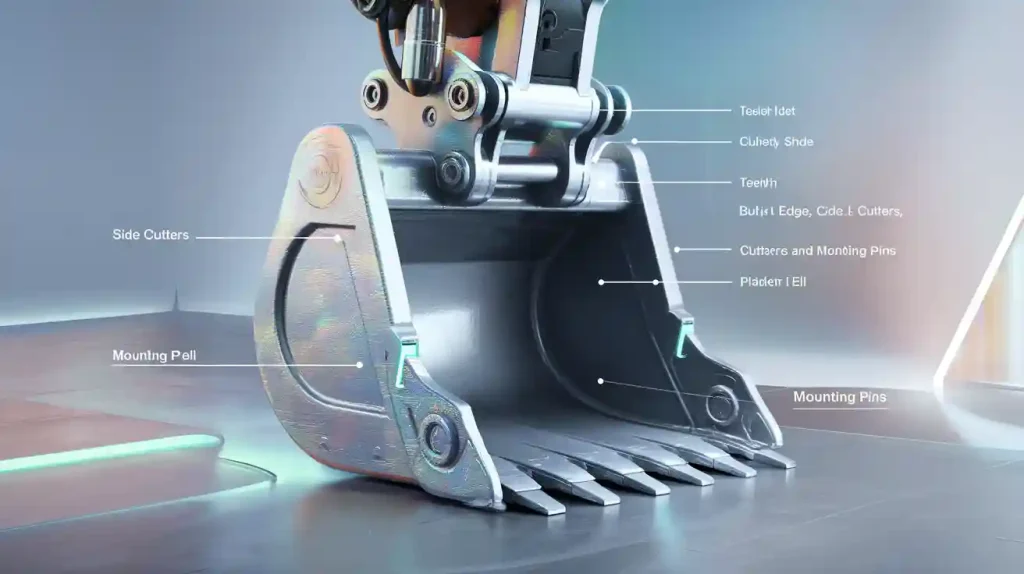

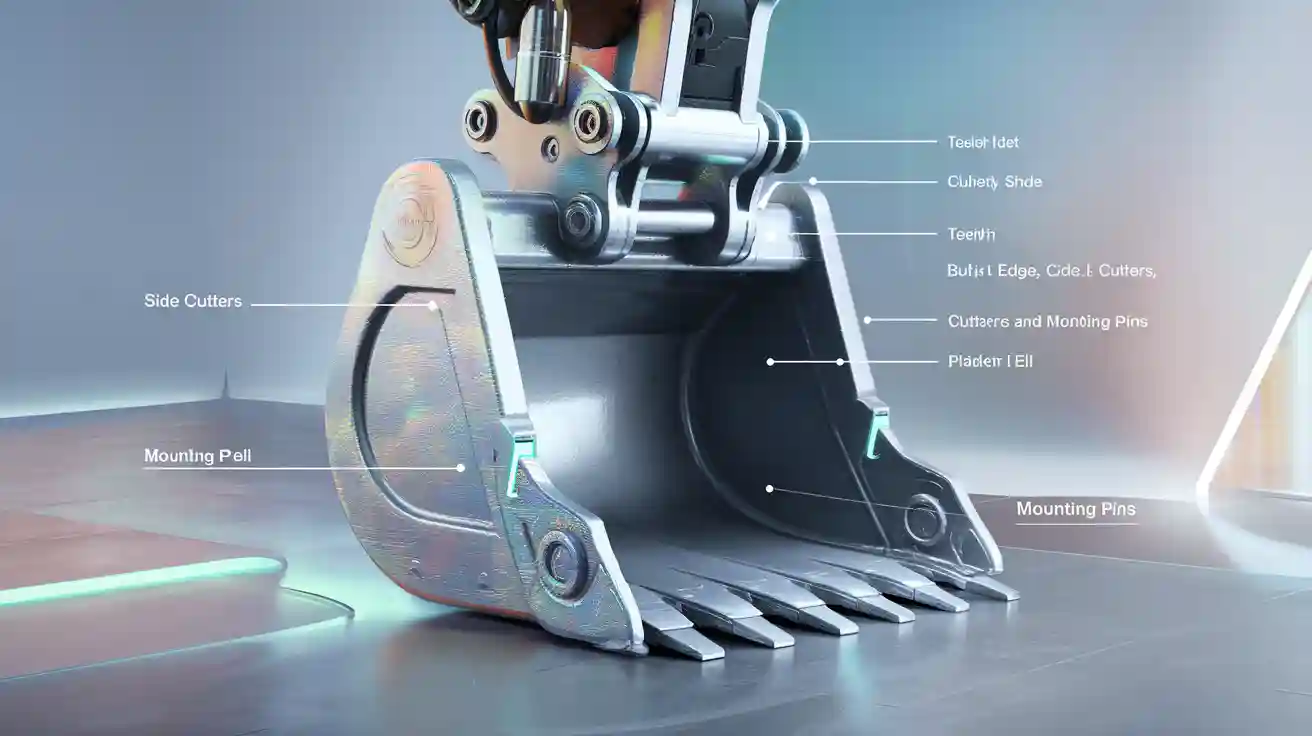

You will see many mini excavator bucket parts. These parts are important for how your machine works. The most common parts are the bucket shell, cutting edge, side cutters, and bucket teeth. Each part helps keep the excavator working well and easy to fix.

Part Type | Market Share | Units Sold (2023) |

|---|---|---|

Bucket | 32% | 140,000 |

Knowing about mini excavator bucket parts helps you make good choices for repairs. You can pick the right parts, stop the machine from breaking down, and help it last longer. Good choices about bucket parts make your work faster and save money on repairs. Checking how the bucket works often helps you get the most out of your machine.

Key Takeaways

Learn about the main parts of a mini excavator bucket. These parts include the bucket shell, cutting edge, side cutters, and bucket teeth. Knowing these helps you pick the right repairs.

Check and change worn parts like bucket teeth often. Doing this keeps your excavator working well. It stops breakdowns and makes your machine last longer.

Pick the best bucket design and attachments for your job. Using the right tools helps you work faster. It also keeps your machine from wearing out quickly.

Always check your excavator before you use it. Look for cracks, loose bolts, or other problems. This keeps you safe while working.

Buy good parts from trusted suppliers like YNF Machinery. Good parts help your machine work better and last longer. This saves you money on fixing it.

Mini Excavator Bucket Parts Overview

Mini excavator bucket parts are very important. They help your excavator work every day. You should know the main parts to keep your machine working well. Here is a simple look at the main parts you will see on most buckets:

Bucket Shell

The bucket shell is the main part of the bucket. It holds dirt, rocks, and trash. Most bucket shells are made from strong metals. These include carbon steel, manganese steel, and special alloy steels. These metals help the bucket last longer and not break easily.

Material Type | Durability Rating (Brinell Hardness) |

|---|---|

Carbon steel (ASTM A36) | N/A |

Manganese steel (Hadfield) | N/A |

Wear-resistant alloy steels | 400 – 500 HB |

High-tensile strength steels | N/A |

Cutting Edge

The cutting edge is at the front of the bucket. It helps cut into dirt and other things. Different cutting edges help you dig, sort, or move stuff better. For example, a clamshell bucket fits in small spaces. A rock bucket carries heavy things without spilling. The cutting edge wears out the fastest.

Clamshell Bucket: Good for small spaces.

Skeleton Bucket: Helps sort trash.

Trenching Bucket: Digs deep holes.

V Bucket: Holds more dirt.

Tilting Bucket: Moves at angles.

Ripper Bucket: Breaks hard ground.

Grapple Bucket: Picks up trash.

Frost Bucket: Digs frozen dirt.

Cleanout Bucket: Cleans up fast.

Rock Bucket: Carries rocks.

Side Cutters

Side cutters go on the sides of the bucket. They protect the bucket shell and help cut tough ground. They are made from strong steel. This makes them last longer. Side cutters help make trenches wider and digging easier. They are important for making the bucket strong.

Material Type | Contribution to Longevity |

|---|---|

High-strength steel | Makes the bucket strong for digging and loading. |

Abrasion-resistant (AR) steel | Helps the bucket last longer when digging rough stuff. |

Hardness Requirements | Makes sure the steel is hard enough to last. |

Bucket Teeth

Bucket teeth are sharp points at the front. They help break up dirt, rocks, and frozen ground. Bucket teeth wear out fast because they hit hard things. You need to change them often to keep working well. There are many types of bucket teeth. Some are for normal jobs, some for rocks, and some for heavy work. Picking the right teeth helps you dig faster and fix less.

Type of Bucket Teeth | Description | Wear Resistance Characteristics |

|---|---|---|

Standard Bucket Teeth | Used for normal digging. | Good for most jobs. |

Rock Bucket Teeth | Thicker and harder for rocks or frozen dirt. | Very strong against wear. |

Heavy Duty Bucket Teeth | Made for tough jobs like breaking big things. | Great at handling hard hits. |

Twin or Double-Acting Teeth | Has two points and sharpens itself. | Lasts longer and needs less changing. |

Through-Hardened Alloy Steel | Used for moving dirt. | Good at handling hits and wear. |

Heat-Treated Alloy Steel | Harder for tough jobs. | Wears down slower. |

Premium Chromium Carbides | Super hard for the hardest jobs. | Lasts the longest. |

Tip: Check all mini excavator bucket parts often. Change old parts to keep your excavator safe and working well.

Functions Explained

Knowing how each mini excavator bucket part works helps you use your machine better. Here are the main jobs of each part. This helps you know what to check when you use or fix your excavator.

Material Containment

The bucket shell holds and moves dirt, rocks, and trash. It needs to be strong so nothing falls out when you dig or lift. The bucket’s shape helps keep things inside and stops messes.

The clamshell bucket lets you control what you pick up. It helps stop dirt and rocks from spilling out.

Its up-and-down movement helps you grab things carefully. This is good for places like rivers and wetlands.

The clamshell bucket keeps water clean by not stirring up too much dirt.

Design Feature | Benefit |

|---|---|

Abrasion-resistant bottom | Makes the bucket last longer and not wear out fast. |

Wide, shallow shape | Helps you scoop up dirt evenly and keeps things from spilling. |

DeltaWing Lip Saver teeth | Protects the front edge and lets you carry more. |

Spade penetration enhancement | Makes digging into hard dirt easier and faster. |

The right bucket design keeps dirt inside and stops messes. This helps you work faster and keeps your work area clean.

Ground Penetration

Your excavator needs to dig into many types of ground. The bucket teeth and cutting edge help with this job. Their shapes and sizes match the dirt and the work you need to do.

Bucket teeth break into the ground. Their shapes fit your machine and the dirt.

You can pick different shapes and sizes for digging or making trenches. This helps you dig better in different soils.

The cutting edge loosens dirt. This makes it easier for the bucket to go into the ground.

Pick teeth that fit your machine and the dirt. This helps you work faster.

Make sure the teeth size matches your excavator’s power. Bigger machines need bigger teeth.

Using the wrong teeth makes digging harder. Always use the right teeth for the job.

When you use the right teeth and cutting edge, your excavator digs faster and easier. This saves time and helps your machine last longer.

Edge Protection

Edge protection keeps your bucket strong and working longer. Side cutters and wear plates protect the bucket’s weak spots.

Side cutters make the bucket sides and edges stronger. They are made from tough steel for hard jobs.

Things like double bottoms and replaceable knives add more protection.

Buckets for tough jobs use thicker metal to last longer.

Tapered sides and extra straps help stop wear.

A thick cutting edge with a wear plate helps the bucket last longer.

Edge damage can happen from rubbing, hitting things, bad welding, or weak metal. You can stop these problems by:

Getting buckets with extra protection.

Using a blade that bolts on to cover the edge.

Picking the right bucket for each job.

Checking and cleaning your bucket often.

Making weak spots stronger and using good materials.

Stress happens at welds, corners, tooth holders, and side cutters. Protecting these places keeps your bucket working well.

Wear Resistance

Wear resistance means your bucket lasts longer and needs fewer fixes. The bucket’s materials and design help with this.

Material/Feature | Description |

|---|---|

High-strength steel | Makes the bucket strong and able to carry heavy things. |

Wear-resistant alloys | Used in important spots to stop wear. These have manganese, chromium, and nickel. |

Reinforced edges | Extra hard steel or special metals protect the front edge and weak spots. |

If your bucket resists wear, you spend less on repairs. Following the maker’s care tips helps your excavator last longer. Taking care of your bucket keeps your machine running well and saves money. Using your excavator the right way puts less stress on the bucket and other parts. This means fewer breakdowns and lower costs.

Tip: Check your bucket for wear often. Change old parts early to keep your excavator working well.

Additional Mini Excavator Parts

Mini excavator parts do more than dig holes. Some extra bucket parts make your machine last longer. They also help keep you safe and let you use more tools. These features help your excavator work better every day. You can get good mini excavator bucket parts from YNF Machinery. Their strong tracks and undercarriage help your machine stay steady.

Adapters

Adapters let you connect your bucket to other tools. You can switch tools fast with adapters. This keeps your excavator working all the time. Each adapter type has special things that help it fit and stay safe.

Type of Adapter | Function | Compatibility Impact |

|---|---|---|

Bolt-on adapters | Connect tools to the excavator jib or hookup. | Allows for easy attachment of various tools. |

Pin-on adapters | Serve as a direct connection point for attachments. | Ensures secure fitting of attachments. |

Reversible adapters | Enable the use of tools in multiple orientations. | Increases versatility of attachment options. |

Suspension links | Provide flexibility in tool positioning. | Enhances compatibility with different tool designs. |

Adapters help you use many attachments. You can change tools quickly and keep your excavator safe.

Wear Plates

Wear plates protect your bucket from getting hurt. You need them when you dig rocks or rough stuff. These parts take the hits and stop wear. The plates act like a shield for your bucket. This helps your bucket last longer and need fewer fixes. You save money and keep your excavator working with these safety features.

Pins and Bushings

Pins and bushings help your bucket move smoothly. You find them where the bucket joins the arm and boom. They help the bucket move and lower rubbing. Here are their main jobs:

Pins are metal rods that let the bucket turn.

Bushings go around pins and lower rubbing between parts.

Bushings guide and protect the bucket pin or shaft.

Good bushings help pins last longer and lower repair costs.

Pins and bushings take hits, keeping your excavator safe.

Bushings stop holes from wearing out or breaking.

These parts help your tracks and undercarriage stay steady.

You should check pins and bushings often. Change old parts to keep your tracks and tools working well.

Lifting Eye

The lifting eye adds safety and lets you lift things. You use it to hook ropes or shackles for heavy loads. This part lets your machine work like a crane. Here are some key things about it:

The lifting eye gives you a safe spot to lift stuff.

Certified lifting eyes help you lift things the right way.

You use a certified shackle to stop unsafe lifting.

These features help you move things safely and fast.

Always use the lifting eye with certified tools. This keeps your excavator safe and protects your tracks and other parts.

Tip: Pick mini excavator parts from YNF Machinery for strong safety, good tracks, and tough tools. Check and change parts often to keep your excavator working and your undercarriage steady.

Hydraulic Connection and Attachments

Hydraulic Linkage

You use a hydraulic linkage to connect the bucket. This linkage lets you move the bucket with controls. The hydraulic system has a pump that moves fluid. The main control valve sends fluid to different places. Hydraulic cylinders help the bucket go up, down, or tilt. Look at the table to see what each part does:

Component | Function |

|---|---|

Hydraulic Pump | Moves fluid from the tank to the system; piston pumps work better than gear pumps. |

Main Control Valve | Sends fluid where it needs to go in the hydraulic circuit. |

Hydraulic Cylinders | Make the bucket move by pushing or pulling. |

The hydraulic system lets you control the bucket fast and smooth. If you need to stop quickly, use the emergency stop button. This button turns off the pump and stops everything. Always know where the emergency stop button is before you start.

Mini Excavator Attachments

Mini excavator attachments help your machine do more jobs. You can change attachments fast with the hydraulic system. The system lets you use tools like augers, grapples, and hammers. Each tool connects to the bucket and uses hydraulic power. Operator controls help you use each tool easily.

Here are some common mini excavator attachments and how they work:

Augers drill deep holes with hydraulic power.

Grapple buckets pick up heavy stuff and help control loads.

Trenching tools dig straight trenches using hydraulic cylinders.

Thumb attachments grab and move odd shapes.

Hammers break hard things with hydraulic force.

Mulchers cut and mulch plants using hydraulic power.

Rakes clear trash and get soil ready.

Rippers break tough ground.

Couplers let you switch tools quickly.

Buckets carry dirt, rocks, and more.

The hydraulic system lets you change tools quickly. This helps you finish jobs faster and safer. You also get better control and less damage to your machine. If you need to stop in an emergency, the emergency stop button shuts off the pump and all tools right away.

Tip: Always check your hydraulic system and controls before using attachments. This keeps you safe and your machine working well.

When you know about each bucket part, you make your mini excavator safer and work better. All the parts work together to help your machine need less fixing and keep running. You should always check your machine to stay safe. These checks help you find problems early and stop big repairs. Look for cracks or rust every day to keep your machine safe. Checking your machine often protects your money and keeps everyone safe. Always remember to put safety first. If you check and fix your machine often, you can stop it from breaking down. This keeps your team safe and your machine ready to use. Safety depends on how well you take care of your machine and check it often. Never skip any safety steps. Checking and fixing your machine often is the best way to stay safe.

Always make safety the most important thing.

Check your machine often to stay safe.

Fixing your machine helps keep it safe.

Never forget about safety when you fix things.

Plan to check your machine often for safety.

Think about safety every time you fix your machine.

Checking your machine often helps keep it safe.

Let safety lead you when you fix things.

Checking your machine often makes it safer.

Fixing your machine and being safe go together.

Safety gets better when you check your machine a lot.

Fixing your machine keeps it safe every day.

Checking your machine often keeps it safe.

Safety begins with taking care of your machine.

Remember: Safety, fixing your machine, and checking it often help your mini excavator stay strong and work well.

FAQ

What is the most important mini excavator bucket part to check for wear?

You should check the bucket teeth first. These wear out quickly because they dig into hard ground. Worn teeth make digging harder and can damage other parts.

How often should you inspect mini excavator bucket parts?

Check your bucket parts before each use. Look for cracks, loose bolts, or worn edges. Regular checks help you find problems early and keep your machine safe.

Can you replace bucket teeth by yourself?

Yes, you can replace bucket teeth with basic tools. Always follow the instructions in your manual. Wear gloves and use the right size teeth for your bucket.

Why do you need side cutters on your bucket?

Side cutters protect the bucket’s sides from damage. They help you dig wider trenches and make the bucket last longer. Strong side cutters also keep the bucket shell safe.

Where can you buy quality mini excavator bucket parts?

You can buy strong and reliable mini excavator bucket parts from YNF Machinery. They offer tough parts that help your machine work better and last longer.