You can perform a hydraulic pump coupling replacement by following easy steps. Make sure you pay close attention to safety. Always get the right tools and parts before you start. Replacing a hydraulic pump coupling requires care, as hydraulic systems can have very high pressure. Sudden fluid leaks can be dangerous.

Common safety tips:

Wear gloves and safety glasses.

Let out all pressure before you disconnect any coupler.

Never touch hoses or fittings if there is pressure.

Check couplers for damage or dirt.

If you notice slow operation, new sounds, leaks, or heat, these signs may indicate that a hydraulic pump coupling replacement is necessary. Careful planning and following each step in order will help you complete the job safely and effectively.

Key Takeaways

Always put safety first when you work on hydraulic systems. Wear gloves and safety glasses. Make sure to release all pressure before you start.

Get all the tools and parts you need before you begin. Being prepared helps you work faster and make fewer mistakes.

Look for signs that show the coupling needs to be replaced. These signs include leaks, strange noises, or slow working. Fix these problems quickly to keep the system working well.

Make sure the coupler halves line up right when you install them. If they do not line up, it can cause too much wear and damage the system.

Check and take care of your hydraulic pump coupling often. Monthly checks help you find problems early and make your equipment last longer.

Preparation

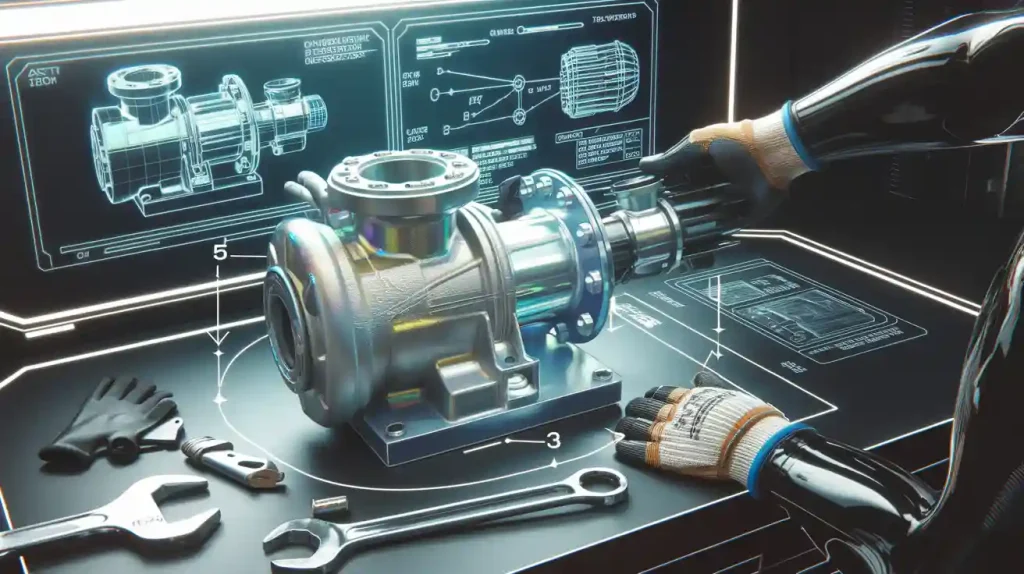

Gather Tools and Parts

Get all your tools and parts before you start. This helps you work faster and make fewer mistakes. You need these items ready:

Tool/Part | Purpose |

|---|---|

Wrenches | Loosen and tighten bolts |

Rags | Clean surfaces and catch spills |

Puller tool | Remove old couplings |

Replacement hydraulic pump coupling | Install new coupling |

Flexible pump coupler | Connect pump and motor |

Safety gloves | Protect your hands |

Safety glasses | Shield your eyes |

Always use good parts for your hydraulic pump coupling and flexible pump coupler. YNF Machinery sells strong couplings and other parts. Their products help you get a tight fit and last a long time.

Safety Precautions

Safety is very important when you work on hydraulic systems. Follow these steps to keep yourself and others safe:

Turn off the power. Make sure no one can turn it on by mistake.

Let out all hydraulic pressure before you begin. Never touch hoses or fittings if there is pressure.

Wear safety gloves and glasses every time.

Do not leave the hydraulic system alone while it is running.

Rules for hydraulics, like OSHA standards, tell you how to work safely and what is allowed.

You should also get ready for emergencies:

Put emergency phone numbers near your work area.

Practice emergency drills often.

Check fire extinguishers, first aid kits, and spill tools regularly.

Go to training and safety classes to learn more.

Keep your certifications and join skill programs.

When you follow these safety rules, you keep yourself and your equipment safe. You also help stop accidents during flexible pump coupler installation and hydraulic pump coupling replacement.

Access and Remove Old Coupling

Remove Covers

Start by making sure your work area is safe and clean. You need to see the hydraulic pump coupling clearly before you begin. Follow these steps:

Check that the power is off and all pressure is released.

Look for any covers or guards around the coupling.

Use the correct tool, like a screwdriver or wrench, to remove these covers.

Place the covers and screws in a safe spot so you do not lose them.

Tip: Wipe away any dirt or oil from the area. This helps you see the flexible pump coupler and prevents debris from falling into the system.

Loosen Bolts or Set Screws

Once you have access, you can start to remove the old coupling. Most hydraulic pump couplings use bolts or set screws to hold them in place. Here is how you do it:

Inspect the coupling for corrosion or debris. Clean it if needed.

Find all bolts or set screws on the flexible pump coupler.

Use the right size wrench to loosen each bolt. Apply steady pressure.

If a bolt feels stuck, spray a little penetrating oil and wait a few minutes.

For stubborn bolts, use extra leverage, but do not use too much force.

Note: Always loosen bolts in a crisscross pattern if there are several. This keeps the pressure even and prevents damage.

Use Puller Tool if Needed

Sometimes, the coupling will not slide off easily. In this case, you need a puller tool. This tool helps you remove the coupling without damaging the shaft or the flexible pump coupler.

Attach the puller tool to the coupling hub.

Turn the puller slowly and steadily. Do not rush.

If the coupling is still stuck, apply more penetrating oil and let it sit.

For very tight couplings, you can use a hydraulic puller and heat the hub gently with a torch. Always monitor the temperature so you do not overheat the shaft.

If needed, tap the puller gently with a hammer to help loosen the coupling.

Be patient. Forcing the coupling can damage the shaft or the new parts you plan to install during your hydraulic pump coupling replacement.

When you finish these steps, you will have removed the old coupling and prepared the area for the new one. This careful process protects your equipment and makes the next steps easier.

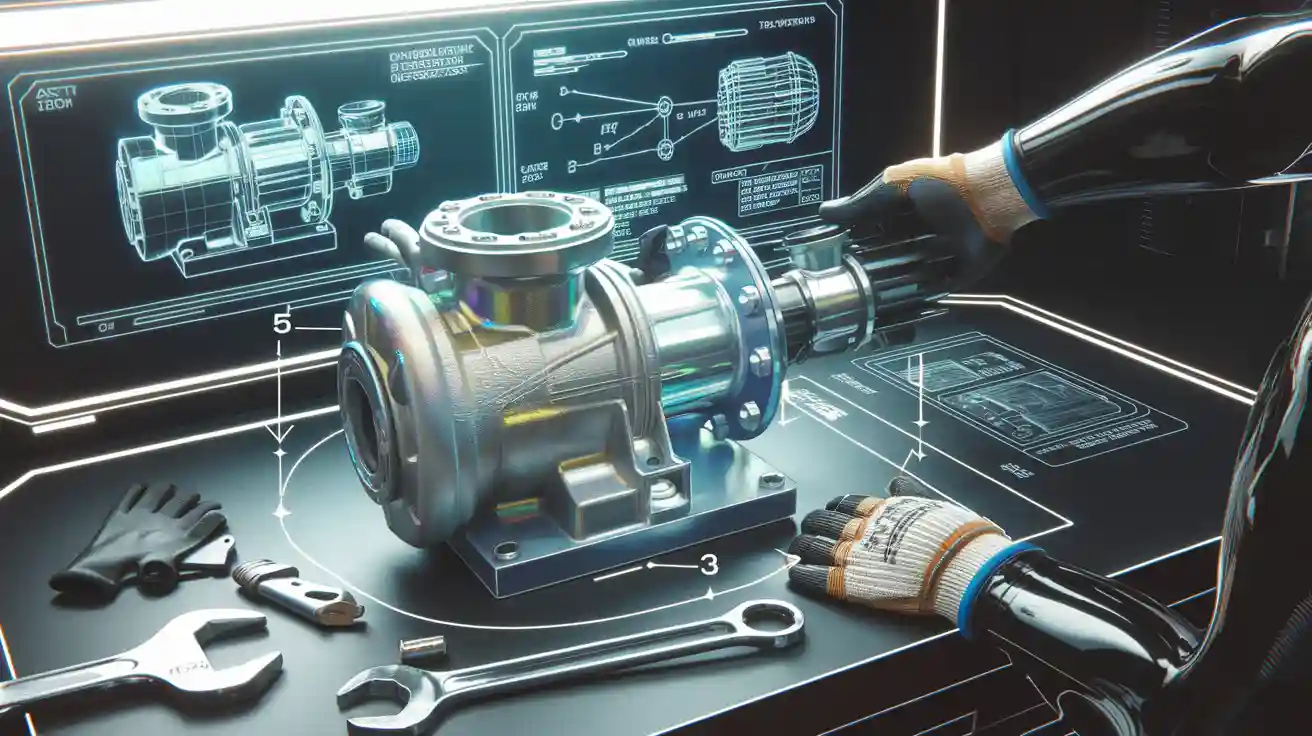

Install Coupling

Align Coupler Halves

You need to line up the coupler halves carefully. Good alignment helps the flexible pump coupler work well. It also stops damage from happening. There are different ways to check if things are lined up right:

Laser alignment systems use a laser beam. They show you where the shafts do not match up.

Manual tools like straightedges, taper gauges, feeler gauges, or dial indicators help check alignment. These tools let you see if the coupler faces and shafts fit together.

For a quick check, put gauges between the coupling faces. This helps you see if the angle is right. Use a straightedge across the rims to check if they are even.

The dial indicator method gives very good results. It works even if the coupling faces are not perfect.

Tip: Always check both the angle and if the parts are even. If things are not lined up, the flexible pump coupler can shake, wear out, or break.

Consequence | Description |

|---|---|

High vibration | Can make parts wear out faster or break. |

Premature failure of the coupling | Happens when misalignment puts too much stress on it. |

Excessive wear on parts | Means you need to fix or replace parts more often. |

Potential damage to pump and driver | Misalignment can cause big problems for the pump and driver. |

Increased maintenance costs | You will need to repair or replace things more often. |

Safety concerns | Broken equipment can be dangerous for people nearby. |

Misalignment can happen if the shaft is bent, there is not enough grease, or you use the wrong coupling. About half of all rotating equipment problems come from misalignment. You can stop these issues by using the right tools and checking your work.

Secure Bolts

After lining up the coupler halves, you must tighten the bolts. Tightening bolts the right way keeps your hydraulic pump coupling replacement safe. Here is what you should do:

Look at the manufacturer’s guide for how tight the bolts should be. This depends on the flange, bolt size, and what it is made of.

For some machines, like the CAT 259D skid steer, the bolts should be 30-40 ft-lbs tight.

Use a torque wrench to tighten each bolt. Tighten them in a crisscross pattern and make sure the force is even.

Do not make the bolts too tight. Too much force can break the coupler or make it not line up.

After tightening, look for cracks or bent parts. Checking often helps you find problems early.

Note: Tightening bolts the right way stops leaks, shaking, and uneven pressure. Always check the manufacturer’s guide or SAE J518 standards for your flexible pump coupler.

If you do not tighten bolts right, the coupler can move, shake, or wear out fast. Paying attention to these steps helps your system work well.

Reassemble Components

When the bolts are tight, you can put the other hydraulic pump parts back together. Follow the instructions from the manufacturer. This helps your pump work like new.

Use old and new parts as needed. Clean every part before putting it back.

Put covers and guards back where they belong. Make sure all fasteners are tight.

Check that hoses, fittings, and connections are clean and have no dirt.

After putting everything together, test the pump with a checklist. Watch for leaks, strange sounds, and make sure it works right.

Callout: YNF Machinery makes strong couplings and flexible pump coupler parts. Their products help you get a good fit and last a long time.

You need to follow these steps to finish your hydraulic pump coupling replacement. Careful work and testing help you avoid trouble and keep your equipment safe.

Test System

Check Alignment

When you finish putting in the new coupling, check if it lines up right. Good alignment helps your hydraulic pump work well and stops damage. Follow these steps to make sure everything fits:

Make sure set screws are tight enough. Use a torque wrench to check.

Look for worn or loose keys. Change any broken parts.

Check the shaft for cracks or wear. A loose hub can cause trouble.

Make sure all coupling parts are bolted tight.

Look at the guard. If it touches the coupling, fix or change it.

Add lubricant if your coupling needs it. Check for leaks and change gaskets or sealing rings if needed.

Tip: Always check if the angles and positions match the design. This helps your system last longer and wear less.

Look at your system often to find cracks or bent parts early. If you hear strange noises or feel shaking, you may need to fix the alignment.

Run and Inspect

After you check the alignment, turn on the hydraulic pump and look at the system. Do these steps to make sure your hydraulic pump coupling replacement works right:

Look for damage like cracks, rust, or worn seals.

Check the system pressure and see if it matches the guide.

Listen for odd noises or shaking. These can mean things are not lined up or are worn inside.

Look at the hydraulic fluid. Make sure it is not dirty or a strange color.

Watch the pump temperature. It should stay in the safe range.

Check valves and filters. Clean or change them if needed.

Measure the pump shaft’s RPM to see if there are alignment or motor problems.

Leaks can happen after you put in the new parts. Leaks can come from worn parts, bad installation, dirt, or broken seals or O-rings. If you see leaks, use UV dye or pressure tests to find them. Fix any problems before you use the pump like normal.

Callout: YNF Machinery sells strong couplings and replacement parts. Their products help you line things up right and stop leaks.

Careful testing and checking keep your hydraulic system safe and working well.

Hydraulic Pump Coupling Replacement Tips

Common Mistakes

You can stop many problems if you know common mistakes. These mistakes often make machines stop and cost more money:

Using the wrong replacement parts

Not checking part numbers

Not making sure the system pressure and fluid are right

Not using OEM-equivalent parts, which can cause bad fluid flow and system problems

Here is a real example. In one factory, a worker put in a new directional valve without checking if it fit. The new valve did not work with the system. The machine stopped for 18 hours until they fixed it.

Tip: Always check part numbers and use OEM-equivalent parts from good suppliers like YNF Machinery. This helps you avoid mistakes and keeps your system working well.

Maintenance Advice

You can make your hydraulic pump coupling last longer with good care. Regular checks help you find problems early and stop breakdowns.

Maintenance Practice | Description |

|---|---|

Regular Inspection and Lubrication | Check often to find wear or misalignment early. Lubrication stops friction and damage. |

Correct Alignment and Installation | Lining up parts right is very important. Bad alignment puts stress and makes couplings wear out faster. |

You should check couplings every month as part of your plan. This helps you find problems before they get worse.

If you see problems after you finish, try these steps:

Look at the relief valve and coupling to see if they work.

Check if things are lined up right. Bad alignment can make things shake.

Look for wear or damage on the coupling. Change any parts that are not good.

Note: Good suppliers like YNF Machinery have strong couplings and replacement parts. Using good products makes care easier and helps your equipment last longer.

If you follow these tips, your hydraulic system will be safe and work well. Checking often and putting parts in right saves money and keeps your equipment working.

You can change a hydraulic pump coupling if you follow each step. Make sure you check your work as you go. Safety and alignment are very important before you start the pump. Look at this table to help you remember what to check:

Check Type | Description |

|---|---|

Safety | Lock out and tag out equipment before you begin. |

Soft Foot Check | Look for soft foot problems on the driver, both parallel and angular. |

Alignment Procedure | Align shafts with the coupling spacer taken off for best results. |

Shaft Runout Verification | Measure shaft runout; fix it if it is more than 0.002 inches. |

Test the system all the way before you use it normally. If you do not feel sure, read the manual or ask someone who knows more. YNF Machinery sells strong couplings and parts for your hydraulic system.

FAQ

How often should you inspect a hydraulic pump coupling?

You should check your hydraulic pump coupling every month. Regular inspection helps you find wear, misalignment, or leaks early. This keeps your system safe and working well.

What signs show a coupling needs replacement?

Look for new noises, leaks, shaking, or slow operation. If you see cracks or worn parts, you should replace the coupling soon. These signs mean your system may not work right.

Can you use any coupling for your hydraulic pump?

No, you must use the correct type and size for your pump. Always check the part number and match it with your system. YNF Machinery offers strong couplings for many pumps, including the log splitter pump coupler.

Do you need special tools to replace a coupling?

You need basic tools like wrenches and a puller tool. Some jobs may need a torque wrench or alignment tools. Using the right tools helps you finish the job safely and quickly.

Where can you buy quality hydraulic pump couplings?

You can buy strong and reliable hydraulic pump couplings from YNF Machinery. They offer many types, including flexible couplers and log splitter pump coupler options.