Hitachi excavator parts diagrams play a vital role in ensuring precise repairs and effective maintenance. These diagrams provide clear visual representations of components, making it easier for you to identify parts and understand their interactions. By consulting these diagrams, you can detect worn or damaged components early, preventing costly breakdowns. They also streamline maintenance activities by helping you cross-reference part numbers for quick ordering. Reliable suppliers like YNF Machinery enhance this process by offering high-quality parts, ensuring your excavator operates efficiently and safely.

Key Takeaways

Hitachi excavator parts diagrams show parts and their uses, helping with repairs.

Learn the common symbols and notes in diagrams to prevent errors during fixes.

Set up your workspace and collect tools before using diagrams for easy repairs.

Check part numbers with catalogs to make sure they match and avoid wrong orders.

Keep a collection of diagrams to make repairs faster and save time.

Understanding Hitachi Excavator Parts Diagrams

Common Symbols and Notations in Diagrams

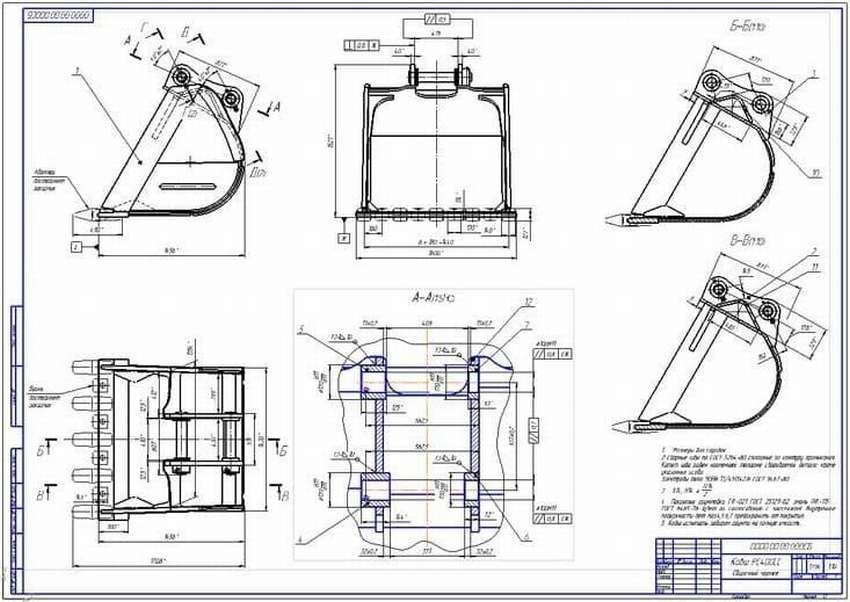

Hitachi excavator parts diagrams use standardized symbols to represent various components, making it easier for you to identify and understand them. Mechanical symbols often depict critical parts like the boom, bucket, and undercarriage. For instance, the boom symbol represents the arm extending from the excavator, while the bucket symbol indicates the attachment used for digging. Electrical symbols, on the other hand, illustrate wiring and electrical systems. These symbols are essential for troubleshooting and maintaining the excavator’s electrical components. Familiarizing yourself with these notations ensures you can quickly locate and address issues during maintenance.

Interpreting the Layout and Legend for Maintenance

The layout of Hitachi excavator parts diagrams provides a clear visual representation of how components fit together. Each diagram includes a legend that explains the meaning of the symbols used. Start by reviewing the legend to understand the significance of each symbol. This step is crucial for accurate identification and effective communication, especially when working with different models. Misinterpreting symbols can lead to incorrect assembly or skipped maintenance steps. By carefully studying the layout and legend, you can streamline your maintenance tasks and avoid costly errors.

Importance of Accurate Diagrams for Repairs

Accurate diagrams are indispensable when performing repairs on complex machinery like excavators. They provide detailed visual guidance, helping you follow the correct steps and avoid mistakes. Technical manuals often include these diagrams, serving as a valuable resource even for experienced mechanics. Keeping these manuals accessible ensures you don’t overlook any critical steps during repairs. Whether you’re tackling an unfamiliar task or refreshing your knowledge, accurate diagrams save time and enhance the efficiency of your work.

Step-by-Step Guide to Using Hitachi Excavator Parts Diagrams

Preparing for Maintenance with the Right Diagram

Before starting any maintenance task, you must prepare thoroughly to ensure efficiency and accuracy. Begin by cleaning the excavator to remove dirt and debris. This step prevents contamination during disassembly. Next, inspect the machine for visible issues like leaks or worn-out components. Record the model and serial number to ensure you use the correct Hitachi excavator parts diagram. Organize your workspace by gathering all necessary tools and ensuring the area is clean and well-lit.

Familiarize yourself with the diagram layout before diving into the task. Study the labeling of each section to locate components quickly. If the diagram includes small details, use a magnifying glass for better clarity. Keep a notepad handy to jot down part numbers or notes for easier reference during the process. These preparatory steps streamline your workflow and reduce the chances of errors.

Tip: A well-prepared workspace and a clear understanding of the diagram save time and prevent mistakes during maintenance.

Identifying Parts and Cross-Referencing with Catalogs

Identifying excavator parts accurately is crucial for effective maintenance. Use the Hitachi excavator parts diagram to locate the required components. Cross-reference the part numbers from the diagram with a parts catalog to confirm compatibility. This step ensures you order the correct parts and avoid delays caused by mismatched components.

Modern tools, like AI-enabled systems, have made cross-referencing faster and more accurate. These systems retrieve data quickly, reducing the time spent searching for parts. By combining the diagram with a catalog, you enhance precision and efficiency in repair processes. This method minimizes errors and ensures the right parts are available when needed.

Applying Diagrams for Repairs and Reassembly

Using diagrams during repairs and reassembly simplifies complex tasks. Start by noting the part numbers and descriptions from the diagram. Include any annotations, such as torque values or material specifications, to ensure proper installation. Capture exploded views or annotated sections of the diagram for reference. Highlight the specific components you are working on to avoid confusion.

Log the date of the repair and any observations about the parts’ condition, such as wear or damage. Organize your findings by system, such as the hydraulic system or engine, to maintain a clear record. These practices ensure smooth reassembly and help you track maintenance history for future reference.

Note: Accurate documentation and careful use of diagrams improve the efficiency of repair processes and reduce downtime.

Troubleshooting Common Issues with Hitachi Excavator Parts Diagrams

Resolving Ambiguities in Diagrams

Ambiguities in diagrams can make it challenging to identify the correct parts or understand their placement. To resolve these issues effectively, you can adopt several strategies:

Use models and diagrams to represent the system architecture clearly. This approach helps you visualize the design intent and pinpoint inconsistencies.

Collaborate with stakeholders or team members to gather diverse perspectives. Their feedback can clarify confusing elements and improve the overall understanding of the diagrams.

Apply techniques like Event Storming to break down complex systems into simpler components. This method ensures that every part is accounted for and reduces confusion.

By implementing these strategies, you can minimize errors and ensure accurate interpretation of Hitachi excavator parts diagrams during maintenance or repairs.

Tip: Always double-check the legend and layout of the diagram to confirm your understanding before proceeding with any task.

Avoiding Misinterpretations During Repairs

Misinterpreting diagrams can lead to incorrect assembly or skipped steps, which may cause further damage to your excavator. To avoid this, focus on the following:

Pay close attention to the labeling and numbering of parts in the diagram. Cross-reference these details with the parts catalog to confirm compatibility.

Highlight or mark the specific components you are working on to avoid confusion. This practice keeps you organized and ensures you don’t overlook critical details.

Keep a record of your observations, such as the condition of parts or any deviations from the diagram. This documentation helps you track progress and identify potential issues.

By staying organized and methodical, you can reduce the risk of misinterpretation and complete repairs efficiently.

Leveraging YNF Machinery’s Support for Accurate Parts

YNF Machinery provides valuable support to ensure you use diagrams effectively and source the right parts for your excavator. Their services include:

Expert guidance to help you identify specific parts and navigate the cat parts lookup system.

High-quality diagrams that simplify the process of locating and understanding components.

Comprehensive support to assist you in interpreting diagrams correctly, ensuring informed decision-making.

With YNF Machinery’s assistance, you can confidently address maintenance tasks and repairs, knowing you have access to accurate information and reliable parts.

Note: Partnering with a trusted supplier like YNF Machinery ensures you receive the best support and high-quality parts for your excavator.

Tips for Mastery of Hitachi Excavator Parts Diagrams

Building a Reference Library for Maintenance

Creating a reference library of Hitachi excavator parts diagrams can significantly enhance your maintenance processes. This library serves as a centralized resource for quick access to diagrams and manuals, ensuring accurate identification of components during repairs. By organizing diagrams by model and system, you can streamline preventive maintenance tasks and reduce downtime.

Benefit | Description |

|---|---|

Reduced Downtime | Swift identification of faulty parts minimizes repair time, keeping the excavator operational. |

Cost Savings | Avoiding incorrect parts orders and optimizing maintenance schedules leads to significant savings. |

Enhanced Safety | Precise identification of components contributes to a safer work environment. |

Improved Efficiency | Clear instructions empower technicians to carry out repairs more efficiently. |

Streamlined Ordering Process | Knowing exact part numbers simplifies orders and ensures prompt delivery of components. |

Building this library ensures you always have access to high-quality diagrams, enabling accurate maintenance and efficient repairs.

Continuous Learning with Updated Diagrams

Staying updated with the latest diagrams is essential for mastering Hitachi excavator parts diagrams. Manufacturers often release updated manuals and diagrams to reflect design changes or new models. Regularly reviewing these updates helps you stay informed about the latest configurations and ensures accurate identification of components.

You can subscribe to updates from trusted suppliers like YNF Machinery or access online resources to keep your library current. Continuous learning not only improves your understanding of parts diagrams but also enhances your ability to perform preventive maintenance effectively. This proactive approach minimizes errors and keeps your excavator in top condition.

Using YNF Machinery’s Excavator Engine Parts and Seal Kits

YNF Machinery’s products, such as excavator engine parts and hydraulic cylinder seal kits, complement the use of parts diagrams perfectly. Understanding diagrams simplifies complex repairs and ensures the reliability of your excavator’s engine. Diagrams help you identify the correct components and ensure proper installation, which is crucial for effective machinery operation.

Hydraulic cylinder seal kits prevent oil leaks and ensure smooth operation of your excavator’s hydraulic system. Diagrams play a crucial role in installing these kits correctly. They show the precise placement of seals within the cylinder, helping you avoid misalignment or improper assembly.

By combining high-quality diagrams with YNF Machinery’s reliable parts, you can achieve accurate maintenance and extend the lifespan of your excavator.

Understanding and using Hitachi excavator parts diagrams is essential for efficient excavator maintenance and repairs. These diagrams simplify identifying components, ensuring precise assembly and reducing downtime. By following the outlined steps, you can streamline your maintenance process, extend your excavator’s lifespan, and enhance operational efficiency.

Relying on trusted suppliers like YNF Machinery ensures access to high-quality parts that meet industry standards. Certified components guarantee durability and performance, while expert support helps you select the right parts and resolve technical issues. Durable parts also reduce long-term costs, making them a valuable investment for your machinery.

Apply these strategies to keep your excavator running smoothly and maximize its productivity. A structured approach to maintenance not only prevents unexpected breakdowns but also ensures your equipment operates at peak efficiency.

FAQ

How do you identify the correct Hitachi excavator parts diagram for your machine?

You can identify the correct diagram by checking your excavator’s model and serial number. These details ensure you select the diagram that matches your machine’s specifications. Always verify the diagram’s accuracy before starting maintenance.

Why is identification of parts important when using diagrams?

Identification ensures you locate the right components and avoid errors during repairs. It simplifies identifying replacement parts, saving time and effort. Accurate identification also prevents ordering mismatched parts, reducing downtime.

Can diagrams help with preventive maintenance?

Yes, diagrams provide a clear view of your excavator’s components. They help you spot wear and tear early, allowing you to replace parts before they fail. This proactive approach keeps your machine running efficiently.

What should you do if a diagram seems unclear?

If a diagram appears unclear, consult the legend or key for clarification. You can also reach out to suppliers like YNF Machinery for expert guidance. Their support ensures you interpret diagrams correctly.

How do diagrams contribute to reducing downtime?

Diagrams streamline the repair process by providing detailed visuals of components. They help you identify issues quickly and guide you through repairs. This efficiency minimizes delays, reducing downtime significantly.