Understanding excavator parts and functions is essential for anyone new to operating these powerful machines. An excavator consists of several key components, each with a specific role. The engine powers the machine, while the boom and arm extend its reach. The bucket digs and scoops materials. The cab houses the operator, and the undercarriage provides stability. Knowing these parts helps you operate the excavator efficiently and safely. This knowledge forms the foundation for mastering excavator operations, ensuring you can handle various tasks with confidence.

The Engine (one of the most important parts of an excavator)

The engine serves as the heart of an excavator, providing the necessary power to drive its hydraulic and mechanical functions. When you operate an excavator, the engine’s performance directly influences how effectively you can complete tasks.

Function of the Engine

The engine’s primary role is to generate power. This power is crucial for operating the hydraulic system, which controls the movement of the boom, arm, and bucket. Without a robust engine, these components would lack the force needed to perform efficiently. For instance, Caterpillar engines are known for their reliability and fuel efficiency, ensuring that the excavator can tackle demanding tasks with ease.

Importance of the Engine

Regular maintenance, such as replacing filters and using high-quality fluids like engine oil and coolant, is essential for keeping the engine in top condition. This attention to detail helps prolong the life of the excavator and enhances its efficiency.

Understanding the engine’s function and importance is a fundamental step in mastering excavator parts and functions. By appreciating the engine’s role, you can ensure that your excavator remains a reliable and powerful tool for any construction task.

The Boom

The boom is a vital component of an excavator, playing a crucial role in its overall functionality. As you familiarize yourself with excavator parts and functions, understanding the boom’s purpose and structure will enhance your ability to operate the machine effectively.

Function of the Boom

The boom significantly contributes to the excavator’s reach and height. It allows you to extend the machine’s capabilities, enabling it to perform tasks that require lifting and moving materials over considerable distances. This extension is particularly beneficial when working on projects that demand a wide range of motion or when accessing hard-to-reach areas.

“Super Long Front excavators stretch the digging reach of regular excavators by as much as double,” notes Matthew Hendry, a product consultant specializing in hydraulic excavators and ADTs at Deere & Company.

The boom’s ability to lift and move materials efficiently makes it indispensable in construction and earthmoving tasks. By mastering the boom’s operation, you can ensure that your excavator performs optimally, handling heavy loads with precision and ease.

Subcomponents of the Boom

Understanding the subcomponents of the boom is essential for maintaining its functionality and longevity. The boom cylinders play a pivotal role in its operation. These hydraulic cylinders provide the necessary force to lift and lower the boom, allowing you to control the excavator’s reach and height with precision.

“Failing to lower the digging forces will cause rapid damage to pins and bushings at the boom/arm connection and possibly cause other structural damage,” explains Matthew Hendry. This highlights the importance of proper maintenance and operation to prevent costly repairs.

The connection to the arm is another critical aspect of the boom’s design. This connection ensures that the boom and arm work seamlessly together, providing the stability and strength needed to handle various tasks. Proper alignment and maintenance of this connection are vital to prevent wear and tear, ensuring the excavator remains a reliable tool on the job site.

By understanding the boom’s function and its subcomponents, you can enhance your knowledge of excavator parts and functions. This understanding will empower you to operate the machine more effectively, maximizing its potential and ensuring successful project outcomes.

The Arm

The arm of an excavator plays a pivotal role in its operation, providing the necessary reach and flexibility for various tasks. As you delve deeper into understanding excavator parts and functions, recognizing the arm’s capabilities will enhance your operational skills.

Function of the Arm

The arm extends the excavator’s reach, allowing you to access areas that would otherwise be out of range. This extension is crucial for tasks that require digging or lifting materials from a distance. For instance, Bobcat Compact Excavators offer an extendable-arm option that can be hydraulically extended up to 30 inches, providing greater reach and versatility. This feature is particularly beneficial when working in confined spaces or on projects that demand precision.

The arm also aids in digging and lifting, making it an indispensable component of the excavator. Its design allows for precise control over digging depths and angles, ensuring that you can perform tasks efficiently and accurately. Whether you’re excavating a trench or lifting heavy materials, the arm’s functionality is essential for achieving optimal results.

Subcomponents of the Arm

Understanding the subcomponents of the arm is vital for maintaining its performance and durability. The arm cylinders are key elements that facilitate its movement. These hydraulic cylinders provide the force needed to extend and retract the arm, allowing you to maneuver the excavator with precision. Regular maintenance of these cylinders ensures smooth operation and prevents potential breakdowns.

The connection to the bucket is another critical aspect of the arm’s design. This connection allows for seamless integration between the arm and the bucket, enabling efficient digging and scooping of materials. Various bucket types, such as general-purpose or heavy-duty options, can be attached to suit specific job requirements. Ensuring a secure and well-maintained connection is crucial for maximizing the excavator’s performance and versatility.

By mastering the arm’s function and its subcomponents, you can enhance your understanding of excavator parts and functions. This knowledge empowers you to operate the machine more effectively, ensuring successful outcomes on any construction or earthmoving project.

The Bucket

The bucket stands as one of the most crucial excavator parts and functions. It serves as the primary tool for digging and scooping, making it indispensable in construction and earthmoving tasks. Understanding the bucket’s role and its various types will enhance your ability to choose the right tool for the job.

Function of the Bucket

The bucket’s primary function is to dig and scoop materials. It allows you to move soil, gravel, and other materials efficiently. Different types of buckets cater to specific tasks, ensuring that you can handle a variety of projects with ease.

Grading Buckets: Ideal for leveling and smoothing surfaces. They have a wide, flat edge that helps in creating even surfaces.

V Buckets: Designed for trenching and digging narrow trenches. Their V-shaped design allows for precise cuts.

Utility Buckets: Versatile and suitable for general-purpose tasks. They can handle a range of materials and are often used in everyday operations.

Raking Buckets: Used for clearing debris and separating materials. They have tines that allow for effective raking.

Trenching Buckets: Perfect for digging trenches. They have a narrow design that makes them suitable for creating deep and narrow trenches.

Digging Buckets: Commonly used for heavy-duty digging tasks. They are robust and can handle tough materials.

“Choosing the right bucket type can significantly impact the efficiency of your project,” says John Doe, a construction equipment expert.

Subcomponents of the Bucket

Understanding the subcomponents of the bucket is essential for maximizing its performance. The teeth and quick couplers play vital roles in its functionality.

Teeth and Their Role in Digging

The teeth on a bucket are crucial for effective digging. They break through tough materials, allowing the bucket to scoop efficiently. Regular inspection and maintenance of the teeth ensure optimal performance and prevent wear and tear.

Quick Couplers for Easy Attachment Changes

Quick couplers facilitate easy attachment changes, enhancing the excavator’s versatility. They allow you to switch between different bucket types quickly, saving time and increasing productivity on the job site. Ensuring that the quick couplers are in good condition is essential for seamless operation.

By mastering the bucket’s function and its subcomponents, you can improve your understanding of excavator parts catalog. This knowledge empowers you to select the right tools for your projects, ensuring successful outcomes and efficient operations.

The Cab

The cab of an excavator serves as the operator’s control center. It is where you manage all the machine’s functions and ensure that operations run smoothly. Understanding the cab’s features and components is crucial for efficient and safe excavator use.

Function of the Cab

Operator’s Control Center

The cab acts as the command hub for the excavator. From here, you control every aspect of the machine’s operation. The layout is designed to provide easy access to all controls, allowing you to perform tasks with precision. You can adjust the excavator’s movements, monitor its performance, and make necessary adjustments to optimize efficiency.

Features for Comfort and Safety

Comfort and safety are paramount in the design of modern excavator cabs. Komatsu Crawler Excavators offer a new-generation cab that prioritizes these aspects. The cab includes UV-protective rear window tint and customizable design options to enhance your comfort during long hours of operation. Safety features such as the Safe SpaceCab™ design, tool-less mirror, and visible handrails ensure that you can work confidently and securely.

Subcomponents of the Cab

Controls and Displays

The cab houses various controls and displays that are essential for operating the excavator. These include joysticks, pedals, and digital screens that provide real-time data on the machine’s status. You can easily monitor fuel levels, engine performance, and hydraulic pressure, ensuring that the excavator functions optimally. The intuitive layout of these controls allows for quick adjustments, enhancing your ability to respond to changing job site conditions.

Visibility and Ergonomic Design

Visibility is a critical factor in the cab’s design. The Komatsu cab features enhanced visibility, allowing you to have a clear view of the work area. This is crucial for precise operations and avoiding obstacles. The ergonomic design of the cab ensures that you can operate the machine comfortably, reducing fatigue and increasing productivity. Features like adjustable seats and strategically placed controls contribute to a user-friendly experience.

By understanding the cab’s function and subcomponents, you can improve your operational skills and ensure safe and efficient excavator use. This knowledge empowers you to make the most of the excavator’s capabilities, leading to successful project outcomes.

The Undercarriage

The undercarriage of an excavator plays a vital role in its overall performance. It provides the necessary stability and mobility, allowing you to navigate various terrains with ease.

Function of the Undercarriage

Provides Stability and Mobility

The undercarriage ensures that your excavator remains stable during operation. This stability is crucial when lifting heavy loads or working on uneven surfaces. The design of the undercarriage allows the machine to maintain balance, preventing tipping and ensuring safe operation. Mobility is another key function. The undercarriage enables the excavator to move smoothly across different types of ground, from soft soil to rocky terrain.

Tracks vs. Wheels for Different Terrains

When choosing between tracks and wheels, consider the specific needs of your project. Track excavators have a larger footprint and sit lower to the ground, providing extra stability and higher load capacity. They are ideal for high-intensity production digging and offer better traction on slopes. Tracks allow the excavator to dig more deeply and handle challenging terrains effectively.

On the other hand, wheel excavators are faster and more pavement-friendly. They are easier to maintain and more maneuverable in urban areas. Wheel excavators can negotiate paved surfaces without causing disturbance, making them suitable for projects in city environments. They also have lower long-term operating costs, which can be a significant advantage for certain applications.

Subcomponents of the Undercarriage

Tracks and Their Maintenance

Tracks are a critical component of the undercarriage. They provide the traction needed for the excavator to move efficiently. Regular maintenance of the tracks is essential to ensure optimal performance. Inspect the tracks for wear and tear, and replace them as needed to prevent breakdowns. Proper tensioning of the tracks is also important to avoid slippage and ensure smooth operation.

Drive Motors and Their Role

Drive motors power the movement of the tracks or wheels. They play a crucial role in the excavator’s mobility, allowing you to control its speed and direction. Maintaining the drive motors is vital for ensuring that the excavator operates efficiently. Regular checks and servicing of the drive motors help prevent mechanical issues and extend the lifespan of the machine.

By understanding the function and subcomponents of the undercarriage, you can enhance your knowledge of excavator parts and functions. This understanding empowers you to choose the right equipment for your projects and maintain it effectively, ensuring successful outcomes and efficient operations.

The Hydraulic System

The hydraulic system is a powerhouse within an excavator, driving the movement of critical components like the boom, arm, and bucket. Understanding this system is essential for mastering excavator parts and functions.

Function of the Hydraulic System

Powers the Movement of the Boom, Arm, and Bucket

The hydraulic system provides the force needed to move the boom, arm, and bucket. This system uses hydraulic fluid to transmit power, allowing you to control these parts with precision. When you operate the excavator, the hydraulic system ensures that each movement is smooth and efficient. This precision is crucial for tasks that require careful handling of materials or intricate digging operations.

Importance in Overall Excavator Operation

The hydraulic system plays a vital role in the overall operation of the excavator. It enhances the machine’s efficiency and power, making it capable of handling heavy-duty tasks. Without a well-functioning hydraulic system, the excavator would struggle to perform its essential functions. Regular maintenance of this system is crucial to ensure that it operates at peak performance. By keeping the hydraulic components in good condition, you can prevent costly breakdowns and extend the life of your excavator.

Subcomponents of the Hydraulic System

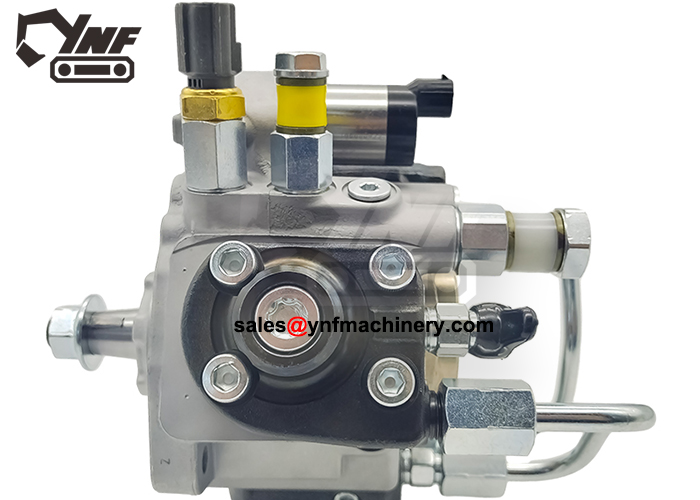

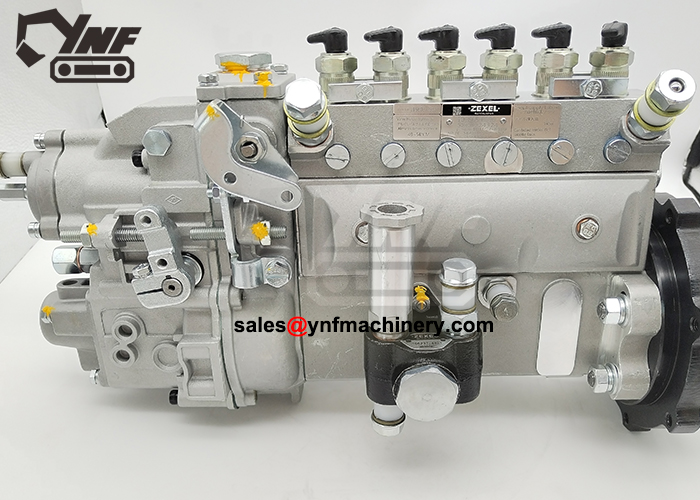

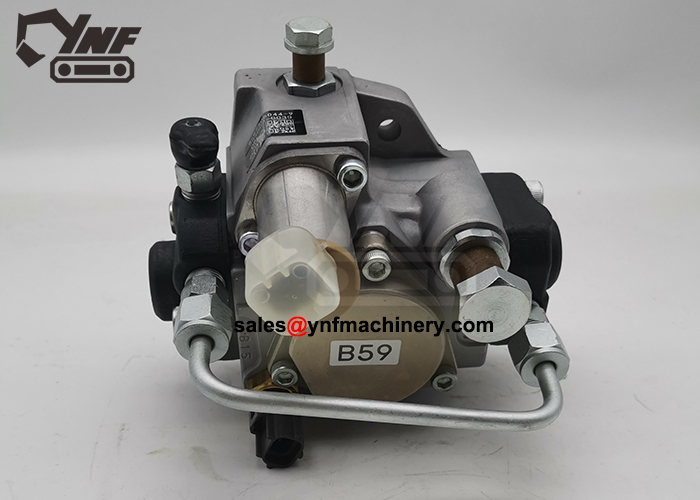

Hydraulic Pumps and Their Function

Hydraulic pumps are the heart of the hydraulic system. They convert mechanical energy into hydraulic energy, powering the movement of the excavator’s parts. These pumps are essential for maintaining the flow of hydraulic fluid, ensuring that the system operates smoothly. Regular inspection and maintenance of the pumps are necessary to prevent leaks and maintain optimal performance.

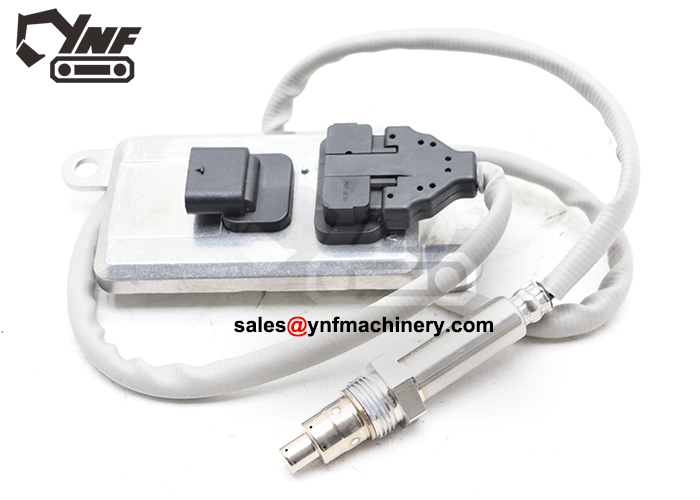

Hoses and Valves for Fluid Control

Hoses and valves play a critical role in controlling the flow of hydraulic fluid. They ensure that the fluid reaches the right components at the right time, allowing you to operate the excavator with precision. Regular checks for wear and tear on hoses and valves are important to prevent leaks and maintain the system’s integrity. By understanding the function of these subcomponents, you can ensure that the hydraulic system remains reliable and efficient.

Mastering the hydraulic system is a key step in understanding excavator parts and functions. This knowledge empowers you to operate the machine effectively, ensuring successful outcomes on any construction project.

Understanding excavator parts and functions is crucial for effective operation. Key components like the engine, boom, arm, bucket, cab, undercarriage, and hydraulic system each play a vital role in the machine’s performance. To remember these parts, consider creating a visual diagram or using mnemonic devices. Exploring more about excavators will deepen your knowledge and enhance your skills. As you learn, you’ll appreciate how these specialized components contribute to the machine’s efficiency and reliability in construction and industrial applications. Keep exploring and mastering these essential elements to become proficient in excavator operations.