You need to change 130 excavator parts often. This helps your machine work well. Here are some parts you replace a lot and when you should do it:

Track shoes: 2,000 to 3,000 hours

Rollers: 3,000 to 5,000 hours

Idlers: 4,000 to 6,000 hours

Sprockets: 3,000 to 4,000 hours

Track chains: 3,000 to 5,000 hours

Engine oil filters: 250 to 500 hours

Fuel injectors: 1,500 to 4,000 hours

Pistons: Over 10,000 hours

Cooling fans: 2,000 to 5,000 hours

Batteries: 3 to 5 years

Radiators: 5,000 to 10,000 hours

These parts wear out because you use them a lot. Vibration and dirt also make them wear out faster. Changing 130 excavator parts often stops surprise problems. It keeps your excavator working well. If you follow a maintenance plan, every part lasts longer. You also save time and money.

Regular maintenance makes excavators last more years. Checking parts, fixing small problems, and adding oil helps stop wear. If you do not take care of your machine, small problems get worse quickly.

Looking after 130 excavator parts helps you finish more jobs. You also avoid big repair bills. Simple care and regular checks help your machine and its parts last much longer.

Key Takeaways

Change important excavator parts often to keep your machine working well and stop expensive fixes. – Look at hydraulic hoses and seals every day for damage, like leaks or cracks, so the machine does not break down. – Check undercarriage parts like track chains and shoes often to make sure they are still good. – Take care of engine and cooling system parts by looking for leaks and cleaning filters so the machine does not get too hot. – Write down all maintenance work to remember which parts you changed and find problems early.

Hydraulic System 130 Excavator Parts

The hydraulic system works hard every day. You need to check and change hydraulic parts often. This keeps your machine working well. If you ignore these parts, your excavator can break down. Repairs can cost a lot of money. You can find problems early if you know the signs of wear. You can also use maintenance tips to stop parts from wearing out too soon. This helps your excavator stay in good shape.

Hydraulic Hoses and Seals

Hydraulic hoses and seals move fluid and keep it inside. These parts face a lot of pressure and dirt. You should check them every day. Look for these signs of wear:

Scratches or cuts on the hose

Bubbles or blisters on hoses

Leaks near the ends or along the hose

Cracks or hard seals

If hoses or seals break, you may see leaks. The machine may not work as well. These are clear signs of wear. Listen for hissing sounds. This can mean a leak. If you see oil on the ground, fix it fast.

Many things can make hoses and seals wear out:

Dirt or water in the fluid

Rubbing against metal or other hoses

Oil film breaking down

Bending and flexing too much

Air bubbles in the fluid

You can do these things to stop early wear:

Check hoses and seals every day before work

Clean dirt from the hydraulic system

Change hoses that show any signs of wear

Use the right hydraulic fluid

Make sure hoses do not rub on sharp edges or each other

Tip: Always check tight spots where hoses bend or touch metal. These places wear out first.

If you do maintenance, you will stop sudden breakdowns. Clean fluid and daily checks help your hydraulic system last longer.

Hydraulic Pumps and Valves

Hydraulic pumps and valves move fluid and control pressure. These parts work under a lot of stress. If they break, your machine may stop or lose power. You need to know the signs of wear for these parts:

Jerky or shaky movements

Warnings on the dashboard

Leaks near the pump or valve

Banging or knocking sounds

High heat (over 180°F or 82°C)

Weak final drive motor

You may see leaks or hear strange sounds if pumps or valves have problems. These are important signs of wear. If the machine moves slowly or shakes, check the hydraulic system right away.

These things can make pumps and valves wear out:

Dirt or metal in the fluid

Air in the fluid

Using the machine all the time

Not enough oil

Dirty fluid can hurt hydraulic parts fast. Dirt and metal scratch the parts and make them work worse. You can do these things to stop early wear:

Change hydraulic fluid and filters on time

Check for leaks and fix them fast

Listen for new sounds when you use the machine

Watch fluid heat and pressure

Test the system if you see any signs of wear

Note: Clean fluid is the best way to protect your hydraulic system. Dirty oil causes most problems.

If you follow these tips, your excavator will last longer. You will also save money on repairs and lost time.

Common Hydraulic System Problems | Signs and Symptoms of Wear | Maintenance Tips to Prevent Premature Wear |

|---|---|---|

Hose leaks | Oil on ground, hissing | Daily checks, replace worn hoses |

Pump failure | Jerky movement, noise | Change fluid, monitor temperature |

Valve sticking | Slow or weak response | Clean fluid, check for contamination |

You should always watch the hydraulic system parts in your excavator. If you find signs of wear early, you can fix problems before they get worse. Use these tips to stop early wear and keep your machine working well.

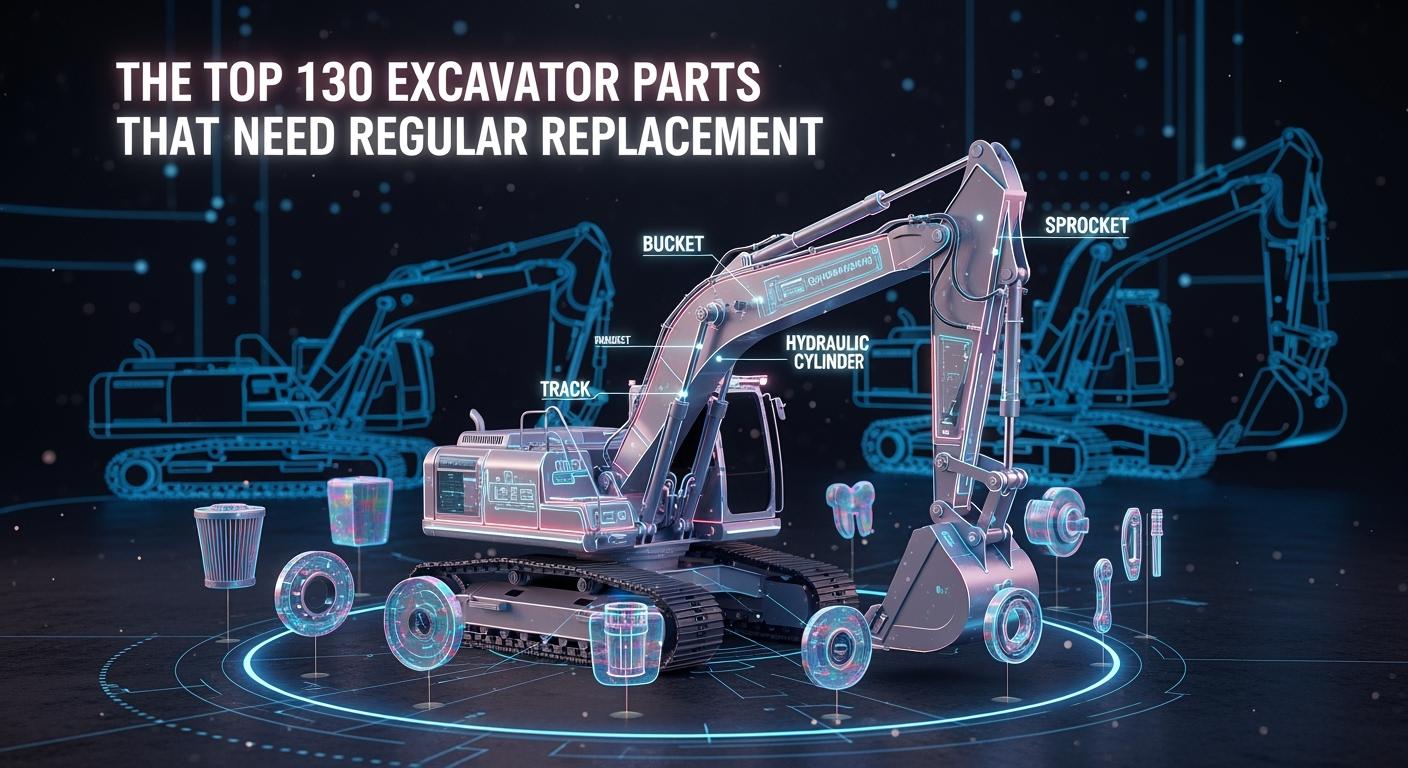

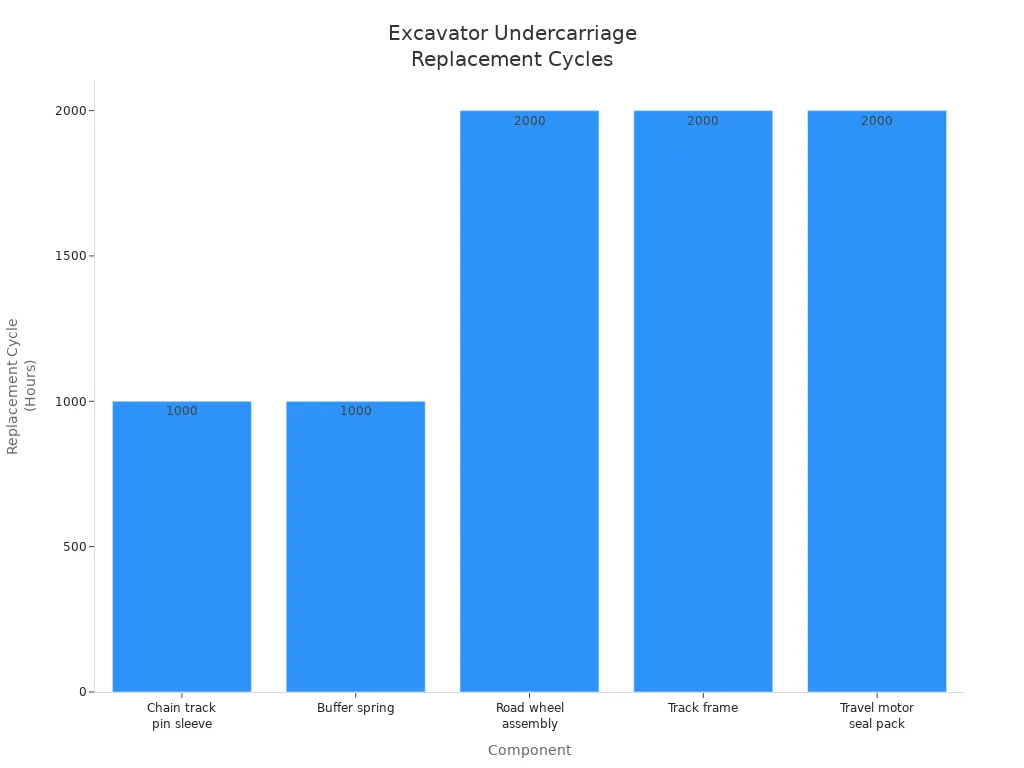

Undercarriage and Track Parts

The undercarriage supports your excavator and lets it move across different surfaces. You need to check undercarriage parts often because they face heavy loads and tough conditions every day. If you ignore these parts, your machine can break down or stop working. Good maintenance helps you avoid expensive repairs and keeps your excavator running smoothly.

Track Chains and Shoes

Track chains and shoes help your excavator move and grip the ground. These excavator undercarriage parts wear out faster when you work on rough or wet soil. You should check them often for cracks, loose pins, or missing bolts. If you see uneven wear or the chains look stretched, you need to replace them soon.

The replacement cycle for track chains is usually between 3,000 and 5,000 hours. Track shoes last about 2,000 to 3,000 hours. You can see the typical cycles in the table below:

Component | Replacement Cycle (Hours) |

|---|---|

Track Chains | 3,000 to 5,000 |

Track Shoes | 2,000 to 3,000 |

Many things can make track chains and shoes wear out faster:

Using wide track shoes increases wear and can damage the structure.

Wide shoes do not last longer. They can slip and cause more wear.

If you use very wide shoes on slopes or rocky ground, pins and bushings can loosen.

Wide shoes can also cause lubricant to leak out, which dries out the joints.

Poor alignment of the roller frame, idler, and sprocket causes uneven wear.

Abrasive soil, high moisture, heavy excavator weight, and fast movement speed all increase wear.

Tip: Choose the right shoe width for your job. Check alignment often to keep your undercarriage in good shape.

Regular maintenance helps you spot problems early. Clean mud and debris from the undercarriage after each use. Grease the pins and bushings to keep them moving smoothly. Replace worn track chains and shoes before they break.

Rollers and Idlers

Track rollers and idlers support the weight of your excavator and guide the tracks. These undercarriage parts roll along the track frame and keep the tracks tight. You need to check them for flat spots, cracks, or leaks. If you hear grinding or see oil leaking, the rollers or idlers may need replacement.

Track rollers usually last 3,000 to 5,000 hours. Idlers last about 4,000 to 6,000 hours. The table below shows the replacement cycles for these excavator undercarriage parts:

Component | Replacement Cycle (Hours) |

|---|---|

Track Rollers | 3,000 to 5,000 |

Idlers | 4,000 to 6,000 |

Soil type and moisture affect how long rollers and idlers last. Mud and clay can pack around these parts and stop them from working right. This increases track tension and puts more load on the rollers and idlers. Moist soil makes metal wear out faster. Hard, rocky ground also wears down the rollers and idlers quickly.

You can keep your track rollers and idlers in good shape by:

Cleaning mud and debris after each job.

Checking for leaks and adding oil if needed.

Watching for uneven wear or strange noises.

Keeping the track tension correct.

Note: If you see packed mud or clay, clean it out right away. This helps your undercarriage last longer.

Sprockets and Tensioners

Sprockets drive the tracks and help your excavator move. Tensioners keep the tracks tight. If these parts fail, your machine can stop moving or the tracks can fall off. You should check for worn out sprockets, broken teeth, or loose tensioners.

Here are some warning signs that sprockets and tensioners need replacement:

Warning Sign | Description |

|---|---|

Abnormal wear patterns | Shows misalignment or bad tension. |

Persistent track tension issues | Points to problems with the idler or recoil assembly. |

Unusual noises | Grinding or squealing means internal damage. |

Leaking seals | Needing to add grease often means a leak and a failing tensioner. |

Grinding noise | Shows a lack of lubrication and possible bearing damage. |

You should replace sprockets every 3,000 to 4,000 hours. Check tensioners if you have trouble keeping the tracks tight. Always listen for new noises and check for leaks.

Callout: If you see abnormal wear or hear grinding, stop and inspect your undercarriage right away.

Regular maintenance of these excavator undercarriage parts keeps your machine safe and working well. Clean, inspect, and replace parts as needed. This helps you avoid downtime and costly repairs.

Engine and Cooling System Parts

The engine is the heart of your excavator. You need to keep it in top shape to avoid breakdowns and costly repairs. Good maintenance of engine parts helps your machine run smoothly and last longer. You should check these important engine and cooling system parts often.

Turbochargers and Injectors

Turbochargers help your engine get more power. Injectors spray fuel into the engine. Both parts work under high pressure and heat. If you see black smoke, hear whistling, or notice a loss of power, you may have a problem with these engine parts. Dirty fuel or oil can damage injectors and turbochargers. You should change filters on time and use clean fuel. Regular maintenance keeps your engine strong and helps you avoid expensive repairs.

Radiators and Coolant Hoses

Radiators and coolant hoses keep your engine cool. If these parts fail, your engine can overheat. Overheating can cause severe engine damage and lead to high repair costs. You should check the radiator and coolant hoses for cracks or leaks. Clean the radiator core every day, especially in dusty places. Check coolant levels every week. Replace coolant every 2,000 hours or as your manufacturer suggests.

A broken cooling system can make your engine overheat.

Overheating can damage your engine and cost a lot to fix.

Always check the radiator and coolant levels.

Watch for cracks or leaks in the hoses.

Tip: Clean radiators and check coolant often to keep your engine safe.

Belts and Pulleys

Belts and pulleys help run the engine fan, alternator, and other parts. If a belt slips or breaks, your engine can stop working. The tensioner can wear out and cause the pulley to move out of line. If the belt does not run in the center, check the tensioner. Worn bearings or pulleys can make noise or feel rough. A bad idler pulley can make the belt slip off.

Check all bearings and pulleys for noise or roughness.

Make sure the belt runs straight on the pulley.

Replace worn belts and pulleys during regular maintenance.

Note: Good maintenance of belts and pulleys keeps your engine running without trouble.

You should always follow a maintenance plan for your excavator engine. This helps you spot problems early and keeps your machine working hard.

Commonly Replaced Excavator Filters and Electrical Parts

Fuel, Oil, and Hydraulic Filters

You need to change filters often. This keeps your excavator working well. Clean filters stop dirt from hurting the engine. They also protect the hydraulic system. Most makers say to change filters every 2,000 to 4,000 hours. If you work in tough places, change them every 2,000 hours. Oil changes, fuel filters, and belts need service at 500 hours. If you follow the plan, your excavator lasts longer. Bad fuel can cause problems. Water or dirt in fuel clogs filters fast. Filters wear out quicker if fuel is dirty. You might see rust or damage to the separator. Always use clean fuel. Good fuel protects your parts and helps the system work better.

Tip: Write down each filter change in your log book. This helps you remember and keeps you on track.

Batteries and Cables

Batteries and cables give power to your excavator. Check them often for rust, loose ends, or swelling. If you see white powder, clean it right away. Weak batteries make the engine hard to start. Old or broken cables stop power from getting to parts. You can help batteries last longer by keeping them clean and tight. Change batteries every 3 to 5 years. Look at cables every time you do maintenance. If you see cracks or fraying, change the cables to stop breakdowns.

Starter Motors and Alternators

Starter motors and alternators help your excavator start and run. Watch for these signs that you need new parts: Grinding or screeching when you start the engine. Trouble starting or the engine stops a lot. Lights that dim or flicker. Weak or dead battery. Warning lights on the dashboard. Gauges or sensors that do not work. If you hear whining or grinding from the alternator, there may be a problem inside. Regular checks help you find issues early. Change bad starter motors and alternators before they break.

Note: Early checks and quick fixes keep your excavator ready for work.

Attachments and Wear Parts

Attachments help you get more work done with your excavator. You use different attachments for digging, lifting, or breaking. These parts face heavy loads and tough ground every day. Good maintenance keeps your attachments strong and safe.

Buckets, Teeth, and Cutting Edges

Buckets, teeth, and cutting edges do most of the hard work. You need to check these attachments often for cracks, chips, or worn spots. If you see missing teeth or thin edges, replace them right away. Worn parts make your excavator attachments less effective and can slow down your job.

The material in bucket teeth and cutting edges changes how long they last. Carbon steel works well for many jobs, but it may not hold up in rocky ground. Boron steel lasts longer and handles tough digging. Chromium and nickel alloys resist rust, so they work well in wet or harsh places. Carbide-embedded edges give the best wear resistance when you dig in rock. Each material has its own strengths and weaknesses. Some materials get stronger as you use them, a process called work hardening. This helps them last longer under tough conditions.

Material Type | Wear Mechanism | Work Hardening Influence |

|---|---|---|

Martensitic Steels | Abrasion, Impact-Abrasion | Significant effect on wear resistance |

Commercial 500HB Steels | Surface and Subsurface Shear Bands | Clear differences in wear rates observed |

Tip: Choose the right material for your attachments based on your job site. This helps you save money and reduce downtime.

Quick Couplers and Pins

Quick couplers and pins let you switch excavator attachments fast. You need to keep these parts in good shape to stay safe and work quickly. Many things can cause quick coupler and pin wear:

Rushing or not paying attention when you attach tools.

Forgetting to lock the coupler.

Using worn or poorly maintained locking parts.

Overloading the coupler or bucket.

Any mix of these problems.

Improper installation or poor maintenance can also cause early failure. The table below shows some common issues:

Factor | Description |

|---|---|

Underestimating Torque | Not allowing for sudden loads can break the coupler or pins. |

Incorrect Service Factor | Using the wrong size coupler increases the risk of failure. |

Ignoring Alignment | Misaligned parts wear out faster and can break. |

Overlooking Maintenance | Skipping checks or cleaning leads to more breakdowns and downtime. |

You should check quick couplers and pins every day. Look for loose pins, worn locks, or signs of bending. Clean and grease these attachments as part of your regular maintenance. Replace any damaged parts before they fail.

Note: Good maintenance of your excavator attachments keeps your machine safe and ready for any job.

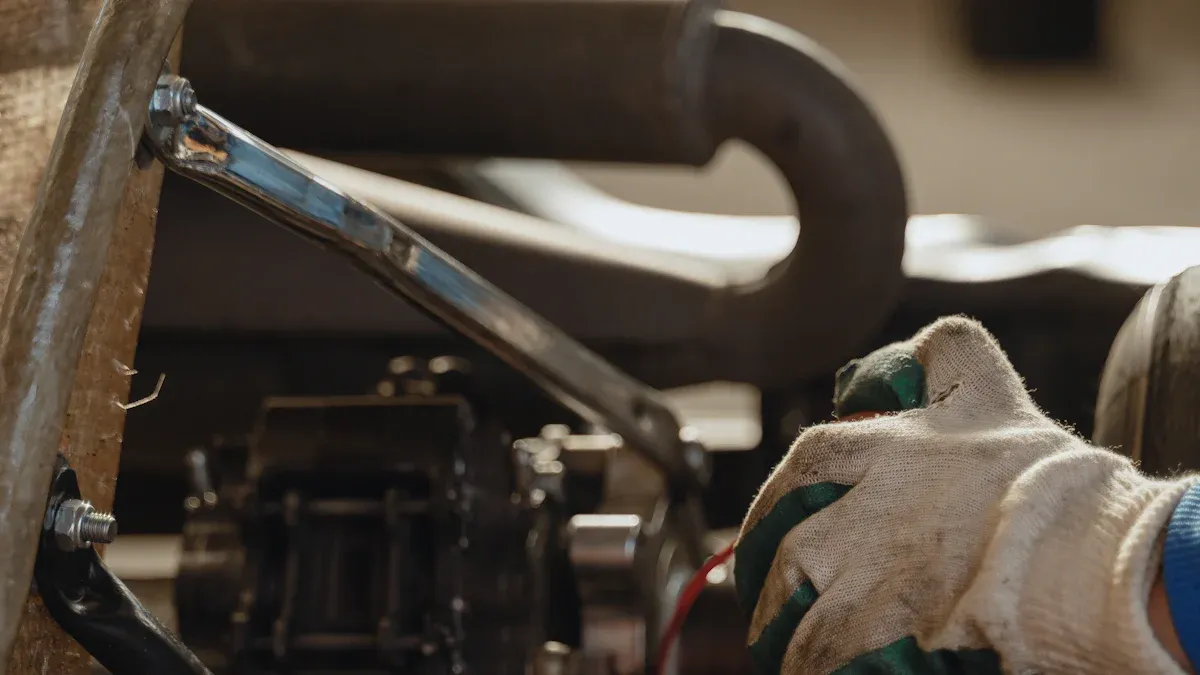

You save money and keep your excavator safe when you check and change important parts on time. Doing regular maintenance helps your machine work longer. It also means less time when your excavator is broken. Checking your machine often helps you find small problems early. Write down every time you do maintenance. This list helps you see problems and plan for repairs. If you have a big repair, ask an expert for help.

FAQ

How often should you check excavator parts for wear?

You should check key parts every day before you start work. Look for leaks, cracks, or loose bolts. Early checks help you find problems before they get worse.

What signs show that a hydraulic hose needs replacement?

Watch for leaks, bulges, cracks, or hissing sounds. If you see oil on the ground or the hose feels soft, replace it right away.

Why do you need to change filters so often?

Filters trap dirt and protect your engine and hydraulic system. Dirty filters block oil and fuel flow. You keep your machine running well when you change filters on time.

Can you use non-original parts for replacements?

You can use aftermarket parts, but always check quality. Poor parts may wear out faster or not fit right. Use trusted brands for important parts.