Monolastic couplings are important in conveyor systems. They link spinning shafts and allow small misalignments. These parts lower stress on machines for smoother work. They also cut downtime by absorbing shocks and vibrations. This stops damage to other machine parts. They help keep systems efficient and reliable in tough conditions. By reducing wear, they make equipment last longer. This keeps operations running without problems.

Key Takeaways

- Monolastic couplings lower stress on conveyors by fixing small misalignments. This helps the system run smoothly.

- These couplings are strong and can handle tough conditions. They work well in industries like mining and food production.

- It’s important to maintain them. Check for damage and keep shafts lined up to make them last longer.

- Picking the right coupling means knowing what your system needs. Think about how much weight it carries and the environment it works in.

- Monolastic couplings, such as KE-088 and KE-086, save money. They don’t need oil and are simple to install.

Key Benefits of Monolastic Couplings

Flexibility and Misalignment Compensation

Monolastic couplings handle small misalignments between connected shafts. This helps conveyor systems work smoothly, even if parts aren’t perfectly aligned. They adjust for angular, parallel, or axial misalignments. This lowers stress on machines and avoids early damage to other parts.

These couplings absorb vibrations and shocks caused by misalignment. This protects equipment and reduces noise during use. For systems with frequent movement or load changes, this flexibility is very helpful. It keeps performance steady and lowers the chance of sudden breakdowns.

Durability in Harsh Environments

Conveyor systems often face tough conditions like extreme heat, humidity, or chemicals. Monolastic couplings are made to survive these challenges. Strong materials like rubber and thermoplastic elastomers resist wear and damage over time.

These couplings are great for industries like mining, manufacturing, and food processing. They stay reliable in harsh conditions, keeping operations running smoothly. Their resistance to corrosion and abrasion makes them a dependable choice for long-term use.

Cost-Effective Maintenance

Monolastic couplings are easy to maintain and save money. They don’t need lubrication, so you avoid regular oiling or greasing. This saves time and effort.

Their simple design makes installation and replacement quick. You can fix problems fast and reduce downtime. With less maintenance needed, these couplings lower costs while keeping systems efficient.

Tip: Check your couplings often for wear to make them last longer and work better.

Types of Monolastic Couplings

KE-088 and KE-086 Couplings

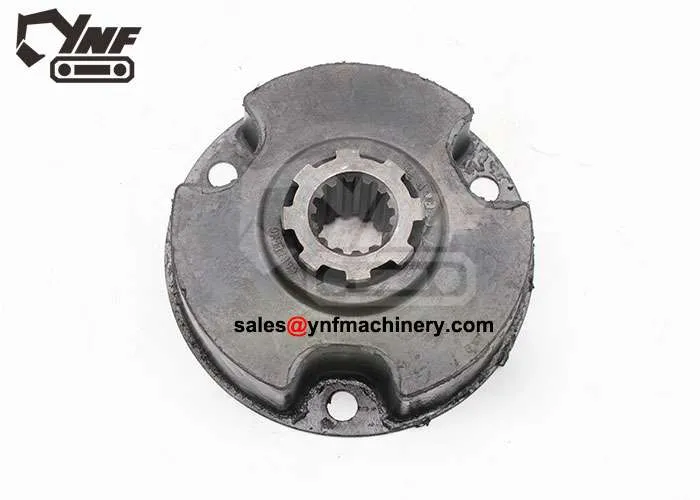

KE-088 and KE-086 couplings are great for tough jobs. They are made in one piece, so they don’t need oiling. This makes them easy to care for and saves money.

YNF Machinery uses strong materials like rubber to make these couplings. This helps them last longer and resist damage. They absorb shocks and vibrations, keeping conveyor systems safe from harm.

These couplings come in different sizes and setups. You can use them with pumps, compressors, and generators. Their flexibility makes them useful for mining and manufacturing conveyor systems.

Applications in Conveyor Systems

Monolastic couplings are key parts of conveyor systems. They join spinning shafts and fix alignment problems. This keeps the system running smoothly, even if parts don’t match perfectly.

In conveyors, these couplings reduce vibrations from heavy loads or sudden moves. This lowers wear on other parts and cuts down noise. They work well in places with changing loads and keep performance steady.

Industries like food processing and construction use these couplings often. They handle extreme heat, moisture, and chemicals, making them perfect for tough conditions.

Comparison with Other Coupling Types

Monolastic couplings are simpler and work better than other types. Unlike rigid couplings, they adjust for misalignments and protect connected parts.

Flexible couplings like KE-088 and KE-086 absorb vibrations better than regular ones. This keeps machines safe and helps them last longer. They also don’t need oiling, which means less upkeep.

Compared to complex designs, monolastic couplings are cheaper and easier to use. They are quick to install, saving time and reducing delays. For conveyor systems, they are a smart and dependable choice.

Size List

YNF03858

YC18

YNF-107

YC18-9T

YNF02574

YC18-15T

YNF03853

YC35

YNF-108

YC35-9T

YNF-109

YC35-13T

YNF-110

YC35-14T

YNF-111

YC35-15T

YNF01765

YC60-7 9T

YNF01766

YC60-7 13T

YNF01767

YC60-7 14T

YNF-112

YC60-7 15T

YNF01769

YC60-8 240-13T

YNF01770

YC60-8 240-14T

YNF-113

YC60-8 240-15T

YNF-114

FR60 180-15T

YNF033837

FR60 E304 E305.5 13T

YNF03836

FR60 KE-086 E304-15T

YNF12595

E304-14T Coupling

Installation of Monolastic Couplings

Step-by-Step Installation Process

Installing monolastic couplings needs care to work properly. Follow these steps:

- Inspect the Coupling and Shafts: Look at the coupling and shafts for damage or wear. Make sure the shafts are clean and have no dirt.

- Align the Shafts: Move the shafts close to their correct positions. This lowers stress on the coupling when it works.

- Attach the Coupling: Fix the coupling to the shafts with the right fasteners. Tighten them evenly to avoid uneven pressure.

- Test the Installation: Turn the shafts by hand to check smooth movement. Watch for misalignment or resistance.

- Finalize the Setup: After installation, run the system slowly to check performance.

Tip: Always read the manufacturer’s instructions for proper installation steps.

Tools and Equipment Needed

Using the right tools makes installation easier. Below is a table of common tools for monolastic coupling setups:

| Coupling Type | Description |

|---|---|

| Centaflex Rubber Coupling | Engine Drive Coupling, hydraulic pump motor coupling |

| Bowex MONOLASTIC coupling | MONOLASTIC Coupling size 28, Size 32 |

| Jurid Rubber Coupling | Jurid S25S, S29S, S32S |

You might also need tools like wrenches, alignment gauges, and torque wrenches. These help you align and secure the coupling correctly.

Avoiding Common Installation Errors

Mistakes during setup can cause problems or damage. Avoid these errors:

- Skipping Shaft Alignment: Misaligned shafts put extra stress on parts. Always align shafts before attaching the coupling.

- Overtightening Fasteners: Tightening too much can harm the coupling or shafts. Use a torque wrench to apply the right pressure.

- Ignoring Manufacturer Guidelines: Each coupling has specific needs. Not following instructions can hurt performance.

By avoiding these mistakes, you can install couplings smoothly and make them last longer.

Maintenance and Troubleshooting

Routine Maintenance Guidelines

Regular care keeps monolastic couplings working well. Check them often to find problems early. Look for cracks or changes in shape. Clean the coupling and nearby parts to remove dirt.

Make sure the shafts stay aligned. Misaligned shafts add stress and wear out the coupling faster. Use a tool to check alignment. Tighten all bolts to the right level. Loose bolts can cause shaking or damage.

Plan a maintenance schedule based on how your system works. If the system is in tough conditions, check the couplings more often. Keep a record of maintenance to track their condition over time.

Tip: Follow the maker’s care instructions for the best results.

Identifying and Resolving Common Issues

Common issues include misalignment, too much shaking, and strange sounds. Misalignment happens when shafts move during use. Fix this by realigning and securing the shafts.

Too much shaking might mean the coupling is worn or damaged. Look for cracks or changes in shape. Replace it if needed. Strange sounds, like squeaks or grinding, often mean bolts are loose. Tighten them to fix the problem.

If the coupling doesn’t work right, check for things like high heat or chemicals. These can weaken the material over time. Fixing these problems quickly avoids more damage.

Signs of Wear and Replacement Indicators

Knowing when to replace a coupling avoids sudden breakdowns. Look for cracks, tears, or changes in shape. A worn coupling may not absorb shaking as well.

Watch for changes in how your system works. More noise, shaking, or misalignment could mean the coupling is wearing out. Regular checks help you spot these signs early.

If you see these problems, replace the coupling right away. Using a damaged coupling can harm other parts of the system. Always pick good-quality replacements for long-lasting use.

Choosing the Right Monolastic Coupling

Evaluating System Requirements

To pick the right coupling, know your system’s needs. Start by checking the machines and their tasks. Find out the speed and torque of the shafts. These details help decide the coupling’s size and material.

Think about your system’s alignment. If shafts often misalign, choose couplings that handle angular, parallel, or axial shifts. For systems with high vibrations, use couplings that absorb shocks well.

Tip: Write down shaft sizes, speeds, and load types. This helps you find the perfect coupling for your system.

Load Capacity and Environmental Factors

The load your system carries affects the coupling choice. Heavy loads need couplings with high torque capacity. If loads change often, pick couplings that stay steady during shifts.

Environment is also important. For systems in heat, moisture, or chemicals, use couplings made of strong materials like rubber or thermoplastic elastomers. These materials resist damage and last longer.

Use this table to match coupling features to tough conditions:

| Environmental Factor | Recommended Coupling Feature |

|---|---|

| High Temperature | Heat-resistant materials |

| Moisture or Humidity | Corrosion-resistant design |

| Chemical Exposure | Non-reactive elastomers |

Checklist for Selection

Use this checklist to make choosing easier:

- Know Your System: Check shaft alignment, load type, and conditions.

- Pick the Right Material: Choose materials that fit your system’s needs.

- Check Size and Torque: Match the coupling to shaft size and torque.

- Look for Flexibility: Get couplings that handle misalignment and vibrations.

- Think About Maintenance: Choose low-maintenance couplings to save time and money.

Reminder: Always check the manufacturer’s guide to ensure compatibility.

By following these steps, you can pick the best coupling for your system. Monolastic couplings like KE-088 and KE-086 are flexible, strong, and cost-effective. They work well in many situations.

Monolastic couplings are key to keeping conveyor systems running well. They lower stress, take in vibrations, and fix misalignments. This helps machines work smoothly, even in tough conditions. Picking the right coupling is very important. Installing them correctly and checking them often makes them last longer and work better.

Check out strong options like KE-088 and KE-086 couplings. These tough and bendable choices fit many industries’ needs. They also save money while working well. Choosing the right coupling boosts system performance and cuts downtime.

Pro Tip: Check your couplings often to spot wear early and keep them working their best.

FAQ

“Are you in need of high-quality flexible couplings for your industrial machinery? Look no further than YNF machinery! We offer a wide range of analog couplings that are comparable in performance to well-known brands such as KTR and Centaflex but at a more affordable price point.

Our analog couplings are made of high-quality materials and are designed to provide excellent shock absorption, misalignment compensation, and vibration reduction. They are available in a range of sizes and configurations to meet the needs of various industrial applications.

By choosing YNF machinery for your coupling needs, you can save money without sacrificing performance or reliability. Being a flexible couplings manufacturer, our analog couplings are engineered to meet or exceed industry standards, and we stand behind our products with a commitment to quality and customer satisfaction.

So why pay more for KTR or Centaflex couplings when you can get comparable performance from YNF machinery? Contact us today to learn more about our analog coupling options and how they can benefit your industrial machinery.”

Monolastic Couplings:

- The single-piece design of Monolastic Couplings eliminates the need for lubrication and maintenance, making them a low-maintenance option for industrial machinery.

- Monolastic Couplings are typically made of materials such as rubber or thermoplastic elastomers, which provide excellent flexibility and shock absorption.

- Monolastic Couplings are available in a range of sizes and configurations to accommodate different types of machinery and loads.

- Some common applications for Monolastic Couplings include pumps, compressors, generators, and conveyor systems.

Send Your Inquiry Today

Monolastic couplings join spinning shafts in conveyor systems. They take in vibrations, fix alignment issues, and lower machine stress. This helps the system run smoothly and keeps other parts safe.

Check for cracks, tears, or bent shapes. More noise, shaking, or alignment problems mean wear. Regular checks help you spot these issues early and avoid sudden failures.

Yes! Monolastic couplings, like KE-088 and KE-086, handle heat, wetness, and chemicals well. Strong materials like rubber and thermoplastic elastomers make them great for tough jobs like mining and factories.

No oiling is needed. Their one-piece design skips greasing, making them easy to care for. This saves time and effort.

Check your system’s alignment, load size, and conditions. Match the coupling’s size, material, and flexibility to your needs. Use a checklist to pick the best fit for your system.

Tip: Follow the maker’s instructions for setup and care to make the coupling last longer.