When you pick a new excavator hydraulic pump, you must match the pump’s flow rate, pressure, and compatibility to your machine. This careful match helps your excavator work well and stay safe.

A good fit makes your machine work better. It also stops your equipment from getting too hot or wearing out quickly.

If the pump does not match, you may see slow movement, too much heat, or loud sounds.

The right pump can save you money over time. It also helps your machine last longer.

Safety is important. Always watch your equipment, look for leaks, and use lockout steps before fixing anything.

Key Takeaways

Make sure the hydraulic pump matches your excavator. Check the flow rate, pressure, and compatibility. This helps your machine work well. It also stops damage from happening.

Read your excavator’s manual for what you need. Knowing the model and specs is important. It helps you pick the right pump. This can save you money and trouble.

Think about how strong the pump is. Good materials make the pump last longer. This means you will fix it less and spend less money.

Choose brands people trust and look at warranty choices. A strong warranty keeps your money safe. It also shows the product is reliable.

Take care of your pump often. Check fluid levels and look for leaks. Change filters when needed. This keeps your hydraulic system working well.

Excavator Requirements

Model and Specs

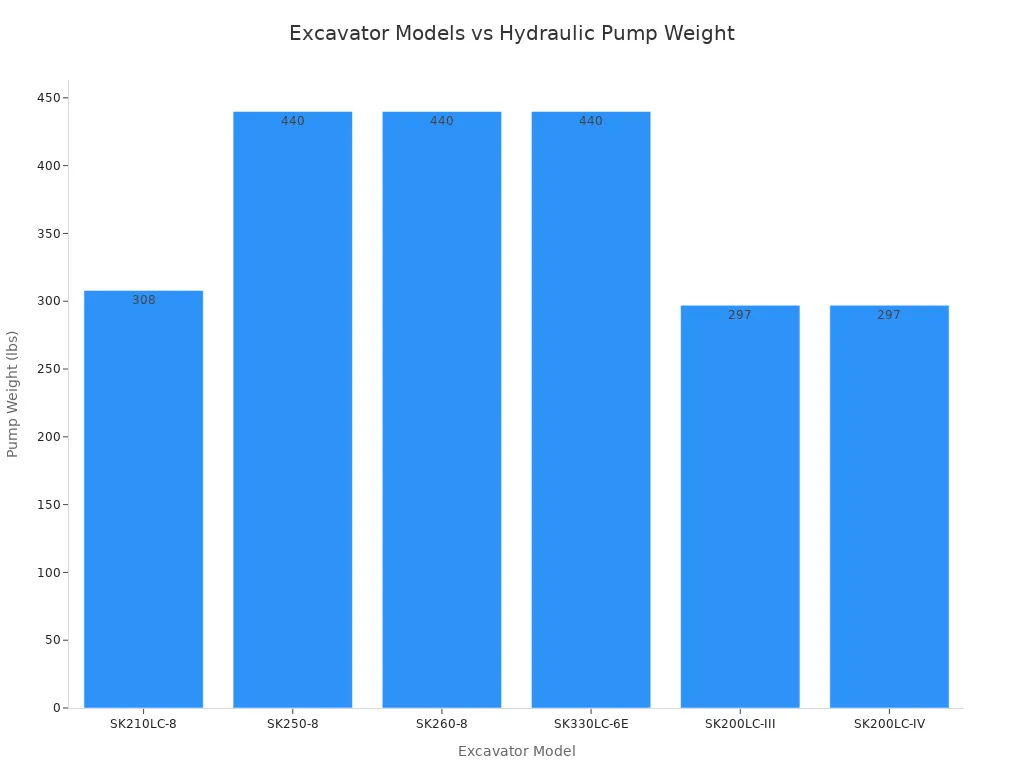

When you pick a new excavator hydraulic pump, you need to check your excavator’s model and specs first. Every excavator needs a certain hydraulic flow, pressure, and fluid volume. If you choose a pump that does not match, your machine may not work well or could get damaged.

Here is a table that lists common excavator models and their hydraulic pump specs:

Excavator Model | Hydraulic Pump Weight |

|---|---|

SK210LC-8 | 308 lbs |

SK250-8 | 440 lbs |

SK260-8 | 440 lbs |

SK260LC-9 | N/A |

SK295-8 | N/A |

SK295-9 | N/A |

SK330LC-6E | 440 lbs |

SK200LC-III | 297 lbs |

SK200LC-IV | 297 lbs |

You should look in your excavator’s manual for the right hydraulic pump weight, flow rate, and pressure. If the pump is too heavy or too light, it can put stress on the frame or mounting points. Always match the pump’s specs to your excavator so it works safely and well.

Compatibility

You need to make sure your new excavator hydraulic pump fits your machine. If it does not fit, you could get leaks, control problems, or broken parts. Some common problems are:

Issue Type | Description |

|---|---|

Pressure and flow matching | If the long arm cylinder needs more pressure than the valve can handle, it may break the valve body. |

Control logic compatibility | Some brands use special electro-hydraulic systems. The CAN bus protocol might need reprogramming to stop control problems. |

Pin size tolerance | SANY SY75C uses an 80mm boom pin, but some other long arms are made for 75mm. You may need a custom bushing or change the hole size. |

Tip: Always check the hydraulic connections, control systems, and pin sizes before you buy. If you skip these steps, you might spend more time and money fixing problems later.

You also need to use the right hydraulic fluid for your pump and excavator. If you use the wrong fluid, it can cause overheating, poor lubrication, or seals to fail.

Application

What your excavator does changes which hydraulic pump you need. Different jobs need different pump features. For example, construction, mining, and demolition all need special things from excavator hydraulic pumps.

Application | Requirements |

|---|---|

Construction | Pumps need to last through many cycles, have smooth control, strong seals to keep out dust, and work with many functions. |

Mining | Pumps must be heavy-duty, have high flow and pressure, strong hoses, and parts that can take shock loads. |

Demolition | Pumps need strong cylinders, special circuits for hydraulic breakers, and pressure-relief systems for sudden impacts. |

If you use your excavator for mining, you need a hydraulic pump that can handle lots of fluid and high pressure. For demolition, you need pumps with strong pressure-relief systems to protect against sudden hits. Construction jobs need pumps that control smoothly and have seals to keep out dust.

Note: Always tell your supplier what you use your excavator for. YNF Machinery can help you choose the right new excavator hydraulic pump for your needs.

You need to match the pump’s flow rate, pressure, and fluid type to your excavator’s job. This helps stop breakdowns and keeps your machine working well.

New Excavator Hydraulic Pump Features

When you pick a new excavator hydraulic pump, you should look at its main features and technology. These things change how your excavator works every day. The right pump helps your machine move easily, lift heavy things, and last longer in tough places.

Flow Rate

Flow rate means how much hydraulic fluid the pump moves each minute. You need to match the flow rate to what your excavator needs. If the flow rate is too low, your machine will move slowly. If it is too high, you could hurt the system or waste energy.

Most medium excavators use pumps with flow rates up to 150 gallons per minute.

The hydraulic fluid must move fast enough for all the machine’s jobs.

A good flow rate helps your excavator lift, dig, and swing quickly and smoothly.

You should check your excavator’s manual for the right flow rate. Using the wrong flow rate can make your machine work badly and wear out parts faster. The flow rate also helps the hydraulic fluid cool and oil the pump.

Tip: Always match the pump’s flow rate to your excavator’s size and job. YNF Machinery can help you pick the right new excavator hydraulic pump for your needs.

Pressure

Pressure is another important part of a hydraulic pump. It shows how much force the pump makes with the hydraulic fluid. The right pressure lets your excavator do hard jobs like lifting rocks or digging deep.

Most excavators work at pressures up to 4,500 psi.

The pressure rating changes how much weight your machine can lift and how fast it moves.

Pressure relief valves keep your system safe from too much pressure. If the pressure gets too high, these valves send extra hydraulic fluid back to the tank.

Using the right pressure helps your excavator work safely and well. If the pressure is too low, you cannot lift heavy things. If it is too high, you might break hoses or valves. The pump’s pressure rating must match your excavator’s needs and the hydraulic fluid you use.

Note: Always check the pressure rating before you buy a new excavator hydraulic pump. This helps you stay safe and keeps your machine working well.

Build Quality

Build quality decides how long your hydraulic pump will last. Pumps made with strong materials can do hard jobs and last for years. You should look at what the pump is made of and how it stands up to heat, dust, and rust.

Material Used | Durability Features and Technology | Common Use in Pumps |

|---|---|---|

Cast Iron | Strong, lowers vibration | Pump body |

Aluminum | Light, does not rust | Lighter-duty pumps |

Steel | Tough, does not wear out fast | Main structure |

Hardened/Stainless Steel | Does not rust, lasts long | Inside parts |

Bronze/Polymers | Slippery, does not wear out fast | Bearings, vanes |

Rubber (Nitrile, PTFE, Polyurethane) | Stretches, resists hydraulic fluid | Seals, gaskets |

Ceramics | Handles heat and chemicals | High-wear pumps |

Good pumps can last from 5,000 to 10,000 hours. If you use pumps made from weak materials, they break more and do not last long. Dust, water, and bad hydraulic fluid can also make pumps wear out faster. You need to clean and check your pump often to keep it working well.

Pumps with strong seals keep hydraulic fluid inside and stop leaks.

Good build quality means less time fixing and lower repair costs.

The right materials help your pump fight rust and wear.

Alert: Always ask about the materials and build quality when you buy a new excavator hydraulic pump. YNF Machinery has pumps with strong durability and advanced features and technology.

Hydraulic pump features and technology help your excavator work in tough places. The pump moves hydraulic fluid to lift, dig, and swing heavy things. If you pick a pump with the right flow rate, pressure, and build quality, your machine works better and lasts longer. Your excavator will run smoothly and stay strong, even in hard conditions.

Quality and Reliability

When you buy a new excavator hydraulic pump, you should care about quality and reliability. These things help your machine work well and last longer. You do not want to replace parts often or have your machine stop working. If you pick a high-quality hydraulic pump, your machine works better and you worry less.

Brand Reputation

You need to check if the brand is trusted before you buy. Good brands make pumps that last a long time and work well. Pumps from these brands give you fewer problems and better results. Here are some brands people trust for excavator pumps:

Moog Inc. makes strong hydraulic pumps for many excavators.

Rexroth WaldrichCoburg GmbH builds pumps for hard jobs.

Staffa Hydraulics has pumps with high torque and low speed.

Aichi Machine Industry Co. makes pumps that work well for many excavators.

YNF Machinery is a top choice for new excavator hydraulic pumps. You get good quality and helpful service from YNF Machinery. It is very important to use quality hydraulic pumps. Good brands help your machine last longer and work smoothly.

Certifications

Certifications show the hydraulic pump meets industry rules for quality and performance. You should look for pumps with certifications from trusted groups. These certifications mean the pump passed tough tests. Certified pumps work better and last longer. Buying certified hydraulic pumps helps your excavator work safely and well.

Note: Ask YNF Machinery about certifications for their new excavator hydraulic pumps. Certified pumps help you trust the quality and reliability.

Quality is important for every part of your excavator. If you pick a pump with a good brand, strong warranty, and the right certifications, your machine works better and needs fewer replacements. Always choose quality first to keep your machine working its best.

Cost Considerations

Price vs. Value

When you look at the cost of excavator hydraulic pumps, you need to think about more than just the price tag. The value you get from your investment depends on several factors. Different pump types have different price ranges. For example:

Pump Type | Price Range |

|---|---|

Gear Pumps | $100 – $2,000 |

Vane Pumps | $200 – $3,000 |

Piston Pumps | $500 – $5,000 |

You also see price differences by brand and specification. For example:

Main Hydraulic Pump for Kobelco SK200LC-III, SK200LC-IV: $4,340.00

Main Hydraulic Pump for Kobelco SK220LC-III: From $3,661.00

Main Hydraulic Pump for Kobelco SK210LC-8: From $5,110.00

The best value for your investment comes from matching the pump’s features to your excavator’s needs. Look at the pump type, material, brand, efficiency, durability, and maintenance needs. These factors affecting excavator hydraulic pump cost can change the total cost of ownership over time. A pump with higher efficiency and better materials may cost more at first, but it can save you money on repairs and downtime.

New, Rebuilt, or Used

You have three main choices when buying an excavator hydraulic pump: new, rebuilt, or used. Each option has its own value and cost.

Option | Pros | Cons | Price Range |

|---|---|---|---|

New Pump | Full warranty, latest tech | Highest cost | $200 – $20,000+ |

Rebuilt Pump | 50–70% cheaper than new | Shorter warranty | $150 – $10,000 |

Used Pump | Very cheap | Unreliable, no warranty | $100 – $5,000 |

New pumps give you the latest technology, longest lifespan, and lower maintenance bills. You pay the highest cost.

Rebuilt pumps save you 20–40% compared to new. They can work like new if rebuilt well, but quality can vary.

Used pumps cost the least. You may get a known history, but you risk more wear and no warranty.

Tip: Always ask about the pump’s history and warranty. YNF Machinery offers reliable options to help you get the most value.

Total Ownership Cost

The total cost of ownership includes more than the price you pay at first. You must think about how long the pump lasts, how much fluid it uses, how often you need repairs, and how much downtime costs you. A pump with a higher upfront cost may give you better performance and lower costs over time.

Factor | Description |

|---|---|

Pump Type | Some pumps cost more but last longer. |

Material | Stronger materials mean higher cost but better durability. |

Brand | Trusted brands may cost more but offer better reliability. |

Efficiency | Efficient pumps use less fluid and save on energy. |

Durability | Durable pumps lower repair and replacement costs. |

Maintenance | Pumps that need less maintenance save you money in the long run. |

You want to focus on maximizing the value of your investment. Think about how the pump’s cost, fluid needs, and maintenance affect your total cost of ownership. YNF Machinery can help you choose a pump that fits your excavator and gives you the best value over time.

Common Mistakes

Ignoring Compatibility

Some people think any hydraulic pump will work. But using the wrong pump can cause big problems. Your excavator might get damaged or not work well. Here are some things that can go wrong:

Your machine may not work as fast and could break.

Using the wrong hydraulic fluid can make your excavator act up.

If the pump is the wrong size, it can hurt your excavator.

Bad piping design can make the pump work too hard.

Always look at your excavator’s specs before buying a pump. Make sure the pump matches the flow rate, pressure, and fluid type. Doing this helps you avoid expensive fixes and keeps your excavator working well.

Overlooking Maintenance

Many people forget about maintenance when picking a hydraulic pump. Good maintenance helps your hydraulic system last longer. If you skip regular checks, your excavator might break down and cost more to fix. Here are some easy maintenance steps:

Check fluid levels often so your machine does not get too hot.

Use clean fluid that the maker says is best.

Look for leaks near the pump and hoses to stop pressure loss.

Change filters on time to keep fluid moving right.

Watch system pressure to catch problems early.

Listen for strange sounds that could mean something is wrong inside.

Doing regular checks and service helps your excavator stay strong. Maintenance means checking fluid, looking at hoses, and changing filters. Always follow what the maker says for taking care of your hydraulic system.

Skipping Supplier Checks

You should pick a supplier you can trust for your hydraulic pump. If you do not check your supplier, you might get bad parts or poor help. Find a supplier with good reviews and a strong history. Make sure they give expert advice and help when you need it. YNF Machinery gives trusted pumps and support for your excavator.

Tip: Always learn about your supplier before you buy. Good suppliers help you get the best pump and keep your excavator working great.

When you buy a hydraulic pump for your excavator, you should follow some important steps. First, learn what your excavator needs and pick the right pump type. Then, check the pump’s flow rate, pressure, and if the brand is trusted. Always look at the checklist below before you choose:

Checklist Item | Frequency | Description |

|---|---|---|

Fluid Levels | Daily | Check hydraulic oil, engine oil, and coolant every day to stop big problems. |

Leaks and Safety Equipment | Daily | Look for leaks and make sure safety gear works. |

Hydraulic System Evaluation | Monthly | Check for worn parts and leaks in the hydraulic system each month. |

Hydraulic System Filters | Critical | Make sure filters are clean so the hydraulic fluid stays good. |

Hydraulic Fluid Level, Color, Viscosity | Critical | Check these often to keep the hydraulic system working well. |

Hydraulic System Seals | Critical | Look at seals for damage so you do not get leaks. |

Pre-use Inspection | Pre-use | Before you use the excavator, look for damage, wear, or leaks. |

You should always make sure the pump fits your excavator, is good quality, and does not cost too much. If you need help, ask YNF Machinery for advice. You can ask about piston, vane, or gear pumps and get tips for your excavator’s size and job.

FAQ

What should you check before buying a new excavator hydraulic pump?

You should check your excavator’s model, flow rate, and pressure needs. Make sure the pump matches your machine. Always ask YNF Machinery for help if you feel unsure.

How often should you maintain your hydraulic pump?

You should check fluid levels and look for leaks every day. Change filters and inspect hoses often. Regular maintenance helps your pump last longer and work better.

Can you use any hydraulic fluid in your new pump?

No. You must use the fluid type listed in your excavator’s manual. The wrong fluid can cause damage or leaks. YNF Machinery can help you choose the right fluid.

Why does pump compatibility matter?

A pump that does not fit your excavator can cause leaks, slow movement, or even damage. Always match the pump’s specs to your machine for safe and smooth operation.

Where can you buy a reliable new excavator hydraulic pump?

You can buy a reliable pump from YNF Machinery. They offer quality products, expert advice, and strong support for your excavator needs.