When you choose the right excavator equipment parts, you keep your machine and job site safe. Always ensure the excavator equipment parts fit your specific model and are of good quality. Using the wrong or poor-quality excavator equipment parts can lead to problems like faster wear, unexpected breakdowns, and safety hazards. For instance, faulty excavator equipment parts can cause hydraulic leaks, electrical issues, or clogged filters. By using the correct excavator equipment parts, you save both time and money. Always rely on trusted suppliers for your excavator equipment parts.

Key Takeaways

Always know your excavator’s model and what jobs it will do before you buy parts. This helps make sure the parts fit and work safely.

Check part numbers and if the parts match your machine. This helps you avoid expensive mistakes and keeps your machine running well.

Choose high-quality parts. Try to get OEM parts for important pieces. This makes your machine last longer and work better.

Pick suppliers with good reviews, quick shipping, and strong warranties. This helps protect your money and your machine.

Take care of your parts and change them on time. Follow a schedule to stop breakdowns and help your excavator last longer.

Know Your Machine

Identify Model and Specs

Before you look for parts, learn about your machine. Write down the make, model, year, and main specs. Every excavator has special features. These features decide which excavator spare parts and excavator accessories fit. Crawling excavators use tracks for grip and balance. Wheeled excavators move faster but need other stability parts. Skid steer excavators can use many excavator attachments. Backhoe excavators have a different arm shape. Long-reach, dragline, and suction excavators all need special excavator parts.

Tip: Always check your owner’s manual or the manufacturer’s website for the right part numbers and details.

You should also check how your excavator’s mounting system works. Some machines use special ways to attach booms, arms, and excavator buckets. Hydraulic systems can be different in pressure, flow, and hose size. These differences mean not all excavator spare parts or excavator accessories fit every machine. Sometimes, you need custom help or expert advice. This makes sure your new excavator attachments, like hydraulic breakers or excavator grapples, fit and work safely.

Match to Job Site Needs

Picking the right excavator parts means thinking about your job site. Look at the soil, weather, and the work you do. If you work on rocks, you need strong excavator buckets and tough undercarriage excavator accessories. For soft ground or grass, rubber tracks and lighter excavator spare parts protect the surface. Think about what you move—sand, clay, stone, or concrete—and pick excavator attachments that fit.

If you use your excavator for digging, grading, or demolition, you may need different excavator accessories like hydraulic breakers, excavator shears, or excavator thumbs.

For lifting or sorting, think about bucket and breaker choices and add-ons like excavator shears or excavator grapples.

If you use the wrong excavator parts or excavator attachments, you could hurt your machine or the job site. Using an excavator that is too heavy or the wrong size can cause accidents or slow your work. Always match your excavator spare parts and excavator accessories to your machine and the job. This keeps your equipment safe, efficient, and lasting longer.

Check Compatibility of Excavator Equipment Parts

Confirm OEM Specs and Fit

You must make sure each part fits your excavator. First, check the original equipment manufacturer part numbers. These numbers help you pick the right parts. If you use the wrong part, your excavator might not work right or could break.

Here are some steps to help you find the right excavator equipment parts:

Use your machine’s serial number and OEM codes to find the right parts.

Check the packaging and labels for real and good quality parts.

Match the serial numbers or codes with what the maker says.

Pick parts that have warranties. Warranties protect you from broken or bad parts.

Read your equipment manual to see if the part fits your excavator.

Double-check part numbers to make sure they match your machine.

Ask for help from mechanics or technicians who know your machine.

Look at the parts before you buy. Check the size, weight, and shape. Make sure there is no damage.

Tip: Always buy from suppliers who sell parts made to exact standards and tested for fit. This helps you avoid problems and keeps your excavator working well.

When you pick excavator parts undercarriage, like rollers or sprockets, match each part to your machine’s brand and model. For example, undercarriage parts for a Caterpillar E307B have special part numbers. This makes sure the parts fit right and last longer.

Avoid Compatibility Issues

Many people have trouble when they buy excavator equipment parts that do not fit their machine. These problems can cause bad fit, poor work, or even machine failure. You can stop these problems by following some easy steps:

Always give your excavator’s model and serial number to your parts supplier.

Work with suppliers who have many parts and can check if the part fits.

Pick parts made for your exact excavator model. Aftermarket parts may fit many brands, but model-specific parts work best.

Ask the supplier’s team to help you check if the part fits your undercarriage, cab, arm, or boom.

Talk to mechanics, service technicians, or OEM reps. They know many brands and can suggest good excavator parts.

Use only certified parts and check product info before you buy.

Note: Checking compatibility is important for all main parts of your machine, like the undercarriage, cab, and arm or boom. If you skip this step, you could break your excavator or stop work on your job site.

When you check for compatibility, you protect your money and keep your excavator working well. You also save money by not buying parts that do not fit or work right. Careful checks help you get the most from your excavator parts undercarriage and other main parts.

Choose High-Quality Excavator Parts

OEM vs Aftermarket

When you pick good excavator parts, you must choose between OEM and aftermarket. OEM parts are made by the original company. These parts always fit well and work as they should. They cost more, but they last longer and have a strong warranty. Aftermarket parts are made by other companies. Some aftermarket parts are as good as OEM, but some are not. Aftermarket parts can save you money and are easy to find if you need them fast. But the quality and fit can be different.

Here is a table to help you compare:

Factor | OEM Parts | Aftermarket Parts | Best Use |

|---|---|---|---|

Cost | Higher, but reliable | Lower, wide range | Budget jobs → Aftermarket |

Quality | Consistent, high-quality parts | Varies, some match OEM, some do not | Critical parts → OEM |

Compatibility | Guaranteed fit | May need adjustments | Older machines → Aftermarket |

Lead Time | Sometimes longer | Usually faster | Emergency repairs → Aftermarket |

Warranty | Strong, 1–2 years | Varies, some match OEM | Warranty focus → OEM |

Use OEM parts for important things like hydraulics or engines. For other excavator attachments, good aftermarket parts can work. Always check if the supplier is trusted and offers a warranty.

Tip: Most part failures are not from bad quality. Many times, it is because the wrong part was used or used the wrong way. Always pick the right high-quality parts for your machine and job.

Materials and Durability

Good excavator parts use strong materials. For example, undercarriage parts use tough steel alloys. These alloys help stop wear and damage. If you pick excavator attachments made from Hardox steel or AR steel plate, they last longer and work better. Manganese steel is great for rocky places because it gets stronger as you use it.

Good parts made from strong materials last longer and help you work more.

Strong bolts use carbon steel or stainless steel to stop rust and add strength.

Heat treatment and careful making make the best excavator attachments last even longer.

Always look for clear marks on the material and smooth finishes. Good materials help your excavator attachments do hard jobs and handle bad weather. When you buy high-quality excavator parts, you keep your machine safe and your work on track.

Evaluate Suppliers for Excavator Parts

Reputation and Reviews

When you pick a supplier for excavator accessories, check if people trust them. A trusted supplier helps you avoid trouble and keeps your machine working. You can follow these steps to see if a supplier is good: First, see if they can make enough excavator accessories and deliver them on time. Next, check if their parts use strong materials. Good parts last longer and work better. Ask if the supplier has experts and special certificates like ISO9001/2015. These show they follow strict rules. Look at how many different excavator accessories they have. More choices mean you get what you need faster. Try their customer service to see if they help you fix problems fast. Check the supplier on trusted websites so you can compare them with others. Build a good relationship with the supplier. Talking often helps you get better service.

Customer reviews and certificates are important. User reviews and expert advice tell you if a supplier sends good excavator accessories on time. Good reviews mean you can trust them. Certificates like ISO 9001 show the supplier follows safety and quality rules.

Availability and Delivery

You need quick delivery and enough stock when you buy excavator accessories. Waiting too long for parts can stop your project for months. Many jobs now have delays because of supply chain issues. If your supplier has lots of excavator accessories in stock, you can fix your machine faster and avoid losing money.

Make a list of the excavator accessories you use most.

Pick suppliers who ship fast and have helpful customer service.

Keep track of your parts and plan ahead so you do not run out.

A supplier who delivers fast and has enough stock helps you finish work on time and saves you money.

Warranties and Guarantees

Warranties protect you when you buy excavator accessories. Good suppliers give strong warranties, like a 5-year or 5,000-hour full machine warranty. This covers big parts like engines and hydraulic systems. Some also give a 5-year or 10,000-hour warranty for frames and booms. These warranties do not cover normal wear parts, but they do cover problems with materials or how the part was made.

Ask your supplier about warranty details before you buy. Good warranties and support mean you can trust the excavator accessories you get. Some suppliers also help you check your machine’s health during the warranty.

When you choose a supplier, always check if people trust them, how fast they deliver, and what their warranty is. This helps you get the best deal and keeps your excavator accessories working well.

Maintain and Replace Excavator Spare Parts

Installation Tips

Putting in excavator spare parts the right way keeps your machine safe. It also helps your machine work well. Store new parts in a clean, dry place. Keep them away from sunlight and water. This stops rubber and fluid parts from getting ruined. Sort and label your excavator spare parts by type. Also, sort them by how often you use them. Use the oldest parts first so nothing goes to waste.

Here are some steps for safe installation:

Look at the work area for dangers like loose dirt or trash.

Check the part for cracks or other problems before you put it in.

Clean the spot where you will put the new part.

Use the right tools and follow your machine’s manual.

Change old parts right away to stop bigger problems.

After you finish, look for leaks, loose bolts, or weird sounds.

Write down every change and repair you make.

Tip: When you change filters, also look at hoses, seals, and belts. This helps you find problems early. It also makes your excavator spare parts last longer.

Regular Maintenance

Taking care of excavator spare parts often helps you avoid big repairs. It also stops your machine from breaking down. Check your machine every day to find leaks, worn tracks, or loose bolts. Change important parts like undercarriage pieces, engines, and rubber tracks if you see trouble. Watch for warning lights, strange sounds, or shaking. These signs mean you should check and maybe change important excavator spare parts.

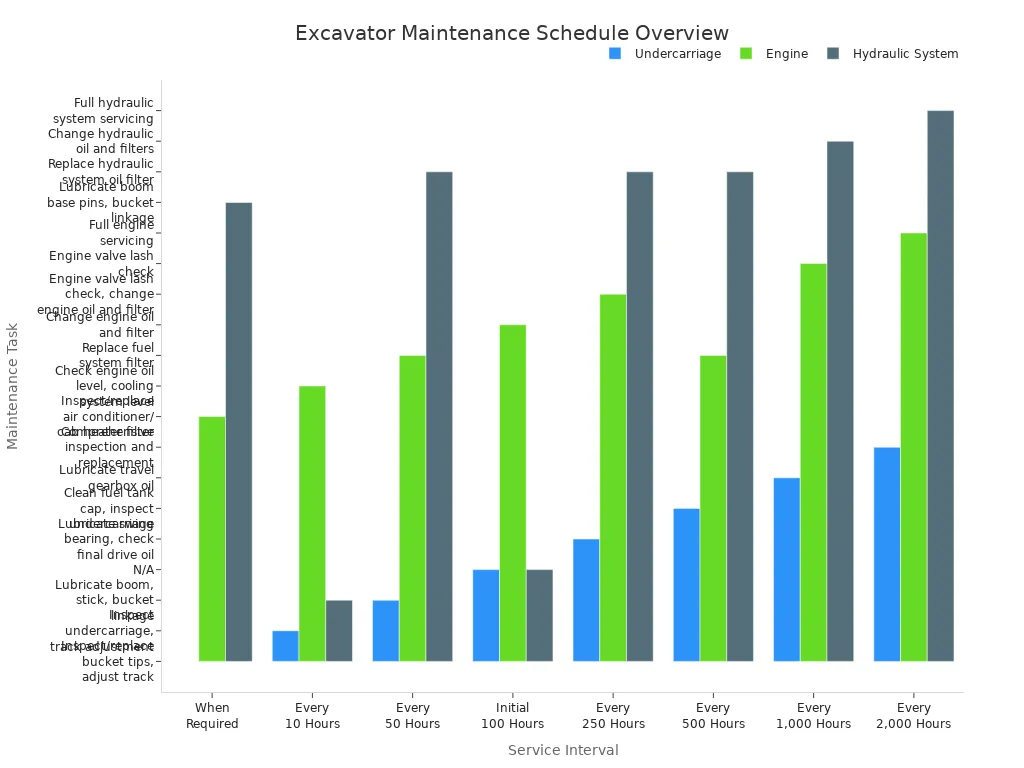

Here is an easy schedule for your main parts:

Service Interval | Undercarriage | Engine | Hydraulic System |

|---|---|---|---|

Daily | Check tracks, clean | Check oil, coolant | Check oil, inspect hoses |

50 Hours | Inspect bucket teeth | Change fuel filter | Lubricate linkages |

250 Hours | Lubricate bearings | Change oil, adjust valves | Replace oil filter |

1,000 Hours | Inspect gearbox oil | Battery maintenance | Change hydraulic oil |

2,000 Hours | Full inspection | Full servicing | Full oil and filter change |

Taking care of your excavator spare parts before they break can cut surprise breakdowns by half. Keeping good notes and using maintenance tools helps you plan better. This saves money on repairs and makes your machine last longer. Most excavators work for about 10,000 hours if you take care of them. Hard work or bad weather can make them wear out faster. Daily checks and changing excavator spare parts on time protect your money and keep your jobs going.

Picking the right excavator parts keeps your machine safe. It also protects the money you spent on it. First, learn about your machine and check if parts fit. Choose parts that are strong and last a long time. Always look at what people say about the supplier. Make sure they help you if you have problems. Take care of your machine by checking and fixing it often.

Try to get good quality and a fair price.

Talk to people who know a lot and read about suppliers.

Think about how well parts work for a long time, not just the price now.

Good parts help your machine break less and save money. Learning and asking experts helps you make smart choices and use your machine longer.

FAQ

What is the difference between OEM and aftermarket excavator parts?

OEM parts are made by your machine’s maker. Aftermarket parts come from other companies. OEM parts fit just right and last longer. Aftermarket parts can cost less money. Always check if the part fits and is good quality before buying.

How often should you replace excavator spare parts?

Check your machine every day for problems. Change worn parts as soon as you see damage. Follow your manual for when to do service. Most machines need new filters, tracks, and oil after certain hours. Regular checks help you stop big repairs.

Can you use parts from a different excavator model?

Do not use parts from another model unless the maker says it is okay. Wrong parts can break your machine or cause safety problems. Always match the part number and ask your supplier or check your manual.

How do you know if a supplier is trustworthy?

Read customer reviews and look at ratings. Check for certificates like ISO 9001. Ask about warranties and support. A good supplier answers questions and delivers parts on time.

Tip: Always ask for proof of quality before you buy. Good suppliers will show you this information.