Choosing the right parts for your excavator can feel overwhelming. Genuine and aftermarket options for Hitachi excavator replacement parts each come with unique benefits and challenges. Your decision directly affects the machine’s performance, cost of ownership, and reliability.

OEM parts ensure reliability and reduce long-term costs by meeting strict manufacturing standards.

Aftermarket parts often cost less upfront but may lead to higher expenses if they fail or void warranties.

Understanding your equipment’s needs and the role of the part helps you make the best choice.

Key Takeaways

Real Hitachi parts are dependable and work best for new machines.

Cheaper aftermarket parts save money now but might cost more later.

Check if parts fit your Hitachi machine to avoid problems.

Think about your budget and needs; good parts reduce repairs and delays.

Reliable sellers like YNF Machinery offer good aftermarket parts at fair prices.

Genuine vs. Aftermarket Hitachi Excavator Parts: Definitions and Key Differences

What Are Genuine Hitachi Excavator Parts?

Genuine Hitachi excavator parts are components manufactured by the Original Equipment Manufacturer (OEM). These parts are specifically designed to meet the exact specifications of Hitachi machinery, ensuring a precise fit and seamless operation. They undergo advanced manufacturing processes, including precision machining and rigorous quality control, to deliver unmatched reliability and durability.

Using genuine parts reduces the frequency of breakdowns and minimizes maintenance costs. Their sealed and lubricated design prevents contaminants from entering, ensuring smooth movement and extending the lifespan of your equipment. Genuine parts also offer easy installation, thanks to bolt-on or pin-and-bushing connections, which save you time during replacements.

Characteristic | Description |

|---|---|

Performance and Longevity | Engineered for optimal performance and durability in harsh environments. |

Advanced Manufacturing Techniques | Precision machining and quality control ensure reliability. |

Sealed and Lubricated Design | Prevents contaminants and ensures smooth operation. |

Bolt-On or Pin-and-Bushing Connections | Allows for easy installation and robust connections. |

Compatibility and Interchangeability | Designed to fit OEM specifications, reducing downtime. |

What Are Aftermarket Hitachi Excavator Parts?

Aftermarket Hitachi excavator parts are produced by manufacturers other than the OEM. These parts are designed to fit various models of Hitachi equipment while offering a cost-effective alternative to genuine components. Manufacturers use high-strength steel alloys and advanced techniques like heat treatment to ensure durability and performance.

Aftermarket parts often feature sealed and lubricated designs to prevent contaminants and reduce friction, which extends their lifespan. They are crafted to meet OEM specifications, ensuring compatibility and easy replacement. While aftermarket parts may not always match the quality of genuine components, they provide a practical solution for budget-conscious buyers.

Key Differences Between OEM Parts and Aftermarket Parts

The primary difference between OEM parts and aftermarket parts lies in their manufacturing origin. OEM parts come directly from Hitachi, ensuring exact specifications and compatibility. Aftermarket parts, on the other hand, are produced by third-party manufacturers and are designed to fit multiple models.

OEM parts guarantee reliability and performance due to their strict quality standards. Aftermarket parts, while more affordable, may vary in quality depending on the manufacturer. Genuine parts often feature advanced designs, such as sealed components and precise machining, which enhance durability. In contrast, aftermarket parts focus on cost-effectiveness and broader compatibility.

Tip: Choose OEM parts for critical components where reliability and performance are essential. Opt for aftermarket parts when budget constraints or availability are your primary concerns.

Comparing Genuine and Aftermarket Hitachi Excavator Replacement Parts

Cost Comparison

Initial Purchase Price

When comparing initial costs, genuine parts often come with a higher price tag. These parts can cost 20% to 60% more than aftermarket options. However, aftermarket parts provide a budget-friendly alternative for those looking to save money upfront. If you are working within a tight budget, aftermarket parts might seem like the better choice.

Long-term Cost Implications

While aftermarket parts may save you money initially, they often lead to higher expenses over time. Frequent replacements and repairs due to lower quality can quickly add up. On the other hand, OEM parts offer better durability and reliability, reducing the need for constant replacements. Investing in OEM parts can save you money in the long run.

Aspect | Genuine Parts | Aftermarket Options |

|---|---|---|

Initial Cost | Higher (20% to 60% more) | Lower initial cost |

Longevity | Higher durability | Frequent replacements |

Warranty Coverage | Comprehensive | Limited or no warranty |

Long-term Value | Better overall investment | Potential hidden costs |

Quality and Durability

Material Standards and Manufacturing Processes

OEM parts are manufactured using high-grade materials and advanced processes. These strict standards ensure consistent quality and performance. Aftermarket parts, while more affordable, may not always meet the same level of quality. Some aftermarket manufacturers use cost-cutting measures that can compromise durability.

Longevity and Reliability

Genuine parts are designed to last longer, even under harsh conditions. Their superior construction reduces the risk of failure, ensuring reliability over time. Aftermarket parts, though cheaper, often require frequent replacements. This can lead to increased downtime and higher maintenance costs.

Performance and Compatibility

Ensuring Compatibility with Hitachi Equipment

OEM parts are specifically designed for Hitachi excavators, guaranteeing perfect compatibility. This ensures seamless integration and optimal performance. Aftermarket parts, while versatile, may not always fit as precisely. Improper fit can lead to inefficiencies and potential damage to your equipment.

Impact on Excavator Efficiency

Using genuine parts enhances the overall efficiency of your excavator. These parts maintain the machine’s original performance levels, ensuring smooth operation. Aftermarket parts, if not of high quality, can negatively impact performance. Reduced efficiency can result in slower operations and increased fuel consumption.

Availability and Accessibility

Lead Times for Genuine Parts

When you choose genuine Hitachi excavator replacement parts, you may encounter longer lead times. These parts are manufactured to exact specifications, which often requires additional production and shipping time. If your equipment needs urgent repairs, waiting for OEM parts can delay operations. However, the wait ensures you receive components that guarantee reliability and performance.

Availability of Aftermarket Options

Aftermarket parts offer greater availability compared to OEM parts. Many suppliers stock a wide range of aftermarket options, making it easier to find the parts you need quickly. This accessibility proves beneficial when you face tight deadlines or unexpected breakdowns. Additionally, aftermarket manufacturers often produce parts compatible with multiple models, increasing your chances of finding a suitable replacement. While availability is a strong point, always verify the quality of aftermarket parts to avoid compromising your equipment’s longevity.

Warranty and Support

Warranty Coverage for OEM Parts

OEM parts typically come with comprehensive warranty coverage. For genuine Hitachi parts, the warranty lasts 12 months from the date of installation or purchase. This coverage reflects the manufacturer’s confidence in their product’s quality and reliability. If a defect arises during the warranty period, you can expect support for repairs or replacements. This assurance adds value to your investment in OEM parts.

Warranty Terms for Aftermarket Parts

Warranty terms for aftermarket parts vary widely depending on the manufacturer. Some suppliers offer limited warranties, while others may not provide any coverage. Before purchasing, review the warranty details to understand what is included. A reliable aftermarket supplier will back their products with reasonable warranty terms, ensuring you receive support if issues arise. Choosing a trusted supplier helps you balance cost and quality while minimizing risks.

Factors to Consider When Choosing Between Genuine and Aftermarket Parts

Equipment Age and Condition

The age and condition of your equipment play a significant role in deciding between genuine and aftermarket parts. For newer machines, oem parts ensure compatibility and maintain the original specifications of your Hitachi excavator replacement parts. These parts protect your investment by preserving performance and warranty coverage. On the other hand, aftermarket parts can be a practical choice for older equipment. They offer cost-effectiveness and availability, especially for models where oem parts are no longer in production.

Choose oem parts for critical components in newer machines to ensure reliability and longevity.

Opt for aftermarket parts for older machinery or less critical components to save on cost without compromising functionality.

Budget Constraints and Cost-effectiveness

Your budget often dictates whether you choose oem or aftermarket parts. Aftermarket parts typically cost less upfront, making them appealing for those with tight budgets. However, their lower quality can lead to frequent replacements and higher long-term costs. Investing in oem parts provides better durability and performance, offering greater value over time.

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Initial Cost | Higher (20% to 60% more) | Cheaper upfront |

Long-term Value | Better longevity and performance | May require frequent replacements |

Warranty Coverage | Comprehensive | Often limited or no warranty |

If you prioritize reliability and long-term savings, oem parts are the better choice.

For immediate cost savings, aftermarket parts may suit your needs, especially for non-critical components.

Urgency of Repairs and Part Availability

When time is of the essence, the availability of parts becomes crucial. Aftermarket parts are often more readily available, allowing for faster repairs. This quick access can minimize downtime, which is essential during urgent situations. However, genuine parts from authorized dealerships ensure repair integrity and safety. While they may take longer to source, their reliability justifies the wait for critical repairs.

Use aftermarket parts for quick fixes when time is limited.

Rely on oem parts for essential repairs to maintain the safety and efficiency of your equipment.

Tip: Always balance urgency with the need for quality and compatibility to avoid compromising your machine’s performance.

Long-term Goals and Operational Needs

Your choice between genuine and aftermarket parts should align with your long-term operational goals. If you aim to maximize your excavator’s lifespan and maintain consistent performance, genuine parts provide a reliable solution. These parts are manufactured to original specifications, ensuring they perform as effectively as the components initially installed in your equipment. Their durability reduces the risk of unexpected breakdowns, keeping your operations running smoothly.

Using genuine parts also enhances fuel efficiency. Optimal operation minimizes energy waste, which can significantly lower fuel costs over time. Additionally, genuine parts undergo rigorous testing to meet safety standards. This ensures your equipment operates safely, reducing the likelihood of accidents or malfunctions.

For businesses planning to sell their excavators in the future, genuine parts help preserve resale value. Buyers often prefer machines maintained with original components, as they trust the quality and reliability of OEM parts. Furthermore, many genuine parts come with warranty coverage. This protects your investment and provides peace of mind, knowing you are covered in case of defects.

On the other hand, aftermarket parts may suit operations with short-term goals or tight budgets. These parts offer a cost-effective alternative, especially for older equipment nearing the end of its service life. However, frequent replacements and potential compatibility issues can increase costs in the long run. To ensure you get the best value, prioritize high-quality aftermarket parts from reputable suppliers.

When deciding, consider how your choice impacts operational efficiency, safety, and long-term costs. Aligning your decision with your goals ensures your equipment remains productive and reliable for years to come.

The Role of YNF Machinery in Providing High-Quality Aftermarket Parts

YNF Machinery’s Expertise in Hitachi Excavator Replacement Parts

YNF Machinery brings decades of expertise to the aftermarket industry for Hitachi excavators. You can rely on their parts for heavy-duty applications, as they are built to endure challenging conditions. Their focus on quality ensures that every component meets or exceeds industry standards. This commitment helps you maintain the reliability of your equipment.

Ordering parts from YNF Machinery is simple. Their vast dealer network and efficient online catalog make it easy to find what you need. Whether you are looking for specific components or general heavy equipment parts, their system ensures quick access. This convenience reduces downtime and keeps your operations running smoothly.

Aspect | Description |

|---|---|

Quality and Durability | YNF Machinery is known for providing parts that are designed to endure heavy-duty applications. |

Easy Access to Parts | They offer a vast dealer network and an efficient online catalog for easy ordering of parts. |

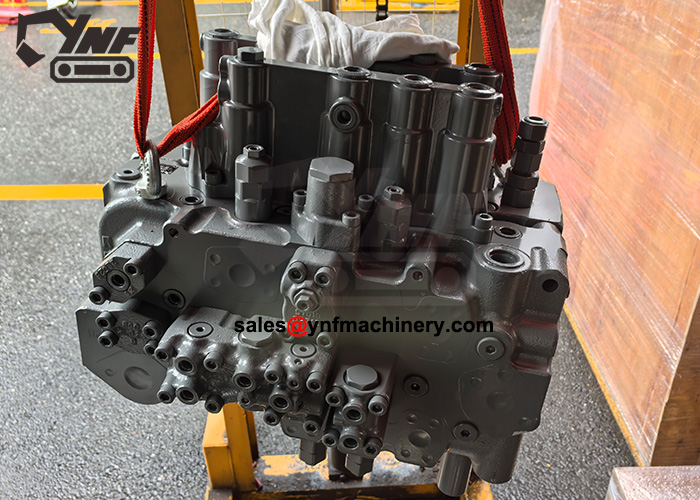

High-Quality Excavator Couplings for Enhanced Performance

Excavator couplings from YNF Machinery enhance the performance of your equipment. These couplings ensure efficient power transmission between the engine and hydraulic pump system. Their robust construction minimizes wear and tear, even in demanding environments.

You will find couplings designed for easy installation and maintenance. This feature reduces downtime and keeps your excavator operating at peak efficiency. YNF Machinery offers various types, such as Centaflex-A and Bowex couplings, to suit different applications. Each coupling is crafted with precision to ensure compatibility with Hitachi excavators.

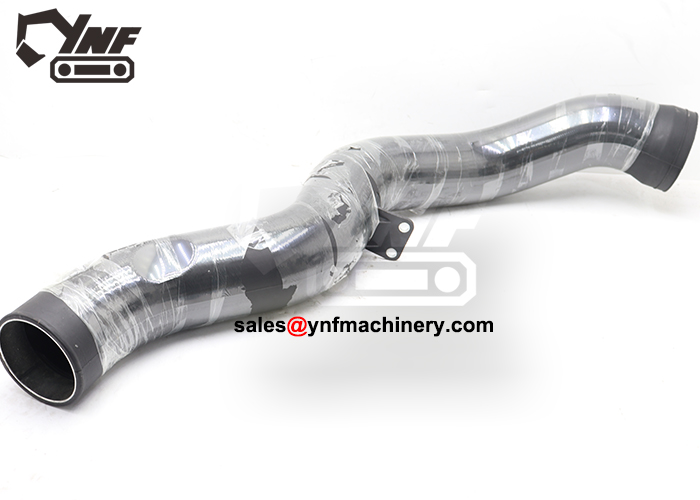

Reliable Excavator Engine Parts for Long-lasting Durability

YNF Machinery provides engine parts that deliver durability and reliability. These components, including pistons, crankshafts, and injectors, are made from high-grade materials. They are designed to withstand high temperatures and pressure, ensuring the longevity of your equipment.

Using these parts helps you reduce fuel consumption and emissions. This efficiency lowers operating costs while maintaining the performance of your excavator. YNF Machinery’s engine parts meet or exceed OEM standards, giving you confidence in their compatibility and quality.

Hydraulic Cylinder Seal Kits for Preventing Oil Leaks

Hydraulic cylinder seal kits play a vital role in maintaining your excavator’s efficiency. These kits prevent oil leaks, ensuring smooth operation and reducing the risk of costly repairs. When you choose high-quality seal kits, you protect your equipment from contamination and extend its lifespan.

You will find that aftermarket hydraulic cylinder seal kits offer a practical solution for maintaining your excavator. These kits are designed to meet the demands of heavy-duty applications. They include seals made from durable materials like NBR and FKM, which resist wear and tear. By using these aftermarket parts, you can address oil leakage issues effectively without overspending.

The precision manufacturing of these kits ensures a perfect fit for your excavator’s cylinders. This alignment minimizes friction and prevents misalignment, which could lead to further damage. Aftermarket parts often provide compatibility with various excavator models, making them a versatile choice for your maintenance needs.

Regularly replacing worn-out seals with reliable aftermarket options helps you avoid downtime. Oil leaks can disrupt operations and increase maintenance costs. By investing in these parts, you maintain the performance of your equipment and reduce the risk of unexpected breakdowns.

When selecting seal kits, always prioritize quality. Look for kits that meet international standards and undergo rigorous testing. Trusted suppliers like YNF Machinery offer aftermarket parts that combine durability and affordability. Their seal kits ensure your excavator operates efficiently, even in challenging conditions.

Preventing oil leaks is essential for keeping your excavator in top condition. With the right hydraulic cylinder seal kits, you can enhance your equipment’s reliability and performance while managing costs effectively.

Pros and Cons of Genuine and Aftermarket Parts

Advantages of Genuine Hitachi Excavator Parts

Genuine Hitachi parts deliver unmatched compatibility and reliability. These parts are specifically engineered to fit Hitachi equipment perfectly, ensuring seamless integration. This precision reduces stress on connected components, leading to fewer breakdowns and extended machine life. You can rely on genuine parts to maintain peak performance, which lowers maintenance and ownership costs over time.

Using genuine parts enhances traction, stability, and movement. This improvement boosts productivity and reduces fuel consumption. Their durability ensures they withstand intense operational conditions, minimizing downtime. Although the initial cost is higher, the long lifespan and reduced maintenance needs make them a cost-effective choice in the long run.

Key Benefits:

Perfect fit ensures optimal functionality and minimizes performance issues.

Rigorous testing guarantees durability, even in demanding environments.

High-quality construction reduces unexpected breakdowns, maximizing uptime.

Limitations of Genuine Parts

Despite their advantages, genuine parts come with certain drawbacks. The higher initial cost can strain your budget, especially for large-scale operations. Lead times for these parts may also delay urgent repairs, as they are manufactured to exact specifications. Additionally, sourcing genuine parts for older equipment can be challenging if the OEM has discontinued production.

For non-critical components, genuine parts may not always justify the expense. In such cases, you might find aftermarket parts a more practical and budget-friendly alternative.

Benefits of Buying High-Quality Aftermarket Parts

High-quality aftermarket parts offer a reliable and cost-effective solution for your excavator needs. These parts improve traction, stability, and efficiency, enhancing overall performance. Their durability minimizes downtime and maintenance costs, making them a smart investment for long-term use.

Aftermarket parts are designed to perform well in tough conditions, ensuring consistent operation. Many high-quality options meet or exceed OEM standards, providing compatibility and reliability. You can also benefit from their availability, as aftermarket manufacturers often stock parts for a wide range of models. This accessibility proves invaluable during urgent repairs.

Key Benefits:

Enhanced performance leads to better productivity and reduced fuel consumption.

Durable construction extends service life, lowering maintenance costs.

Reliable operation in demanding environments ensures consistent performance.

Availability and affordability make them a practical choice for budget-conscious buyers.

By choosing high-quality aftermarket parts, you balance cost and quality effectively. Trusted suppliers like YNF Machinery ensure you receive parts that meet your operational needs without compromising reliability.

Potential Risks of Aftermarket Parts

Aftermarket parts can offer cost savings, but they also come with certain risks that you should consider. These risks can affect your excavator’s performance, reliability, and long-term value. Understanding these challenges helps you make informed decisions when choosing replacement parts.

One of the main risks involves inconsistent quality. Unlike OEM parts, aftermarket parts are produced by various manufacturers, each with different standards. Some manufacturers prioritize affordability over durability. This can result in parts that wear out faster or fail under heavy use. You might face frequent replacements, which increases downtime and maintenance costs.

Compatibility issues also pose a significant challenge. Aftermarket parts are designed to fit multiple models, but they may not match your equipment’s exact specifications. Improper fit can lead to inefficiencies, reduced performance, or even damage to other components. For critical systems like hydraulic pumps or engines, this risk becomes even more pronounced.

Another concern is the lack of comprehensive warranties. While OEM parts often come with robust warranty coverage, aftermarket options may offer limited or no protection. If a part fails prematurely, you could bear the full cost of repairs or replacements. This adds uncertainty to your investment.

Finally, sourcing aftermarket parts from unreliable suppliers can expose you to counterfeit products. These low-quality imitations may look similar to genuine parts but lack the durability and performance you need. Always verify the supplier’s reputation to avoid this risk.

By weighing these risks against your operational needs and budget, you can decide whether aftermarket parts are the right choice for your excavator. Prioritize quality and compatibility to ensure your equipment remains reliable and efficient.

Tips for Buying High-Quality Aftermarket Parts

Researching Reputable Suppliers Like YNF Machinery

Finding a trustworthy supplier is essential when buying high-quality aftermarket parts. A reputable supplier ensures you receive durable and reliable components that meet your equipment’s needs. To identify the right supplier, consider the following factors:

Evaluate the supplier’s range of products to ensure they offer the parts you need.

Assess their customer service and technical support for prompt assistance.

Review warranty options to understand the coverage provided.

Check the quality and performance of their parts through customer reviews or certifications.

Consider availability and lead times to avoid delays in repairs.

Ensure compatibility with your equipment to prevent operational issues.

YNF Machinery exemplifies these qualities. With over 35 years of experience, they provide a wide range of aftermarket parts, including couplings, engine components, and hydraulic seal kits. Their commitment to quality and customer satisfaction makes them a reliable choice for your excavator needs.

Verifying Compatibility with Hitachi Equipment

Ensuring compatibility is crucial for maintaining your excavator’s performance. Aftermarket parts must fit seamlessly with your Hitachi equipment to avoid inefficiencies or damage. Reliable suppliers like YNF Machinery rigorously test their parts to meet production standards and guarantee compatibility.

When verifying compatibility, focus on the specific components you need. For example, aftermarket parts for Hitachi equipment include engine components, hydraulics, and electrical systems. These parts undergo strict testing to ensure they match the original specifications. Always confirm the part number and model details before purchasing. This step minimizes the risk of improper fit and ensures smooth operation.

Evaluating Warranty and Support Options

Warranty and support options play a vital role in your purchasing decision. A clear warranty provides peace of mind and protects your investment. Aftermarket parts may come with varying warranty terms, so understanding the details is essential.

Aspect | Details |

|---|---|

Warranty | Aftermarket parts may or may not come with warranties, which can vary in coverage and duration. |

Customer Support | OEM parts typically offer robust customer service and technical support, which is critical for many businesses. |

Look for suppliers that prioritize customer support. A proactive supplier will address post-purchase concerns and resolve issues efficiently. YNF Machinery, for instance, offers comprehensive support and ensures their customers receive high-quality parts with reliable warranty coverage. This commitment enhances your confidence in their products and services.

Balancing Cost and Quality for Long-term Value

Finding the right balance between cost and quality when purchasing aftermarket parts requires careful consideration. You need to ensure that the parts you choose meet your equipment’s needs without exceeding your budget. By following a few key strategies, you can make informed decisions that provide long-term value.

Start by evaluating suppliers that offer a wide variety of parts. This gives you the flexibility to compare options and select components that align with your budget and operational requirements. Reputable suppliers often provide aftermarket parts that meet or exceed industry standards, ensuring durability and reliability comparable to OEM parts. Researching customer reviews and supplier reputations can help you identify trustworthy sources.

Comparing prices among different suppliers is another effective way to balance cost and quality. While lower prices may seem appealing, prioritize parts that offer proven performance and compatibility with your equipment. Look for components with warranties, as these provide added protection against defects and reduce the risk of unexpected expenses.

Availability plays a crucial role in minimizing downtime. Aftermarket parts are often more readily available than OEM options, making them a practical choice for urgent repairs. Quick access to parts ensures your operations remain uninterrupted, saving you time and money in the long run.

When assessing long-term value, focus on more than just the upfront cost. High-quality aftermarket parts may cost slightly more initially but often last longer and perform better. This reduces the frequency of replacements and maintenance, ultimately lowering your total cost of ownership. Additionally, ensure the parts you choose are compatible with your equipment to avoid inefficiencies or damage.

By prioritizing quality, reliability, and supplier reputation, you can confidently invest in aftermarket parts that deliver both cost savings and dependable performance. These strategies help you maintain your equipment’s efficiency while managing expenses effectively.

Choosing between genuine and aftermarket parts depends on your priorities. Genuine parts ensure a perfect fit, optimal performance, and warranty protection. They maintain resale value and meet rigorous safety standards. Aftermarket parts, while cost-effective, may lack the same quality and compatibility.

Align your decision with your equipment’s needs, budget, and long-term goals. Prioritize quality and reliability to avoid frequent replacements or costly repairs. Trusted suppliers like YNF Machinery offer high-quality aftermarket options, ensuring durability and performance. By making informed choices, you can keep your excavator running efficiently and minimize downtime.

FAQ

1. How do you decide between genuine and aftermarket parts for your excavator?

You should consider your equipment’s age, budget, and repair urgency. Genuine parts ensure reliability and performance, while aftermarket parts offer cost savings and availability. Evaluate your long-term goals and operational needs to make the best choice.

2. Do aftermarket parts void your excavator’s warranty?

Using aftermarket parts may void your warranty if they cause damage or fail to meet OEM standards. Always check your warranty terms before installing aftermarket components to avoid unexpected issues.

3. Are aftermarket parts as durable as genuine parts?

High-quality aftermarket parts can match the durability of genuine parts. However, their performance depends on the manufacturer. Choose parts from reputable suppliers like YNF Machinery to ensure reliability and longevity.

4. Can you mix genuine and aftermarket parts in your excavator?

Yes, you can mix them. Ensure the aftermarket parts meet OEM specifications and are compatible with your equipment. Mixing parts works best for non-critical components where cost savings are a priority.

5. How do you verify the quality of aftermarket parts?

Research the supplier’s reputation and customer reviews. Look for certifications and warranty coverage. Trusted suppliers like YNF Machinery provide high-quality parts that meet industry standards, ensuring reliable performance.

Tip: Always prioritize quality over cost to avoid frequent replacements and downtime.