You help your Komatsu excavator work well by checking it often, including inspecting the komatsu excavator wear parts. You change filters and look at lubrication points. If you follow Komatsu’s maintenance plan, you stop parts from wearing out too soon, including those crucial wear parts. This can make your machine last much longer. Doing things in order lowers the chance of sudden problems. Taking care of your excavator early saves money and ensures that your excavator is ready to work.

Key Takeaways

Doing regular maintenance checks helps you find problems early. This keeps your Komatsu excavator working well and makes it last longer.

Always use real Komatsu parts. They fit better and lower the chance of damage than fake parts.

Follow the suggested times for checking and changing parts. This stops expensive repairs and keeps your machine from breaking down.

Write down all the work you do for maintenance. Good records help you plan fixes and stop surprise problems.

Check your excavator every day before you use it. Simple checks can stop big problems and keep your machine safe.

Maintenance Importance

Equipment Longevity

You want your Komatsu excavator to last a long time. Doing regular maintenance helps you find problems early. When you check your parts often, you can fix small issues fast. This stops bigger problems from happening. Your machine will run better and last longer. Industry studies show these things:

Regular checks help you spot problems early. You can fix them quickly and keep your machine working well.

Following the service schedule keeps your engine strong. It also stops big repairs from costing a lot.

Using real Komatsu excavator wear parts makes sure they fit right. This lowers the chance of damage from fake parts.

Cost and Downtime

If you skip maintenance, you can have big problems. Not checking or using cheap parts is risky. You might face:

Sudden breakdowns

Poor performance

Higher repair bills

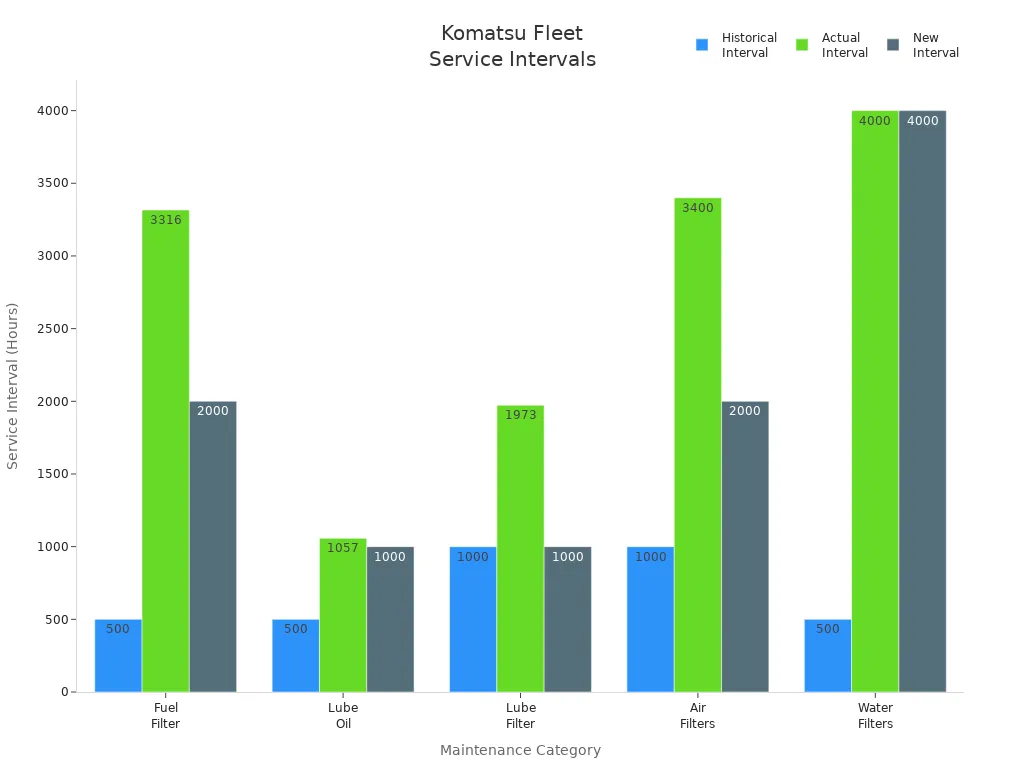

Look at this chart. It shows how doing checks early made service times better and cut down on hours spent fixing things:

Companies that do regular checks save money by:

Stopping downtime

Making machines work better

Avoiding expensive repairs

Tracking maintenance with tools

Getting the most from their machines

“Now that they find problems early, they fix them before they get worse and cost more.”

Downtime costs can grow fast. Using real parts and checking often means fewer breakdowns and lower costs later.

Safety Benefits

You keep your team and job site safe when your excavator works well. Regular checks lower the chance of accidents from bad parts. If you skip maintenance, you may have more repairs and safety problems. One time, using bad parts caused a big breakdown and safety issues. Other companies who did checks finished jobs on time and had no delays. Keeping your equipment safe and working should always come first.

Komatsu Excavator Wear Parts Inspection

To keep your Komatsu excavator working well, you must check it often. Finding wear early helps stop bigger problems. If you look after your machine, it will last longer. This also saves you money.

Visual Checks

Start each inspection by looking at your machine. Here are some steps to follow so you do not miss anything:

Look at the outside of your Komatsu excavator. Check the bucket for cracks or other damage. Look at the teeth for signs of wear.

Take out any big debris from the bucket. This keeps your parts clean and working right.

Make sure all bolts are tight and not missing. Check that every greasing point has enough grease.

Look at the arm and boom. Check under the machine for leaks.

Look around the engine for debris, leaks, or damage.

Check all hydraulic lines for leaks.

Look at the fluids and filters. Make sure oil is not leaking. Clean or change filters if needed.

Tip: Always use the Komatsu manual for when to check and how to do it. This helps you keep your checks on schedule.

Oil and Filter Checks

Checking oil and filters is very important. Clean oil and new filters protect your Komatsu excavator wear parts. You should:

Change oil and filters every 250 hours.

Change engine oil every 250 to 500 hours. This depends on how hard and where you use your machine.

Doing these checks keeps your parts in good shape. Dirty oil or blocked filters can cause damage. This means more repairs and more time when your machine cannot work.

Lubrication Points

Lubrication is needed for all moving parts. If you miss a lubrication point, your Komatsu excavator wear parts can get damaged. Here is a table with some important lubrication points and what to know:

Unique Point | Access Method | Technical Specification | Critical Notes |

|---|---|---|---|

Track frame pivot | Side panel removal | EP grease, 250-hour intervals | Hidden behind inspection covers |

Boom offset (if equipped) | Boom raised 45° | Heavy-duty grease, 4-6 pumps | Additional pivot point, often missed |

Hydraulic tank breather | Tank top access | Light grease, monthly service | Prevents contamination ingress |

Check these points every time you do maintenance. Missing one can cause breakdowns and more wear on your parts.

Inspection Intervals

Komatsu says you should check your machine at certain times. These checks help you find problems before they get worse. Here is a chart that shows when to check key wear parts:

Plan your checks at:

250 hours

500 hours

1,000 hours

1,500 hours

2,000 hours

A trained technician should do a 50-point inspection at each time. This means checking Komatsu fluids, oils, filters, and other parts. Komatsu also says to do oil and wear tests for all parts with grease or oil.

Note: Sticking to a strict inspection plan helps your Komatsu excavator wear parts last longer. It also keeps your machine safe and working well.

Preventive Maintenance Schedule

Daily and Hourly Checks

You should check your Komatsu excavator every day. Begin each shift by looking at your machine. Check the oil level. Look at the hydraulic hoses. Inspect the tracks or wheels. These steps help you find problems early. If you see leaks, fix them right away. Tighten any loose bolts you find. Check the air filter too. Make sure all fluids are at the right level. Doing these checks often keeps your machine safe. It also helps you avoid big repair bills.

Service Intervals

A good maintenance plan uses set times for service. Komatsu gives a schedule for checking wear parts:

Service Interval | Description |

|---|---|

Daily Inspections | Look at oil, hydraulic hoses, and tracks or wheels. |

250-Hour Service | Change engine oil and filter. Check air cleaner, fuel, and hydraulic systems. |

500-Hour Service | Check hydraulic oil. Replace filters. Look at fuel and cooling systems. |

1,000-Hour Service | Change hydraulic oil. Check engine air filter, swing machinery, and travel system. |

2,000-Hour Service | Replace hydraulic hoses and coolant. Check final drives. |

4,000-Hour Service | Inspect big parts like swing circle and undercarriage. |

Following this plan helps you keep your machine working well. You lower the chance of breakdowns. Your excavator will last longer.

Record Keeping

Always write down your maintenance work. Record every check and repair you do. Good records can stop 70% of surprise equipment failures. If you use a good plan, you can stop 82% of unplanned downtime. You also cut maintenance costs by 55%. You could save up to $95,000 per machine each year. Companies that do not keep records pay more for emergency repairs. When you track your work, you plan repairs instead of reacting. Your excavator stays reliable. You spend less money on fixing it.

Tip: Use a notebook or an app to record every maintenance job. This helps you see patterns and plan future work.

Signs to Replace Excavator Parts

Wear Indicators

You need to watch for clear signs of wear and tear on your Komatsu excavator. These signs help you decide when to replace spare parts before bigger problems start. Follow these steps to check for wear indicators:

Remove debris from your machine and look for cracks or loose parts.

Measure track sag using a straight edge from the front idler to the rear idler. The distance at the midpoint should be small.

Inspect rollers for damage or wetness underneath. Wetness can mean leaks.

Use calipers to measure the width of pins and bushings. Record any changes.

Measure the width and depth of track shoes with a tape measure and depth gauge.

Check rail height with a depth gauge across the bottom of the rails.

Measure the idler with a smaller depth gauge to reach the outer flange.

Compare your measurements to a wear percentage chart. This shows how much wear and tear each part has.

If you see high wear levels, you should plan to replace those spare parts soon.

Performance Issues

Performance problems often mean you need new spare parts. You might notice your excavator does not work as well as before. Look at this table to see common issues and what you should do:

Performance Issue | Description | Recommended Action |

|---|---|---|

Leaking Fluids | Hydraulic fluid, engine oil, or coolant pooling under your machine shows damage to seals or hoses. | Inspect hoses and fittings, replace worn seals, and monitor fluid levels. |

Uneven Track Wear | Tracks wearing more on one side can mean alignment problems or worn parts. This lowers efficiency. | Inspect undercarriage, adjust track tension, and replace worn tracks as needed. |

Slow Hydraulic Response | Lag in movement can mean clogs or failing parts. This reduces how well your excavator works. | Replace hydraulic filters regularly and check pump performance for needed repairs. |

If you see these problems, you should check your machine and replace the right spare parts. This keeps your excavator working and helps you avoid costly repairs.

Leaks and Noises

Leaks and strange noises are warning signs. You should not ignore them. These problems often mean wear and tear has damaged your excavator’s parts.

Leaks can show up as puddles under your machine. They often mean seals or hoses need new spare parts.

Unusual noises, like knocking or grinding, can mean parts are failing. If you ignore these sounds, you might need expensive repairs later.

Fix leaks and noises quickly. Regular maintenance, including lubrication and seal replacement, helps prevent these problems.

Tip: Address leaks and noises right away. Quick action stops small problems from turning into big failures.

Replacing Wear Parts

Preparation

Get ready before you change any Komatsu excavator wear parts. First, turn off all power to the machine. Let out any pressure in the hydraulic system. This keeps you safe from accidents. Use the parts diagram to see where each part goes. This is very important for the bucket. The bucket has many pins and bushings. You must pay close attention to these. Gather all the tools you need for the job. Make sure you have real Komatsu parts to use. If you want good parts, YNF Machinery sells Komatsu excavator wear parts. They have parts for your bucket too.

Tip: Clean the bucket and the area around it before you start. Dirt and debris can make installation harder.

Removal and Installation

Take out the broken part first. Use the right tools so you do not break anything else. For bucket teeth, remove the retaining pins first. Pull out the old teeth and check the adapter for damage. If the adapter is bad, replace it too. When you put in new parts, use the diagram to line them up right. Make sure every piece is tight. For the bucket, check that all pins, bushings, and teeth fit well. Double-check every connection before you finish. Using real Komatsu parts keeps your bucket and excavator strong.

Step | Action |

|---|---|

1. Remove | Carefully take out old bucket parts. |

2. Inspect | Look for hidden damage on the bucket and adapters. |

3. Install | Put in new parts using the diagram for help. |

4. Secure | Tighten bolts and pins so nothing moves during work. |

Testing

After you finish, test your excavator in a safe place. Move the bucket through all its motions. Listen for strange sounds and look for leaks. Make sure the bucket moves smoothly and works with the controls. If you see a problem, stop and check your work. Follow Komatsu’s steps to keep your bucket working well. Using real parts and testing helps stop future problems. This keeps your machine reliable.

Note: Always test the bucket in a safe spot before using it for real work. This makes sure your excavator is safe and ready.

You help your Komatsu excavator last by sticking to a good plan. Check if the oil is clean. Change filters when they get dirty. Look at the undercarriage often for any problems. Clean the tracks so dirt does not build up. Make sure the track tension is right to stop extra wear. Turn the machine in wide circles. Try not to drive on steep slopes. This keeps rollers and idlers safe. Write down every repair in a logbook. Plan your checks before something breaks. Taking care of your machine early saves money. It also helps your excavator work well for a long time.

Doing regular checks and using good parts from YNF Machinery stops surprise repairs and downtime. Keep good notes and follow a schedule to stay ready.

FAQ

How often should you inspect Komatsu excavator wear parts?

You should inspect wear parts daily before using your excavator. Follow Komatsu’s service schedule for deeper checks at 250, 500, and 1,000 hours. Regular inspections help you find problems early and keep your machine running well.

What are the most common signs that you need to replace a wear part?

Look for cracks, leaks, or strange noises. If you see uneven wear or your excavator does not work as smoothly, you may need to replace a part. Always check for loose bolts or missing pins.

Can you use non-genuine parts for Komatsu excavators?

You should always use genuine parts. Non-genuine parts may not fit well or last as long. Genuine parts protect your machine and help you avoid costly repairs. YNF Machinery offers reliable Komatsu excavator wear parts.

Why is record keeping important for excavator maintenance?

Good records help you track what you have checked or replaced. You can spot patterns and plan repairs before something breaks. This saves you time and money.

Where can you buy quality Komatsu excavator wear parts?

You can buy quality Komatsu excavator wear parts from YNF Machinery. They offer reliable parts that fit your machine and help you keep it working safely.