The main parts of an excavator are the engine, hydraulic pump, swing motor, hydraulic cylinders, main control valve, and cylinder block. Each motor part excavator has its own job. The engine makes power. The hydraulic pump and main control valve work together. They help control the power and systems. The swing motor and hydraulic cylinders help the excavator move. The cylinder block helps the engine work. Knowing these important parts helps people stay safe and work well with excavator parts. When you know the main parts, it is easier to find and take care of each motor part excavator during daily work with excavator parts.

Key Takeaways

The engine gives power to the excavator. It needs clean fuel and air to work well. This helps it follow emission rules.

The hydraulic pump and main control valve move oil. This makes the excavator move smoothly and with strength.

Hydraulic cylinders help lift and move parts. They need regular checks to stop leaks and damage.

The swing motor and travel motor help the excavator turn. They also help it move over rough ground safely.

Regular care of all parts stops big repairs. It saves fuel and helps the machine last longer.

Engine Motor Part Excavator

The engine is like the heart of an excavator. It changes diesel fuel into power. This power runs all the main systems. Most excavators use strong diesel engines. For example, a Cat 325 has about 175 horsepower. Mini excavators have less than 25 horsepower. Compact ones have between 25 and 75 horsepower. Standard excavators have more than 75 horsepower. This power helps the machine dig and lift heavy things.

Cylinder Block

The cylinder block is the backbone of the engine. It holds the cylinders, pistons, and crankshaft. The cylinder block must handle high heat and pressure. Makers use iron or aluminum alloy to build it. These materials help the motor part excavator last longer. A strong cylinder block supports moving parts and keeps the engine working well.

Tip: Check the cylinder block often to avoid big repairs. Watch for rust, cracks, or leaks.

Cylinder block problems can come from dirt, heat, or rust. Dirty hydraulic fluid can scratch the cylinder walls. This can also hurt the seals. High heat can change the seals and fluids, causing leaks. Side loads can wear out the cylinder and cause cracks. Good mounting and regular care can stop these problems.

Fuel and Air Systems

The fuel and air systems are important for the engine. The fuel injection system sends the right amount of diesel to each cylinder. Newer fuel injection systems help burn fuel better and cut pollution. Keeping the fuel injection pump in good shape helps the engine run well. If the pump breaks, the engine may lose power or use too much fuel.

The air system brings clean air into the engine. Air filters keep dust out of the cylinders. Dirty air can wear out the engine faster. Operators should check the air filter every day. Change the filter when needed. Most makers say to change the air filter every 250 to 500 hours.

Good fuel and air systems help the motor part excavator save fuel. They also lower costs. Turbochargers help the engine get more air and do more work. Idle management systems turn off the engine when not needed. These features and good training help save fuel and make the excavator last longer.

System | Function | Maintenance Tip |

|---|---|---|

Sends fuel to each cylinder | Calibrate pump often | |

Air Filtration | Keeps air clean for the engine | Check and change filter as needed |

Turbocharging | Brings in more air for better burning | Look for leaks or damage |

Laws also affect how engines are made. The EPA’s Tier 4 rules need better emission controls. They also need special diesel fuel. Taking care of the engine helps meet these rules and lowers pollution.

Hydraulic Excavator Parts

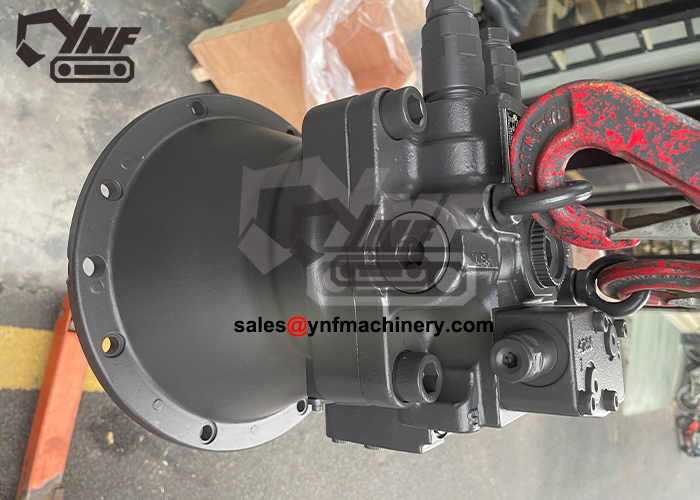

Hydraulic Pump

The main hydraulic pump gives power to the excavator’s hydraulic system. The engine makes this pump work. It pushes oil into the system under high pressure. In a mid-sized excavator, the pump sends oil at about 4,500 psi. This strong pressure lets the machine lift heavy things and dig hard ground.

How well the hydraulic pump works is very important. If the pump works well, the excavator moves fast and strong. The boom, arm, and bucket get more power. If the pump has leaks or too much friction, the machine slows down. It also loses strength. At low speeds, leaks and friction make it hard to start moving. It can also be hard to do careful work. Using the right fluids and taking care of the pump helps stop these problems.

Hydraulic pump efficiency changes how fast and strong the excavator moves.

If the pump leaks or loses power, the machine gets slower and weaker.

At low speeds, friction and leaks make it hard to start or move carefully.

Fluids with the right properties help the pump work better and faster.

Better pump design and less leakage make the excavator work faster and stronger.

Tip: Check the main hydraulic pump often for leaks or strange sounds. If you find problems early, you can avoid big repairs.

Variable-displacement pumps change how much oil they send out. This saves energy when the job is easy. It also uses less fuel and costs less to run. New hydraulic parts like accumulators and good pumps help the excavator work longer and better.

Main Control Valve

The main control valve is like the brain of the hydraulic system. It sends oil from the pump to different parts of the excavator. These parts include the boom, arm, stick, and bucket. The operator uses controls to move the machine exactly how they want. The main control valve makes sure each move is smooth and safe.

Many types of valves work together in the system:

Valve Type | Function Description |

|---|---|

Pressure Control Valves | Keep the hydraulic system pressure safe and steady. |

Relief Valves | Let out extra pressure to keep the system safe. |

Spool (Directional) Valves | Send oil to the right part so the machine moves the right way. |

Check Valves | Make sure oil only goes one way and does not flow back. |

Ball Valves | Control oil flow with a simple turning part. |

Flow Control Valves | Change how fast oil moves to control how fast parts move. |

Proportional Valves | Allow many positions and oil amounts for tricky jobs. |

Servo Valves | Give very exact and quick control for special systems. |

The main control valve controls where the oil goes and how fast. This lets the operator move the boom, stick, and bucket very carefully. The valve is made to last a long time, even when used a lot. Its small and light shape also helps save energy.

The main control valve controls oil flow and direction for careful moves.

It helps the operator do tricky jobs easily and well.

The valve gives quick and exact control, making the system work better.

It is made to last and work well in tough jobs.

Its small size makes it easy to put in and saves energy.

Note: Safety release valves let out extra pressure if something goes wrong. This keeps the system safe from damage.

Hydraulic Cylinders

Hydraulic cylinders use oil pressure to make things move. There are three main cylinders in an excavator: the boom cylinder, stick cylinder, and bucket cylinder. Each one does a special job.

The boom cylinder lifts and lowers the boom. It keeps the machine steady when digging.

The stick cylinder moves the stick in and out. It helps the arm reach and dump dirt.

The bucket cylinder tilts and curls the bucket. It gives the most digging power for hard ground or heavy loads.

Hydraulic Cylinder | Typical Force Output (kN) | Role/Notes |

|---|---|---|

Arm Cylinder | 153.03 | Makes the arm move for digging and lifting. |

Bucket Cylinder | 56.56 | Makes the bucket curl for digging and scooping. |

Boom Cylinder | N/A | Lifts and moves the bucket; keeps it steady while digging. |

How strong each cylinder is depends on its size and oil pressure. Bigger cylinders in bigger machines can dig harder. The arm cylinder moves the arm in and out. The bucket cylinder tilts the bucket to pick up or drop things. The boom cylinder mostly lifts and moves the bucket.

Hydraulic cylinders can have many problems:

Leaks from old seals or bad parts can waste oil and lower power.

Leaks from hoses or fittings can happen if parts are loose or broken.

Cylinder drift, or unwanted movement, comes from leaks or bad valves.

Rod damage, like scratches or bends, can happen from dirt or rough use.

Slow or jumpy moves may come from low oil, air in the system, or bad pumps.

Misalignment happens if parts are not put in right or are worn out.

Rust from water or bad materials can weaken the cylinder.

Dirty oil with dust or dirt can wear out the inside and break the system.

Alert: Check cylinders often, watch oil levels, clean parts, and fix problems fast. This keeps the excavator safe and working well.

Good design of hydraulic excavator parts saves energy and money. Strong, high-quality parts last longer and break less. Using clean, safe fluids and keeping the system clean also helps the environment.

Hydraulic systems can fail for many reasons. These include dirty oil, leaks, too much heat, bubbles, worn parts, air in the system, or bad installation. To stop these problems, check and fix parts often, use clean oil, change filters, get rid of air, and follow the maker’s rules.

Tip: Operators should look for leaks, check oil, and listen for odd sounds. Fixing problems early keeps the excavator running well.

Swing and Travel Parts of an Excavator

Swing Motor

The swing motor lets the top of the excavator turn. This top part holds the cab, boom, arm, stick, and bucket. The swing motor uses hydraulic power to turn smoothly. It connects to the swing gear and swing bearing. These parts help hold up the heavy top. The operator can spin the machine all the way around. The undercarriage does not need to move. This helps the excavator dig or lift in any direction.

The swing motor turns hydraulic energy into movement.

Control valves help set the speed and direction.

The swing motor lets the operator work with care.

The swing motor keeps the excavator steady when lifting heavy things. This is important on bumpy ground or with a full bucket. For example, a Komatsu HB365LC-3 can swing at 9.5 rpm. It has a swing torque of 11,386 kg-m (82,313 ft-lbs). This strong torque helps it turn with heavy loads.

Final Drive

The final drive is the last part before the tracks. It takes power from the travel motor and sends it to the tracks. Inside, gears change the speed and make the force stronger. This helps the machine move over dirt, rocks, or mud.

The final drive uses a hydraulic travel motor to move the tracks. The gears inside can be offset or use a planetary system. These gears help the excavator move smoothly and with enough power to climb or turn.

Tip: Operators should check the final drive often. Low oil, worn gears, or leaks can cause big problems. Cleaning the undercarriage and checking for loose parts helps prevent breakdowns.

Common problems are broken shafts, worn friction plates, and leaks. Changing oil, cleaning, and checking for loose sprockets help the final drive last longer.

Travel Motor

The travel motor makes the undercarriage move. It lets the excavator go around the job site. The travel motor works with the final drive to push the tracks. It uses hydraulic power for strong and steady moves. The machine can go forward, backward, or turn in place.

Travel motors let the operator pick two speeds. One is slow for careful work. The other is fast for moving across the site. The undercarriage has rubber or steel tracks and strong rollers. This helps keep the machine stable. Some excavators can change the width of the undercarriage. This helps in tight spaces.

Feature Category | Description |

|---|---|

Undercarriage | Rubber or steel tracks, strong rollers, and a tough frame for stability on all terrains. |

Travel Motors | Give efficient movement and support two travel speeds for different jobs. |

Maneuverability & Stability | Adjustable undercarriage and travel motors help the excavator stay stable and move easily in small or rough areas. |

The travel motor and undercarriage help the arm, boom, stick, and bucket reach many places. This makes the excavator good for digging, lifting, and moving things on all kinds of ground.

Knowing the main parts of an excavator helps operators work safely. These parts include the engine, hydraulic pump, swing motor, and undercarriage. When operators take care of these parts, the machine works better and lasts longer. Doing regular checks stops parts from breaking and keeps the excavator running well. If operators understand what each part does, they can find problems early. They can fix small issues before they turn into big, expensive ones. This guide will help you learn how to spot, care for, and fix all the parts of an excavator.

Some good things about regular maintenance are:

Less friction and less heat

Fewer big repairs and less time stopped

Better safety and higher value if you sell

Main Motor Part | Common Issue | Troubleshooting Tip |

|---|---|---|

Hydraulic System | Fluid leaks | Look at hoses and change bad seals |

Boom | Moves slowly | Check fluid and look at cylinder seals |

Undercarriage | Wears out | Check it every day |

FAQ

What is the most important motor part in an excavator?

The engine is the key motor part. It gives power to all other systems. If the engine does not work, the excavator cannot move or dig.

How often should operators check hydraulic fluid levels?

Operators need to check hydraulic fluid every day before work. If fluid is low, pumps and cylinders can get damaged. Checking often helps stop breakdowns.

Why does the swing motor make noise?

A swing motor can be noisy if oil is low or parts are worn. Loose parts can also make noise. Operators should stop and check the swing motor. Fixing problems early stops bigger issues.

What causes hydraulic cylinders to leak?

Hydraulic cylinders leak when seals are worn or rods are damaged. Dirty oil can also cause leaks. Operators should change seals and keep oil clean. Checking often helps find leaks early.

How can operators extend the life of the final drive?

Operators can help the final drive last longer by cleaning the undercarriage, checking oil, and tightening bolts. Doing regular care keeps gears and bearings working well.