When you look for excavator parts brand new, you need to check if each part fits your machine. It is important for your excavator to work well and stay safe. Good quality helps your excavator last longer. Pick a supplier that many people trust for high-quality parts. A good supplier keeps you away from bad products and gives you help when needed. Always choose reliable suppliers for excavator parts brand new.

Key Takeaways

Always know your excavator’s make, model, and serial number. This helps you buy the right parts. It also keeps your machine safe to use.

Make a clear list of the parts you need. Include main components and common replacements. This helps you avoid mistakes when ordering. It also saves you time.

Check if the parts fit by using OEM codes and manuals. You can also use trusted online tools. This stops damage and keeps your machine working well.

Pick parts from good manufacturers with quality certifications. This gives you strong, safe, and reliable excavator parts.

Follow the right steps for installing and taking care of parts. Wear safety gear every time. Use supplier warranties to protect your money. This helps your parts last longer.

Choosing Excavator Parts

Machine Details

Before you pick excavator parts, you must know your machine. This helps you not make mistakes. It also makes sure the part fits. If you use wrong details, you might get parts that do not work. This can even hurt your excavator.

Write down the make, model, and serial number. These are the most important details for picking parts.

Find out if your machine is a crawler excavator or a mini excavator. Each type uses different parts. Mini excavator parts are smaller and lighter. Crawler excavator parts are made for tough jobs.

Check if your machine still has a warranty. If it does, use original parts to keep the warranty safe.

Look at the main parts of your machine. These are the undercarriage, cab, boom, arm, bucket, hydraulic systems, engine, fuel tank, hydraulic fluid tanks, main control valve, cylinders, and attachments.

Check your machine’s maintenance history and telematics data. This tells you which parts may need to be replaced soon.

See if you have other machines that are the same model. If you do, you can use the same mini excavator parts or crawler excavator parts for all of them.

Always check your machine details again before you order. If you use the wrong model or serial number, you might get parts that do not fit. This can be unsafe or break your machine.

Tip: Always match the model and serial number. This helps you order the right parts and keeps your excavator working well.

Parts Needed

After you get your machine details, make a list of the parts you want to change. A good list helps you not make mistakes and saves time.

Write down all the main controls, ROPS, counterweight, engine, hydraulic fluid tanks, fuel tank, and main control valve.

Add the digging parts: boom, arm (also called dipper or stick), bucket, and cylinders (boom, arm, bucket).

List attachments like rotators, brush cutters, stump cutters, boom extensions, augers, breakers, tree shears, pipelayers, and grading buckets. Picking the right attachments helps your machine work better.

For mini excavator parts and crawler excavator parts, check if you need special pins, couplers, or connectors. Each model may need different sizes, so always match the part to your machine.

Do not forget common replacement parts like filters, belts, seals, hoses, and bucket teeth. These parts wear out faster and need to be checked often.

Here is a table that shows some of the most replaced excavator parts and when to replace them:

Excavator Part | Common Replacement Interval | Notes on Replacement Criteria and Conditions |

|---|---|---|

Hydraulic filters | Every 1,000 hours | Change if you lose power, flow drops, pressure drops, noises, or leaks |

Oil filters | Every 250-500 hours or at least yearly | Change if you lose power, hear knocking, or lose oil pressure |

Fuel filters | At least once per year | Change if the engine sputters, works poorly, or misfires |

Belts | Inspect often; change if worn or damaged | Listen for squeaks, see less power, or see wear; heat can hurt belts |

Seals | Check during maintenance; change if damaged | Seals stop leaks; broken seals can break the engine |

Hoses | Last 1 to 4 years depending on use | Change if torn, crushed, or leaking; bad hoses can break hydraulics or engine |

Air filters | Change based on wear and how it works | Check often for best results |

Bucket teeth | Varies by use and soil type | Check every day; change if worn, dull, or loose |

When you make a good list, you are less likely to order the wrong parts. You also help your supplier find the right mini excavator parts or crawler excavator parts for you. This is very important for anyone who wants the right parts for their machine.

Note: Keep clear records of your machine’s model and the parts you use. This makes future repairs easier and helps you not make costly mistakes when you order new excavator parts.

Compatibility

You must check compatibility before buying new excavator parts. If you skip this step, the parts might not fit. This can break your machine or make it unsafe. You could also waste money. Each excavator has a model and serial number. These numbers help you find the right parts. When you check compatibility, your machine works better and stays safe.

OEM Codes

OEM codes are very important for finding the right parts. OEM means Original Equipment Manufacturer. Each part has its own special number from the maker. You use these numbers to get parts that fit your machine. Here is why OEM codes matter:

OEM parts are made by the same company as your machine.

They fit well because they match the original size and shape.

Model and serial numbers are like ID cards for your excavator.

Searching with these numbers helps you find the right parts.

Tools like Cat SIS2.0, SIS2GO, and Cat Central App help you search by number. They show you pictures and details for each part.

OEM parts often have a warranty. They last longer and work better.

Start your search with the serial number and OEM code. Good suppliers like SPARKLING MACHINERY sell OEM-compatible parts for brands like Caterpillar, Komatsu, Hitachi, and Volvo. These suppliers test their parts to make sure they are strong and meet OEM rules. Using OE Link™ helps you find the right codes and specs for engines and drive systems. This makes it easy to pick real parts that fit your machine.

Manuals and Tools

Manuals and online tools help you check if a part fits. These resources give you the newest info for your machine. Here is how they help:

Manuals have pictures and part numbers for your model and serial number. This helps you pick the right parts.

Online tools let you type in your serial number or model. They show you only the parts that fit your machine.

Parts can change with different serial numbers. These tools help you avoid mistakes.

You can save your machine info online. This makes it easy to find parts next time.

Manuals and online catalogs update often. You always get the latest info for your machine.

If you do not use the manual or tools, you might buy the wrong parts. Here are some problems you could have:

You might get parts that do not fit, since each model needs special parts.

If you buy parts just because they look the same, your machine could work badly or even be unsafe.

Wrong parts can cause more downtime and less work.

Always read your manual or ask a technician for help.

Use lookup systems or apps to make sure you get the right parts.

Tip: Always use your manual and trusted supplier tools before you buy. This helps you avoid mistakes and keeps your excavator safe and working well.

Excavator Parts Manufacturers

Reputation

When you pick excavator parts manufacturers, choose one people trust. A strong reputation means you get good parts. These parts help your excavator work safely. Big brands like Caterpillar, Komatsu, Volvo, and Hitachi have made parts for many years. They are famous for making tough and smart products. Here are some top excavator parts manufacturers you can trust:

Caterpillar: Makes strong and useful attachments.

Komatsu: Known for tough and reliable parts.

Volvo: Focuses on safety and high performance.

Hitachi: Makes quality parts with advanced engineering.

JCB

Liebherr Group

Doosan Infracore

Bobcat

Kubota

Hyundai

Always read reviews from other buyers before you buy. Reviews tell you if the company ships fast and if the parts last. Good excavator parts manufacturers have strong reviews and quick service. They also help you after you buy. You can check how many parts they make and what materials they use. Good materials help parts last longer and work better.

Manufacturer | Country | Main Products | Key Strengths |

|---|---|---|---|

Caterpillar Inc. | United States | Construction and mining equipment, engines | Globally recognized for durable machinery, fast service, and continuous innovation. |

Komatsu Ltd. | Japan | Construction and mining equipment | Uses advanced technology (e.g., Komtrax), focuses on sustainability and fuel efficiency. |

Hitachi Construction Machinery | Japan | Hydraulic excavators, wheel loaders, trucks | Known for skilled engineering, advanced hydraulics, reliability, and smart control systems. |

Volvo Construction Equipment | Sweden | Excavators, wheel loaders, haulers | Emphasizes sustainability, operator safety, fuel efficiency, and innovative controls. |

SPARKLING MACHINERY | China | Excavator spare parts (hydraulic, undercarriage, engine, electrical, attachments) | Provides quality, compatible parts for major brands with fast delivery and global distribution. |

Tip: Stay in touch with your supplier. Talking often helps you get help faster.

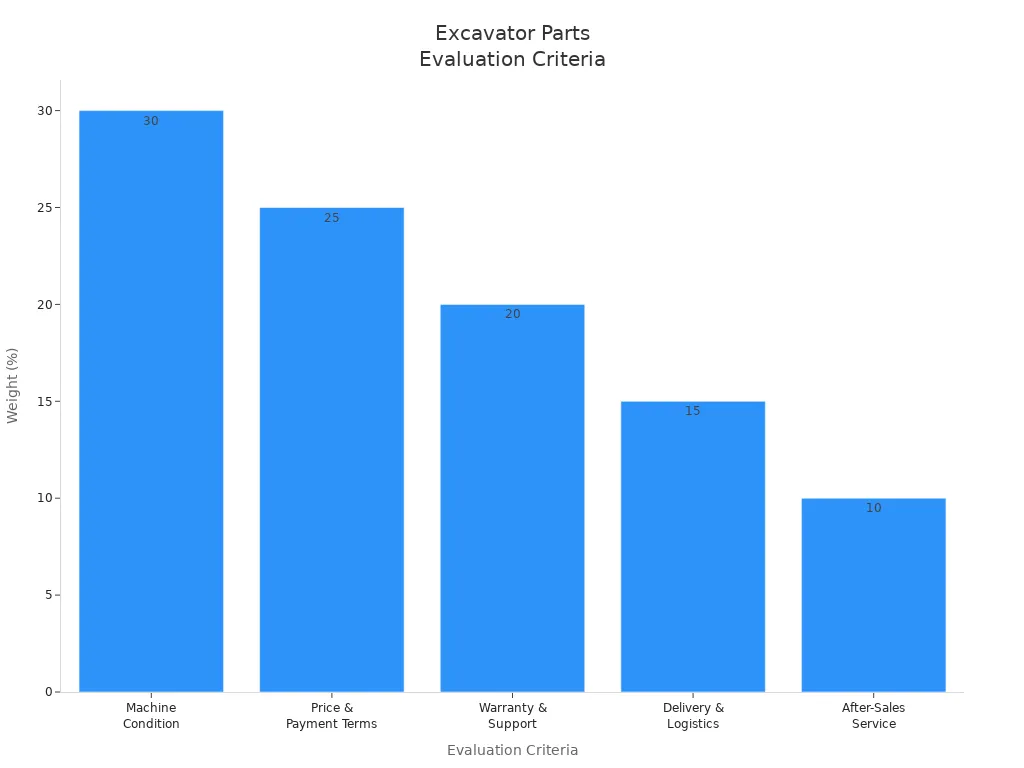

You can also use a chart to see what matters most when picking good excavator parts manufacturers:

Certifications

Certifications show that excavator parts manufacturers follow strict rules. The most important one is ISO 9001. This means the company checks quality very well. You can trust their parts to be safe and strong. If you want to buy parts in Europe, look for the CE mark. This means the parts are safe and healthy to use. For special jobs, like oil and gas, API certification is needed.

Certification | Importance for Excavator Parts Manufacturers | Benefits | Challenges |

|---|---|---|---|

ISO 9001 | Ensures a robust quality management system for consistent product quality | Builds customer trust by guaranteeing high-quality products; requires continuous quality improvement | Costs of implementation and maintenance; requires regular system reviews |

CE | Mandatory for selling products in the European Economic Area (EEA); ensures compliance with EU health and safety standards | Enables access to the European market, expanding market reach | Complex standards to understand and comply with |

API | Relevant for parts used in the oil and gas industry; ensures performance and reliability under harsh conditions | Allows targeting oil and gas industry customers; certifies parts withstand extreme environments | Detailed and specific standards; requires staff training and ongoing compliance |

Certified manufacturers check every part for problems. They test parts and listen to what customers say. This helps them get better and keep a good name. When you pick certified excavator parts manufacturers, you get parts that help your excavator work well and last longer.

High-Quality Excavator Parts

Material Standards

You want your excavator to work well for many years. High-quality excavator parts help make this happen. These parts are made from strong materials like high-strength steel alloys. This makes them harder and tougher. They can handle tough jobs every day and do not wear out fast.

Good excavator parts are made with special machines. They are shaped and heated to fit right and work under heavy loads.

Some parts are sealed and have oil inside. This helps stop friction and keeps dirt and water out. These features help the parts last longer.

When parts use good materials, your excavator stays safe and steady. It can carry heavy things and move without slipping.

Tip: Always check if your parts follow strict quality rules. This helps stop breakdowns and keeps your excavator working well.

Durability

Durability means your excavator parts can handle hard jobs and bad weather. High-quality excavator parts do not break or wear out quickly. You will not need to fix your machine as often.

Listen for odd sounds, look for leaks, or slow hydraulics. These signs mean a part might be worn out.

Check important parts like tracks, rollers, sprockets, cylinders, pumps, hoses, and seals.

Clean, check, and oil your parts often. This helps them last longer.

Many good excavator parts have warranties, like a 2-year warranty on final drives. This means the supplier trusts their parts.

Durability Benchmark | What to Look For |

|---|---|

Wear-resistant materials | Advanced steel and alloys |

Reliable performance | Less downtime, better fuel efficiency |

Warranty | At least 2 years on critical components |

Maintenance support | Easy to inspect, clean, and replace |

If you pick high-quality excavator parts, your machine works better and costs less to fix. It will last longer and stay safe, even when you use it in tough places.

OEM vs Aftermarket

When you need new excavator parts, you have two choices. You can pick OEM or aftermarket parts. This choice changes how your machine works and how long it lasts. It also affects how much money you spend. If you know the differences, you can make a better choice for your equipment.

OEM Pros and Cons

OEM stands for Original Equipment Manufacturer. These parts are made by the same company as your excavator. They are real parts that fit your machine just right. Many people like OEM because they check quality very carefully.

Advantages of OEM:

You get real parts that fit your machine perfectly.

OEM parts are strong and safe for your excavator.

Using OEM parts can help keep your warranty safe.

These parts fit well and do not cause other problems.

OEM parts are easy to put in and come with good help from the maker.

Disadvantages of OEM:

OEM parts cost more than other kinds.

Sometimes you have to wait longer if they are not in stock.

There are not as many choices if you want something special.

Note: If you pick real OEM parts, your excavator stays safe and works well. But you will pay more for this safety.

Aspect | Advantages of OEM Parts | Disadvantages of OEM Parts |

|---|---|---|

Cost | Backed by warranty and durability | Higher upfront cost |

Durability | Tested for long life and tough jobs | N/A |

Compatibility | Exact fit, prevents extra wear | N/A |

Availability | N/A | Can be limited, causing downtime |

Performance | Reliable in all conditions | N/A |

Aftermarket Pros and Cons

Aftermarket parts are made by other companies, not the original maker. You can find many different aftermarket parts for your machine. Some aftermarket parts are as good as OEM, but some are not.

Advantages of Aftermarket:

Aftermarket parts usually cost less than OEM parts.

Many stores have aftermarket parts ready, so you get them faster.

Some aftermarket parts have new features or better designs.

You can find good options for many different needs.

Disadvantages of Aftermarket:

Not all aftermarket parts are the same quality. Some may not last as long.

Using aftermarket parts can make your warranty not work anymore.

Some parts may not fit right, so you might need expert help.

A few aftermarket parts are fake or not safe.

Tip: Always check if the supplier is trusted before you buy aftermarket parts. Make sure the parts are real and have a clear warranty.

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Durability | High, due to strict specs and testing | Varies; some may not last as long |

Warranty | Strong, from the original manufacturer | Varies; some limited, some none; may void equipment warranty |

Compatibility | Exact fit for your machine | Must check carefully; may need expert advice |

When you look at OEM and aftermarket parts, think about what you need. Also think about your budget and if you want only real parts. Real parts give you peace of mind. But good aftermarket parts can save you money and time if you choose carefully.

Supplier Support

Warranties

When you pick a supplier for excavator parts, check their warranty choices. A good supplier gives strong warranties to protect your money. Most trusted suppliers have three main kinds of warranties:

Standard warranty: This covers your machine for a set time or hours. It protects most parts, but not things like fluids or filters. Some brands give a four-year or 4,000-hour warranty on new excavators.

Extended warranty: This adds more coverage after the first warranty ends. It often covers big systems like powertrain and hydraulics. Some suppliers let you choose which parts to cover, so you get what you need.

Specialized or promotional warranty: Sometimes, suppliers have special deals for certain parts. These can cover the engine or hydraulic system. They may last up to 10 years or 10,000 hours, based on what you need.

A good supplier uses real OEM parts for repairs during the warranty. This means your replacement parts are high quality. Always read reviews to see if the supplier keeps their warranty promises.

Tip: Warranties help you avoid big repair costs and keep your excavator working longer.

Availability

You need a supplier who can send parts fast. Quick delivery means your machine is not down for long. A good supplier keeps many common excavator parts in stock. This helps you get parts without waiting a long time.

Check reviews to see if other buyers like the supplier’s delivery speed. Many suppliers show live stock numbers on their websites. This helps you know if your parts are ready to ship. If your machine is rare, ask about special orders or custom parts.

Some suppliers have 24/7 help or emergency shipping. This is useful if your machine breaks down. Always pick a supplier with a good record for fast and correct deliveries. Reading reviews and ratings helps you find the best choice.

Supplier Feature | Why It Matters |

|---|---|

Large inventory | Faster access to needed parts |

Real-time stock updates | Know what is available right away |

Emergency shipping | Get parts quickly in urgent cases |

Positive reviews | Shows the supplier is reliable |

Note: Good supplier support helps your excavator keep running and stops costly delays.

Maintenance Tips

Installation Tips

You need to follow the right steps when you install new excavator parts. Good installation keeps your machine safe and helps parts last longer. Always read the manual before you start. The manual explains the safety requirements for hydraulic excavators and shows you the correct way to install each part.

Wear the right gear. Use gloves, safety glasses, and boots to protect yourself.

Turn off the engine and release all pressure from the hydraulic system. This step prevents accidents and keeps you safe.

Clean the area where you will install the part. Dirt or old grease can cause problems.

Check the new part for damage before you put it in. Never use a part that looks broken or bent.

Use the right tools for each job. The wrong tool can damage the part or hurt you.

Tighten bolts and fittings to the correct level. Too loose or too tight can cause leaks or breakage.

Test the part after installation. Watch for leaks, odd noises, or warning lights.

Tip: Always follow the manual and double-check your work. This helps you meet safety rules and keeps your excavator running well.

Longevity

You can make your excavator parts last longer with the right care. Daily checks and regular cleaning help you spot small problems before they grow. Here are some proven ways to extend the life of your parts and keep safety high:

Inspect your machine every day. Look for leaks, cracks, or loose bolts. Check the undercarriage, hydraulic lines, and attachments.

Lubricate moving parts like bearings and joints. This reduces friction and wear.

Monitor hydraulic fluid levels and keep them clean. Dirty or low fluid can damage the system and lower safety.

Clean debris from the undercarriage and tracks after each use. Dirt and rocks can cause early wear.

Use only attachments that fit your machine. Wrong attachments can stress parts and lower safety.

Store your excavator in a dry, covered place. This protects it from harsh weather.

Follow a set maintenance schedule. Change filters, oil, and fluids at the times listed in your manual.

Here is a table to help you remember how to care for different parts:

Component | Maintenance Steps | Signs of Wear | Lifespan Estimate |

|---|---|---|---|

Electrical System | Inspect wires, keep dry, use quality parts | Battery issues, errors | 3-5 years (battery) |

Attachments | Lubricate, check for cracks, store inside | Cracks, worn teeth | 7,500-10,000 hours |

Filters | Replace on schedule, use clean fluids | Clogging, low power | 500-2,000 hours |

Cooling System | Clean fans, check for leaks, replace pumps | Overheating, leaks | 2,000-10,000 hours |

Note: Good maintenance keeps your machine safe and helps you avoid costly repairs. Always put safety first when you work on your excavator.

Common Mistakes

Price Focus

Some people only look at price when buying excavator parts. They think saving money now is a good idea. But this can cost more later. If you only care about price, you miss other things. Durability and reliability are important too. Cheap parts may not last long or work well. Better-quality parts often work better and last longer.

Here are some problems if you only care about price:

You might not get features that help your machine work well.

Short or weak warranties can mean big repair bills later.

Bad maintenance or wrong attachments can wear out your machine fast.

Your machine may use more fuel and break down more often.

Rubber tracks and other parts wear out fast if you do not care for your machine.

Tip: Think about how much you spend over time, not just today. Good parts save money because they last longer and work better.

Ignoring Compatibility

Not checking compatibility is another big mistake. If you do not check if a part fits, you can have many problems. Always check the model, serial number, and OEM codes. Skipping this step can break your machine or waste money. It can also make your machine unsafe.

Consequence Category | Description |

|---|---|

Operational Inefficiency | Parts that do not fit right can make your machine work badly. You may get poor results and less work done. |

Equipment Damage | Using the wrong parts can break your machine and cost a lot to fix. |

Safety Hazards | Parts that do not fit can fall off and hurt people nearby. |

Hydraulic Mismatches | Wrong hydraulic parts can make your machine work badly and wear out faster. |

Weight and Balance Issues | Parts that do not fit can make your machine tip over or be hard to drive. |

Always check if parts fit before you buy. This keeps your machine safe and saves you money.

When you pick excavator parts brand new, make sure they fit your machine. Look for good quality and buy from brands people trust. Use catalogs, manuals, and diagrams to help you find the right parts. A good supplier has strong parts, helpful support, and keeps many parts in stock. This helps you not make mistakes and keeps your machine safe. If you work with trusted suppliers and use these tools, you protect your money and get more value from each part.

FAQ

What should you check before installing new excavator parts?

First, always read your manual. Make sure the part matches your machine’s model and serial number. Clean the area before you start working. This helps you stay safe and stops damage.

How do you keep safety a top priority when working on your excavator?

Wear gloves, boots, and safety glasses every time. Turn off the engine before you start. Let out all the hydraulic pressure. Always follow the steps in the manual. These steps help keep you and others safe.

Why is safety important when choosing excavator parts?

Safety keeps you and your team from getting hurt. If you use the wrong parts, accidents can happen. Your machine could also break. Always pick parts that fit your machine. This helps you avoid danger and keeps your job site safe.

Can you use aftermarket parts without losing safety?

Yes, you can use aftermarket parts if you pick trusted suppliers. Make sure the parts are good quality. Check reviews and ask about warranties. Good aftermarket parts help your machine stay safe and work well.