The John Deere 290D excavator is a reliable machine that handles demanding tasks in construction and excavation. To keep it running smoothly, you need to understand its key components and address common issues related to John Deere 290D excavator parts. Overheating often occurs in the travel motor. You can prevent this by inspecting the exhaust system and keeping the radiator clean. Another frequent problem is failure to move, usually caused by defects in the main control valve. Adjusting or replacing the PC and LS valves can resolve this. Regular maintenance of your John Deere 290D excavator parts ensures your excavator performs at its best.

Key Takeaways

Taking care of your John Deere 290D parts is important. Check fluids daily and grease joints to avoid problems.

Learn how main parts, like the engine and hydraulics, work. This helps you fix issues more easily.

Buying good replacement parts from YNF Machinery makes your excavator last longer and work better.

Pick the right tracks, steel or rubber, for your job. Each type works best in certain conditions.

Know safety features like ROPS and emergency controls. These keep you safe in tough areas.

Engine and Powertrain Components

Engine Assembly

Function and Importance

The engine serves as the heart of your John Deere 290D excavator. It generates the power needed to operate the machine’s hydraulic systems and other components. A well-functioning engine ensures smooth digging, lifting, and moving operations. Without it, the excavator cannot perform its tasks efficiently. The engine’s role in converting fuel into mechanical energy makes it one of the most critical parts of the machine.

Maintenance Tips

Regular maintenance keeps the engine running at peak performance. Start by checking the oil levels and replacing the oil filter as needed. Clean or replace the air filter to prevent debris from entering the engine. Inspect the fuel system for leaks or blockages. Keep the cooling system in good condition by cleaning the radiator and ensuring proper coolant levels. These steps help you avoid costly repairs and extend the life of your excavator.

Excavator Engine Parts by YNF Machinery

Overview of YNF Machinery’s Engine Parts

YNF Machinery offers a wide range of engine parts designed for durability and efficiency. Their selection includes pistons, crankshafts, gaskets, and turbochargers. These parts meet or exceed OEM standards, ensuring compatibility with your John Deere 290D excavator. YNF Machinery provides both OEM and aftermarket options, giving you flexibility in choosing the right parts for your needs.

Benefits of Using High-Quality Engine Parts

High-quality engine parts improve your excavator’s performance and reliability. They reduce the risk of breakdowns and minimize downtime. Durable components also lower maintenance costs over time. YNF Machinery’s parts are built to withstand harsh conditions, ensuring your excavator operates smoothly even in demanding environments. By investing in quality parts, you enhance the longevity of your machine.

Transmission System

Function and Maintenance Tips

The transmission system transfers power from the engine to the tracks, enabling movement. It plays a vital role in the excavator’s mobility and efficiency. To maintain it, inspect the undercarriage and tracks regularly. Significant wear and tear on these parts can lead to transmission issues. Damaged tracks or tires may cause the machine to move slowly or deviate from its path. Address these problems promptly to avoid further complications. Regular lubrication of moving parts also helps maintain smooth operation.

Hydraulic System Essentials

Hydraulic Pumps and Cylinders

Importance in Excavator Operation

Hydraulic pumps and cylinders are vital for the operation of your excavator. These components ensure smooth and efficient performance during heavy-duty tasks.

Hydraulic pumps convert mechanical energy into hydraulic pressure energy.

They supply high-pressure hydraulic oil to various parts of the excavator.

Hydraulic cylinders transform this fluid pressure into mechanical force, enabling movement and lifting.

Without these components, your excavator cannot perform essential functions like digging, lifting, or rotating. Their role in powering the hydraulic system makes them indispensable for the machine’s operation.

Maintenance and Troubleshooting

Proper maintenance of hydraulic pumps and cylinders prevents costly failures. Regularly filter and replace hydraulic fluid to keep the system clean. Inspect seals and piston rods for wear and replace them as needed. Keep the excavator free of debris to avoid contamination. Follow the manufacturer’s maintenance schedule to ensure optimal performance.

Common hydraulic system failures include slow or erratic movement, leaks, and overheating. These issues often result from low oil levels, aging seals, or pump failure. Regular monitoring of oil levels and component conditions helps you prevent these problems. Contamination, caused by air or water, accounts for most hydraulic failures. Water can lead to oxidation and freeze damage, so addressing contamination promptly is crucial.

Hydraulic Cylinder Seal Kits by YNF Machinery

Features and Benefits

YNF Machinery offers high-quality hydraulic cylinder seal kits designed to prevent oil leaks and maintain efficiency. These kits use durable materials like NBR and FKM, ensuring flexibility and resistance to wear. They provide a tight seal, preventing contamination and ensuring smooth operation. Each kit undergoes rigorous quality checks to meet international standards.

Using these seal kits reduces downtime and extends the lifespan of your excavator. Their precise design ensures a perfect fit, minimizing the risk of misalignment. With YNF Machinery’s seal kits, you can maintain the performance of your John Deere 290D excavator parts effectively.

How to Choose the Right Seal Kit

Selecting the correct seal kit depends on your excavator’s model and specifications. Check the part number of your hydraulic cylinder to ensure compatibility. YNF Machinery offers a wide range of kits for various brands and models, making it easy to find the right one. If you’re unsure, their customer support team can guide you in choosing the best option for your needs.

Control Valves and Hoses

Function and Maintenance Tips

Control valves and hoses play a critical role in directing hydraulic fluid to different parts of the excavator. Valves regulate the flow and pressure of the fluid, while hoses transport it between components. Together, they ensure the hydraulic system operates efficiently.

To maintain these parts, inspect hoses for cracks or leaks and replace them immediately if damaged. Clean the valves regularly to prevent blockages. Ensure all connections are secure to avoid fluid loss. Proper maintenance of these components helps you avoid system failures and keeps your excavator running smoothly.

Undercarriage and Mobility

Tracks and Track Chains

Steel vs. Rubber Tracks

Choosing between steel and rubber tracks depends on your excavator’s operating environment. Steel tracks excel in durability and perform well in harsh conditions like rocky terrains or demolition sites. They provide excellent traction on loose or uneven ground, making them ideal for quarries or construction zones. However, steel tracks generate more noise and vibration, which can be disruptive in residential areas.

Rubber tracks, on the other hand, are quieter and cause less vibration. They work best in urban settings where minimizing surface damage is crucial. These tracks offer better stability on soft surfaces but are less durable in demanding conditions. Their flexibility reduces load points, making them suitable for less abrasive environments.

Maintenance and Replacement Tips

Regular inspection of tracks and track chains ensures optimal performance. Loose tracks can lead to de-tracking, while over-tightened tracks may cause power loss and excessive wear. Look for signs of damage, such as exposed cables or missing rubber chunks. Evaluate the track links; losing links indicates the need for replacement. Addressing these issues promptly prevents further damage and extends the life of your excavator.

Rollers, Idlers, and Sprockets

Function and Wear Indicators

Rollers, idlers, and sprockets play a vital role in your excavator’s mobility. The bottom rollers support the machine’s weight and distribute it evenly across the tracks. Upper rollers prevent the tracks from sagging. Idlers maintain track tension, while sprockets convert engine power into movement by engaging with the track’s bushings. Together, these components ensure smooth operation.

Signs of wear include oil leaks around seals, excessive noise, and uneven wear. Missing or broken sprocket teeth and chain slippage also indicate the need for maintenance. Heat around seals or bearings suggests potential failure. Regular checks help you identify these issues early.

Replacement Guidelines

Replace worn components promptly to avoid further damage. Uneven wear on rollers or idlers can affect track alignment. Damaged sprockets reduce efficiency and increase the risk of breakdowns. Always use high-quality replacement parts to maintain your excavator’s performance.

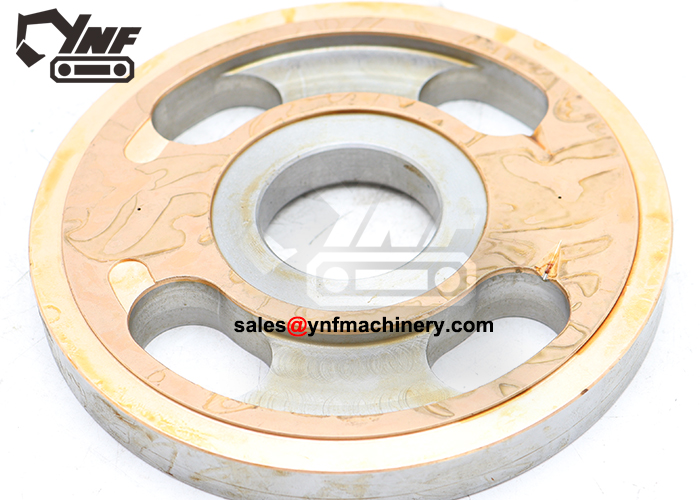

Excavator Couplings by YNF Machinery

Role in Power Transmission

Excavator couplings connect the engine to the hydraulic pump system, ensuring efficient power transmission. They compensate for misalignment and reduce vibration, which protects the engine and hydraulic components. This connection is essential for smooth operation and optimal performance.

Advantages of YNF Machinery’s Couplings

YNF Machinery provides durable and reliable excavator couplings. These couplings are crafted from high-quality materials and designed for easy installation. They handle tough conditions, minimizing downtime and maintenance needs. With options like Centaflex-A and Bowex couplings, YNF Machinery ensures compatibility with various excavator models. By choosing their products, you enhance your machine’s efficiency and longevity.

Operator’s Cabin and Controls

Control Panel and Electrical Components

Key Features and Troubleshooting

The control panel in your John Deere 290D excavator serves as the command center. It houses essential electrical components that regulate the machine’s operations. Key features include intuitive controls, digital displays, and warning indicators that help you monitor performance. These features ensure smooth operation and quick identification of potential issues.

Electrical problems can disrupt your excavator’s performance. Regular voltage testing helps you detect issues early, avoiding costly repairs. Monitoring the electrical system improves reliability and extends the lifespan of critical components. Load evaluations can identify hidden problems before they escalate.

To troubleshoot, visually inspect for loose wires or corrosion. Check for frayed wiring harnesses and secure all connections with a torque wrench. Grounding connections often reveal hidden faults. Simple fixes, like tightening connections or replacing fuses, can restore functionality and improve performance.

Seat and Ergonomics

Importance of Operator Comfort

Operator comfort plays a significant role in productivity. A comfortable seat reduces fatigue, allowing you to work longer hours with better focus. Ergonomic designs enhance performance by minimizing strain on your body. Features like adjustable seats, lumbar support, and armrests improve posture and reduce discomfort.

Additional conveniences, such as Bluetooth radios, storage compartments, and cup holders, make long shifts more manageable. These features create a more pleasant working environment, boosting efficiency and overall job satisfaction.

Maintenance Tips

Maintaining the operator’s seat ensures long-term comfort and functionality. Regularly clean the seat to remove dirt and debris. Inspect for tears or wear in the upholstery and repair them promptly. Check the adjustment mechanisms to ensure smooth operation. Lubricate moving parts to prevent stiffness. These steps keep the seat in optimal condition, enhancing your comfort during operation.

Safety Features

ROPS (Roll-Over Protective Structure)

The ROPS in your excavator provides critical protection during rollovers. These structures are ISO-certified and designed to withstand the forces of a rollover, keeping you safe in challenging terrains. With the increasing use of excavators on steep sites, ROPS has become essential. Advances in materials and design ensure these structures meet modern safety standards, offering peace of mind during operation.

Emergency Controls

Emergency controls are vital for ensuring safety in critical situations. These controls allow you to quickly shut down the machine or stop specific functions during emergencies. Familiarize yourself with their locations and operation to respond effectively when needed. Regularly test these controls to ensure they function correctly. Proper training and maintenance of emergency systems enhance safety and reduce risks.

Attachments and Accessories

Buckets, Boom, and Arm

Types of Buckets and Their Uses

Buckets, booms, and arms are essential attachments for your excavator. Buckets come in various types, each suited for specific tasks. General-purpose buckets handle digging and loading efficiently. Heavy-duty buckets work best for tough materials like rock or compacted soil. Trenching buckets create narrow trenches for utilities, while grading buckets excel in leveling and finishing tasks. Choosing the right bucket ensures optimal performance for your project.

Maintenance Tips for Attachments

Proper maintenance extends the life of your attachments. Follow these best practices:

Power wash hydraulic breakers to remove dirt and grime.

Inspect retaining pins weekly and check tool shank and bushings monthly.

Look for cracks in mounting hinges and repair them immediately.

Visually inspect bucket edges and corners for thinning or cracking. Re-plate or replace edges if necessary.

Rotate worn teeth regularly to maximize their lifespan.

Daily checks help you identify potential issues early, ensuring safe and efficient operation.

Quick Couplers

Benefits of Quick Couplers

Quick couplers simplify attachment changes, enhancing the versatility of your excavator. They allow you to switch tools rapidly from inside the cab, reducing downtime and boosting productivity. High-quality couplers include safety features like locking mechanisms to prevent accidental releases. Tilting quick couplers add flexibility by enabling tools to tilt at various angles, making them ideal for diverse tasks.

Maintenance and Replacement Tips

Maintaining quick couplers ensures their reliability. Inspect hydraulic components for leaks and check locking mechanisms regularly. Keep safety features functional to avoid unintended attachment releases. Discuss potential risks with your team to promote job site safety. Proper care minimizes the risk of failure and extends the lifespan of your couplers.

YNF Machinery’s Excavator Attachments

Overview of Available Attachments

YNF Machinery offers a wide range of high-quality attachments for your John Deere 290D excavator. Their selection includes buckets, booms, arms, and quick couplers designed for durability and efficiency. These attachments meet international standards, ensuring compatibility and reliable performance. Whether you need tools for digging, grading, or lifting, YNF Machinery provides solutions tailored to your needs.

Why Choose YNF Machinery for Attachments

Choosing YNF Machinery guarantees quality and reliability. Their attachments improve efficiency by reducing the risk of breakdowns. Advanced engineering enhances durability, allowing the tools to withstand rigorous use. High-quality materials contribute to better fuel efficiency and lower emissions. With YNF Machinery, you invest in attachments that enhance safety, performance, and longevity.

The John Deere 290D excavator depends on its essential parts to deliver reliable performance. Regular maintenance ensures these components function efficiently, reducing the risk of costly breakdowns. Daily checks, such as inspecting fluid levels, greasing joints, and monitoring the undercarriage, help you identify potential issues early. High-quality replacement parts, like those from YNF Machinery, enhance durability and operational efficiency. These parts also improve fuel economy and reduce emissions, offering long-term savings. By understanding your excavator’s key systems and maintaining them properly, you can minimize downtime and extend its lifespan.

FAQ

1. How often should you perform maintenance on your John Deere 290D excavator?

You should perform maintenance daily for basic checks like fluid levels and greasing. Schedule more thorough inspections, such as hydraulic system checks, every 250 hours. Follow the manufacturer’s maintenance schedule for optimal performance.

Tip: Regular maintenance prevents costly repairs and extends your excavator’s lifespan.

2. What are the signs of a failing hydraulic pump?

Look for slow or erratic movements, unusual noises, or overheating. Leaks and reduced hydraulic pressure also indicate pump issues. Address these signs immediately to avoid further damage.

Note: Regularly replacing hydraulic fluid helps prevent pump failure.

3. How do you choose the right replacement parts for your excavator?

Identify the part number and model of your excavator. Check compatibility with OEM or aftermarket options. YNF Machinery offers expert support to help you find the correct parts.

Tip: Always use high-quality parts to ensure durability and efficiency.

4. Why should you inspect the undercarriage regularly?

The undercarriage supports the machine’s weight and ensures mobility. Regular inspections help you detect wear on tracks, rollers, and sprockets. Prompt repairs prevent further damage and maintain performance.

Reminder: Clean the undercarriage after each use to avoid debris buildup.

5. What makes YNF Machinery a reliable choice for excavator parts?

YNF Machinery provides high-quality parts that meet international standards. Their products are durable, efficient, and competitively priced. With over 35 years of experience, they offer excellent customer support and fast shipping.

Emoji: Pro Tip: Investing in quality parts reduces downtime and saves money in the long run.