You make sure your cat excavator hydraulic pump works well by doing regular maintenance. Using good Cat fluids and parts helps stop problems like getting too hot, seals breaking, and inside parts wearing out.

Doing maintenance often stops the arm from moving slowly and keeps lifting power strong.

You can make your parts last up to 30% longer.

You have fewer surprise breakdowns and spend less on repairs.

Key Takeaways

Regular maintenance helps your Cat excavator hydraulic pump work well. It makes sure the pump runs smoothly and does not slow down.

Daily checks let you find leaks and low fluid early. This stops big repairs that cost a lot of money.

Using real Cat fluids and filters can make your hydraulic pump last longer. It can add up to 30% more life to your pump.

Changing hydraulic oil and filters when needed makes the pump work better. It also stops the pump from breaking down often.

Keeping good records of maintenance helps you know what service was done. It lets you plan for future care in a smart way.

Maintenance Importance

Performance Benefits

You want your Cat excavator to work well every day. Doing regular maintenance helps you reach this goal. If you check your hydraulic pump often, you keep dirt and water out. Dirt and water can make your system work up to 20% less. When this happens, your machine uses more fuel and does less work. Doing daily maintenance keeps your hydraulic system clean and strong. It also helps your equipment last longer and stops expensive repairs. Taking care of your machine helps it keep its value. You can get more work done with less effort.

Tip: A clean hydraulic system works smoother and lifts better. You save money on fuel and repairs when you follow a good maintenance plan.

Preventing Breakdowns

You can stop most breakdowns by finding small problems early. Many failures happen because fluid is low, hoses are damaged, or hydraulic oil is dirty. If you check these parts often, you stop bigger problems before they start. Here are some common reasons hydraulic pumps break down and how you can stop them:

Low hydraulic fluid levels

Damaged hoses or seals

Contaminated hydraulic fluid

Air and water contamination

High temperatures and low-pressure readings

You can stop these problems by adding or changing hydraulic fluid, checking hoses and seals, and cleaning the system to remove dirt. Regular maintenance keeps your equipment working well and safely. You also lower the chance of sudden failures that stop your work and cost a lot to fix. By keeping up with maintenance, you make sure your Cat excavator is ready for any job.

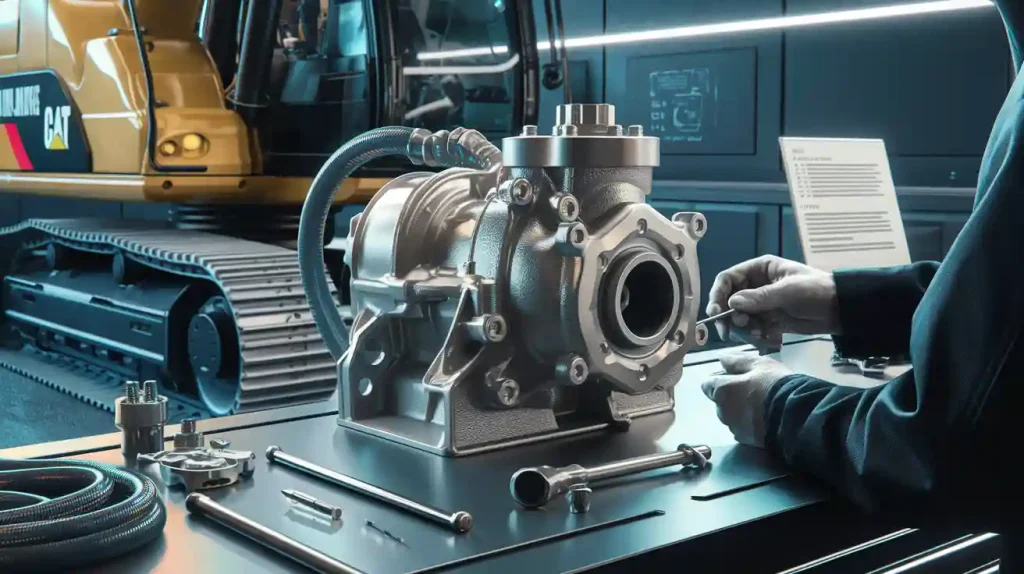

Cat Excavator Hydraulic Pump Daily Checks

You keep your cat excavator hydraulic pump working well by doing daily inspections. These checks help you find problems early and keep your machine safe. You lower the risk of downtime and expensive repairs when you follow daily maintenance tips. Here are the steps you should take every day:

Do a visual check of the hydraulic system before you start work.

Listen for strange sounds like whining or grinding when you turn on the engine.

Shut down the machine and release hydraulic pressure by moving the levers.

Check sight gauges for fluid levels.

Look for leaks and damage near the steering and brake valves and around the pump.

Tighten or replace loose or damaged hose clamps.

Inspect the oil cooler and condenser lines for leaks.

Watch for dirt buildup around seals on lift and tilt cylinders. Dirt can mean leaks.

Check cylinder rods, linkage pins, and joints for damage.

Tip: Companies that do daily inspections have 40% fewer emergency repairs and 35% lower yearly maintenance costs. You save time and money by catching problems early.

Fluid Level Inspection

You need to check the hydraulic fluid level every day. This step keeps your excavator hydraulic pump running smoothly. Low fluid can cause the pump to overheat and lose power. Always use the sight gauge to see if the fluid is at the right level. If you see the level dropping, refill with the recommended Cat fluids. These fluids clean the system, keep it sealed, and help control temperature. They also prevent friction and wear inside the pump.

Filter Type | Benefits |

|---|---|

Standard efficiency | Stops dirt and foreign matter in lighter-duty jobs. |

Advanced high efficiency | Protects against wear in tough conditions. |

Ultra-high efficiency | Controls contamination in hard jobs. |

Fire-resistant UHE | Works with fire-resistant fluid and prevents filter decay. |

Note: Using genuine Cat filters and fluids helps your excavator hydraulic pump last longer. Non-genuine parts may not fit right and can cause failures. They also void your warranty and lower reliability.

Leak Detection

Leaks are a common problem in hydraulic systems. You need to look for leaks every day. Check for fluid around seals and fittings. If you see fluid, the pump may have worn seals, loose fittings, or cracked hoses. Leaks lower hydraulic pressure and can damage the pump. You should fix leaks right away to keep your excavator hydraulic pump working well. Regular inspections help you catch leaks before they get worse.

Alert: If you see leaks, stop the machine and fix the problem. Waiting can lead to bigger damage and higher repair costs.

Sight Gauge Review

The sight gauge shows you the fluid level in the hydraulic system. You should check it before you start work. If the fluid is low, add more right away. The sight gauge helps you spot leaks and other problems early. If you see dirt or cloudy fluid, the system may have contamination. Clean fluid keeps the pump strong and helps the excavator hydraulic pump work at its best.

Reminder: Always use the sight gauge for daily inspections. This simple step helps you avoid breakdowns and keeps your machine safe.

You keep your cat excavator hydraulic pump in top shape by following these daily maintenance tips. Use genuine Cat fluids and filters for the best results. Daily inspections help you find leaks, check fluid levels, and spot damage before it causes trouble.

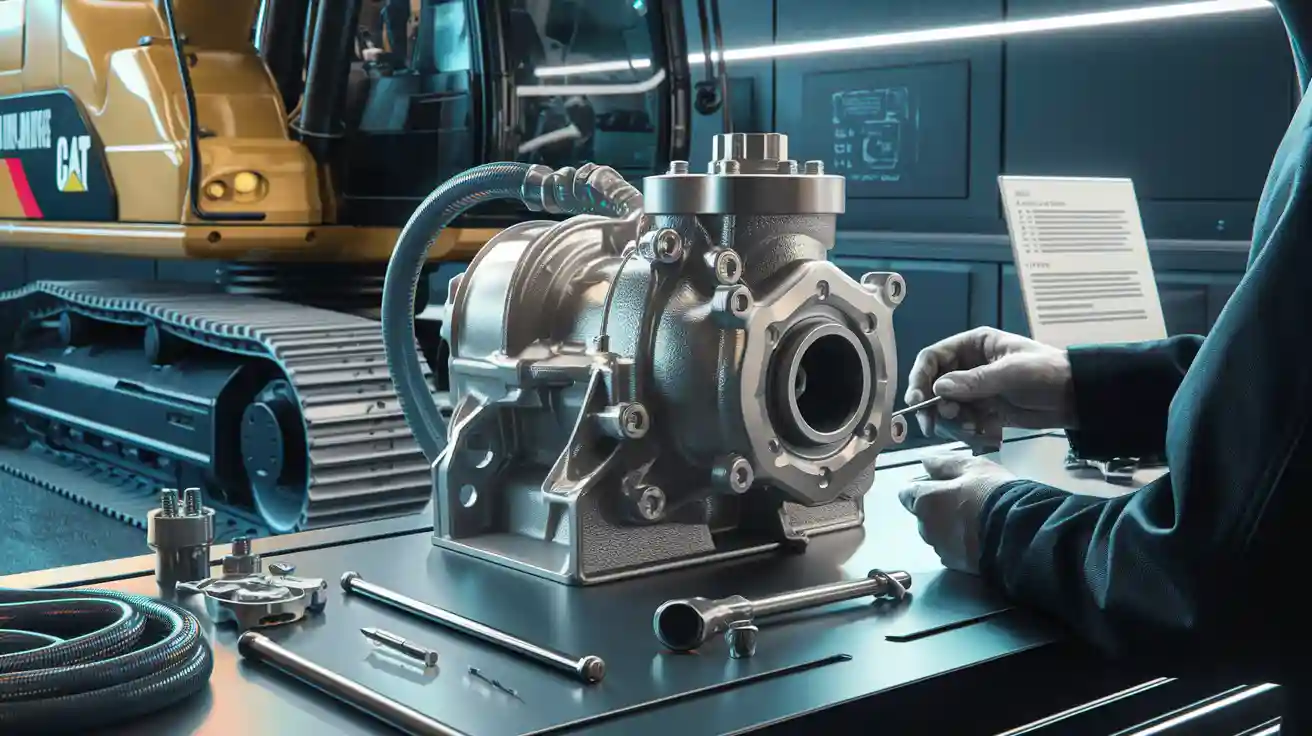

Excavator Hydraulic Pump Periodic Maintenance

Filter Replacement

You should change the hydraulic filters in your cat excavator hydraulic pump often. Clean filters help your excavator hydraulic pump work well. Most experts say to change filters every 250 to 500 hours. You also need to change filters when you change the hydraulic oil. Always look at your machine’s service manual for the right times. Clean filters keep dirt and water out of the hydraulic system. Dirty filters make the pump wear out faster and work less well.

Change hydraulic filters every 250-500 hours.

Replace filters when you change hydraulic oil and filters.

Use the service manual for guidance.

Tip: Clean filters help your pump last longer and lower repair costs.

Hydraulic Oil Change

You should change the hydraulic oil in your cat excavator hydraulic pump every 1,000 hours or once a year. New oil helps the pump run smoothly and keeps the system safe from harm. Good hydraulic oil and filters help the oil flow better and stop wear. Good oil can make your system work 18% better and lower repairs by 45%. Premium oils keep the system clean and help your excavator hydraulic pump last longer.

Interval | Maintenance Task |

|---|---|

Every 1000 Hours | Hydraulic Oil Change, Filter Replacement |

Every 500 Hours | Hydraulic Tank, Water Separator |

Note: Always fill oil to the right level after changing it. Using the correct oil saves money and keeps your pump strong.

Suction Filter Care

You need to check and change suction filters often. Clogged suction filters make the pump work less well and can cause damage. If you forget suction filter care, you may have expensive repairs and downtime. Clean suction filters help your excavator hydraulic pump work well and stop wear on important parts.

Reduced efficiency

Increased wear and damage

Costly repairs and downtime

Alert: Change clogged suction filters right away to stop pump problems.

You keep your cat excavator hydraulic pump working well by changing filters and hydraulic oil on time. Regular care helps you stop breakdowns and keeps your excavator hydraulic pump working hard every day.

Troubleshooting and Issue Identification

When you take care of your excavator hydraulic pump, you need to find problems early. This helps you save money and keeps your hydraulic system working well. Here are ways to spot issues before they get worse.

Signs of Wear

Look for these signs that show your hydraulic system has wear:

Leaks near the pump or hoses. These leaks can lower pressure and make the machine weaker.

Loud banging or knocking sounds. These noises can mean air is trapped or the pump is too hot.

High fluid temperature. If fluid gets hotter than 82°C, seals can break and fluid gets worse.

Weak final drive motor. If you feel less power, your excavator hydraulic pump might have low fluid pressure.

Slow or jumpy movements. These mean the pump is not working right.

Grinding or screeching sounds. These sounds mean you need to fix the pump soon.

Tip: Finding these signs early helps you stop big problems and keeps your machine running.

Contamination Checks

Keeping your hydraulic system clean is very important. You should:

Take fluid samples every 500 hours. This helps you find dirt or water in the hydraulic system.

Watch fluid levels. Low fluid can mean leaks or other issues.

Change hydraulic filters at least every 500 hours. Always use good filters to keep the system clean.

If you see cloudy or dirty fluid, you need to fix the system and put in new fluid. Clean fluid helps your excavator hydraulic pump last longer.

When to Seek Help

Some problems need a professional to fix. You should call for help if you see:

Pump action that is not steady or is strange

Weird noises like buzzing, grinding, or screeching

Burnt or black joints, which show the system is too hot

Fault codes or alarms on your screen

Cylinders that do not move smoothly or are weak

Slower speed or parts that do not work

Slow movements or less power

If you see leaks you cannot fix, or if the hydraulic system keeps losing power, you need an expert. Fixing leaks fast can help you avoid bigger repair costs.

Common Issue | Symptoms/Description | Recommended Solutions |

|---|---|---|

Clogged filter | Pressure drop, possible pump damage | Clean or replace filters often |

Loud sucking or screeching | Inlet supply stress, belt slipping | Check lines, adjust belts, or replace them |

Worn seals or bearings | Leaks, oil around bearing cover | Check and replace seals and bearings |

Excessive heat | Damaged seals, fluid breakdown | Keep fluid temperature safe |

You keep your hydraulic system strong by looking for these signs and acting quickly. Regular care and fixing problems help your excavator hydraulic pump last longer and work better.

Hydraulic Excavator Parts and Pro Tips

Best Practices

You can keep your Cat excavator working well by following some simple best practices for hydraulic excavator parts. Take care of your machine every day, sometimes, and over the long term. Each type of care helps your pump work better. Use this table to help you remember what to do:

Maintenance Type | Best Practices |

|---|---|

Daily Maintenance | Look for leaks or damage, check fluid levels, clean parts, and watch the hydraulic cylinder seals. |

Periodic Maintenance | Change filters and hydraulic oil, check and tighten fittings, and look at couplings for wear. |

Long-Term Maintenance | Get professional inspections, use high-quality parts, and keep the hydraulic pump working well. |

Always pick real hydraulic excavator parts when you need new ones. YNF Machinery gives you Cat excavator hydraulic pump parts and other important parts. Good parts help stop breakdowns and keep your machine running strong.

Tip: Using good hydraulic excavator parts helps your pump last longer and makes your machine work better.

Storage Tips

Storing your hydraulic excavator parts the right way keeps them safe from harm. It also makes sure your equipment is ready to use. Follow these steps for the best results:

Put oil on the hydraulic cylinder so it does not rust.

Keep your machine in a dry place with a roof. Inside storage is best.

Use covers that keep out water, dust, and sun.

Drain all fluids if you will store it for a long time.

Put grease on all hydraulic excavator parts to keep away moisture.

Check fluid levels and make sure they look clean.

Fix or change any worn hydraulic excavator parts before you store them.

Look for bugs or animals while your machine is stored.

Note: Storing your parts the right way helps them last longer and saves you money on repairs.

Maintenance Records

Writing down all the work you do on your hydraulic excavator parts gives you many good things. You can see when you did service, find problems, and plan repairs. Good records help your equipment last up to 60% longer. You can also save a lot of money each year on running costs for each machine. Companies that do not keep records often have big breakdowns that cost a lot.

Write down every time you do service or change a part.

Look at your records before you start a job.

Use your notes to plan future care for hydraulic excavator parts.

Reminder: Keeping good records helps you make smart choices and keeps your Cat excavator working well.

You keep your Cat excavator hydraulic pump working at its best by following these steps:

Inspect the hydraulic system often.

Check fluid levels and quality every day.

Replace filters on schedule.

Look for worn hoses and belts.

Test for leaks and fix them quickly.

Clean the system to prevent damage.

Using genuine Cat parts and fluids gives you strong performance and protects your warranty. You get parts that fit perfectly and last longer. You also enjoy peace of mind from strict quality control. Stay alert for warning signs and ask a professional for help when needed. Protect your investment and keep your machine ready for every job. 🚜

FAQ

How often should you check your excavator hydraulic pump?

Check your excavator hydraulic pump every day before work. Daily checks help you find leaks or low fluid. You can also spot damage early. Regular inspections keep your excavator safe. They help your machine work well.

What type of hydraulic fluid works best for your excavator?

Use the hydraulic fluid your manual recommends. Genuine Cat fluids protect your excavator pump. They help it last longer. The right fluid keeps your excavator running smoothly.

Why does your excavator lose power or move slowly?

Your excavator can lose power if fluid is low. Dirty filters or leaks also cause problems. Check for these issues often. Fixing them helps your excavator work strong.

How do you spot leaks in your excavator hydraulic system?

Look for wet spots or puddles near the pump. Check hoses and seals for dirt or fluid. Leaks lower pressure and can hurt your excavator. Fix leaks fast to keep your machine safe.

Where can you buy reliable excavator hydraulic pump parts?

You can buy good excavator hydraulic pump parts from YNF Machinery. They sell quality parts for your excavator. Using good parts helps your excavator last longer and work better.