You must always match hitachi excavator hydraulic parts to your exact model and serial number for the best results. Quality and durability matter most when you choose parts for your hitachi ex60-g or any other excavator. Select genuine or trusted OEM hydraulic components to protect your machine. Reliable suppliers help you avoid costly mistakes. The right hydraulic oil also keeps hitachi excavator hydraulic parts running smoothly.

Key Takeaways

Always match hydraulic parts to your Hitachi excavator’s exact model and serial number to avoid costly mistakes and ensure safety.

Choose high-quality or genuine parts to improve performance, reduce breakdowns, and save money on repairs and downtime.

Work with trusted suppliers who offer fair prices, reliable delivery, and good after-sales support to protect your investment.

Inspect all parts carefully before installation to catch defects early and keep your excavator running smoothly.

Plan and follow regular maintenance, including oil checks and changes, to extend the life of your hydraulic system and avoid failures.

Why Quality Matters

Performance & Reliability

You depend on your excavator to work hard every day. High-quality hydraulic parts keep your machine running smoothly and safely. When you choose the right hydraulic components, you get better power, faster response, and more precise control. These parts help your excavator handle tough jobs without breaking down.

Durable hydraulic parts also protect you from sudden failures. If you use low-quality or mismatched parts, you risk leaks, weak performance, and even dangerous accidents. Reliable hydraulic systems mean fewer surprises and more time working on the job site.

Tip: Always check that your hydraulic parts match your machine’s model and serial number. This step helps you avoid costly mistakes and keeps your equipment safe.

Cost & Downtime

Quality matters for your wallet, too. High-quality hydraulic parts may cost more at first, but they save you money over time. Take a look at this comparison:

Metric | Low-Quality (Standard) Parts | High-Quality (Premium) Parts | Impact / Difference |

|---|---|---|---|

Initial Cost Premium | N/A | 20-40% higher | Higher upfront investment |

Failure Rate | Baseline | 35-50% fewer failures | Fewer breakdowns |

Monthly Downtime (Forestry) | ~12 hours | ~7.8 hours | ~35% downtime reduction |

Annual Downtime Cost (Forestry) | $172,800 | $112,320 | $60,480 annual savings |

Premium Cost for Upgrade | N/A | $3,000-$5,000 | Cost offset by savings |

Maintenance Costs | Higher | Lower | Less spent on repairs |

Repair Time | Longer | Shorter | Faster recovery |

Additional Benefits | N/A | Extended asset life, improved reliability, reduced safety/environmental risks | Long-term advantages |

You can see that premium hydraulic parts reduce downtime and lower repair costs. They also extend the life of your equipment. Here are more benefits you get with high-quality hydraulic parts:

Improved equipment uptime and fewer breakdowns.

Less time and money spent on emergency repairs.

Lower risk of safety incidents and environmental problems.

Longer asset life and better reliability.

A return on investment that can be ten times higher due to less downtime.

When you choose the right hitachi excavator hydraulic parts, you protect your investment and keep your business running strong.

Checklist for Hitachi Excavator Hydraulic Parts

Model & Serial Number

Start your selection process by checking your excavator’s model and serial number. Every Hitachi machine, including the hitachi ex60-g, has a unique set of hydraulic parts. You must match these numbers to the parts you buy. This step helps you avoid ordering the wrong components. Always look for the identification plate on your excavator. Write down the details before you contact a supplier or search online.

Tip: Use the Hitachi parts manual or ask your dealer for help if you are unsure about the correct numbers.

Genuine vs. Aftermarket

You face a choice between genuine Hitachi parts and aftermarket or OEM options. Genuine parts come from the original manufacturer. They fit perfectly and meet strict quality standards. OEM (Original Equipment Manufacturer) parts also offer high quality, but some aftermarket parts may not. When you choose aftermarket parts, check for certifications and reviews. Look for parts that meet or exceed Hitachi’s standards.

A genuine hydraulic part will last longer and protect your excavator from damage. Aftermarket parts can save money, but only if you pick trusted brands. Always compare the warranty and return policy before you decide.

Supplier Reputation

Your supplier plays a big role in the quality of your hydraulic parts. Top-rated suppliers offer more than just parts. They provide fair pricing, reliable delivery, and strong after-sales support. When you choose a supplier, check their reputation and customer reviews. Reliable suppliers often have exclusive contracts and real-time monitoring systems. These features help you get the best price and protect your business from contract issues.

Identifying active exporters with good prices and reliability helps you save money and increase profits.

Price analysis lets you negotiate better deals, sometimes giving you a huge return on your investment.

Exclusive supply contracts and real-time tracking protect your market position.

Custom alerts help you stay ahead of competitors and adapt quickly.

Note: A good supplier will answer your questions, offer a warranty, and help you solve problems after the sale.

Inspection Before Installation

Before you install any hydraulic part, inspect it carefully. Check for damage, defects, or missing pieces. Make sure the part matches your model and serial number. Look for signs of poor workmanship, such as rough edges or loose fittings. If you find any problems, contact your supplier right away.

A careful inspection helps you avoid costly mistakes. It also keeps your excavator safe and running smoothly. Never skip this step, even if the part looks new.

Maintenance Planning

Plan your maintenance before you install new hydraulic parts. Good planning extends the life of your components and reduces downtime. Keep a log of all maintenance activities. Schedule regular checks and replace filters and fluids as needed. Use predictive tools like vibration analysis and fluid sampling to spot problems early.

Scheduled maintenance includes steps like choosing the right machine and installation environment.

Predictive maintenance uses tests to find early signs of wear or failure.

Preventive maintenance means routine checks, filter changes, and leak detection.

Good record-keeping helps you track machine health and plan future work.

These steps lower repair costs and keep your excavator working longer.

Tip: Follow the maintenance advice in your Hitachi manual. Consistent planning and record-keeping will help you get the most from your hitachi excavator hydraulic parts.

Key Components

Hydraulic Pumps

You rely on the hydraulic pump to power your excavator’s movements. When you select a pump, check for quality materials and precise manufacturing. Look for pumps that meet or exceed OEM standards. Quality pumps last longer and resist common problems like cavitation, contamination, and overheating.

Clean hydraulic fluid (ISO 16/14 or better) keeps pumps running smoothly.

Regular inspections help you spot leaks or wear early.

Proper installation with correct alignment and torque prevents premature failure.

Monitoring pressure, temperature, and flow rates avoids overloading.

Vibration analysis can detect misalignment or bearing wear before breakdowns.

You can choose new, remanufactured, or reconditioned pumps. Remanufactured pumps from trusted sources often match new ones in performance and reliability.

Valves

Hydraulic valves control the flow and direction of fluid in your system. High-quality valves improve safety and efficiency. Electronic control systems and precise manufacturing give you better response and less energy loss.

Stable operation at high pressure means fewer leaks and longer life.

High-strength materials and tight tolerances reduce wear and improve sealing.

Real-time monitoring lets you adjust settings for better performance.

Performance Indicator | High-Quality Valves | Low-Quality Valves |

|---|---|---|

Pressure Testing | Stable, no leakage | Prone to leakage |

Durability | 10+ million cycles | 200,000-300,000 cycles |

Service Life | Long, heavy-duty use | Short, high maintenance |

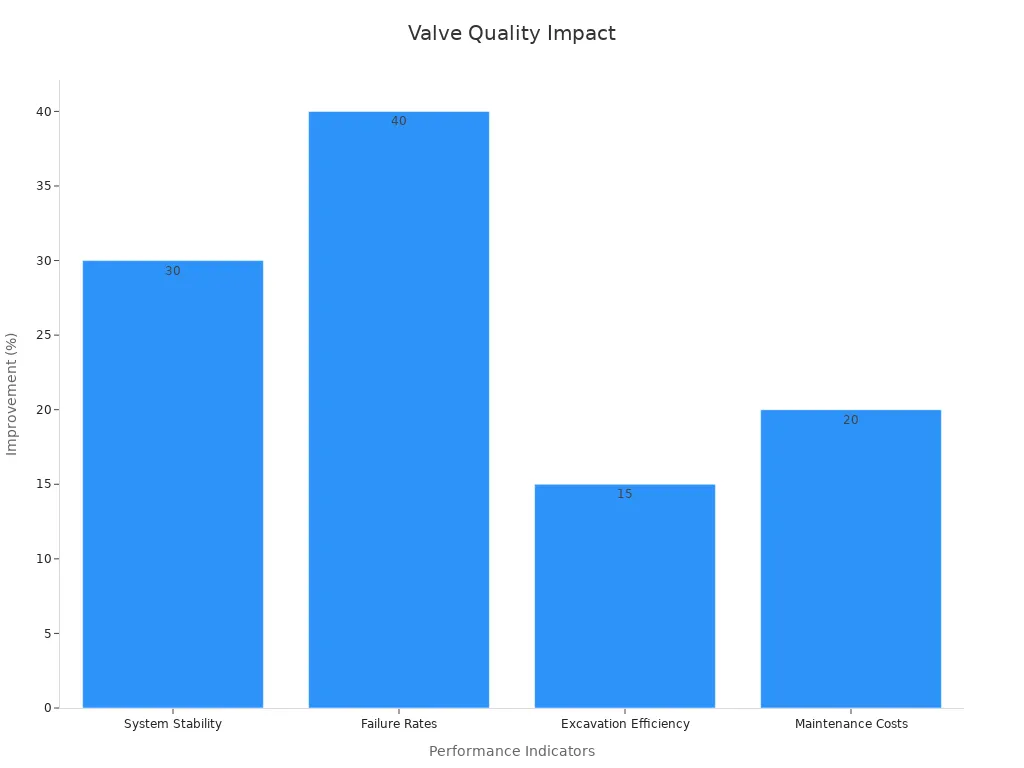

Upgrading to high-end valves can boost system stability by 30% and cut failure rates by 40%. You get better safety and less downtime.

Hoses & Fittings

Hoses and fittings connect every hydraulic part. Always choose hoses and fittings that meet SAE J517 or EN standards.

High-quality fittings prevent leaks and injuries, even at 4000 PSI.

Proper torque, alignment, and cleanliness during installation keep your system safe.

Regular inspection finds wear or leaks before they cause problems.

Use abrasion sleeves and match pressure ratings to extend hose life.

A mining operation tripled hose life by redesigning layouts and using better fittings. This reduces leaks, downtime, and maintenance costs.

Cylinders

Hydraulic cylinders move your excavator’s arms and bucket. Proper cylinder selection reduces wear and tear.

Match cylinder size and line dimensions to your machine’s flow rate.

Use heavy-duty hydraulic oil with anti-wear additives for better lubrication.

Inspect pins and cylinders often and replace them when needed.

Choosing the right cylinder and oil prevents seal failure and metal contact, keeping your system running longer.

Hydraulic Motors

Hydraulic motors drive movement in your excavator, including the travel motor leaking hydraulic oil. Quality motors show high efficiency, often above 95%.

New and remanufactured motors from reputable sources meet or exceed OEM specs.

Remanufactured motors get full testing and new parts, offering reliability close to new units.

Reconditioned motors may not last as long or perform as well.

Pick motors that pass strict tests for efficiency and durability. This choice keeps your excavator working hard and reduces the risk of leaks or breakdowns.

Hydraulic Oil Selection

Oil Type & Compatibility

Choosing the right oil is a key step in hydraulic oil selection. You need to use the correct hydraulic oil for your Hitachi excavator to keep the system running at its best. Hitachi recommends oils like Genuine Hydraulic Oil Super 46HN, which meet strict standards such as JCMASHX-1 and ISO11158. These standards make sure the oil matches the chemical and physical needs of your machine.

Hydraulic oils come in different types. You will find mineral-based, synthetic, multi-grade, and water-based oils. Each type has a unique base oil and additives. The oil viscosity is very important. It affects how well the oil flows and protects parts. Always check your manual for the right oil viscosity grade. Using oil with the wrong viscosity can cause poor performance or damage. Bio hydraulic fluids, made from high-oleic base stocks, offer strong oxidation stability and work well with many seal materials. This makes them a good choice if you want better system protection and easy compatibility.

Tip: Always match the oil’s viscosity and type to your machine’s needs. This step helps you avoid leaks and keeps seals in good shape.

Maintenance Tips

Regular maintenance keeps your hydraulic system healthy. You should check oil levels every day and look for signs of contamination, such as changes in color or smell. Oil viscosity can change over time, so watch for any thickening or thinning. Clean or replace filters as needed, and inspect hoses and fittings for leaks.

Here is a simple maintenance schedule:

Interval | Maintenance Tasks |

|---|---|

Daily | Check oil levels, temperature, and look for leaks or dirt. |

Every 6 weeks | Inspect and replace filters, clean strainers, check hoses and connections. |

Every 6 months | Send oil samples for testing (viscosity, wear metals), check accumulator pressure. |

Annual | Drain and clean the oil tank, flush the system, inspect pumps, motors, and valves. |

Oil Change | Change oil every 1,000 to 2,000 hours, depending on use and environment. |

Keeping up with these checks helps you spot problems early and keeps your hydraulic system working longer.

You protect your Hitachi excavator when you follow each step in the checklist. Choose quality parts, match them to your model, and plan regular maintenance. Trusted suppliers and manuals help you make the right choices.

Inspection Frequency | Key Tasks and Focus Areas | Impact on Hydraulic Parts Performance |

|---|---|---|

Daily | Check fluid levels, leaks, safety equipment | Early detection prevents pump damage |

Weekly | Inspect system, lubricate moving parts | Prevents wear, keeps system strong |

Monthly | Inspect pump, filters, seals, cooling | Finds hidden faults, extends life |

Preventive maintenance and smart part selection lower costs and reduce downtime.

Good habits extend equipment life and improve performance.

Using this checklist helps you keep your excavator reliable for years to come.

FAQ

What should you check first when buying Hitachi excavator hydraulic parts?

You should always check your excavator’s model and serial number. This step helps you find the right hitachi excavator hydraulic parts. Using the wrong part can cause damage or poor performance.

How do you choose the correct hydraulic oil for your Hitachi excavator?

You need to follow the hydraulic oil selection guide in your manual. The correct hydraulic oil protects your system. Always check oil viscosity and make sure it matches your hitachi ex60-g or other model.

Why does your travel motor keep leaking hydraulic oil?

A travel motor leaking hydraulic oil often means a damaged seal or worn part. You should inspect the hydraulic system and replace faulty hitachi excavator hydraulic parts. Using the right oil and regular checks help prevent leaks.

How often should you change hydraulic oil in your excavator?

You should change hydraulic oil every 1,000 to 2,000 hours. Oil viscosity changes over time. Regular oil changes keep your hitachi running smoothly and protect all hydraulic components.

Can you use aftermarket parts for Hitachi hydraulic systems?

You can use aftermarket parts if they meet hitachi standards. Always check quality and compatibility. Trusted suppliers help you avoid problems with your excavator’s hydraulic system.