Guide to Selecting Bowex FLE-PA Flange Coupling Hubs

Choosing the right Bowex FLE-PA flange coupling hub helps machines work well. Picking the wrong one can cause problems and damage. It may also lead to expensive repairs and delays. Each hub should match your machine’s needs, such as size and strength. The environment where it operates also matters. Custom Bowex FLE-PA flange coupling hubs can improve how machines perform in special cases. This guide helps you learn to choose the best hub, ensuring your machines last longer and work better.

Overview of Bowex FLE-PA Flange Coupling Hubs

Why are Bowex FLE-PA hubs special?

Bowex FLE-PA hubs are unique because they are well-designed. They handle strong forces while keeping machines running smoothly. These hubs adjust to misalignments, preventing machine interruptions. This lowers wear and tear, helping machines last longer. They also work with many coupling brands, making them useful for different systems.

Where do Bowex FLE-PA hubs work best?

Bowex FLE-PA hubs are great for industries needing precise power transfer. They are used in construction machines like excavators for steady force and strength. These hubs also work well in factories, keeping machines running fast and smoothly. Their flexibility makes them fit for many uses, from big machines to special systems.

Main features and advantages of Bowex FLE-PA hubs.

Bowex FLE-PA hubs have features that boost their performance. They are made from strong materials to handle tough conditions. These hubs transfer force efficiently, saving energy and improving machine work. They tolerate misalignments, keeping shafts moving smoothly and reducing repairs.

Here’s a simple look at their performance:

| Metric | Value (Nm) | Rotational Speed (Min-1) |

|---|---|---|

| Maximum Torque | 4000 | 3600 |

| Nominal Torque | N/A | N/A |

| Maximum Rotational Speed | N/A | 4000 |

These numbers show the hubs can handle heavy loads and fast speeds. This makes them dependable for industrial use.

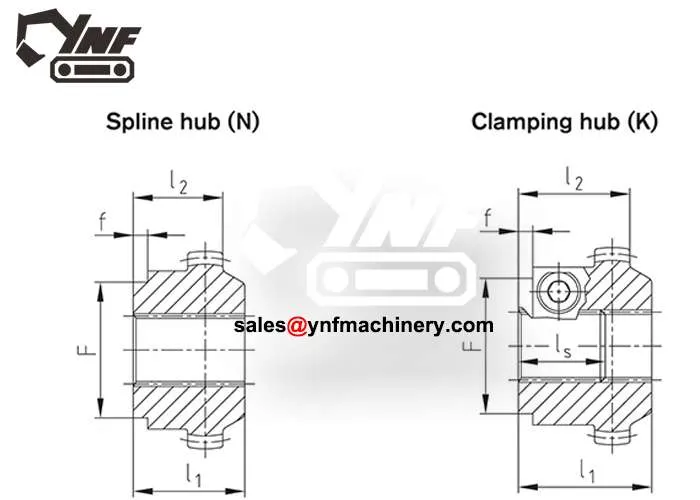

Bowex spline hub & clamping hub

Bowex FLE-PA hubs are great for industries needing precise power transfer. They are used in construction machines like excavators for steady force and strength. These hubs also work well in factories, keeping machines running fast and smoothly. Their flexibility makes them fit for many uses, from big machines to special systems.

| Spline and clamping hubs to SAE J498 | ||||||||

| Size | Dimensions [mm] | Order designation specify coupling size | ||||||

| Type | Spline size | l1 | l2 | ls | F | f | ||

| 42 | K | PH-S 5/8″ 16/32DP,z=9 | 42 | = | = | = | = | P558101 |

| 42 | K | PI-S 3/4″ 16/32DP,z=11 | = | 35 | = | = | = | P559101 |

| 42 | K | PB-S 7/8″ 16/32DP,z=13 | 42 | = | = | 60 | 3 | P567101 |

| 42 | K | PB-BS 1″ 16/32DP,z=15 | 42 | = | 27 | 50 | 6 | P660201 |

| 48 | K | PA-S 3/8″ 16/32DP,z=21 | 50 | = | 45 | 52 | 7 | P663301 |

| 65 | K | PA-S 3/8″ 16/32DP,z=21 | 55 | = | 48 | 52 | 5 | P663301 |

| 65 | K | PC-S 11/4″ 12/24DP,z=14 | 55 | = | 44 | 52 | 5 | P656201 |

Exploring Hub Sizes and Specifications

Standard hub sizes and their uses.

Picking the right Bowex FLE-PA hub size is important. These hubs come in different sizes for various machines. Each size handles specific force levels and work needs. Smaller hubs are good for light machines. Bigger hubs are better for heavy-duty equipment.

Common hub sizes include T48, T55, and T65. These sizes show the hub’s diameter and its fit for machines. Small diameters suit compact systems. Large diameters handle more force and heavier loads. Choosing the right size helps machines work well without extra strain.

Torque capacity and bore size explained.

Torque capacity and bore size are key when picking a hub. Torque capacity means how much turning force the hub can take. If the hub can’t handle enough force, it might break. Always match your machine’s torque needs with the hub’s ability.

Bore size includes the inner diameter and center bore. The inner diameter must fit the shaft tightly for a secure hold. The center bore keeps the hub balanced during use. If the bore size is wrong, it can cause misalignment and damage.

Choosing the right hub size for your machine.

To find the right hub size, check your machine’s details. Measure the hub’s diameter, outer diameter, and inner diameter. Also, check the center bore for proper alignment. These steps help you pick the correct hub size.

Think about how your machine works, like its load, speed, and environment. For fast machines, use a hub with a bigger outer diameter. For heavy loads, pick a hub with higher torque capacity. Matching the hub to your machine helps it run smoothly and avoids problems.

Tip: Check your machine’s manual or ask an expert to confirm the right hub size.

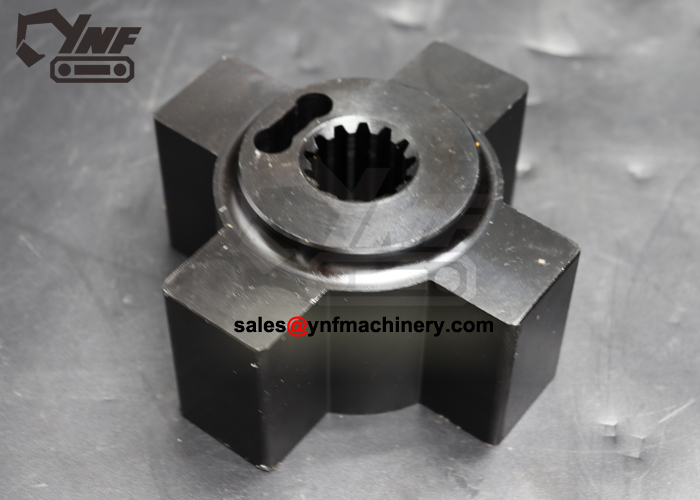

Size List

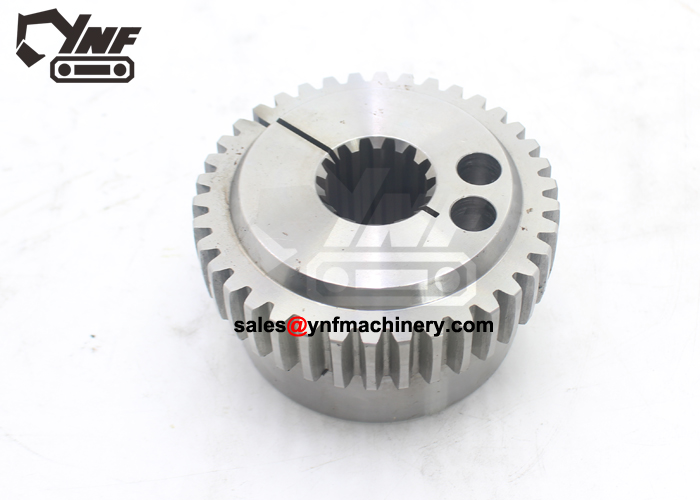

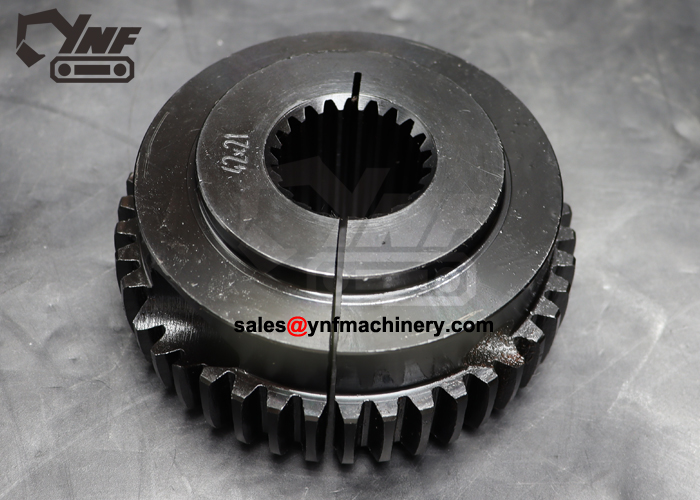

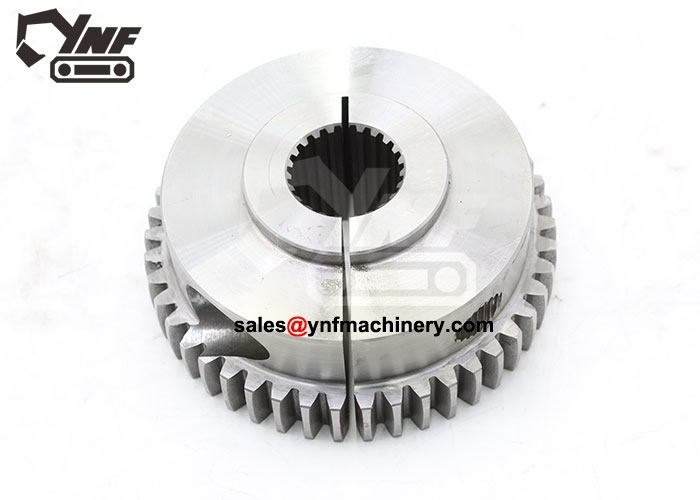

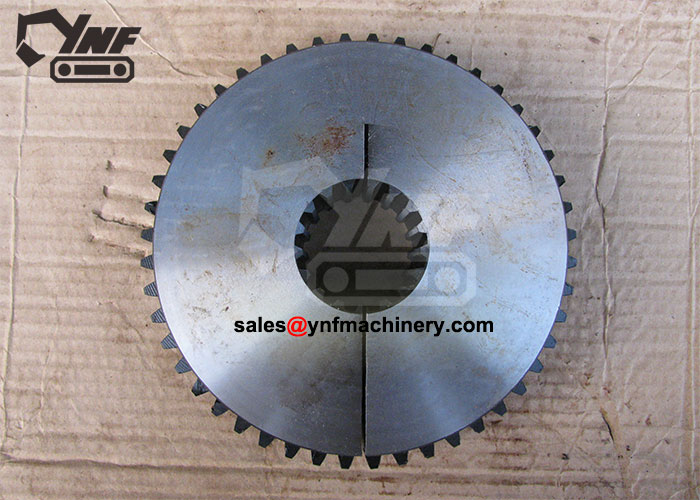

YNF04414

4x13T OD94 Gear ID19.5-23 H42

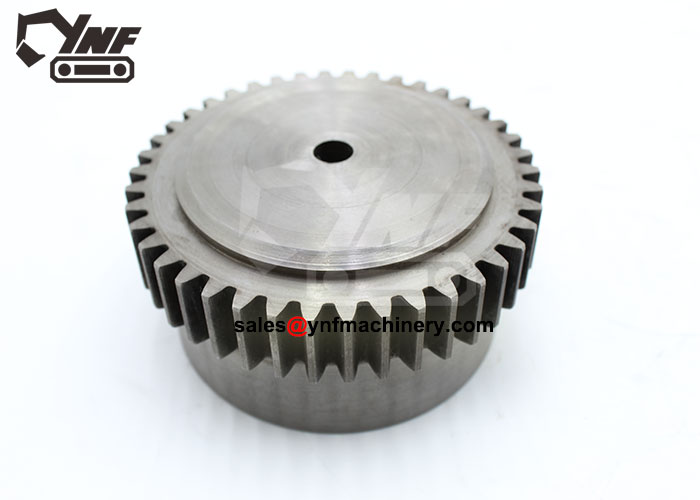

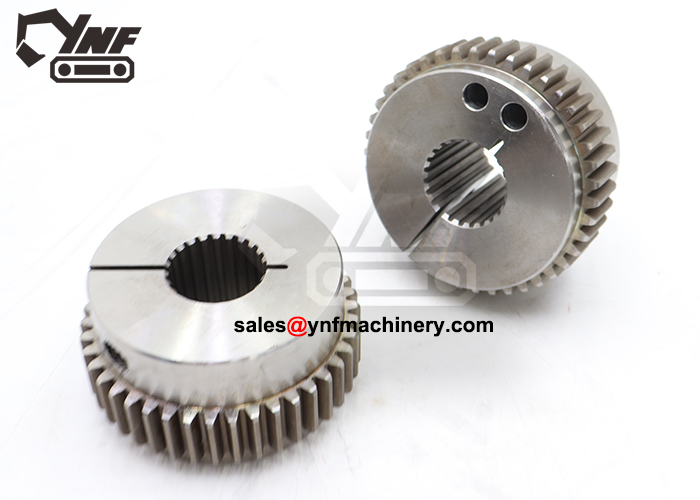

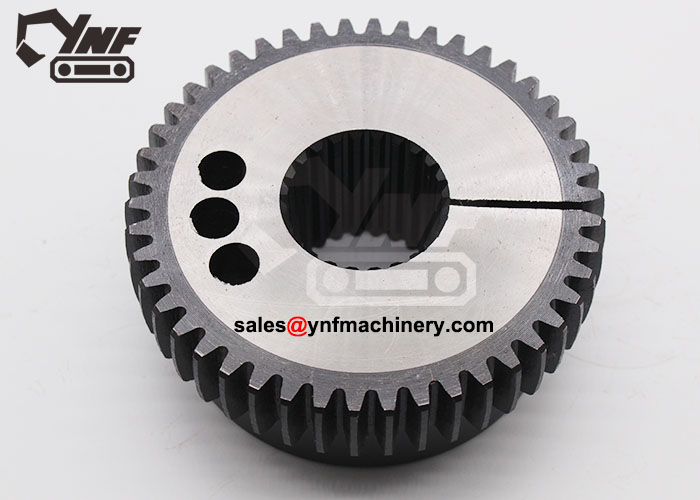

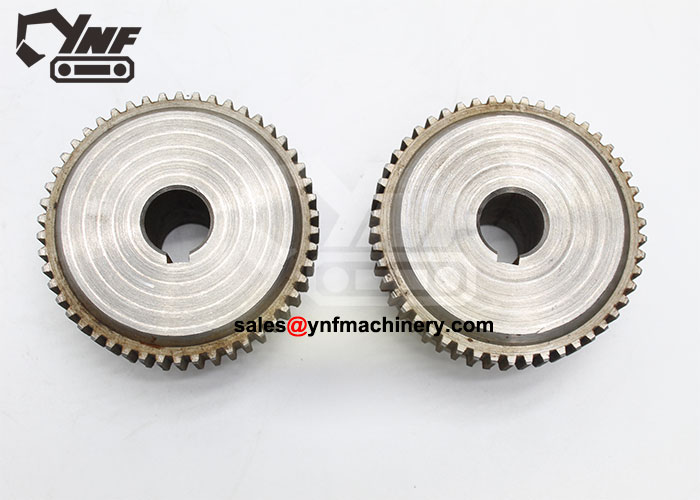

YNF15281

4x13T OD95 ID19.5-22.5 H48

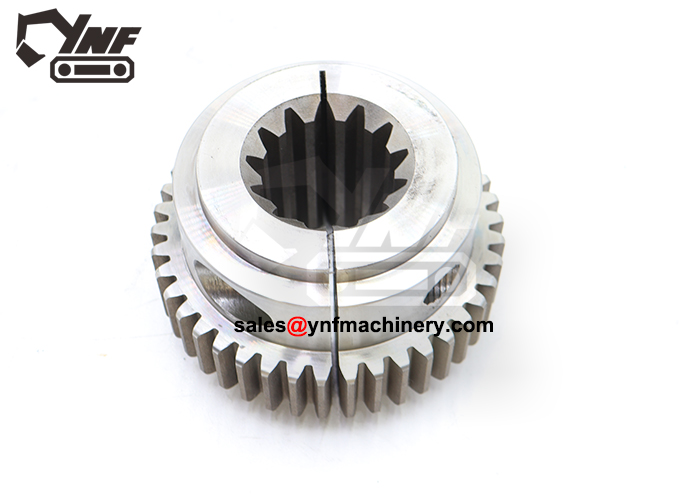

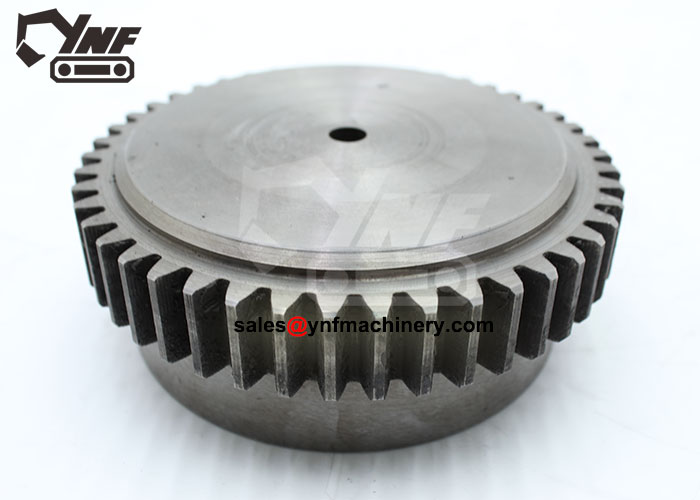

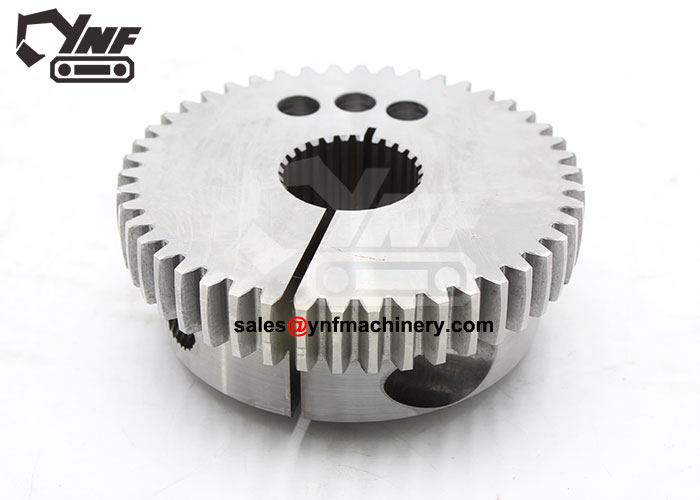

YNF04075

4x14T OD94 ID28-32 H42

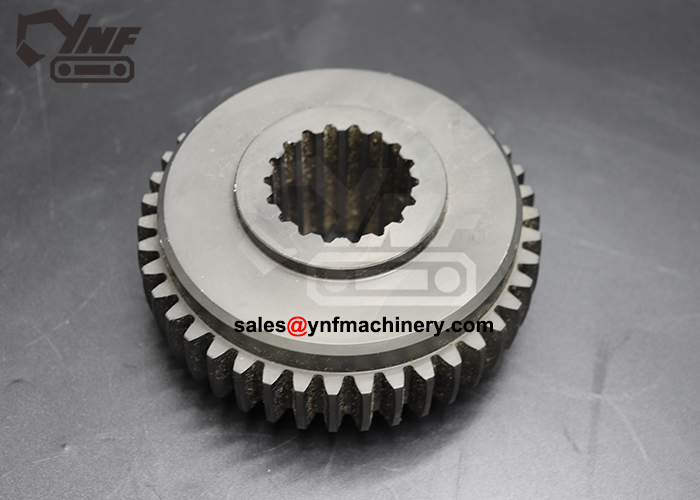

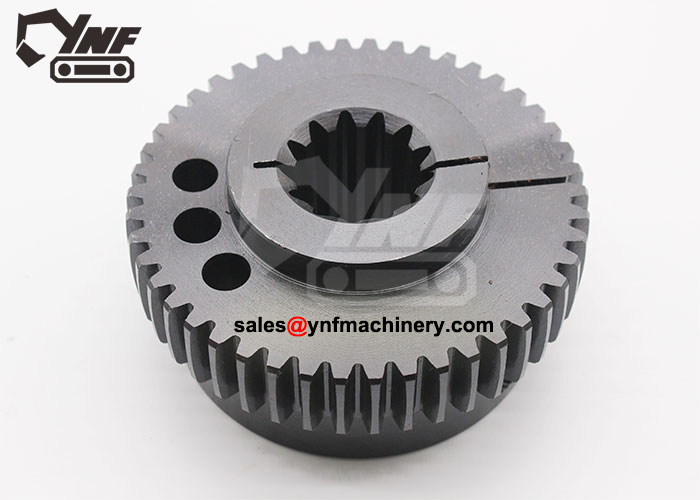

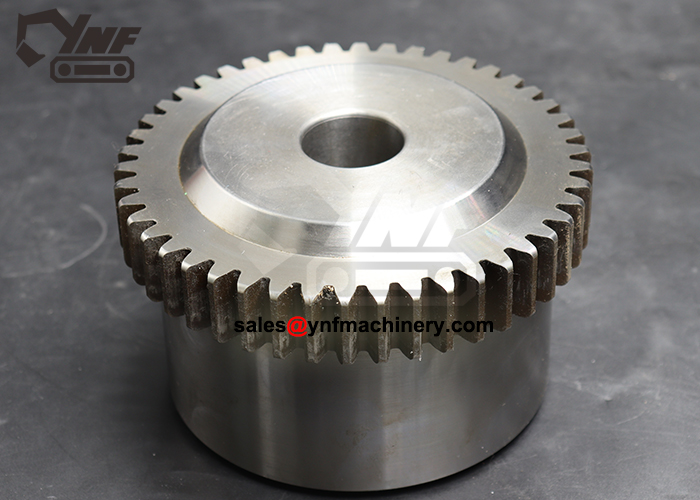

YNF03501

4x14T OD129-97 ID27.5-31.5 H55

YNF04235

4x15T ID22-26 OD94 H42

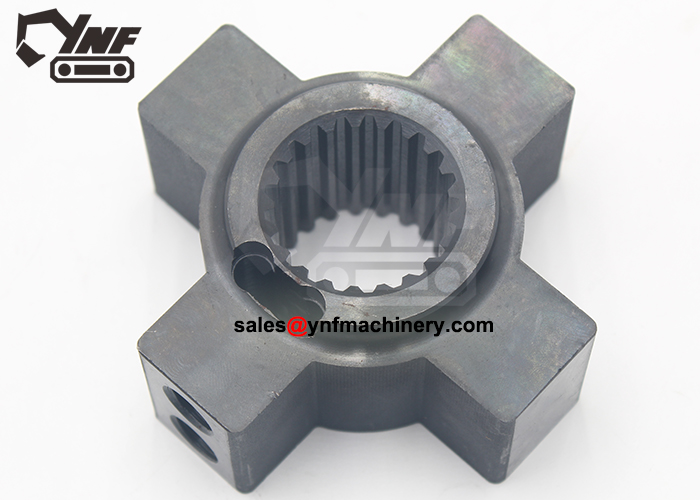

YNF13368

4x21T ID32-35 OD95 H42

YNF13367

4x23T ID35-38 OD94 H42

YNF03536

6x14T OD120-85 ID28-32 H50

YNF03537

6x15T OD120-85 ID22-26 H50

YNF03538

6x15T OD120-85 ID45-51 H50

YNF15261

6X16T OD120 ID30 34 H48

YNF03539

6x16T OD120 ID31-35 H50

YNF03540

6x17T OD120-85 ID27-31 H50

YNF03541

6x17T OD120-85 ID42-47 H50

YNF03542

6x21T OD120-85 ID32-35 H50

YNF02801

6x23T OD120-85 ID35-38 H50

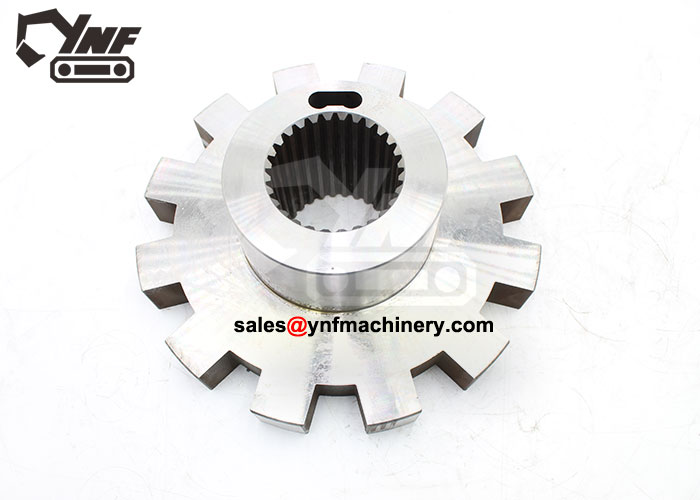

YNF04102

8x15T YNF04102 Gear Hub ID44 51 OD148 H70

YNF01644

8x17T OD148-110 ID42-47 H57 YNF01644

YNF12995

8X23T Gear Hub

YNF04200

8x24T OD148 ID46-51 H60

YNF05242

8x24T OD148 ID46-51 H105

YNF03553

12x17T OD210-170 ID42-47 H79.6

YNF03595

12x18T OD210-170 ID42-47 H79.6 YNF03595

YNF03596

12x21T OD210-170 ID40-45 H55

YNF03498

12x24T OD210-170 ID46-51 H74

YNF15840

12X24T ID46-51 OD210 H98

YNF12540

12x28T ID56-61 OD210 H79

26x13T YNF03568

26x13T

YNF14527

38x14T OD100 ID31.8-27.8 H55

YNF00843

42x0T OD110 ID25.5-29 H55 YNF00843

YNF12405

42x0T Φ10 Mid Hole Gear Hub OD110 H44

YNF03511

42x6T OD110 ID28.5-32.5 H55

YNF01195

42x10T OD110 ID38-46 H55

YNF14847

42x10T OD110 ID28-32 H50

YNF03512

42x12T OD110 ID30-35 H55

YNF01635

42x13T OD110 ID19-22 H55

YNF03400

42x13T OD110 ID38-46.5 H55

YNF16059

42x13T OD110 ID38-46.5 H60

YNF03139

42x14 OD 110 ID 32-35 H56

YNF15225

42x14 OD110 ID32-35 H48

YNF00502

42x14T OD110 ID28-32 H57

YNF03513

42x14T OD110 ID35-40 H55

YNF01636

42x15T OD110 ID22-25.3 H55

YNF03514

42x15T OD110 ID28.5-33 H55

YNF03828

42x15T OD110 ID44-51 H55

YNF03427

42x16T OD110 ID30-35 H53

YNF14325

42x17T ID34 37.8 OD110 H55

YNF02478

42x18T OD10 ID36-40 H70

YNF15787

42x18T OD109-98 ID40.5-34 H47

YNF15174

42x21T Gear for CAT Caterpillar

YNF15535

42X21T OD110 ID32-35 H48

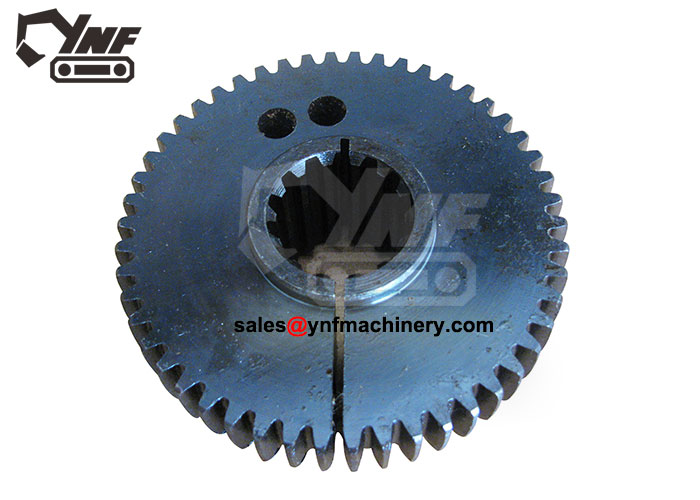

YNF03715

42x21T OD110 ID32-35 H50

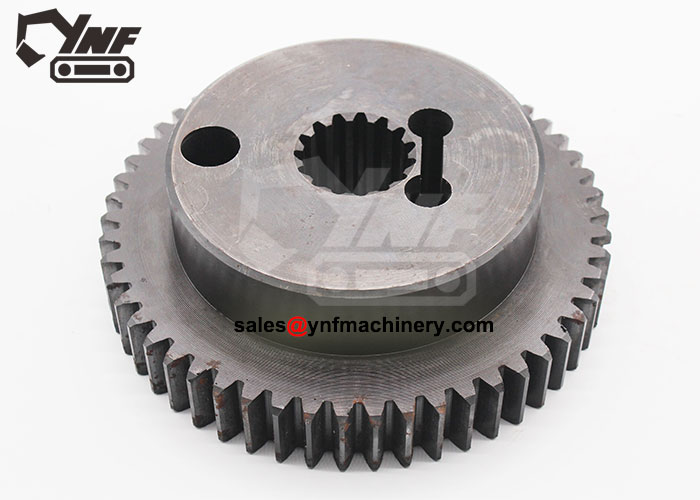

YNF00523

42x21T OD110 ID32-35 H55

YNF00881

42x21T OD110 ID40.5-45.5 H55

YNF15282

42x21T OD110x100 ID35-32 H55

YNF15947

42x23 OD110 ID35.5-38.5 H60

YNF01633

42x23T OD110 ID35.2-38.5 H70

YNF00524

42x23T OD110 ID35-38 H49

YNF03139

42x27T OD110 ID39.5-43 H55

YNF12623

42x27T OD110 ID40-43.5 Gear Hub Metal Sleeve

YNF12404

46x0T Φ10 Mid Hole Gear Hub OD145 H55

YNF13600

46x0T Flat Key Gear Hub ID70 0D145 H102

YNF12753

46x10 Gear Hub ID38-46 OD145 H50

YNF01471

46x12T OD145 ID44-51 H65

YNF01637

46x12T OD145 ID30-35 H56

YNF02643

46x13 OD145 Gear Hub ID38 46 H55

YNF01625

46x13T OD145 ID38-46 H70

YNF01557

46x14T OD145 ID40-46.5 H65

YNF03515

46x14T OD145 ID25-30 H55

YNF00656

46x14T OD145 ID27.2-31.2 H54

YNF03516

46x14T OD145 ID35.3-39.6 H68

YNF01095

46x14T OD145 ID35-40 H53

YNF01289

46x14T OD145 ID40-45 H54

YNF03518

46x15T OD145 ID45-52 H54.6

YNF03517

46x15T OD145 ID45-52

YNF02948

46x16T OD145 ID30-35 H56

YNF01472

46x17T OD145 ID42-47.5 H64

YNF14252

46x18T Gear Hub ID36-40 OD145 H70

YNF01627

46x21T OD145 ID 32-35 H59

YNF01626

46x21T OD145 ID40-45 H59

YNF13303

46x23T ID35-38 0D145 H55

YNF02479

46x23T OD145 ID35-38 H60

YNF01196

46x24T OD145 ID45.8-50.7 H58

YNF03519

46x24T OD145 ID60-65 H57

YNF13304

46x27 ID41.5-45 0D145 H57

YNF03520

46x27T OD145 ID38.5-42.5 H58

YNF16092

46x0T Gear Hub OD145 ID31 H90

YNF01278

47x13T OD98 ID19-22 H55

YNF03521

47x13T OD98 ID38-46.5 H60

YNF03522

47x14T ID28-32 OD98

YNF0343

47x14T OD98 ID28-32 H52

YNF02679

47x15T OD98 ID22-26 H46

YNF01398

48x13T OD176 ID38-46 H65

YNF01634

48x13T OD176 ID38-46 H74

YNF03554

48x13T OD176 ID38-46 H74

YNF01421

48x14T OD176 ID35-40 H66

YNF02600

48x15T OD176 ID45-52 H58

YNF03524

48x17T OD176 ID42-47 H58

YNF01205

48x17T OD176 ID42-47 H65

YNF03523

48x21T OD176 ID40.5-45.5 H57

YNF03525

48X24T OD173.8 ID45.6-50.7 H110.8

YNF01566

48X24T OD174.5 ID 46-50.8 H65

YNF04296

48x27T ID41-45 OD176 H70

YNF03526

48x27T ID45-48 H65

YNF13700

48x27T OD175.8 ID 44.9-48.21 H58.8

YNF02571

48x28 ID56.5-61 H70

YNF15841

48x15 ID45-52 OD176 H58

YNF05203

50T Key Gear Hub OD78 ID18 20.8 W6 OD78 H40

YNF12403

50T Φ10 OD78 Mid Hole Gear Hub OD78 H44

YNF03527

50x6T OD78 ID19.7-23.9 H43

YNF02682

50X10T OD78 ID19-22.8 H36.5

YNF12439

50x10T OD78 ID28-32 H44

YNF14625

50x10T OD78 ID28-32 H67

YNF15422

50x10T OD78 ID28 32 H37 M10

YNF02840

50x10T OD78 ID18.6-22.6 H37.7

YNF01084

50x11T OD78 ID16-19 H43

YNF03594

50X12T OD78 ID22-26 H56

YNF00864

50X13T OD78 ID19-22 H44

YNF03897

50x13T OD78 ID19-22 H60

YNF03472

50x13T OD78 ID20-22.5 H43

YNF00947

50x14T OD78 ID28-32 H44

YNF01638

50x15T OD78 ID22-26 H44

YNF02840

50x15T OD78 ID29-33.2 H44

YNF03472

50x13T OD78 ID20-22.5 H43

YNF00947

50x14T OD78 ID28-32 H44

YNF01638

50x15T OD78 ID22-26 H44

YNF02840

50x15T OD78 ID29-33.2 H44

YNF02837

50x12T OD130 ID30-35 H54

YNF03415

50x13T OD130 ID38-46 H55

YNF00618

50x14T OD130 ID28-32 H55

YNF00619

50x14T OD130 ID28-32 H68 with clip

YNF02833

50x14T OD130 ID35-40 H54

YNF03141

50x14T OD130 ID35-40 H68 with clip

YNF03528

50x15T OD130 ID29-34 H54

YNF03827

50x15T OD130 ID44-51 H55

YNF03529

50x17T OD130 ID42-47 H67

YNF03530

50x21T OD130 ID40.2-45.3 H70

YNF03531

50x23T OD130 ID35-38 H54

YNF03532

50x24T OD130 ID46-51 H53

YNF01427

54X15T OD225 ID44-51 H71.5

YNF03552

54x17T OD225 ID42-47.5 H72.8

YNF02490

54x18T ID 36-40 H71.5

Custom Hub Rings and Their Importance

Why customization matters for specific uses.

Custom hub rings help machines work better and last longer. They are made to fit special needs in different industries. For example, in healthcare, custom rings improve medical imaging, helping with cancer checks. In cars, they make self-driving vehicles safer by spotting signs and people. In online shopping, they help suggest better products for buyers.

These examples show how custom rings solve problems. By making hub rings fit your machine, you get better alignment and less wear. This improves how your machine works. Custom rings make sure your equipment handles heavy loads, fast speeds, or tough conditions.

Types of customizations for Bowex FLE-PA hubs.

Bowex FLE-PA hubs can be customized in many ways. You can change the hub size, bore size, or materials used. These changes make the hub stronger and fit your machine better. For example, you can pick materials that handle heat or resist rust.

You can also adjust the hub’s torque capacity to match your machine’s power. This stops overloading and keeps things running smoothly. Some makers even create hubs based on your drawings or samples. This ensures the hub fits your system perfectly.

How to order custom hub rings.

Getting custom hub rings is simple. First, collect details about your machine, like size and power needs. Share this information with your supplier, along with any design ideas or problems.

Some suppliers, like Guangzhou Xiebang Machinery, use drawings or samples to make custom hubs. Explain your needs clearly and ask for advice if unsure. After the hub is made, test it to see if it works well and improves your machine.

Tip: Always choose trusted suppliers who focus on quality and accuracy for custom hubs.

Step-by-Step Guide to Picking the Right Hub

Measuring your system for the correct hub size

Getting the right measurements is key to choosing the correct Bowex FLE-PA flange coupling hub. Wrong sizes can cause misalignment, poor performance, or even damage. Follow these simple steps to measure your system:

- Measure the total hub width (O.L.D.): Use a caliper for accuracy. Divide this number by two to find the centerline.

- Find dimensions A and B: Place the locknut on a flat surface to steady the hub. Measure from the centerline to each side of the hub.

- Calculate WL and WR: Subtract A and B from the centerline to get the left (WL) and right (WR) distances.

- Check the flange diameter: Measure from the flange’s middle to the locknut’s face. This ensures the hub fits tightly and aligns well.

Tip: Write down all measurements carefully. Don’t assume both sides are the same, as small differences can affect how it works.

By following these steps, you’ll make sure the hub fits your machine perfectly and avoids problems.

Evaluating load, speed, and environmental factors

Think about how your machine works when picking a hub. Load, speed, and the environment are important to find the right hub.

- Load: Check the highest and normal torque your machine creates. The hub must handle these forces without breaking. Tests like flange fatigue checks show how hubs handle heavy loads.

- Speed: Fast machines need hubs that stay balanced and don’t shake. Testing in real conditions ensures the hub stays steady at different speeds.

- Environment: Look at things like heat, moisture, and exposure to harmful materials. For example, hubs used outside must resist rust and handle bad weather.

Testing how hubs react to these factors helps you pick one that works well and lasts long.

Avoiding common mistakes in hub selection

Choosing the wrong hub can cause expensive fixes and delays. Avoid these common mistakes to make the process easier:

- Not knowing your needs: Before picking a hub, figure out what your machine needs, like torque, speed, and environment.

- Skipping accurate measurements: Guessing or using old data can lead to a bad fit. Always measure carefully and check your numbers.

- Ignoring material needs: Make sure the hub material suits your machine. For example, hubs in hot places need heat-resistant materials.

- Choosing price over quality: While saving money is good, pick hubs that meet your needs. Cheap hubs may cost less now but need more repairs later.

- Not asking for help: If unsure, talk to a supplier or engineer. Their advice can help you avoid mistakes and pick the best hub.

Note: Check your hub’s performance often after installing it. Finding wear or misalignment early can stop bigger problems later.

By avoiding these mistakes, you’ll pick the right hub, improve your machine’s performance, and reduce maintenance costs.

Benefits of Proper Hub Selection

Better performance and efficiency

Picking the right Bowex FLE-PA flange coupling hub helps machines work better. It ensures smooth power transfer, cutting down energy waste. Matching the hub to your machine’s torque and speed stops shaking and misalignment. This keeps performance steady and boosts efficiency.

Machines respond faster and parts work well together. For example, in building equipment, a good hub lets excavators lift heavy loads easily. This improves work speed and keeps machines running at their best.

Tip: Check your hub often for wear or alignment problems to keep it working well.

Stronger hubs and less upkeep

Choosing the right hub makes it last longer and need fewer fixes. A well-matched hub handles tough jobs without wearing out quickly. This means fewer replacements and repairs are needed.

Good care plans also help hubs last longer. Using tools like CMMS (Computerized Maintenance Management System) helps track upkeep tasks. This prevents sudden breakdowns, which can cost businesses a lot of money. Watching uptime and equipment readiness keeps hubs dependable over time.

- Why less upkeep is helpful:

- Saves money on repairs.

- Machines stay ready to use.

- Equipment lasts longer.

Saving money and staying reliable

Picking the right hub saves money over time. A hub that fits well stops energy waste and protects other parts from damage. This lowers costs and helps machines last longer.

It also makes machines more reliable. They work smoothly without surprise breakdowns, helping you finish jobs on time. Spending on good hubs avoids problems with cheap ones, like frequent fixes and downtime.

Note: Good hubs save money and make machines safer by lowering the chance of failures.

Comparing Bowex FLE-PA Hubs with Bike Hubs

Key differences in design and use.

Bowex FLE-PA hubs and bike hubs are made for different jobs. Bowex FLE-PA hubs work in big machines, handling strong forces and misalignment. They help transfer power smoothly in tough tasks. Bike hubs are smaller and lighter. They focus on turning wheels and holding the rider’s weight.

Bike hubs, like rear hubs, often have freewheels or cassettes for coasting. Some include disc brakes for better stopping. Bowex FLE-PA hubs are built for strength and accuracy. They handle heavy loads and tough conditions, making them great for construction and factory work.

Why Bowex FLE-PA hubs fit industrial needs.

Bowex FLE-PA hubs are perfect for factories because they are strong and flexible. They use tough materials that last a long time. These hubs handle misalignment, keeping machines running smoothly. For example, they work in rescue vehicles on rough ground, showing their reliability.

Bowex FLE-PA hubs also manage high torque and fast speeds. This makes them great for heavy machines like excavators. They work with many coupling brands, making them easy to use in different systems.

Lessons from bike hubs for hub designs.

Bike hubs teach useful ideas for hub designs. Their lightweight build and smooth power transfer show why picking the right materials matters. Disc brake hubs show how adding features can improve performance. Bowex FLE-PA hubs also use smart designs for industrial needs.

Bike hubs show the value of simple designs. By focusing on key functions, both bike hubs and Bowex FLE-PA hubs stay reliable and efficient. Balancing simplicity and performance is important for making good hubs.

Picking the right Bowex FLE-PA flange coupling hub helps machines work well and last longer. Follow three simple steps: learn about hub sizes, check custom hub rings, and measure your system carefully. These steps stop misalignment and make sure the hub fits right.

Talking to experts or trusted suppliers can help a lot. They give advice to match the hub with your machine’s torque and environment needs. This saves time, lowers repair costs, and makes machines work better.

Tip: Always check if the hub fits your machine before using it.

FAQs:

The hub links two shafts in machines for smooth power transfer. It fixes misalignment and stops damage to machine parts. This helps machines work better and last longer.

Look at your machine’s details like torque and shaft size. Measure the hub’s diameter, bore, and flange width carefully. If you’re unsure, check the manual or ask a supplier for help.

Tip: Correct measurements stop misalignment and ensure the hub fits well.

Yes, these hubs are strong and resist heat, moisture, and heavy loads. They work well in hard places like factories or construction sites. This makes them reliable in tough situations.

Custom hub rings match your machine’s needs for better performance. They improve alignment, reduce damage, and handle special challenges like high torque. This makes machines work efficiently.

Check your hub every 3-6 months or after heavy use. Look for wear, misalignment, or damage signs. Regular checks catch problems early and save repair costs.

Note: Taking care of your hub helps it last longer and keeps machines working well.