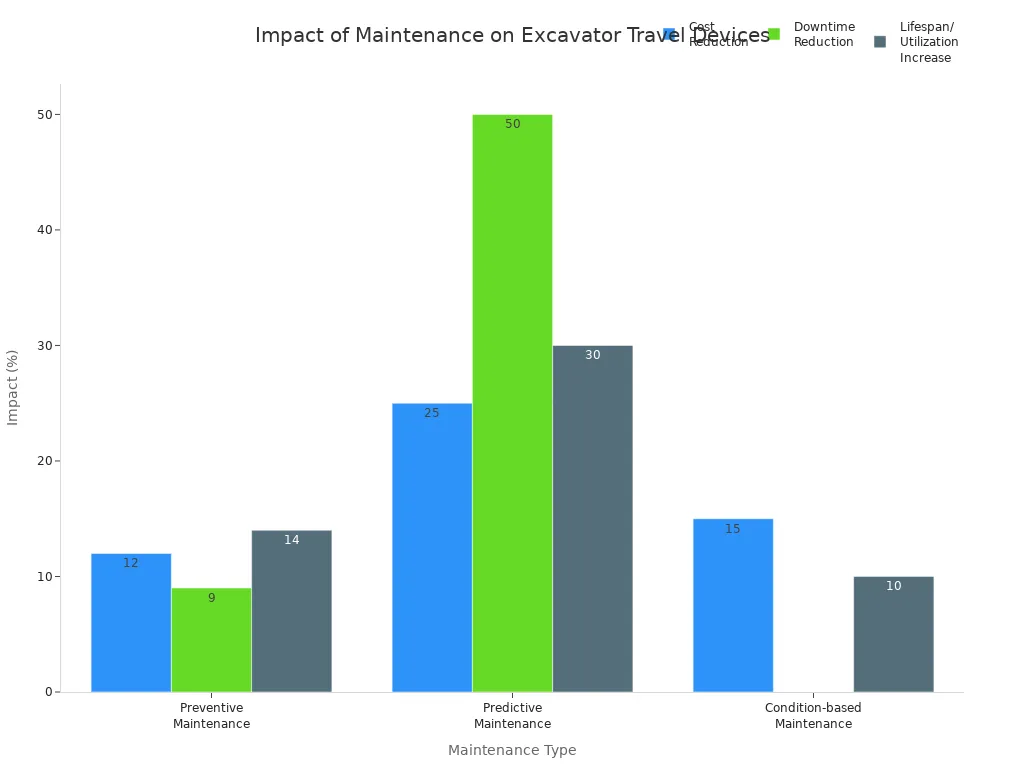

You play a crucial role in keeping your excavator and its parts, including the travel device, safe and running smoothly. Regular maintenance of your excavator and its travel device parts helps prevent costly issues, reduces unexpected breakdowns, and keeps your machine in top condition. Research shows that daily care and proper routines for your excavator’s travel device and other parts can save you up to 25% in overall costs and extend your equipment’s lifespan by 30%.

Metric | Proactive Maintenance | Reactive Repairs |

|---|---|---|

Total Ownership Cost Reduction | Up to 25% lower | N/A |

Equipment Life Extension | 30% longer | N/A |

Emergency Repairs | 40% fewer | N/A |

Annual Maintenance Costs | $15,000 – $25,000 | $35,000 – $60,000 |

Downtime Costs | Minimal | $2,500 per day during repairs |

As you can see, regular maintenance and following best practices help your excavator and its travel device parts perform better and operate more safely. Inspecting your excavator’s travel device and other key parts every day helps you avoid unexpected breakdowns, keeping your job site safer for everyone.

Key Takeaways

Doing daily maintenance on your excavator travel device saves money. It also helps stop breakdowns. This can make your equipment last up to 30% longer.

Learn about the main parts of the travel device. Check them often to find problems early. This helps your machine work well.

Use a simple maintenance plan. Do checks every day, week, and month. This stops expensive repairs and keeps your job site safe.

Look for leaks, odd noises, or if it gets too hot. Fix these problems fast before they get worse.

Call an expert if the problem is big or hard to fix. This keeps your excavator safe and working right.

Travel Device Overview

Function

You need the travel device to move your excavator. The travel device is also called the final drive motor or travel motor. It makes the tracks move forward, backward, and turn. The travel device uses a hydraulic motor. This motor gets power from the main hydraulic pump. The power goes into a planetary gearbox, called the final drive. The gearbox turns hydraulic power into spinning motion. This spinning moves the tracks and lets the excavator travel. If the travel device does not work, your excavator cannot move or get into place for digging or lifting.

Tip: Check the travel device before you start your excavator. Even a small problem can stop your machine and slow down your job.

Key Parts

It is important to know the main parts of the travel device. Each part helps your excavator move and stay steady. Here are the main parts:

Track Shoes: These touch the ground and help your excavator grip.

Track Chains: They link the track shoes and make the track strong.

Drive Sprockets: These gears send engine power to the tracks.

Idler Wheels: They guide the tracks and keep them tight.

Track Rollers: These hold up the track chain and spread out the weight.

Track Tensioners: They make the tracks tight enough to stop wear.

Drive Motor: This motor uses hydraulic or electric power to move the tracks.

Reducer: It slows down the motor and gives more force for moving.

Drive Shaft: This part sends power from the engine to the drive motor.

Support Wheels: They help hold up the track chain and lower wear.

Steering Mechanism: This has swing drives and steering gears for turning and steering.

You should look at these travel device parts when you do your checks. Knowing each part helps you find problems early and keep your excavator working well.

Parts: Travel Device Excavator

The parts travel device excavator system includes three main components: the travel motor, gearbox, and final drive. Each part plays a key role in moving your machine and keeping it reliable on any job site.

Travel Motor

The travel motor acts as the heart of the parts travel device excavator. You use the excavator travel motor to turn hydraulic energy into the force that starts your tracks moving. This motor gets power from the main hydraulic pump. It sends that power to the final drive, which then moves the tracks or wheels.

Tip: If you notice slow or jerky movement, or hear knocking sounds, check the travel motor for leaks or dirty hydraulic oil. Early detection helps you avoid bigger problems.

Common wear points include internal seals and moving parts. Dirt or water in the hydraulic fluid can cause damage. You should check for leaks, sluggish movement, and listen for odd noises every day.

Gearbox

The gearbox sits between the travel motor and the final drive. It reduces speed and increases torque, giving your excavator the strength to climb or push heavy loads. The gearbox uses gears and bearings to transfer power smoothly.

Watch for signs of wear like noisy operation, vibrations, or oil leaks. Worn or cracked gear teeth and damaged bearings can lead to power loss.

Note: Regularly check and change the gear oil. Replace worn seals and adjust track tension to prevent extra stress on the gearbox.

Final Drive

The final drive is the last step in the parts travel device excavator. It takes the power from the gearbox and turns it into movement for the tracks. The final drive uses gear drives or hydraulic drives to provide high torque and precise control. This part ensures your excavator moves smoothly over rough ground.

You should inspect the final drive for oil leaks, worn gears, and loose bolts. Clean away mud and debris after each use. Keeping the final drive in good shape helps your excavator last longer and work more efficiently.

Part | Common Wear Points | Inspection Tips |

|---|---|---|

Travel Motor | Seals, internal components | Check for leaks, sluggish movement, odd noises |

Gearbox | Gears, bearings, seals | Listen for noise, check oil, inspect for leaks |

Final Drive | Gears, bolts, seals | Look for leaks, clean debris, check for cracks |

Maintenance Checklist

Taking care of your excavator starts with a good routine. You should do daily, weekly, and monthly checks. This keeps your travel device safe and working well. A checklist helps you find problems early. It also helps you avoid expensive repairs. Always use your manufacturer’s manual. Follow the rules for maintenance to get the best results.

Daily Checks

Start each day by checking your excavator. This helps you find small problems before they get worse. Daily checks keep your machine safe and ready.

Park your excavator on flat, solid ground before checking.

Measure track sag in the middle of the track.

Adjust track tension if it is not correct.

Check joints and pins for movement or stretching. Make sure all shoes have enough grease.

Look at track hardware for loose or missing bolts.

Check the idler for leaks or strange wear.

Clean and check carrier rollers for dirt or damage.

Look for missing bolts or damage on sprockets, like bends or cracks.

Make sure track tension is right. There should be a little sag. Do not let tracks get too tight or too loose.

Check track shoes for wear, cracks, or loose bolts.

Look at sprocket teeth for wear and if they line up.

Check rollers for leaks, loose bearings, or damage.

Make sure the track frame and wear strips are lined up.

Look over the whole machine for dirt, damage, leaks, and the shape of pins and bushings.

Test the machine. Start the engine, listen for odd sounds or smoke, test travel and hydraulic parts, and check all safety systems.

Tip: Doing daily checks lowers the chance of sudden breakdowns. It also makes the job site safer for everyone.

Daily Maintenance Task | Why It Matters |

|---|---|

Track tension check | Stops tracks from wearing out early |

Lubricate joints and pins | Lowers friction and damage |

Inspect for leaks and damage | Stops small problems from growing |

Clean debris from rollers and tracks | Helps parts move without trouble |

Test safety systems | Keeps workers and the site safe |

Weekly Tasks

Weekly checks help you do more than daily checks. These jobs focus on cleaning, greasing, and finding bigger problems.

Clean under the machine to get rid of dirt and rocks. This stops parts from wearing out fast.

Check tracks, roller sprockets, and idler wheels for damage or oil leaks.

Check and fix track tension for the job and as the manual says.

Grease pins and bushings around the machine. This keeps things moving well and stops damage.

Read the owner’s manual for what to do each week. Use the right fluids and filters to protect your travel device.

Look for strange wear or loose bolts on moving parts.

Make sure all safety features work right.

Note: Weekly checks help you find problems that daily checks might miss. Cleaning and greasing often make your travel device last longer and keep it safer.

Monthly Tasks

Monthly checks help your travel device last longer. These jobs stop big problems and keep your machine running well.

Check the final drive gear oil once a month or every 100 hours. This keeps your travel device working smoothly.

Change the final drive gear oil once a year for good lubrication.

Fix any leaks from the travel motor right away. Leaks can let dirt in and cause bad damage.

Listen for odd sounds like screeching or shaking. Get a pro to check if you hear them.

Go over all maintenance steps in your manual. Follow the schedule for every part.

Check all bolts and fasteners. Tighten any that are loose.

Clean plugs and fittings before checking oil or adding fluids.

Write down all maintenance in a logbook. This helps you remember what you did and when.

Safety Reminder: Monthly checks help you stop dangerous problems and keep your excavator safe for everyone.

Using a checklist makes sure you do all important jobs on time. This cuts down on surprise breakdowns, saves money, and keeps people safe. Daily, weekly, and monthly checks work together to keep your travel device strong and working well. Training and following the rules also help lower downtime and make your machine last longer. Using digital tools or simple lists helps you stay on track and ready.

Callout: When you follow regular maintenance and use your manual, you protect your machine and keep your job site safe.

Troubleshooting

Leaks

Leaks in your excavator’s travel device can lead to serious breakdowns if you do not catch them early. Most leaks come from loose fittings, worn seals, or damaged hydraulic lines. You can spot leaks by cleaning the area with a degreaser and drying it with compressed air. Then, run your machine and watch for fluid to appear. If you see thin fluid, check the case drain filter and hoses. Thick fluid leaking from the planetary side or behind the sprocket often means a main seal or gearbox cover problem.

Tip: Always monitor fluid levels and look for dark spots under your excavator. Early detection helps you avoid major hydraulic system issues.

Leak Type | Common Cause | What To Do |

|---|---|---|

Hydraulic Fluid | Loose fittings, bad seals | Tighten or replace parts |

Gear Oil | Worn seals, cover damage | Replace seals or cover |

Noises

Strange noises from your travel device signal trouble. You might hear grinding, knocking, or whining. These sounds often mean low gear oil, worn bearings, or damaged gears. Start by checking the gear oil level. If it is low, top it off and look for leaks. Listen for changes when you operate the excavator. If noise continues, inspect bearings and gears for wear. Tighten any loose sprocket bolts.

If vibration or shuddering does not stop, you may need a professional to check for deeper problems.

Addressing noises quickly helps prevent costly breakdowns and keeps your hydraulic system issues from getting worse.

Overheating

Overheating can cause your excavator to stop working and lead to breakdowns. Low gear oil, hot hydraulic fluid, or worn bearings are common reasons. Check the gear oil level and top it off if needed. Make sure the radiator is clean and the cap is tight. If the brakes do not release, heat will build up. Replace worn bearings and seals right away.

Cause | Solution |

|---|---|

Low oil | Add oil, fix leaks |

Hot hydraulic fluid | Check cooling system |

Brake drag | Inspect and adjust brakes |

Worn bearings | Replace bearings |

Regular maintenance and quick action help you avoid overheating and keep your excavator running strong.

Weak Motor

A weak travel motor makes your excavator slow or unable to climb. This problem often comes from hydraulic system issues, such as low or dirty fluid, or seal leaks. Check the rotary manifold seals for leaks. Look at hydraulic filters for metal particles, which show internal wear. Test the hydraulic pressure and adjust relief valves if needed.

If you find metal in the oil or filters, replace worn parts right away.

Reseal the rotary manifold if you see leaks.

Keeping your hydraulic system clean and well-maintained stops weak motor problems and reduces the risk of breakdowns.

Professional Support

When to Call

You need to know when to get help from a professional for your excavator travel device. Some problems are too hard or risky for you to fix alone. Getting expert help keeps your machine safe and everyone protected. Watch out for these warning signs:

Tracks are too loose or not lined up right

Track shoes, rollers, idlers, or sprockets look worn or broken

Leaks come from the final drives or track adjusters

The machine shakes in a strange way when moving

Hydraulic fluid leaks from cylinders or hoses

The hydraulic system acts slow or jumps around

You see cracks or broken parts on the machine’s frame

Warning lights turn on while you use the excavator

The engine or machine makes odd noises

Hydraulic hoses look damaged

Track tension is not right

If you notice any of these problems, stop using the excavator right away and call a professional. Acting fast stops bigger problems and keeps you and your team safe. Professionals should check your machine every 500 hours. This helps find hidden problems and keeps the job site safe.

DIY vs. Expert

You can do some maintenance jobs yourself, but others need a trained expert. Knowing which jobs you can do helps keep your machine and everyone safe.

Maintenance Task | DIY Safe? | Explanation |

|---|---|---|

Greasing sliding metal parts | Yes | You can add grease to stop friction and heat. |

Applying grease to slewing drive bearings | Yes | You can do this if you follow the manual. |

Using correct grease | Yes | Always check your manual to use the right grease. |

Draining water separator filters | Yes | You can drain filters, especially if a sensor warns you. |

Checking track tension | Yes | You can check track tension to stop wear and stay safe. |

Cleaning debris and mud from tracks | Yes | Cleaning every day stops damage and keeps things safe. |

Lubricating sliding parts and rollers | Yes | You can do this if you use the right grease. |

Cleaning or replacing filters | Yes, with caution | Follow the steps to avoid dirt and keep things safe. |

Inspecting rotec bearings | No | These are delicate and expensive, so let an expert check them. |

Bearing repairs and replacements | No | These jobs are hard and need expert skills for safety. |

Component replacements involving critical parts | No | Experts should do these jobs to lower risk and keep safety high. |

Professionals often use automatic lubrication systems. These systems can cut maintenance costs by more than half. They also make sure every part gets the right care. Experts have special training and tools to find problems early. This helps you avoid big repair bills and keeps your safety record good. If you only do maintenance yourself, you might miss hidden problems. Professional help gives you peace of mind and keeps your excavator safer for longer.

Tip: Always follow the inspection times in your manual. Regular checks and expert help keep your machine working and everyone safe.

When you take care of your equipment every day, you keep it safe. Good maintenance helps you find problems before they get big. This keeps your excavator working well and safely. Using good parts gives you many benefits:

Your excavator works better, lasts longer, and is more reliable.

You have less downtime and spend less on repairs.

Your machine lasts longer and works harder on the job.

If you follow the manufacturer’s rules and check your machine daily, you lower the chance of breakdowns. Being careful and checking often helps your projects go smoothly and keeps your equipment ready for work.

FAQ

How often should you check the travel device on your excavator?

You should check your travel device every day before you start work. Daily checks help you find small problems early. This keeps your excavator safe and running well.

What signs show your travel device needs repair?

Look for oil leaks, strange noises, or slow movement. If you see loose bolts or worn parts, your travel device may need repair.

Tip: Stop using your machine if you notice these signs.

Can you use any oil for the travel device?

No, you must use the oil type listed in your excavator’s manual. Using the wrong oil can damage parts and shorten the life of your travel device.

What tools do you need for basic maintenance?

You need a grease gun, wrenches, a clean rag, and your owner’s manual.

A flashlight helps you see hidden spots.

Keep a logbook to track your work.