small businesses and large companies alike.

Order Quantity Range | Minimum Order Quantity (MOQ) | Lead Time (days) |

|---|---|---|

1 – 60 pieces | 1 piece | 10 days |

More than 60 pieces | Negotiable | Negotiable |

1 – 1000 pieces | 1 piece | 5 days |

More than 1000 pieces | Negotiable | Negotiable |

Suppliers can deliver orders quickly, often within 3 to 7 working days.

Flexible ordering supports fast global shipping and quick order processing.

Buyers can order only what they need, reducing waste and saving cost.

This practice makes it easier for buyers to test new parts or manage inventory. Flexible orders add value by allowing businesses to adjust to changing needs.

Cons of Sourcing from China

Quality Issues

Many buyers have concerns about the quality of chinese excavators and their engine parts. Factories in china produce a large number of excavators, but not all meet the same standards. Some chinese excavators show strong value, but others may have inconsistent quality. Buyers often find that quality can change from one batch to another. This inconsistency creates concerns for those who want reliable performance and long-term reliability.

Tip: Always check customer reviews and request product samples before making a large purchase.

Some suppliers in china focus on low prices, which can lead to lower quality. These concerns make it important for buyers to verify each supplier. Reviews from other customers help buyers understand the real quality of chinese excavators. Reliable performance depends on strict quality control, but not every factory in china follows the same rules. Buyers should look for certifications and ask for detailed product information to reduce risks.

Reliable Performance Risks

Reliable performance is a top concern for anyone buying excavators. Chinese excavators sometimes face issues with reliability and performance. Some buyers report that their excavators break down more often than machines from other countries. These breakdowns can cause delays and extra costs. When excavators do not work as expected, the value of the investment drops.

A table below shows common performance concerns:

Concern | Impact on Excavators | How to Check |

|---|---|---|

Frequent breakdowns | Lost work time | Read reviews |

Poor engine quality | Lower performance | Ask for test data |

Inconsistent reliability | Higher repair costs | Check warranty |

Buyers need to consider the long-term reliability of chinese excavators. Some machines may work well at first but lose performance over time. Reliable performance comes from strong design and good materials. Not all factories in china use the same parts or follow the same process. These differences create concerns about reliability and value. Customer reviews often mention these issues, so buyers should read them carefully.

Communication Barriers

Communication can be a challenge when buying excavators from china. Many suppliers speak different languages, which can lead to misunderstandings. Buyers sometimes find it hard to explain their needs or get clear answers. These barriers can cause mistakes in orders or delays in shipping.

Note: Use clear, simple language and confirm all details in writing to avoid confusion.

Some buyers report that suppliers do not respond quickly to questions. This slow response can increase concerns about reliability and value. When buyers cannot get the information they need, they may worry about the quality of the excavators. Reviews often mention problems with communication, so it is important to choose suppliers with good customer service.

Shipping and Customs

Shipping excavators and engine parts from china involves extra steps. Buyers face concerns about long shipping times and customs delays. Sometimes, shipments get held up at the border, which can slow down projects. The cost of shipping can also add to the total price, reducing the value of buying from china.

A few common shipping concerns include:

Delays at customs

Extra paperwork

Damage during transport

Unexpected fees

Buyers need to plan for these risks when ordering chinese excavators. Reliable performance depends on getting the right parts at the right time. If shipping takes too long, the value of the purchase drops. Reviews often mention shipping problems, so buyers should ask about delivery times and insurance before placing an order.

Ensuring Quality and Reliability

Supplier Verification

Verifying suppliers is essential when sourcing excavators and engine parts from China. Buyers should start by researching the supplier’s background and reputation. Checking certifications ensures that the products meet international quality standards. Requesting samples allows buyers to assess the quality and performance of the parts before committing to a large order. Customer reviews provide valuable insights into the supplier’s reliability and after-sales support. Reliable suppliers often have a proven track record of delivering high-quality excavators and parts.

Tip: Look for suppliers with ISO certifications or other recognized quality assurance credentials.

Buyers should also evaluate the supplier’s communication skills. Clear and timely responses indicate a commitment to customer satisfaction. A supplier who prioritizes quality assurance and reliability is more likely to provide durable and well-performing excavators.

Product Specifications

Defining product specifications clearly helps avoid misunderstandings. Buyers should provide detailed requirements, including dimensions, materials, and performance expectations. Suppliers in China often offer customization options, making it easier to meet specific needs. Negotiating payment terms can also ensure that buyers receive the agreed-upon quality before completing the transaction.

Note: Always confirm specifications in writing to prevent disputes later.

Testing the product against these specifications ensures that it meets the required standards. This step is crucial for maintaining the reliability and performance of excavators. Buyers should also inquire about warranties and after-sales support to address any potential issues.

Building Trust

Building long-term relationships with suppliers enhances reliability and quality assurance. Buyers should start by placing small orders to evaluate the supplier’s performance. Consistent quality and timely delivery build trust over time. Researching brands and their reputation in the market helps identify reliable suppliers of Chinese excavators.

After-sales support plays a significant role in maintaining trust. Suppliers who offer prompt assistance and spare parts ensure the durability and performance of excavators. Regular communication strengthens the relationship and fosters mutual understanding.

Tip: Establishing a strong partnership with a supplier can lead to better pricing and priority service.

By focusing on supplier verification, clear specifications, and trust-building, buyers can ensure the quality and reliability of excavators and engine parts sourced from China.

Sourcing excavator engine parts from China gives buyers many choices and lower prices. Industry studies show that large-scale production and advanced technology help chinese excavators offer good value. Many excavators meet international standards, but some suppliers may provide parts with lower quality. Risks include counterfeit parts and unreliable suppliers.

Buyers should research suppliers, check reviews, and confirm details before buying.

Clear communication and careful planning help avoid problems.

Each buyer should think about their needs and risk tolerance before choosing excavators from China.

FAQ

What are the main advantages of buying excavators from China?

Buyers benefit from cost savings, a wide variety of parts, and flexible order options. Chinese manufacturers offer competitive pricing and cater to both large and compact excavators, making them an attractive option for businesses seeking affordability and variety.

How can buyers ensure the quality of excavators from China?

Buyers should verify suppliers by checking certifications, requesting samples, and reading customer reviews. Clear communication about product specifications and testing parts before bulk purchases also helps ensure quality and reliability.

What are the common risks when sourcing excavators from China?

Common risks include inconsistent quality, communication barriers, and shipping delays. Buyers may also face challenges with customs and unexpected fees. Proper planning and supplier research can help mitigate these risks.

Are Chinese excavators suitable for long-term use?

Chinese excavators can perform well long-term if sourced from reliable suppliers. Buyers should prioritize quality assurance, check warranties, and ensure proper maintenance to maximize the lifespan of their machines.

How can buyers avoid communication issues with Chinese suppliers?

Using clear, simple language and confirming all details in writing helps avoid misunderstandings. Buyers should choose suppliers with good customer service and quick response times to ensure smooth communication.