Choosing the right Kato excavator parts USA helps your machine work well and prevents expensive delays. Picking quality and matching Kato excavator parts USA makes your excavator last longer and work better. But using the wrong parts can cause breakdowns and surprise costs. Smart choices keep these problems away and make you feel confident. Always look for Kato excavator parts USA that fit your machine’s needs and job requirements to keep it running smoothly.

Key Takeaways

Pick good Kato excavator parts to boost performance and save money.

Match parts to your excavator model to prevent problems and work well.

Think about upfront costs and future expenses to spend wisely on parts.

Check and care for hydraulic parts often to make them last longer.

Look up suppliers and read reviews to find trusted sellers with great parts and service.

Overview of Kato Excavator Parts

Types of Excavator Parts

Excavators have many parts that help them work properly. These parts are grouped by what they do and how they help.

Here are some common excavator parts:

Hydraulic systems

Undercarriage parts

Swing bearings

Boom and arm pieces

Attachments like buckets and hammers

Check out this table for more details about excavators by type, size, and how much work they can do:

Excavator Type | Weight Range (tons) | Productivity Rate (m³/hour) |

|---|---|---|

Small Excavators | 1 to 5 | 10 to 20 |

Medium Excavators | 6 to 10 | 20 to 40 |

Large Excavators | 11 to 50 | 40 to 100 |

Heavy-Duty Excavators | Over 50 | 100 |

Other important parts include hydraulic pumps, travel motors, and cabin controls. These parts help the excavator work well and stay reliable.

Importance of High-Quality Excavator Parts

Good-quality parts are key to keeping your excavator in great shape. They make the machine last longer and work better.

For instance, strong hydraulic cylinders can last over 3,000 hours. This is much longer than average and means fewer replacements. While good parts may cost more at first, they save money over time by needing less fixing.

Also, reliable parts help the excavator handle tough jobs without breaking down. This keeps your work on track and avoids delays.

By choosing strong and well-made parts, your excavator will stay useful for many years.

Factors to Think About When Picking Excavator Parts

Matching Parts to Your Excavator

Picking the right parts means making sure they fit your machine. Every excavator model has its own special features. A part for a small excavator won’t work on a big one. Always check your model number and use a size guide to avoid mistakes. This helps the parts match your machine’s design and needs.

OEM parts are made just for your excavator. They fit better and work more smoothly. These parts lower the chance of breakdowns and keep things running well. Aftermarket parts might cost less, but they’re often less reliable. By choosing parts that fit, you keep your excavator working well and avoid big repair bills.

Strong and Long-Lasting Parts

Good parts last longer and work better. High-quality parts can handle wear and tear, so you don’t replace them often. For example, strong hydraulic parts can handle high pressure and keep your machine running longer. Spending more on good parts now saves money later by needing fewer repairs.

Studies show that better parts give better results. Branded parts may cost more, but they work better and last longer. Simple designs can also make parts stronger and easier to maintain. By picking strong and well-made parts, your excavator stays reliable, even in tough jobs.

Parts for Your Project

Every job is different, so pick parts that fit your project. For example, rocky areas need stronger undercarriage parts. Heavy lifting jobs might need special tools like grapples or hammers. Choosing the right parts for your job helps your excavator work its best.

One example shows how solving specific problems can help. The Top Hat Bush fixed issues with thrust plates in excavators. This made parts last longer, cut labor costs, and reduced downtime. By picking parts that match your project, you get more done and avoid problems.

Cost-Effectiveness

When picking excavator parts, think about cost and performance. You need to check both the upfront price and long-term costs. This helps you make the smartest financial choice.

Initial Purchase Costs

The price of parts depends on if they’re new, used, or aftermarket. New parts often come with warranties, which lower early repair costs. Used parts are cheaper but may wear out faster, leading to more repairs. Aftermarket parts might save money at first but can lack quality and hurt performance.

Long-Term Operational Costs

Long-term costs include fixing, insurance, and moving parts. High-quality parts cost more upfront but last longer. They also need fewer repairs. For example, strong hydraulic parts handle heavy work and reduce downtime. Choosing good parts saves money and boosts productivity over time.

Maintenance Expenses

Maintenance keeps your excavator working well and avoids big problems. Picking parts that are easy to fix or clean saves time and money. Simple designs make repairs quicker and extend the life of your machine.

Depreciation and Value Retention

Depreciation lowers the value of your excavator over time. Used parts lose value slower than new ones, making them a good long-term choice. But you must balance this with possible repair costs. Reliable parts keep their value and help your machine work better.

Balancing Cost and Productivity

Saving money isn’t the only goal. Your excavator should work well and stay productive. Good parts improve efficiency and reduce delays. Cheaper parts might seem like a deal but can cause problems later. Investing in quality parts keeps your machine running smoothly and gets better results.

Tip: Always think about the total cost, not just the price tag. Include purchase, maintenance, and other expenses. This helps you make smart choices and keep your excavator useful for years.

Important Excavator Spare Parts to Understand

Knowing the key excavator spare parts helps keep your machine working well. Each part is important for smooth operation and less downtime. Below is a simple guide to the main parts you should focus on when fixing or upgrading your excavator.

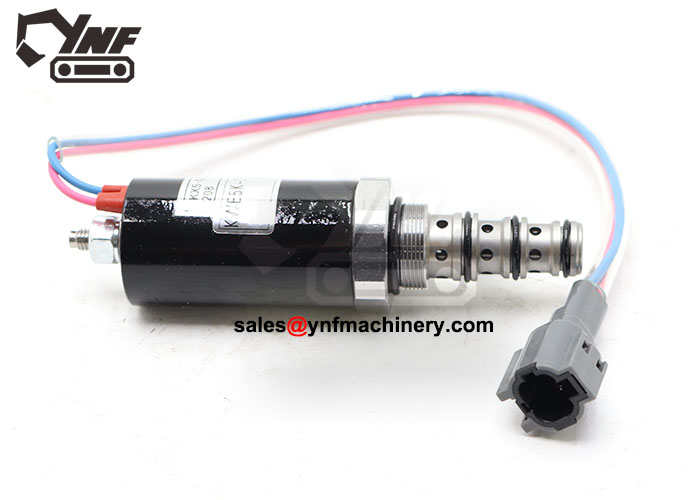

Hydraulic System Parts

The hydraulic system moves most parts of your excavator. This makes its components very important. Check hydraulic parts like pumps, cylinders, and filters often. Regular oil changes and keeping maintenance records can make these parts last longer. Studies show that taking care of these parts prevents cracks and leaks. It also saves energy and reduces emissions, making your machine more efficient.

To avoid sudden problems, always pick high-quality hydraulic parts. Trusted suppliers like Xugong KS provide strong, reliable parts quickly. Spending more on branded parts now can save you time and money later by reducing breakdowns.

Engine and Powertrain Parts

The engine and powertrain give your excavator the power to do heavy work. Parts like pistons, fuel pumps, and turbochargers need to be reliable. Reviews show that engines from Powertrain Products fail 30% less than some OEM options. This means better performance and fewer delays.

When buying engine and powertrain parts, choose suppliers with good reputations. Xugong KS and Yem Parts are great places to find high-quality parts. They offer items like valve seats and gasket kits to keep your excavator running strong.

Undercarriage Parts

Undercarriage parts carry your excavator’s weight and face constant wear. Tracks, rollers, and sprockets must be tough to handle rough ground. Experts say materials with high wear resistance last longer. For example, tungsten carbide works well in light use but may not hold up under heavy stress. Picking the right materials helps your undercarriage parts last.

Cleaning and checking tracks regularly can stop them from wearing out too fast. Strong replacement parts for the undercarriage improve durability and make your excavator more efficient. Suppliers like Xugong KS offer many options to fit your needs.

Tip: Always choose spare parts that match your excavator’s model. This ensures they fit well and work their best.

Attachments and Accessories

Attachments help your excavator do more jobs easily. They make your machine flexible and useful for different tasks. Picking the right attachments helps your excavator work better on projects like building, tearing down, or landscaping.

Each attachment has a special job to do. For example, a thumb attachment helps grab and move heavy items. A stump splitter removes stumps quickly and saves time. Check out the table below to see common attachments and how they help:

Attachment Type | Benefits | Uses |

|---|---|---|

Thumb | Improves grip, making it easier to move things. | Great for lifting and carrying heavy objects. |

Stump Splitter | Works fast and saves money by removing stumps. | Perfect for clearing land and stump removal. |

Grapple | Strong and flexible for grabbing and lifting. | Used in logging and moving heavy materials. |

Circuit Breaker | Breaks concrete and stone with power. | Best for demolition projects. |

Auger | Digs holes quickly for posts and pipes. | Used in roadwork and utility setups. |

Attachments like augers, buckets, and breakers make small excavators more powerful. Quick couplers let you switch attachments fast, saving time and boosting work speed. This makes one machine handle many tasks, saving both time and money.

Think about your project’s needs when picking attachments. For rocky areas, a grapple works well for heavy lifting. If you need to dig holes, an auger is the best choice. Choosing the right tools helps your excavator do its job better and keeps work running smoothly.

Tip: Always check if the attachments fit your excavator model. This ensures they work properly and give the best results.

Avoiding Common Mistakes

Misidentifying Excavator Model Numbers

Getting the wrong model number is a common error. This can make you buy the wrong excavator spare parts. Each model has its own special features. If parts don’t match, you waste time and money. Always find the model number on the machine’s ID plate or in the manual. Check this number carefully before ordering parts. Keeping a detailed list of your equipment can cut mistakes by 5%.

Tip: Write down your excavator’s model numbers and part needs. Keep this list in your toolbox for quick access. It helps avoid costly errors.

OEM vs. Aftermarket Excavator Parts

Deciding between OEM and aftermarket parts is important. OEM parts are made for your excavator and work reliably. They meet high standards and often include good warranties. Aftermarket parts cost less but may not last as long. They might save money at first but could fail sooner.

Affordability: Aftermarket parts are cheaper upfront.

Quality: OEM parts are more reliable, while aftermarket ones may wear out faster.

Warranty and Support: OEM parts have strong warranties; aftermarket ones vary a lot.

Think about cost and reliability. For key parts like hydraulics, OEM is usually better.

Ignoring Warranty Policies

Skipping warranty rules can cost you later. Maintenance is needed to keep your warranty active. If a part breaks, the provider checks for bad care or changes. Keep service logs and receipts to prove proper upkeep. Without these, you might lose coverage.

Note: Read your warranty terms and follow care instructions. This keeps your excavator protected and working well.

Avoiding these mistakes helps you pick the right parts and keeps your machine running smoothly.

Choosing Unverified Suppliers

Getting excavator parts from unknown suppliers can cause big issues. These sellers often skip important quality checks or lack proper certifications. Their parts might not meet industry rules, which can hurt how your excavator works. You could end up wasting money on parts that break quickly.

Some unverified suppliers sell cheaper parts to attract buyers. While the price may seem good, these parts usually wear out faster. Weak materials can lead to breakdowns, costly repairs, and project delays. Always pick quality over low prices when buying parts.

To stay safe, research suppliers before buying anything. Read reviews from other customers. Good reviews mean the supplier sells reliable parts. Check if they offer warranties. A warranty shows they trust their products. Suppliers without warranties may not back up their parts.

Another way to check a supplier is by looking at their certifications. Trusted suppliers follow industry rules and sell parts that fit your excavator well. Unverified ones might sell parts that don’t match your machine. This can cause problems and lower efficiency.

Also, avoid suppliers with unclear return policies. If a part doesn’t work, you need to return or exchange it. Reliable suppliers have clear and simple policies. Unverified ones often don’t, leaving you stuck with bad parts.

Tip: Pick suppliers with a good reputation. Verified suppliers provide high-quality parts that keep your excavator working well.

By avoiding unverified suppliers, you save your excavator from damage and keep your projects on track.

Sourcing Reliable Kato Excavator Parts in the USA

Finding Reputable Dealers

The first step is finding a trusted dealer for parts. Look for dealers who focus on Kato excavator parts USA. These dealers know the equipment well and can help you choose the right parts. Check if the dealer has certifications or works with big brands. Certifications mean they follow industry rules and sell good-quality parts.

Ask about their inventory. A good dealer will have many parts, like hydraulic systems, undercarriage pieces, and engine components. This makes it easier to find what you need quickly. Also, ask about their return policies. Clear policies let you return parts if they don’t fit or work properly.

Tip: If possible, visit the dealer’s store. Seeing the parts in person helps you check their quality and fit.

Evaluating Online Reviews

Online reviews help you learn about a dealer’s reliability. Read reviews from other buyers to see their experiences. Look for comments about part quality, delivery speed, and customer service. Positive reviews show the dealer sells reliable parts and helps customers well.

Pay attention to repeated complaints in bad reviews. If many people mention poor-quality parts or slow shipping, pick another dealer. Reviews on Google, Yelp, or construction forums are usually more trustworthy than those on the dealer’s website.

Note: Don’t just look at star ratings. Read full reviews to understand the dealer’s strengths and weaknesses.

Comparing Prices and Delivery Options

Compare prices to find good deals without losing quality. Check costs from different dealers. Cheap prices might mean lower quality, so aim for parts that are affordable and durable.

Delivery options matter too. Fast shipping ensures you get parts on time. Some dealers offer quick delivery for urgent needs or free shipping for large orders. Check if they ship to your area and provide tracking for your order.

Make a list of dealers with fair prices and reliable delivery. This helps you choose wisely and avoid project delays.

Tip: Ask about discounts for bulk orders or repeat purchases. Many dealers offer deals that save money.

Checking Customer Support Services

Good customer support helps you find the right excavator parts. It saves time, cuts costs, and makes your work smoother. When reviewing support, focus on how fast they reply, their knowledge, and the services they offer.

Why Customer Support is Important

Great customer support can improve your excavator’s performance and project success. Suppliers with helpful support keep your machine running without delays.

Quick replies can cut downtime by 30%.

Expert advice boosts maintenance efficiency by 25%.

Strong supplier relationships lower costs by 25% and improve part availability by 40%.

These points show why choosing suppliers with good support matters.

What to Look For

When checking customer support, look for these key features:

Availability: Make sure support is open when you need it. Some suppliers even offer 24/7 help for emergencies.

Expertise: Staff should know about Kato excavator parts USA and give accurate advice.

Contact Options: Multiple ways to reach them, like phone, email, or chat, are helpful.

Problem Solving: See how quickly they fix issues like wrong orders or broken parts.

Tip: Ask about response times and how they handle problems before buying.

How Good Support Helps You

Reliable support ensures you get the right parts quickly. For example, if you urgently need hydraulic parts, fast help avoids delays. Support teams can also guide you on installation, warranties, and maintenance, making things easier.

Suppliers with great support often offer extras like order tracking or discounts for bulk purchases. These perks add value and improve your experience.

Questions to Ask

To check customer support, ask these questions:

How fast do you answer questions?

Do you give advice on picking the right parts?

What’s your process for returns or exchanges?

Can I see reviews or references from other buyers?

These questions help you see if the supplier is reliable and cares about good service.

Note: A supplier with strong support helps you get the right parts, reduces delays, and keeps your excavator working well.

Picking the right excavator parts needs careful thought. Think about your machine’s needs and the job you’re doing. Choose parts that are strong and fit well. This helps your excavator work better and avoids breakdowns. Always check the model number and buy from trusted sellers. Durable parts save money and make your equipment last longer.

Smart choices keep your excavator working without problems. Research and spend time finding the best parts. This improves how your machine works and reduces delays. Good parts mean better results and fewer issues.

FAQ

How can you find your Kato excavator model number?

Check the ID plate on your excavator. It’s often near the cabin or engine. If it’s hard to locate, look in the user manual. Write down the model number to avoid buying the wrong parts.

Are aftermarket parts good for Kato excavators?

Aftermarket parts work fine for less important components. But for key systems like hydraulics or engines, OEM parts are more dependable. Always check the supplier’s reviews before buying aftermarket parts.

When should hydraulic filters be replaced?

Change hydraulic filters every 500 to 1,000 working hours. This stops dirt from damaging the system and helps it last longer. Check your manual for exact timing.

Do attachments fit different excavator models?

Some attachments, like buckets or augers, fit many models if they use universal couplers. Always check your excavator’s specs to ensure they match. This guarantees they’ll work properly.

What should you look for when buying used excavator parts?

Look for cracks, rust, or wear. Ask for service records and warranties. Good suppliers test used parts for quality. Avoid parts with damage or unclear histories.

Tip: Focus on quality, not just price, when picking excavator parts. Good parts save money over time.