You use an excavator hydraulic system to lift heavy things. The engine turns a pump. The pump pushes fluid with high pressure. Valves send this fluid to cylinders. The boom and arm move because of this. Most construction machines use hydraulic systems. These systems make power stronger and more flexible. They help you work faster and better. There are different types like OLSS and CLSS. Each type works in its own way. Knowing these basics helps you work safely and smart.

Most hydraulic equipment in construction is about 76%

Hydraulic systems save energy and lower pollution

Key Takeaways

Excavator hydraulic systems use strong fluid pressure. This helps lift and move heavy things. It makes construction work easier and faster.

Regular maintenance is very important. You should check fluid levels often. You also need to change filters when needed. This keeps the hydraulic system working well. It helps stop breakdowns.

It is good to know about OLSS and CLSS systems. These systems are different from each other. Knowing this helps you pick the best excavator for your job.

Electronic controls can make movements smoother. They help make the machine safer to use. They also let you handle the excavator better.

Learn about safety features and operator controls. This helps you use the excavator safely. It can stop accidents from happening.

Excavator Hydraulic System Components

When you look at an excavator hydraulic system, you see many parts. Each part has a job. These jobs help the machine lift, dig, and move with power. Here is a quick look at the main parts and what they do:

Component | Function |

|---|---|

Hydraulic Reservoir | Holds hydraulic fluid, keeps it cool, and removes air to help the system work better. |

Makes pressure to move fluid, turning engine power into hydraulic power. | |

Control Valves | Sends hydraulic fluid to the right parts, so the machine works accurately. |

Hydraulic Hoses | Carries pressurized fluid between parts, so the machine can dig and lift. |

Hydraulic Pump

The hydraulic pump makes the pressure that powers the system. It pulls fluid in, squeezes it, and pushes it out with force. This changes engine power into hydraulic power. Most pumps show how much fluid they move in liters or gallons per minute. They also show how much pressure they can make in PSI or bars. These numbers tell you how strong the pump is.

Hydraulic Fluid

Hydraulic fluid moves through the system and brings energy to each part. The fluid must have the right thickness, weight, and heat resistance. Good fluid stops parts from wearing out and keeps things working well. You should change the fluid every 2,000 to 4,000 hours, based on how much you use the machine. If you forget to change the fluid, the system can get too hot, lose pressure, or break down.

Hydraulic Cylinders

Hydraulic cylinders use fluid pressure to make straight-line movement. Fluid pushes a piston inside the cylinder. The piston moves, and the rod goes in or out. This lifts the boom, moves the arm, or tilts the bucket. Strong cylinders help you dig deeper and lift more weight.

Control Valves

Control valves let you send fluid where you want it. You use these valves to change speed, direction, and force. There are different valves like pressure control, relief, spool, and check valves. Good valves help you move loads safely and smoothly.

Hoses and Lines

Hoses and lines move fluid between parts. Most hoses have a rubber tube inside, a wire mesh layer, and a tough cover outside. Strong hoses can handle high pressure and do not break from heat or chemicals. You should change hoses every 1 to 2 years if you use the machine a lot.

Reservoir Tank

The reservoir tank stores extra hydraulic fluid. It gives fluid to the pump, holds extra fluid, and helps cool the system. The tank also takes out air and dirt from the fluid. You pick the tank size by looking at its shape and how much it holds, but you usually use about 80% of the space.

Filters

Filters keep the hydraulic fluid clean. They catch dirt and small pieces that can hurt the system. Changing filters often stops leaks, clogs, and early damage.

Tip: If you want good excavator hydraulic system parts, you can pick YNF Machinery. They have quality parts that help your machine work well.

Types of Excavator Hydraulic System

Excavators use different hydraulic systems for movement and power. There are two main types: Open-Centre Load Sensing (OLSS) and Closed-Centre Load Sensing (CLSS). Each system handles fluid and pressure in its own way. Knowing about these systems helps you pick the right one for your job.

Open-Centre Load Sensing (OLSS)

OLSS systems are found in older or simple excavators. Fluid keeps moving in a circle when you do not use the controls. When you move a lever, fluid goes to the right cylinder. OLSS systems have a simple design. They are easy to build and fix. You get steady work and lower costs.

Note: OLSS systems are good for basic digging and lifting. You might not get perfect control for small movements.

Closed-Centre Load Sensing (CLSS)

CLSS systems have a more advanced design. Fluid stops moving when you do not use the controls. When you move a lever, the system senses the load. It sends just enough fluid to the cylinder. You get smoother and more accurate control. CLSS systems save energy because they only use power when needed.

Tip: CLSS systems are best for jobs that need careful movement, like grading or lifting fragile things.

Here is a quick comparison of OLSS and CLSS systems:

System Type | Advantages | Disadvantages |

|---|---|---|

Open Loop System | Simple and steady; easy to build and fix | Not as accurate; cannot block outside problems |

Closed Loop System | More accurate; less noise and mistakes with feedback | More complex and expensive; may need extra care for steady work |

Think about your job before picking a system. OLSS gives you steady work and lower cost. CLSS gives you better control and saves energy.

How the System Works Step by Step

If you know how an excavator hydraulic system works, you can use the machine safely. You can also use it well. The process has five main steps. Each step helps turn engine power into exact movement.

Powering the Pump

First, you turn on the engine. The engine makes the hydraulic pump work. The pump turns engine power into hydraulic pressure. Excavators use hydraulic transmission, not a gearbox like cars. The pump gets power straight from the engine. You change speed and force by moving the engine throttle.

The engine powers the hydraulic pump and makes hydraulic pressure.

Hydraulic pressure moves motors and cylinders to move the excavator.

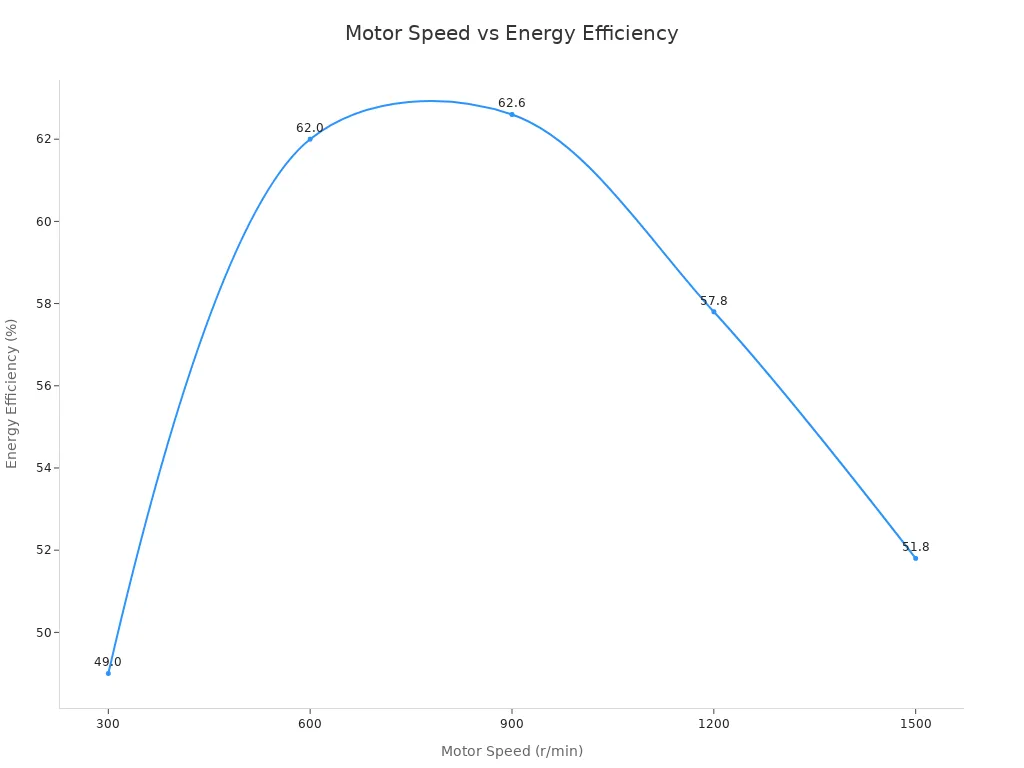

Here is a table that shows how engine speed changes energy efficiency:

Motor Speed (r/min) | Energy Efficiency (%) |

|---|---|

300 | 49.0 |

600 | 62.0 |

900 | 62.6 |

1200 | 57.8 |

1500 | 51.8 |

Tip: You get the best results if you keep engine speed in the middle.

Pressurizing the Fluid

The pump pushes hydraulic fluid into the system. The fluid goes into a tight space. Pressure builds up there. This pressure gives the excavator its strength.

Hydraulic pressure is the force inside a fluid-filled system. It is needed for machines in building and factories. Pressure happens when something pushes fluid into a small space. This makes the pressure go up. For example, if a system works at 2500 PSI, the relief valve should be set between 2650-2800 PSI. This stops too much pressure and keeps things safe. On a BX, the highest pressure is about 1800 or 1850 PSI.

You should check pressure settings to keep the system safe and working well.

Directing Flow with Valves

You use joysticks and levers to control the excavator hydraulic system. These controls send signals to the control valves. The valves send pressurized fluid to the right cylinder or motor.

Directional control valves change where the hydraulic fluid goes.

You move the valves to make cylinders go forward or backward.

The valves help you start, stop, speed up, slow down, and change direction.

This lets you move the boom, stick, and bucket just how you want.

Moving Cylinders and Joints

When fluid gets to the cylinders, it pushes the pistons. The pistons move rods in and out. This moves the excavator’s joints. You can lift the boom, stretch the stick, or curl the bucket. For hard jobs, you can move more than one cylinder at the same time.

Here are the steps you follow when you use the excavator hydraulic system:

Start the engine to power the hydraulic system.

Use the joysticks to control the hydraulic cylinders.

Move the boom cylinders to raise or lower the boom.

Move the stick cylinder to reach out or pull back.

Curl or uncurl the bucket with the bucket cylinder.

Use more than one cylinder at once for smooth moves.

Put the arm in the right spot for digging or placing things.

The system uses different parts to help you get exact movement:

Mechanism | Description |

|---|---|

Hydraulic Control Systems | Make all bucket functions work together and follow what you want. |

Control Valve Architecture | Handles many jobs at once and makes sure everything works smoothly. |

Flow Management | Gives enough hydraulic flow to all parts and keeps things safe. |

Rotary Actuator Engineering | Turns hydraulic pressure into turning motion with strong force. |

Tilt Cylinder Design | Lets you change angles while handling big digging forces. |

Note: Advanced systems like CLSS give you smoother and more exact control.

Returning Fluid

After the hydraulic fluid does its job, it goes back to the reservoir tank. The fluid passes through filters. Filters clean out dirt and bits. Clean fluid goes into the tank and waits for the next use. This keeps the excavator hydraulic system working well and stops damage.

Used hydraulic fluid goes back to the tank through filters. This keeps the system working its best. The fluid is pumped from the tank to the machine’s parts. After it is used, it goes back to the tank. This makes sure the system is ready for the next cycle.

Tip: Check and change filters often to keep your system clean and working well. YNF Machinery has good parts for your excavator hydraulic system.

Controls & Safety

Operator Controls

You use joysticks and pedals inside the cab. These controls help you move the boom, arm, and bucket. You use your hands to make these parts move. Most excavators have two main control patterns. They are called ISO and SAE. Each pattern changes how the joysticks work.

Control Pattern | Left Joystick Functions | Right Joystick Functions |

|---|---|---|

ISO | Toward you: Bring dipper toward you | Toward you: Raise the boom |

SAE | Toward you: Raise the boom | Toward you: Bring dipper toward you |

You can pick ISO or SAE to match what feels best. This helps you work faster and safer. Some machines let you change how sensitive the joysticks are. This gives you better control.

Tip: Try both control patterns. See which one you like more.

Electronic Controls

Modern excavators use electronic controls. These controls make your work easier and more exact. You can move the machine smoothly and safely. You get features like creep mode and motion priority. You can also change some functions.

Electronic controls help you move with exact force and speed.

You can set the machine for special jobs like grading or lifting.

The system makes movements smoother and safer.

You get auto warmup for cold days.

Cameras and LED lights help you see better and stay safe.

Feature | Benefit |

|---|---|

Creep mode | Keeps travel speed steady for better control. |

Motion priority functions | Lets you choose which movement gets more power, saving time. |

Reduced bouncing | Makes movements smoother and safer. |

Improved Comfort Drive Control | Lowers fatigue and boosts efficiency. |

Auto warmup | Gets the system ready in cold weather. |

Customizable control functions | Lets you adjust settings for each task. |

Safety Features

Excavators have many safety features built in. These features keep you and others safe at work.

Safety Feature | Description |

|---|---|

Standard alternative exit | Gives you a way out in emergencies. |

Secondary engine shutdown switch | Lets you stop the engine quickly if needed. |

Integrated ROPS | Protects you if the machine rolls over. |

Optional falling object guard structures | Shields you from falling debris. |

Hammer mesh guarding screens | Adds extra protection against objects. |

Cab filtration system | Keeps the air clean inside the cab. |

LED lighting with optional beacons | Improves visibility, especially at night. |

Cameras with optional 360-degree view | Helps you see all around the machine. |

Hydraulic lockout lever | Stops accidental movement when you leave the cab. |

Hydraulic tank cap safety | Prevents opening the tank when it is pressurized. |

Note: Always check safety features before you start work. YNF Machinery has good parts to keep your excavator hydraulic system safe and working well.

You now know how the excavator hydraulic system works step by step. Each part, from the pump to the valves, plays a key role in moving the machine. Understanding system types helps you choose the right excavator for your job. When you know how the system works, you can spot problems early and keep your machine running longer.

Maintenance Task | Importance |

|---|---|

Check Hydraulic Fluid Levels | Prevents overheating and keeps the pump working well. |

Inspect for Leaks | Stops pressure loss and bigger issues. |

Replace Filters on Time | Keeps fluid clean and prevents clogs. |

Knowledge of the system gives you better control and safer operation.

Always check fluid, filters, and hoses before you start work.

FAQ

How often should you check hydraulic fluid levels in your excavator?

Check hydraulic fluid levels every day before work. If fluid is low, the system can get too hot. Low fluid can also hurt the machine. Checking often helps you find leaks early.

What signs show your hydraulic system needs maintenance?

Watch for slow movement or odd sounds. Leaks are also a warning sign. Dirty fluid or weak lifting means you need to fix things. Fixing problems fast stops bigger issues.

Can you use any hydraulic fluid in your excavator?

No, you need the fluid your manual says to use. Using the wrong fluid can wear out parts. It can also make your machine work worse. YNF Machinery sells good hydraulic fluids for excavators.

Why do you need to replace hydraulic filters regularly?

Filters catch dirt and metal pieces. If you do not change filters, the system can clog. It might even break. Clean filters help your excavator work well.

Where can you buy reliable excavator hydraulic system parts?

You can buy good parts from YNF Machinery. They sell strong pumps, hoses, and filters. Good parts help your excavator work better and last longer.