A coupling is a tool that links two shafts together, playing a crucial role in the various types of coupling used in machinery. It helps send power from one shaft to another. Couplings are utilized in many machines, joining parts that spin and allowing for slight movement. Some types of coupling can handle parts that are not aligned, while others manage force or movement in specialized ways. Choosing the right type of coupling is essential for ensuring your machine operates efficiently and remains safe.

Key Takeaways

Couplings join two shafts to move power. They help machines work well and stay safe.

There are three main types of couplings. These are rigid, flexible, and fluid. Each type has its own job in machines.

Rigid couplings need shafts to line up exactly. They work best in places where things do not move, like conveyor belts and pumps.

Flexible couplings let shafts move a little and not line up perfectly. They help lower shaking and make machines last longer.

Fluid couplings use liquid to move power without touching. They help machines start smoothly and protect from too much force.

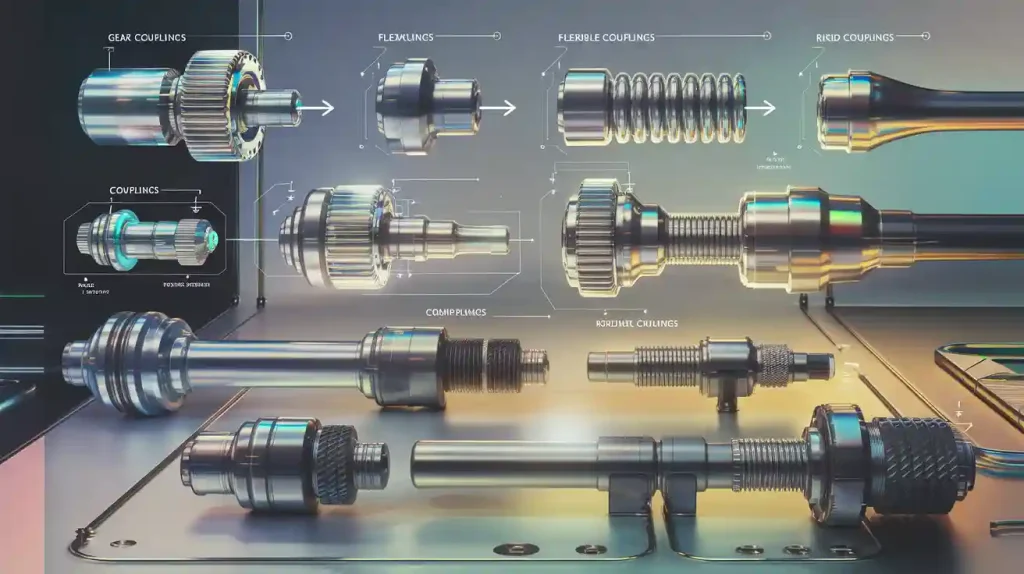

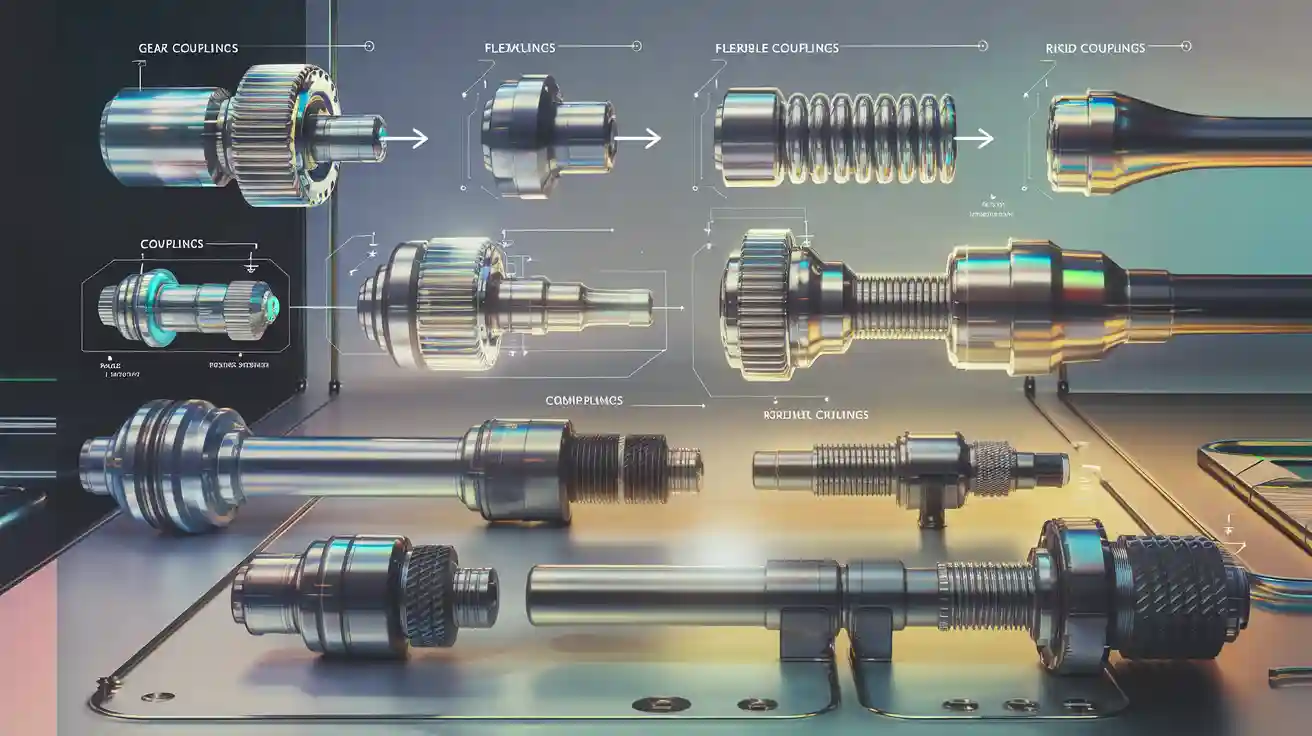

Types of Coupling

There are three main types of coupling. These are rigid, flexible, and fluid. Each one has a special job in machines. Knowing about these types helps you pick the right one.

Tip: Picking the right type of coupling keeps your machines safe and working well.

Rigid Coupling

A rigid coupling links two shafts so they move together. You use this when you need the shafts to line up exactly. Rigid couplings do not let the shafts move or shift. They send torque well and keep things in place.

Type of Coupling | Function | Applications |

|---|---|---|

Rigid Couplings | Maintain precise alignment, transmit torque efficiently | Used in fixed position applications like conveyor shafts and pumps where alignment is crucial. |

You see rigid couplings in conveyor belts and pumps. They are used when the shafts must stay lined up. They also help support and make shafts longer. They can join shafts of different sizes. They are very stiff and strong. Food, medical, and packaging companies use rigid couplings for high-gain rubber type jobs.

Note: Rigid couplings are best when you can keep perfect alignment. If the shafts are not lined up, it can hurt your machine.

Flexible Coupling

A flexible coupling lets the shafts move a little. This type can handle misalignment and cut down on shaking. You find flexible couplings where things move, shake, or change with heat.

Flexible couplings can deal with different misalignments:

Parallel misalignment: Shafts are side by side but not lined up.

Angular misalignment: Shafts point at an angle.

Axial (end-float) misalignment: Shafts move back and forth.

Combined or skewed misalignment: More than one kind at once.

Flexible couplings use soft or moving parts to take in these shifts. This helps your machines last longer and break down less. You see flexible couplings in pumps, fans, and moving equipment. They are great for high-gain rubber type uses, where less noise and shaking is needed.

Advantage | Description |

|---|---|

No lubrication required | Especially in models with polymer-based elastic elements. |

Maintenance-friendly | Particularly in split versions with divided elastic centers. |

Noise and vibration damping | Mechanical isolation between driver and driven equipment. |

Lower costs for fixing

Quicker repairs

Machines last longer

Fewer sudden breakdowns

Safer to use

Flexible couplings stop sudden problems by taking in movement and shaking.

Fluid Coupling

A fluid coupling uses liquid to send power between shafts. It does not need the shafts to touch. It has two wheels inside a case with fluid. The impeller, on the driving shaft, spins and moves the fluid. The fluid turns the turbine, which is on the other shaft. This makes starting smooth and stops overload.

Fluid couplings work with moving fluid and special flow rules.

The impeller spins faster than the turbine. This makes the fluid move and sends energy without touching.

The motor speeds up and the impeller pushes oil to the still turbine. The oil spreads out and slowly gives more torque. When the torque is the same on both sides, the turbine starts to spin and speeds up the load.

You see fluid couplings in many fields:

Industry | Application Description |

|---|---|

Automotive Industry | Used in car transmissions for smooth gear changes and better work. |

Mining and Quarrying | Used in big machines for strong power in tough places. |

Marine Propulsion | Used in ships for smooth starts and speed control. |

Power Generation | Connects motors to machines, giving soft starts. |

Cement, Steel, and Manufacturing | Used in factories for steady speed and overload safety. |

Water and Wastewater Treatment | Helps pumps and fans start slowly, stopping water hammer. |

HVAC Systems | Saves energy in big air and cooling systems. |

Renewable Energy | Controls speed in wind and water power machines. |

Fluid couplings are good for high-gain rubber type jobs. They help with smooth starts and stop overload. You can use them in pumps, fans, and big machines.

If you want to know more about couplings, you can look up more information online.

Different Types of Rigid Couplings

Rigid couplings join two shafts so they spin together. You use them when you need the shafts to line up exactly. They send strong torque from one shaft to another. Rigid couplings do not let the shafts move out of place. If the shafts are not lined up, it can cause stress. This can make the machine shake or break. That is why rigid couplings work best when everything stays straight.

Muff or Sleeve Coupling

A muff or sleeve coupling is very simple. It uses a hollow tube called a sleeve. The sleeve goes over the ends of both shafts. The inside of the sleeve matches the shaft size. You lock the sleeve to each shaft with a key. The key helps send power between the shafts.

Component/Function | Description |

|---|---|

Structure | A round sleeve fits over the shaft ends. The inside is the same size as the shafts. |

Function | Sends power from one shaft to the other with a key and sleeve. |

Assembly | The sleeve can be one piece or two halves bolted together. |

Advantages | Easy to make, simple to put on, and protects against shocks. |

You see this coupling in pumps, fans, and conveyors. It is good for jobs that need a strong, basic link.

Split Muff Coupling

A split muff coupling is also called a clamp coupling. It has a sleeve split into two pieces. You bolt the two halves around the shafts. This makes it easy to put on or take off. You do not have to slide the coupling along the shaft.

Simple to put together and take apart

Works well for tough jobs

No need to move the coupling along the shaft

You find split muff couplings in big machines and mining tools. They are used in pumps, mixers, and turbines.

Industry | Application Description |

|---|---|

Industrial machinery | Used in pumps, compressors, and mixers. |

Power generation | Connects turbines and generators. |

Mining and construction | Powers excavators, cranes, and drilling rigs. |

Flange Coupling

A flange coupling uses two flanges, one for each shaft. You bolt the flanges together for a tight fit. The flanges have holes for bolts. Sometimes you need adapters if the holes do not match.

Construction Details | Main Uses |

|---|---|

Flat discs or shoulders with bolt holes. | Connects pipes or equipment of different sizes. |

Bolts hold the flanges together tightly. | Used for fixing or adding to pipelines. |

Adapters help match different flange types. | Makes it easy to change broken parts. |

Flange couplings do not let the shafts move out of line. You must use them only when the shafts are lined up. They also need extra space around the shafts.

Note: Rigid couplings like muff, split muff, and flange types cannot handle misalignment. If the shafts are not lined up, it can cause shaking, stress, or even break the coupling. Always check the alignment before you install to stop expensive repairs.

Flexible Coupling Types

Flexible coupling joins two shafts. It lets them move a little. This helps with misalignment. These couplings lower stress and take in vibration. They keep your machines safe. Each flexible coupling has its own design. Each one fits a different job.

Gear Coupling

Gear coupling has toothed hubs inside a sleeve. The teeth fit together and send torque. This lets you fix misalignment between shafts. Gear coupling is used in heavy machines. You see it in steel mills and mining tools. It works for tough jobs and high torque. The design has backlash and crowning. These features help gear coupling last longer. They also let it handle more movement.

Type of Coupling | Key Features |

|---|---|

Gear Coupling | High torque density, handles all misalignments, needs periodic lubrication |

Application Area | Description |

|---|---|

Industrial Machines | Used with blowers, pumps, compressors, mixers |

Power Generation | Works for high-speed and low-speed jobs |

Steel Production | Common in mills needing high torque |

Gear coupling connects shafts that are not lined up. It gives strong power and less wear.

Disc Coupling

Disc coupling uses thin discs to send torque. The discs bend a little. This lets you fix misalignment and lowers force. You see disc couplings in pumps and fans. They work for fast and accurate jobs. Disc coupling is used in food and gas turbines.

Disc couplings lower vibration and take in shock.

Composite disc couplings stop electricity from passing through.

You get smooth running and longer machine life.

Industry/Application |

|---|

Pumps |

Compressors |

Fans |

Food Processing |

Printing Presses |

Disc coupling keeps machines working well. It helps even when shafts move.

Oldham Coupling

Oldham coupling has two flanges and a middle plate. The center disk slides between the flanges. This lets you fix high parallel misalignment. Oldham coupling is used in tight spaces. It protects bearings by lowering force. If overloaded, it can break apart. This saves expensive parts.

Oldham couplings stop electricity from passing through.

You use them for parallel shafts in small spaces.

They act as a safety part in some machines.

Oldham coupling lowers wear and keeps equipment safe.

Universal Joint

Universal joint links two rods at an angle. It sends rotary motion even when shafts are not straight. You see universal joint in cars and big machines. The design uses two hinges at ninety degrees. A cross shaft joins the hinges. Universal joint sends torque at different angles.

Universal joint is used in car drives and machines.

It handles heavy loads and high torque.

It is needed for flexible power in vehicles.

Type of Coupling | Key Features |

|---|---|

Universal Joint | Used for shafts at an angle, handles heavy-duty jobs |

Universal joint gives strong performance and longer life. Cars use constant velocity joint for smooth power.

Flexible coupling takes in shock and vibration. This makes machines safer and stronger. You use flexible coupling in many jobs. It protects equipment and lowers repairs. Jaw couplings and disc couplings are popular. They fix misalignment and vibration. Shaft coupling helps you join machine parts easily.

Tip: When picking a coupling, think about misalignment and torque. Jaw coupling works well for pumps and compressors.

Fluid Coupling Function

How Fluid Coupling Works

A fluid coupling uses liquid to send power between two shafts. The driving shaft has an impeller. The driven shaft has a runner. When the impeller spins, it moves the liquid inside. The moving liquid pushes the runner and makes it turn. This lets you send torque smoothly without the shafts touching. Because the parts do not touch, they last longer. You also get less shaking and noise when the machine runs.

Fluid couplings help machines start without jerks. When you turn on the motor, the fluid coupling lets it speed up first. The load moves after the motor is ready. This keeps your equipment safe from sudden shocks. You can also control the torque to stop overload. This helps protect your motor.

Here are some main benefits of using a fluid coupling instead of a mechanical coupling:

Benefit | Description |

|---|---|

Wear Reduction | Sends power with almost no wear, so machines last longer. |

Load-Free Motor Run-Up | Lets motors start without heavy loads, so they speed up fast. |

Torque Limiting | Keeps torque safe to protect motors from too much force. |

Inherent Damping | Cuts down on torque changes, so your drive is more stable. |

Low Maintenance | Less wear means you spend less time and money fixing things. |

Safe Operation | You can use water, which is not flammable, for safer use. |

Tip: Use fluid couplings when you want smooth starts, overload safety, and less upkeep.

Applications of Fluid Coupling

You can use a fluid coupling in many jobs. It works well when you need smooth power and want to protect machines. You see fluid couplings in car gearboxes, mining tools, and ship drives. They also help in power plants, cement factories, and water plants. These couplings help pumps, fans, and conveyors work better and last longer.

If you want a good fluid coupling, check out YNF Machinery. They have strong products to keep your machines safe and working well.

You now know about the main types of coupling and how they help connect a drive shaft to another part. The type of coupling you pick depends on how the shafts line up, how much force is needed, and what the machine does. Before you choose a coupling, think about these key things:

Factor | Description |

|---|---|

Type of misalignment | See if the drive shaft lines up with the other shaft. |

Maximum torque | Check if the coupling can handle your machine’s force. |

Operating conditions | Think about heat, shaking, and speed in your system. |

Torque

Shaft misalignment

Stiffness

RPM

Inertia

Space needs

Shaft mounting

When you pick the right coupling for your drive shaft and machine, your equipment will last longer and work better.

FAQ

What is the main job of a coupling?

A coupling connects two shafts. You use it to send power from one shaft to another. It helps your machine run smoothly and safely.

How do you pick the right coupling for your machine?

You check shaft alignment, torque needs, and space. You look at how much movement or vibration your machine has. YNF Machinery can help you choose the best coupling for your job.

Can flexible couplings fix misalignment?

Yes. Flexible couplings let shafts move a little. You use them to handle misalignment and reduce vibration. This keeps your machine safe and working longer.

Where do you use fluid couplings?

You use fluid couplings in cars, pumps, fans, and big machines. They help with smooth starts and protect your equipment from overload.

Do couplings need much care?

Most couplings need little care. You check for wear and keep them clean. Some types, like gear couplings, need oil. YNF Machinery offers couplings that are easy to maintain.