Heavy-Duty Excavator Undercarriage Parts Supplier for Global Buyers

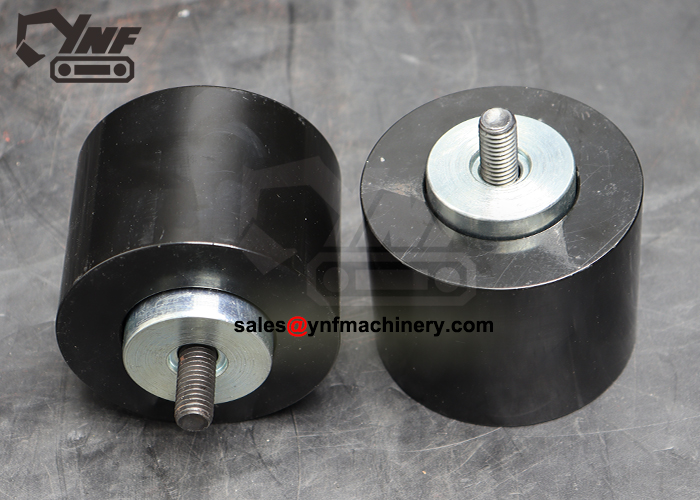

Excavator undercarriage parts are essential for machine mobility and ground stability. YNF Machinery supplies premium-quality components for all major excavator brands, engineered for strength, wear resistance, and long service life.

Key Features:

-

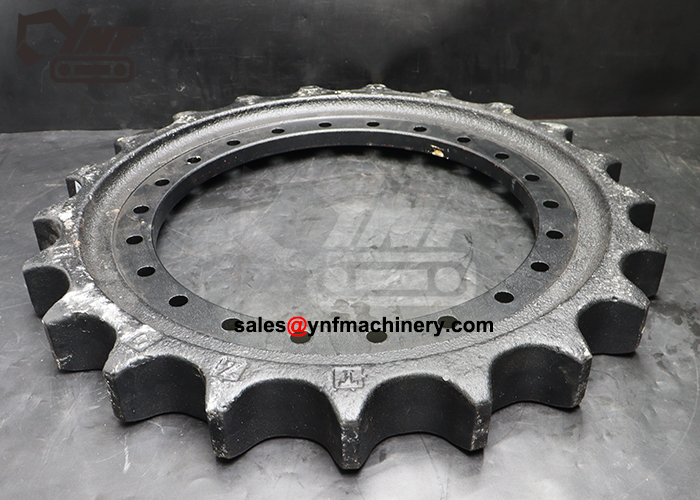

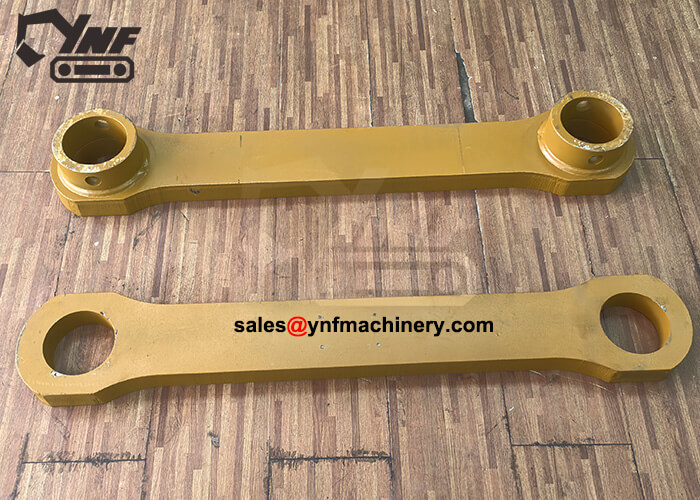

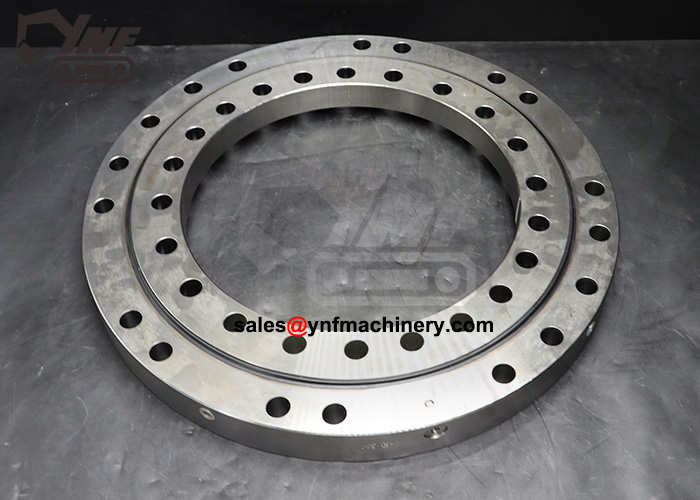

Includes track chains, rollers, sprockets, idlers, and track shoes

-

Manufactured with high-strength alloy steel and heat-treated for wear resistance

-

OEM-compatible with Komatsu, CAT, Doosan, Hyundai, Volvo, Hitachi, and more

-

Supports models from 1.5T to 50T+

-

Available in standard or heavy-duty grades

-

Fast global delivery and technical support for accurate part matching

Undercarriage Parts Series for Excavator Mobility & Stability

Our undercarriage parts range covers critical wear components including bottom rollers, top rollers, track links, idlers, sprockets, and track pads. Designed for excavators working in rough terrains and high-impact environments, each part undergoes strict hardness and dimension testing to ensure durability and OEM compatibility.

Why Our Undercarriage Parts Keep Excavators Working Longer

YNF undercarriage components are precision-machined and surface-hardened for maximum performance and service life. With fast part identification, reliable logistics, and competitive B2B pricing, we help global buyers maintain excavator uptime.

All undercarriage parts—sprockets, rollers, track chains—undergo precision heat treatment to achieve optimal surface hardness. This significantly extends service life even in abrasive environments like mining, demolition, and rocky terrain.

Each part is engineered to match original dimensions and tolerances for excavators from Komatsu, CAT, Doosan, Volvo, and more. This ensures seamless installation without modification, reducing labor time and minimizing installation errors.

We cover a complete range of undercarriage components for compact, mid-size, and large excavators. Whether you’re maintaining a mini excavator or a heavy-duty mining unit, we have the right parts ready to ship.

Our supply chain is designed to support both high-volume buyers and small repair workshops. Mixed model orders, small MOQ, and short lead times help you stay flexible and reduce inventory pressure.

Why Choose YNF Undercarriage Parts to Keep Your Excavators on Track

Our excavator undercarriage parts are built to perform in the toughest environments. YNF Machinery delivers quality parts with exact fitment, short lead times, and global shipping—helping you reduce downtime and save maintenance costs.

Excavator Undercarriage Parts Applications

Earthmoving Projects

Enables smooth machine movement on unpaved and uneven surfaces.

Mining & Quarrying

Withstands abrasion and impact in harsh digging environments.

Road & Bridge Construction

Supports consistent machine tracking on urban and highway projects.

Rental & Fleet Maintenance

Ideal for refurbishing worn undercarriage systems in used equipment.

Complete Guide to Excavator Undercarriage Components

Main Undercarriage Components We Supply

| Part Name | Function |

|---|---|

| Track Chain | Links that drive track movement |

| Bottom Roller | Supports the track from underneath |

| Carrier Roller | Supports the upper side of the track |

| Idler | Guides and maintains track tension |

| Sprocket | Transfers engine power to move the track |

| Track Shoe/Pad | Provides ground contact and traction |

Supported Brands & Models

-

Komatsu: PC60, PC200, PC300

-

CAT: 303.5, 320D, 336D

-

Doosan: DX60, DX225, DX300

-

Volvo, Hyundai, Hitachi: Full range available upon request

Materials & Surface Treatment

-

High-grade alloy steel

-

Heat treatment and quenching for hardness

-

Shot blasting and anti-rust coating available

How to Confirm Fitment

-

Provide machine model, serial number, and part number if available

-

Share photos and basic dimensions for confirmation

-

Fast response within 12–24 hours

Packaging & Delivery

-

Palletized or bulk packaging

-

Export-ready labeling and parts ID tags

-

Sea, air, or express shipping options available

-

Flexible MOQ support

FAQ Section

Q: Can I buy a complete undercarriage kit?

A: Yes, we can supply complete sets for most models.

Q: Are parts interchangeable with OEM brands?

A: Yes, our parts are built to match OEM standards and specifications.

Excavator Undercarriage Parts Explained: A Comprehensive Guide

Excavator undercarriage parts are the foundation of an excavator. They assist in carrying weight, maintaining balance, and ensuring smooth movement. Components such as track chains, rollers, and sprockets work in unison. These parts enable the machine to operate efficiently on various terrains. Understanding undercarriage parts is crucial for effective maintenance. Regular inspections and oil additions can minimize damage and extend the lifespan of these components. Monitoring wear and vibrations can save costs and prevent breakdowns. As construction expands globally, having a reliable Excavator Undercarriage Parts Supplier is essential for optimal performance and durability.

Key Takeaways

- Clean the undercarriage often to stop dirt buildup. This makes parts last longer and lowers repair costs.

- Check track tightness regularly. Correct tightness stops slipping and reduces wear, keeping it smooth.

- Oil moving parts every week. This lowers friction and helps the excavator work better.

- Change worn parts quickly. Replacing early saves money and keeps the machine working well.

- Pick a trusted supplier for undercarriage parts. Good parts improve performance and make your excavator last longer.

Key Parts of an Excavator Undercarriage

The undercarriage of an excavator has important parts. These parts work together to keep the machine stable and moving. Knowing these parts helps you take care of your machine. It also helps you avoid expensive repairs. Below are three main parts: track chains, rollers, and sprockets.

Track Chains

Track chains are the main part of the track system. They connect the track shoes and help the excavator move on different surfaces. These chains handle heavy pressure and give the machine grip to move.

Good track chains are key to keeping the undercarriage strong. Bad chains wear out unevenly and harm other parts. Check for damage like cracks or stretching often. Replace worn chains quickly to make your undercarriage last longer.

Rollers (Top and Bottom)

Rollers help carry the excavator’s weight and make it move smoothly. Top rollers guide the tracks, while bottom rollers spread the weight evenly on the ground.

Good rollers make the undercarriage last longer. Cheap rollers wear out fast and cause breakdowns. These problems can stop work and cost more money. Use good rollers and check them often to reduce wear. This will help your undercarriage last longer.

Sprockets

Sprockets drive the track chains. They connect with the chains and move power from the engine to the tracks. This makes the excavator move properly.

Studies show that over 35% of excavator failures are from chassis issues. Most of these happen because of unnoticed wear. Check sprockets often for damage like broken teeth or uneven spots. Replace bad sprockets quickly to keep your excavator working well. This also prevents sudden breakdowns.

Idlers

Idlers help keep the tracks tight and guide their movement. They are located at the front of the undercarriage. Idlers spread the excavator’s weight evenly across the tracks. This helps the machine work smoothly and reduces wear on other parts.

Many things affect how long idlers last. Below is a table showing key wear factors:

| Factor | Description |

|---|---|

| Weight Distribution | The downhill side wears faster due to shifted weight. |

| Speed of Operation | Faster speeds cause more wear as distance increases. |

| Turning | Turning adds stress, making parts wear out quicker. |

| Track Slippage | Slipping tracks increase wear, especially on track shoe grips. |

| Loaded Side Wear | The loaded side wears faster due to extra pressure and packing. |

Check idlers often for cracks or uneven wear. Replace damaged idlers quickly to avoid harming other parts. Taking care of idlers keeps your excavator running well.

Track Shoes

Track shoes give the excavator grip and stability on different surfaces. They are attached to the track chains and touch the ground. Their design and width affect how well the machine works.

Here are tips for track shoe care:

- Keep track tension correct for longer-lasting shoes. It depends on the machine and conditions.

- Oversized shoes can damage sprockets, rollers, and other parts.

- Use the narrowest shoe size that fits the job to reduce wear.

Look for cracks, bends, or heavy wear on track shoes. Replace bad shoes to keep the tracks working properly. Choosing the right shoes and maintaining them helps your excavator last longer.

Track Frame

The track frame holds all the undercarriage parts together. It supports the chains, rollers, idlers, and sprockets. A strong track frame helps the excavator work well under heavy loads or tough conditions.

Track frames are tough but can still get damaged. Common problems include cracks, rust, and misalignment. These issues can weaken the undercarriage’s stability.

To keep the track frame in good shape:

- Check it often for cracks or rust.

- Make sure all parts are securely attached to the frame.

- Fix misalignment quickly to avoid damaging other parts.

A well-cared-for track frame gives your excavator a solid base. This ensures smooth operation and lowers repair costs.

Functions of Excavator Undercarriage Parts

Supporting Excavator Weight

The undercarriage holds up the excavator’s weight. It spreads the load evenly across the tracks. This stops too much pressure on any one part. Balanced weight helps parts like rollers and chains last longer.

When weight is spread well, the excavator works better. It avoids extra stress on the tracks. This makes the undercarriage last longer. Check rollers and chains often for wear. Fixing problems early keeps the weight balanced and saves money on repairs.

Helping the Excavator Move

Undercarriage parts help the excavator move. Track chains, sprockets, and rollers work together for smooth movement. A good undercarriage gives strong grip and stops sliding. This lets the excavator handle rough ground easily.

Replacing old parts improves movement and saves energy. New parts give better grip and smoother operation. This also helps use less fuel. Taking care of the tracks stops breakdowns and keeps the excavator moving well, even on tough terrain.

Keeping Balance on Uneven Ground

Undercarriage parts keep the excavator steady on uneven ground. They stop tipping and wobbling, keeping the machine balanced. This makes it safer and easier to use.

The table below shows how undercarriage parts help balance:

| Feature | How It Helps |

|---|---|

| Balance | Parts keep the excavator steady on uneven ground. |

| Grip | They improve grip, helping the machine stay firm on the ground. |

| Easy Movement | Parts make it easier to move on rough surfaces. |

Good balance makes work safer and more accurate. Check parts often and replace worn ones quickly. This keeps the excavator steady and ready for any job.

Reducing Wear on Other Components

The undercarriage helps protect other parts from wearing out fast. Taking care of it reduces stress on the engine, hydraulics, and tracks. This keeps your machine running longer and smoother.

Parts like track chains, rollers, and shoes share the machine’s weight. They also absorb shocks. If these parts wear out, stress moves to other areas. For example, bad track chains can cause uneven movement. This adds pressure to sprockets and idlers. Over time, this can lead to expensive repairs or downtime. Checking parts often helps catch problems early.

Cleaning the track assembly also reduces wear. Dirt and debris can get stuck in rollers and chains. This causes friction and makes parts wear out faster. Use a pressure washer to clean after each use. This is especially important in muddy or sandy areas. Cleaning helps your undercarriage last longer and protects other parts.

Track tension is important too. Loose tracks can slip, and tight tracks cause friction. Both can damage the undercarriage and other parts. Follow the maker’s instructions to adjust tension correctly. A small fix like this improves how your excavator works.

By doing these things, you protect your undercarriage and other parts. A cared-for undercarriage lasts longer and avoids sudden breakdowns.

Signs of Wear and Tear in Undercarriage Parts

Knowing when your excavator’s undercarriage is wearing out is important. It helps keep the machine working well and avoids expensive fixes. Below are common signs of wear to watch for.

Uneven Track Wear

Uneven track wear shows there might be undercarriage problems. Worn tracks can make the excavator unstable and less efficient. To stop this, adjust track tension and switch track rollers often. The table below explains key points about uneven track wear:

| Diagnostic Data | What It Means for Undercarriage Life |

|---|---|

| Correct Track Tension | Helps parts last longer |

| Switch Track Rollers | Prevents uneven wear |

| Check Wear Patterns | Spots problems early to avoid failures |

Check your tracks regularly and fix uneven wear quickly. This keeps your undercarriage lasting longer and improves how your machine works.

Excessive Noise During Operation

Strange noises during use often mean undercarriage trouble. You might hear odd sounds when the excavator moves. These could be caused by loose tracks, worn parts, or alignment issues. Common reasons for noise include:

- Tracks too loose or too tight

- Uneven wear on track parts

- Broken or thrown tracks

- Leaking rollers or idlers

- Steering or alignment problems

Listen for these noises every day while working. Fixing them early stops bigger problems and keeps your excavator running smoothly.

Visible Damage to Rollers or Sprockets

Damaged rollers or sprockets are a clear warning sign. Look for cracks, worn spots, or broken teeth during daily checks. Weekly checks can help you spot tread wear and fix small issues before they grow. Ignoring damaged parts can cause uneven tracks and stress other components.

By checking often and fixing problems early, you avoid costly delays. Taking care of rollers and sprockets keeps your excavator reliable and ready for work.

Reduced Excavator Performance

Worn parts can make your excavator work poorly. If track chains, rollers, or sprockets are worn out, the machine slows down. You might notice it moves slower, digs less powerfully, or uses more fuel. These problems lower productivity and raise costs.

Here are some reasons performance drops:

- Undercarriage parts last 2,000 to 7,000 hours. Tough jobs on rough ground wear them out faster.

- Working in rocky or mining areas adds stress to the undercarriage. This causes quicker wear, higher repair costs, and a shorter machine life.

- Worn parts like track chains and rollers make tasks harder to do.

Taking care of your excavator can stop these issues. Check for worn parts like damaged rollers or uneven tracks often. Replace bad parts quickly to keep the machine running smoothly. Using strong, high-quality parts helps too. They last longer and reduce how often you need replacements. This keeps your excavator working well.

Cracks or Breaks in Track Shoes

Cracked or broken track shoes show your undercarriage is damaged. These problems make the excavator less stable and harder to control. Damaged shoes can also harm other parts, like track chains and rollers, by spreading pressure unevenly.

Track shoe damage happens for several reasons. Bad tension, heavy loads, or rough ground can cause cracks. Using shoes that are too big can also add stress and lead to damage. To avoid these issues:

- Check track shoes often for cracks, bends, or heavy wear.

- Keep track tension correct to lower stress on the shoes.

- Use the smallest shoe size that works for the job to reduce wear.

Ignoring damaged shoes can lead to expensive repairs and delays. Replacing them quickly keeps your excavator steady and working well. Taking care of track shoes helps them last longer and protects other parts from wearing out too soon.

Maintenance Tips for Excavator Undercarriage Parts

Taking care of your excavator’s undercarriage helps it last longer. Ignoring maintenance can cause expensive repairs and delays. Follow these simple tips to keep your machine in great shape.

Clean Dirt and Debris Regularly

Mud and dirt can build up on the undercarriage during use. This buildup wears out parts like track chains, rollers, and sprockets faster. Cleaning after every use helps avoid these problems.

- Use a pressure washer to clean off stuck dirt. Focus on rollers, sprockets, and track shoes.

- Check the track assembly for soil buildup. Dirt here causes friction and faster wear.

- If working in tough places like mines, clean more often to prevent damage.

Tip: Cleaning regularly helps you find problems early. This saves money on big repairs later.

Check for Damage Often

Looking for damage is key to keeping your undercarriage in good shape. Broken parts, like cracked track shoes or worn sprockets, can make your excavator less stable.

- Check track tension daily. Tracks should lift ½ to ¾ inch when tapped.

- Look for cracks, bends, or uneven spots on track shoes, rollers, and idlers.

- Make sure the track frame is aligned. Misalignment wears out parts faster.

Note: Driving fast or in reverse too much can wear out parts quickly. Operate carefully to reduce stress.

Lubricate Moving Parts

Lubrication keeps moving parts working smoothly. It reduces friction and stops parts from wearing out too soon. Skipping lubrication can cause loose tracks and part failures.

- Grease moving parts weekly, especially rollers, idlers, and sprockets.

- Add grease to the tensioning cylinder to keep track tension correct. Loosen the grease valve if tracks are too tight.

- Check lubrication levels often. Poor lubrication can loosen tracks and cause damage.

Tip: Use high-quality grease and follow the maker’s instructions for best results.

By cleaning, inspecting, and lubricating regularly, you can avoid common problems. These simple steps help your excavator last longer and work better.

Adjusting Track Tension

Keeping the right track tension is very important. Loose tracks can fall off, and tight tracks wear out faster. Adjusting the tension often helps the excavator move smoothly and avoids damage to other parts.

Steps to Adjust Track Tension:

- Check the Tracks: Look for sagging or if they are too tight. A good track should lift about ½ to ¾ inch when tapped.

- Park the Excavator: Place it on a flat surface. Use the boom and arm to lift the track off the ground.

- Find the Tensioning Cylinder: Locate the grease valve near the idler. This valve adjusts the track’s tension.

- Make Adjustments:

- Add grease with a grease gun to tighten the track.

- Open the valve slowly to release grease and loosen the track.

- Check Again: Lower the track and measure the sag. Repeat if needed until the tension is correct.

Tip: Always follow the instructions for your excavator model. Wrong adjustments can cause uneven wear or damage parts.

Adjusting track tension regularly keeps the excavator working well. It also prevents expensive repairs and keeps the undercarriage in good shape.

Scheduling Professional Inspections

Daily checks are helpful, but professional inspections find hidden problems. Experts can spot issues you might miss, keeping your machine safe and efficient.

How Often to Inspect:

- Daily: Do quick checks before and after using the machine.

- Monthly: Look closely at parts like rollers, sprockets, and track shoes.

- Quarterly or Yearly: Have professionals inspect the entire undercarriage for long-term issues.

What Affects Inspection Needs:

- How You Use It: Machines used for tough jobs need more frequent checks.

- Where You Use It: Mud, sand, and rocks wear out parts faster, so check often.

Regular inspections help you notice problems early. This reduces downtime and saves money on repairs.

Note: Professional checks follow safety rules and keep your excavator reliable.

By mixing daily care with expert inspections, you can fix problems early. This keeps your excavator running well and makes its parts last longer.

When to Upgrade or Replace Undercarriage Parts

Signs It’s Time to Replace Parts

Knowing when to replace undercarriage parts keeps your excavator working well. Worn parts can cause problems, safety risks, and expensive repairs. Here are signs you need new parts:

- Frequent Track Failures: Tracks slipping off or breaking often show wear.

- Uneven Wear Patterns: Irregular wear on chains, rollers, or sprockets affects stability.

- Reduced Performance: Slower speed, more fuel use, or trouble on rough ground means worn parts.

- Visible Damage: Cracks, bends, or missing sprocket teeth need quick attention.

Regular care stops bigger problems. For example, Cat undercarriages last longer because of strict quality checks. Replacing worn parts early avoids failures and helps your excavator last longer.

Benefits of Upgrading to High-Quality Components

Switching to high-quality undercarriage parts has many benefits. These parts handle tough jobs better and improve how your machine works.

- Lower Maintenance Costs: Strong parts need fewer repairs, saving money over time.

- Improved Fuel Efficiency: Good parts use power better, cutting fuel use.

- Enhanced Safety: Reliable parts lower the chance of sudden breakdowns.

- Increased Productivity: A strong undercarriage means smoother work with fewer stops.

- Extended Equipment Lifespan: Quality parts protect your machine, helping it last longer.

For example, upgrading parts can improve grip on rough ground, make jobs faster, and keep workers safer. These benefits make high-quality parts worth the cost.

Cost vs. Performance Considerations

When choosing parts, think about long-term value. Cheaper parts may cost less now but wear out faster and need more repairs.

| Factor | Cheaper Parts | High-Quality Parts |

|---|---|---|

| Initial Cost | Lower | Higher |

| Durability | Wears out quickly | Lasts longer |

| Maintenance Frequency | Needs frequent repairs | Requires less upkeep |

| Long-Term Savings | Minimal | Significant |

Good undercarriage parts save fuel, improve grip, and work better overall. They also prevent delays from breakdowns. Choosing quality over low cost ensures reliable and efficient operation.

Tip: Always pick parts that fit your excavator’s needs. This keeps it running smoothly and safely.

Picking the Best Supplier for Excavator Undercarriage Parts

Choosing a good supplier helps your excavator work well. It also prevents expensive repairs and delays. A trustworthy supplier offers strong parts that last longer. Here are tips to find the right one.

First, check the supplier’s reputation. Ask for references and contact three past customers. Find out if deliveries were on time and parts were correct. Positive reviews mean the supplier is dependable.

Look for certifications like ISO 9001 or CE compliance. These show the supplier follows strict quality rules. Certified parts meet industry standards and work well in tough jobs.

Online reviews can also help. A supplier with many good reviews is likely reliable. Read comments about how long their parts last and how easy they are to replace.

Check the supplier’s inventory and customer service. They should have many parts, like track chains, rollers, and sprockets. This makes it easier to find what you need. Good customer service means they answer questions quickly and offer helpful advice.

Compare prices and warranties too. Don’t just pick the cheapest option. Better parts may cost more but last longer and save money over time. A good warranty shows the supplier trusts their products.

By following these tips, you can choose a supplier who keeps your excavator working smoothly.

Knowing about excavator undercarriage parts helps keep your machine strong. Taking care of these parts stops costly repairs and sudden breakdowns. Important steps include:

- Clean the undercarriage to stop damage.

- Check track tension to avoid early wear.

- Lubricate parts to lower friction and rust.

- Replace worn parts to keep the machine running well.

- Align parts correctly to reduce extra wear.

| Maintenance Task | How It Helps |

|---|---|

| Regular checks | Prevents breakdowns and makes parts last longer. |

| Lubricating wheels and rollers | Cuts down wear and helps parts work better. |

| Checking suspension system | Reduces shaking, improving balance and machine performance. |

Focus on undercarriage care and work with a reliable parts supplier. This keeps your excavator working smoothly and lasting longer.

FAQ

What is the most important part of an excavator undercarriage?

Track chains are very important. They link the track shoes and help the excavator move well. Checking them often and replacing them on time keeps everything working smoothly and avoids damage to other parts.

How often should you clean the undercarriage?

Clean the undercarriage after each use. Dirt and mud can wear out the tracks and other parts. A pressure washer is great for cleaning, especially in muddy or sandy areas.

Why is track tension important?

Correct track tension stops slipping and reduces wear. Loose tracks can fall off, and tight tracks cause too much friction. Adjusting the tension often helps the excavator move better and makes the undercarriage last longer.

How do you know when to replace undercarriage parts?

Watch for uneven track wear, strange noises, or damaged rollers and sprockets. If the excavator moves slower or uses more fuel, it’s time to replace parts.

Can upgrading undercarriage parts improve performance?

Yes, better parts last longer and work more efficiently. They need less fixing, save fuel, and give better grip on rough ground. This makes your excavator safer and more productive.