When you pick excavator thumb parts, make sure they fit your machine. Excavator thumbs help you grab, lift, and move things with better control. The right excavator thumb parts keep your excavator tools safe and working right. You should think about fit, the kind of thumb, and how strong the parts are. Many people make mistakes by choosing the wrong part or using weak parts that break.

Key Takeaways

Always make sure the excavator thumb parts fit your machine. Check the size, model, and hydraulic system to match.

Pick the right thumb type for your job. Use manual thumbs for easy jobs. Use hydraulic thumbs for more control and hard work.

Match the thumb size and design to your bucket. This helps you grip things safely and well.

Use strong steel parts so your thumb lasts longer. This also helps you fix it less often.

Do not make mistakes like using the wrong fit. Avoid bad installation and using it the wrong way. This keeps your machine safe and working right.

Key Factor

Compatibility

When you choose excavator attachments, you must check if they fit your machine. Compatibility means the thumb will work safely and correctly with your excavator. If you pick the wrong part, you can damage your machine or make your work harder. You should always match the thumb to your specific excavator model. Each machine has its own size, weight, and bucket type. These details matter when you select excavator attachments.

Here are the most important things to check for compatibility:

The size and weight of your excavator

The weight class and bucket size

The model of your excavator

The hydraulic system capacity, especially for hydraulic thumbs

The type of thumb: hydraulic thumbs give you more control, while rigid thumbs offer strength for heavy lifting

Customization options for special models

You should talk to a trusted dealer or manufacturer before you buy. They can help you find the right fit for your machine and job needs. If you skip this step, you might end up with a thumb that does not work well or even causes damage.

Machine Specs

You need to know your machine’s specs before you buy any excavator attachments. Start by checking your excavator’s weight class. This tells you how much your machine can handle. Next, look at the bucket size. The thumb must match the bucket for safe and easy use. Check the hydraulic system if you want a hydraulic thumb. Your machine must have enough power and the right controls.

Write down your excavator’s model number and year. This information helps you and your dealer find the best excavator thumb parts. When you know your specs, you can avoid mistakes and keep your machine working safely.

Types of Excavator Thumb Parts

To pick the right excavator thumb parts, you need to know the main types. Each type gives you different control and flexibility for your work. Some types also give you more value.

Manual Thumbs

Manual thumbs are the simplest kind. You move them by hand, and they stay in one spot. You use the bucket to grip things. Manual thumbs are good for easy jobs like moving brush or logs. They cost less and do not break easily. You do not need a hydraulic system for these thumbs.

Tip: Manual thumbs work best if you only use them sometimes. If you want more control, try other types.

Common uses for manual thumbs:

Clearing land like brush or trees

Simple gripping jobs

When you want to save money

Manual thumbs have some limits. You cannot change them from inside the cab. You must stop and move them by hand. This can slow you down on big or hard jobs.

Hydraulic Thumb for Excavator

A hydraulic thumb for excavator gives you much better control. You can open and close it from inside the cab. This makes it easy to grab and move many things. Many people like a hydraulic thumb for excavator because it works for lots of jobs.

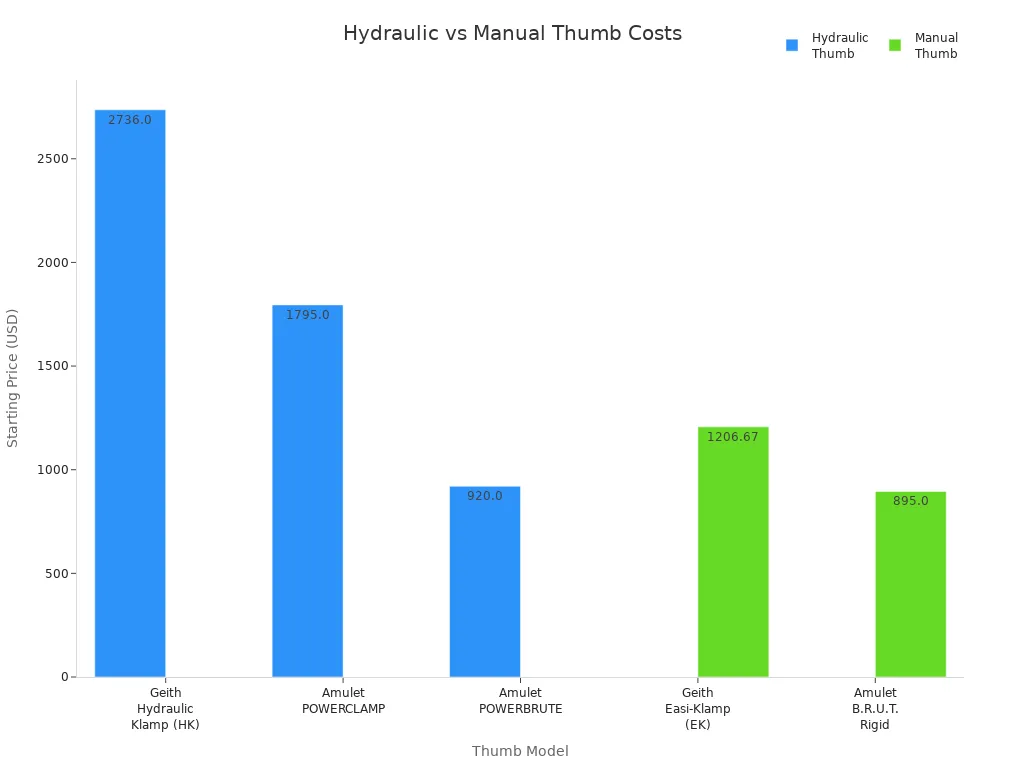

Note: Most companies now say a hydraulic thumb for excavator is better than manual thumbs. The extra money is worth it for more speed and control.

A hydraulic thumb for excavator costs more than a manual thumb. You pay more so you can adjust it without leaving your seat. For work, the best hydraulic thumb saves time and helps you do more.

Why choose a hydraulic thumb for excavator?

You control it from the cab

You can grab odd or heavy things

You finish jobs faster

The best hydraulic thumb fits many machines

Progressive Link Thumbs

Progressive link thumbs are the best hydraulic thumb for hard jobs. They use an extra link for a bigger range of motion, up to 180 degrees. You can grip things closer to the cab and work in tight spots. A progressive link hydraulic thumb for excavator is great for demolition or moving rocks.

Key benefits of a progressive link hydraulic thumb for excavator:

Biggest range of motion and flexibility

You can work close to the boom

The best hydraulic thumb for tough jobs

Tip: If you want the best hydraulic thumb for full control, pick a progressive link hydraulic thumb for excavator.

Comparison Table:

Thumb Type | Operation & Control | Installation & Design | Typical Applications | Advantages & Limitations |

|---|---|---|---|---|

Manual Thumb | Fixed position, manually adjusted | Simple weld-on, no hydraulics | Light or occasional use, debris removal | Low flexibility, cost-effective, easy to maintain |

Hydraulic Thumb for Excavator | Hydraulic cylinder, cab control | Stick- or pin-mounted, needs hydraulics | Land clearing, demolition, stump removal | Flexible, precise, more costly |

Progressive Link Thumb | Extra link for greater rotation and control | Heavy-duty, complex install | Complex tasks, precise handling | Max range, high durability, complex install |

A progressive link hydraulic thumb for excavator gives you the most control and movement. If you want the best hydraulic thumb for your machine, this type is best for hard and careful work.

Selection Guide

Picking the right excavator thumb parts can seem hard at first. You can make it easier by using a simple checklist. This guide helps you find the best hydraulic thumb and other excavator attachments for your job.

Assess Needs

First, think about what jobs you need to do. Different jobs need different thumbs. If you want to move rocks or tree stumps, you need a strong thumb. In construction, thumbs help grab big things like timber or debris.

Ask yourself these questions: What materials will you move most? Do you need to grip big or odd-shaped things? Will you use the thumb for land clearing or demolition?

Tip: The best hydraulic thumb gives you more control for hard jobs. If you only do light work, a manual thumb might be enough.

Check Compatibility

You must check if the thumb fits your machine. Each excavator has its own size and weight. If you pick the wrong part, it might break or not work.

Here is a checklist to help you: Know your excavator’s model and year. Check the weight class and bucket size. Make sure your hydraulic system can use a hydraulic thumb for excavator. Look for a thumb that fits your mounting system. Some need special brackets. If your machine has a thumb base plate, tell the maker so you get the right pins and cylinder.

You can use charts like the Excavator Bucket Pin Size Chart from Attachment Co. This chart shows pin sizes and stick widths. You can also ask your dealer for help. Always check these details before you buy any excavator attachments.

Note: Experts say you should test the thumb with your machine if you can. A demo lets you see if it fits and works well.

Match Bucket and Thumb

The thumb and bucket must work together well. If they do not match, you cannot grip things right. The best hydraulic thumb should fit your buckets.

Check these things: Match the thumb width and length to your bucket. Pick the number of tines for what you will grab. More tines help with small debris. Fewer tines are better for big things. Make sure the thumb can fold back close to the stick when not in use. This saves time. Check the welds and steel. Strong welds make the thumb last longer. Look at the cylinder mount, base, and pivot pin. These must be strong and fit your bucket.

Callout: Good bushings cut down on wear and friction. This is important if you use your thumb a lot or move heavy things.

Consult Experts

You should talk to an equipment expert before you buy. Experts help you match the thumb to your buckets. They make sure you get the best hydraulic thumb for your machine. They can spot problems like bad fit or too much weight.

Benefits of talking to an expert include: Getting the right fit for your bucket and thumb. Avoiding mistakes and damage. Learning about care and safe use. Making your machine work better and your excavator attachments last longer.

Tip: Experts can help you know what you need for install. Some thumbs need welding or special pivot points. Plan for a pro to install it to keep your machine safe.

Quick Checklist for Selecting Excavator Thumb Parts:

Pick the type of thumb you need (manual or hydraulic)

Choose the thumb design (main pin, quick coupler, stick mounted, or progressive link)

Match the thumb to your machine and bucket

Check if your machine has a base plate

Pick the right thumb size (width, length, tines)

Plan for install (welding, pivot points)

Think about your main jobs

Allow time for custom orders if needed

Read maker instructions and check fit

If you follow these steps, you can pick the best hydraulic thumb and other excavator attachments for your work. This helps you move all kinds of materials safely and easily.

Features and Mistakes

Durability

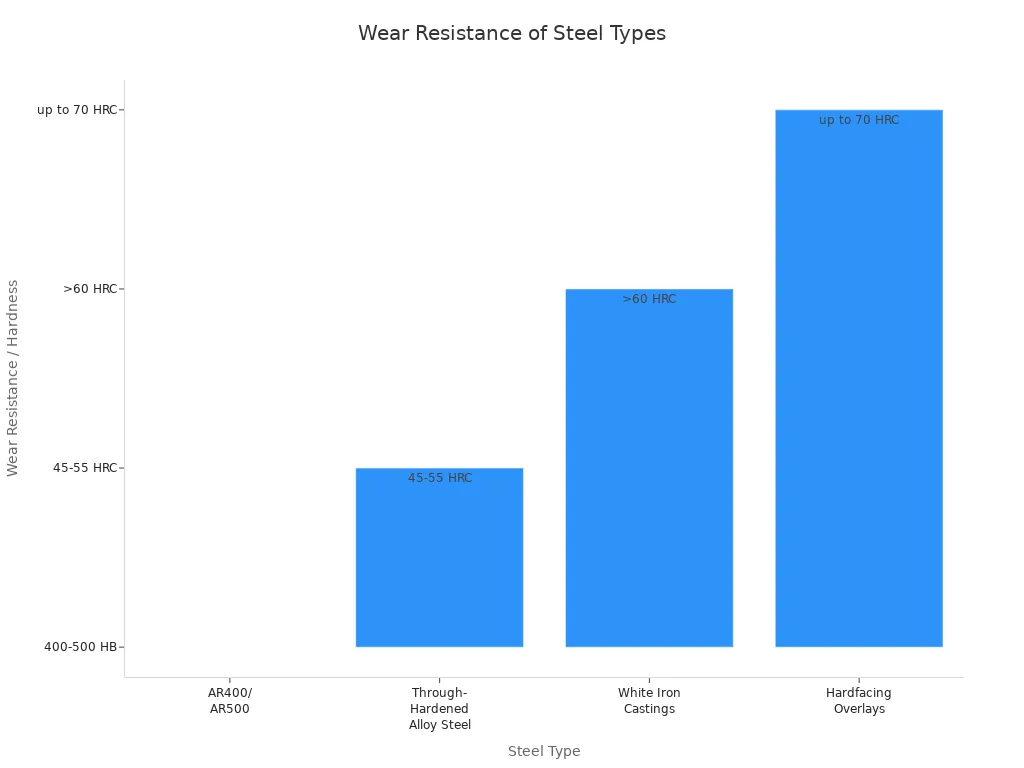

You want excavator thumb parts that last a long time. Strong steel helps them last longer. Most good thumbs use special steels like AR400, AR500, S355, or manganese steel. These steels are tough and do not wear out fast. The table below lists steel types and what makes them special:

Steel Type | Typical Use in Excavator Parts | Wear Resistance / Hardness | Key Properties and Notes |

|---|---|---|---|

AR400, AR500 | Bucket shells, wear plates, thumb parts | 400-500 HB (Brinell Hardness) | High abrasion resistance, balances toughness and hardness |

S355, S690 | Structural components, thumb parts | 355-690 MPa (Yield Strength) | High strength-to-weight ratio, keeps shape under heavy loads |

Manganese Steel | Cutting edges, thumb parts | Work hardens under impact | Gets tougher with use, very durable |

Through-Hardened Alloy Steel | Bucket teeth, high-impact parts | 45-55 HRC (Rockwell Hardness) | Uniform hardness, good for wear and impact |

White Iron Castings | Extreme wear areas | >60 HRC | Very high wear resistance, but brittle |

Hardfacing Overlays | Surface overlays | Up to 70 HRC | Extreme surface wear resistance, base stays tough |

Tip: Always check what steel your thumb uses. Stronger steel means longer life and fewer repairs.

Installation

Putting on excavator thumb parts needs some skill. Manual thumbs are easier to put on. You bolt or weld them, and you do not need to hook up any hydraulic lines. Hydraulic thumbs are harder to install. You must weld a base plate, hook up hydraulic hoses, and pin the cylinder to the thumb. Some new excavators already have a base plate, which makes things easier.

Manual thumbs: Easy to install, no hydraulics, less flexible.

Hydraulic thumbs: Need welding and hydraulic work, more control, best done by a pro.

Always tell your dealer if your machine has a base plate before you order.

Note: Many mechanics take special classes to learn about hydraulic systems. Courses like Mobile Hydraulic Mechanic Certification or IFPS Hydraulic Mechanic Training help them work on hydraulic thumbs safely.

Common Mistakes

You can stop many problems by avoiding these mistakes:

Putting the thumb in the wrong place, so it does not close with the bucket.

Picking a thumb that does not fit your bucket or excavator size.

Using the wrong hydraulic hoses or fittings, which can cause leaks or weak movement.

Running hydraulic lines the wrong way, which can pinch or damage them.

Using the thumb for prying or digging, which can break it.

Not cleaning the area before welding, which makes the weld weak.

Forgetting to check for loose bolts, worn hoses, or dry pivot points.

Using too much power for the hydraulic system, which can hurt your machine and cause safety problems.

Not checking if the thumb and bucket mounting systems work together.

⚠️ Using the wrong excavator attachments or pushing them too hard can cause expensive repairs, safety problems, and lost work time. Always follow the maker’s instructions and ask an expert if you are not sure.

Choosing the right excavator thumb parts helps you work safely and save money. You should:

Check your machine’s specs and thumb compatibility.

Pick the right thumb type for your jobs.

Match the thumb to your bucket.

Use strong, durable materials.

Remember, using the checklist and tips in this guide makes your decision easier and helps your machine last longer.

FAQ

What size thumb should I choose for my excavator?

You should match the thumb size to your bucket width and your machine’s weight class. A thumb that is too small will not grip well. A thumb that is too large can damage your equipment.

Can I install a hydraulic thumb by myself?

You can install a manual thumb with basic tools. For a hydraulic thumb, you should ask a trained mechanic. Hydraulic systems need careful setup to avoid leaks and safety risks.

How do I know if my excavator is compatible with a thumb?

Check your machine’s model, year, and hydraulic system. Look at the mounting points on your stick. You can also ask your dealer or check the manufacturer’s compatibility chart.

What maintenance does an excavator thumb need?

You should grease the pivot points often. Check for loose bolts and worn hoses. Clean dirt from moving parts. Regular care helps your thumb last longer and work safely.