An excavator shovel is a strong machine used to dig and move lots of dirt. It has a boom, dipper, and bucket. These parts are attached to a cab that can turn. The whole machine sits on crawler tracks. The excavator shovel is important in construction and mining. It helps with digging, getting sites ready, and loading materials. Excavators used to run on steam. Now, they use modern hydraulic systems. This makes digging faster and easier. More people want excavator shovels now. In 2023, the market was worth over $74 billion. By 2030, it may reach $114 billion.

Aspect | Statistic / Insight |

|---|---|

Market Size 2023 | USD 74.27 billion |

Projected 2030 Value | USD 114.66 billion |

Key Industries | Construction, Mining |

Key Takeaways

Excavator shovels have strong parts like the boom, arm, bucket, hydraulic system, cab, and tracks. These parts help them dig, lift, and move heavy things quickly.

Different bucket types let excavators do many jobs. They can dig soil, break rocks, and clean surfaces.

Hydraulic systems make the excavator move. This helps it dig and load faster, smoother, and more accurately.

Excavator shovels are important in construction. They help with site preparation, trenching, and demolition. This makes work faster and safer.

In mining, excavator shovels take away overburden and load ore. They work with haul trucks to help get more done and have less waiting time.

Excavator Shovel Components

An excavator shovel is strong because of its smart parts. Each part helps the machine work well and safely. The main parts are the boom, arm, bucket, hydraulic system, and cab with tracks. These parts let the machine dig, lift, and move heavy things at job sites.

Boom and Arm

The boom and arm stick out from the excavator’s body. The boom connects to the body and holds the arm. The arm links the boom to the bucket. It controls how deep and far the bucket goes. Both boom and arm use hydraulic cylinders to move. They can go up, down, out, and in. This lets the operator control digging depth and angle very well.

The boom and arm help the excavator dig, lift, and place things where needed. The hydraulic system gives them power for hard jobs like digging deep or lifting rocks.

Component | Role in Digging and Lifting |

|---|---|

Boom | Stretches from the body to help the arm and bucket reach. It lets the machine dig, lift, and place things. A hydraulic cylinder controls it. |

Arm (Stick) | Connects the boom to the bucket. It controls how deep and far the bucket goes. It helps with digging, grading, and lifting. A hydraulic cylinder moves it. It can dig, load, and place materials. |

Bucket

The bucket does the digging. It scoops, lifts, and dumps dirt or rocks. Buckets come in many shapes and sizes for different jobs. Standard buckets have a V-shape to dig and load soil easily. Rock buckets use strong steel and sharp teeth to break hard ground. Mud shovels are wide and smooth to scoop wet dirt. Tilt buckets can angle for grading. Cleaning buckets remove debris from surfaces.

Bucket Type | Design Features and Performance Impact |

|---|---|

Standard Excavation | V-shape helps dig and load soil. Made of strong steel. |

Rock Bucket | Strong steel and sharp teeth break hard ground. Wide opening for rocks. |

Rake Bucket | Good for grading and clearing land. Removes surface debris. |

Cleaning Bucket | Cleans surfaces and removes debris easily. |

Mud Shovel | Wide and smooth for scooping wet, sticky dirt. |

Tilt Bucket | Can tilt for grading and leveling slopes. Makes work more accurate. |

Clamshell Bucket | Digs in tight spaces with good control. |

V-Type Bucket | Grabs loose materials well. |

Hard-Pan Bucket | Digs through tough, packed soil. Very strong. |

Heavy Bucket | Carries big, heavy loads like clay and dirt. |

The right bucket helps the excavator shovel do many jobs. It can dig trenches, move rocks, or clean up.

Hydraulic System

The hydraulic system gives power to most parts of the excavator shovel. It uses high-pressure fluid to move pistons and cylinders. These control the boom, arm, bucket, and tracks. The operator uses joysticks and pedals in the cab. These send signals to valves that move the fluid. This makes the parts move smoothly and with strength.

Modern excavators have advanced hydraulic controls. Some even help with tricky moves. This makes digging and lifting easier and more exact. The hydraulic system also moves the tracks so the machine can travel over rough ground.

Cab and Tracks

The cab is where the operator sits and works. Modern cabs keep the operator safe and comfortable. They use strong glass, armored windows, and emergency switches. Operators can see well with cameras and LED lights. The cab has comfy seats, easy joysticks, and climate control.

The tracks help the excavator move. Strong tracks and rollers let it go over dirt and rocks. The undercarriage uses tough steel and keeps the tracks tight. The drive sprocket and idler sprocket turn engine power into movement. This lets the excavator travel and get into position.

The cab and tracks keep the operator safe and help the machine move, even on hard ground.

How Components Work Together

Each part of the excavator shovel is important. The hydraulic system powers the boom, arm, and bucket. This lets the machine dig with strength and control. The bucket’s shape matches the job, making work faster. The cab keeps the operator safe and comfy. The tracks let the machine move and get ready for each task. When all parts work together, the excavator shovel can dig, lift, and move things on construction and mining sites.

How an Excavator Shovel Works

The excavator shovel does three main jobs. It moves, digs, and loads. Each job uses strong hydraulic and power systems. These systems help the work go fast and stay safe.

Movement

Operators drive the excavator shovel to where it needs to dig. The tracks help it move over rough ground. The cab can turn, so the operator faces the work area. The whole machine does not need to turn.

Operators keep the tracks pointed at the digging spot for safety.

They put the machine at a small angle on slopes for balance.

The cab turns so the operator can see trucks and line up the boom and arm.

Tip: Operators use gentle controls to save fuel and keep the machine in good shape.

Hydraulic systems make the tracks and cab move. These systems use high-pressure fluid for smooth, careful movement. New excavator shovels have electronic controls. These controls help the machine move better and use less energy.

Digging

Digging is the first step in excavation. The operator lowers the boom and arm. The bucket teeth push into dirt or rock. The bucket moves in a curved path to scoop up material. Hydraulic cylinders control the boom, stick, and bucket. This gives the operator good control over digging power and angle.

The digging process has these steps:

The operator checks for safety and removes debris.

The bucket teeth cut into the ground. The bucket’s weight and the boom and stick help.

The operator digs from the top layer down, not all at once.

The hydraulic system moves the boom, stick, and bucket to match the job.

Different digging styles fit different jobs. A front shovel works best for digging above ground. A backhoe digs below the ground. The hydraulic system lets the operator change the digging angle and force. This makes digging faster and more exact.

Loading

After digging, the excavator shovel loads dirt or rocks. The operator turns the cab to the side. The bucket moves over the truck bed. Loading is done carefully to keep everyone safe and work fast.

The operator lines up the truck and bucket for easy dumping.

The swing action spreads the load in the truck bed.

The operator honks to tell the truck driver to get ready.

Material is loaded from front to back to keep it even.

For big rocks, the operator puts smaller stuff in first.

The boom only lifts enough to clear the truck side.

The operator fills the bucket each time to move more dirt.

The operator swings less to save time and fuel.

Note: Operators do not dump over the truck cab. They use the left side or back for better safety and to see better.

Hydraulic systems help with loading. They let the operator lift, swing, and dump the bucket smoothly. Power systems with two engines and electronic controls help the excavator shovel do many things at once. It can swing and lift at the same time. This makes the work cycle fast and saves time.

Good hydraulic control, strong design, and careful operators make each step safe and quick. The excavator shovel is important for all digging jobs, big or small. It works well in both construction and mining.

Excavator in Construction

Excavator shovels are very important in construction. They do many jobs, like getting land ready and knocking down old buildings. Their special design and tools help them move dirt and materials. Operators use them on building sites, roads, and other big projects. These machines are strong and can do careful work.

Site Preparation

Site preparation is the first thing done in most building jobs. Excavators clear land, pick up trash, and make the ground flat. They dig holes for new buildings and shape land for roads. New excavators use GPS and 3D maps to help dig. This tech helps workers dig to the right depth and slope. It also helps stop mistakes and saves time.

Excavators with GPS finish jobs faster and more accurately.

Automatic controls help stop mistakes and extra work.

Fewer workers are needed, so labor costs go down.

Operators use these machines to move lots of dirt fast. Small excavators can move 10 to 20 cubic meters each hour. Big ones can move up to 100 cubic meters per hour. This speed helps keep building jobs on time.

Trenching

Trenching is another job for excavator shovels. Workers use them to dig long holes for pipes, wires, and drains. Excavators can dig trenches over one foot wide and more than five feet deep. They can use different buckets, like V-shaped or trenching buckets, for different soil and trench sizes.

Excavators work well in hard dirt and can dig deep or wide.

Mini-excavators are easy to move and fit in small spaces.

Operators can switch tools fast, so the machine does many jobs.

Excavators often take the place of other trenching machines. They are more flexible and can do many trenching jobs on roads and buildings.

Demolition

Demolition jobs also need excavator shovels. Operators use them to knock down old buildings, break concrete, and clear trash. Hydraulic breakers and clamps attach to the boom for more power. The cab can turn, so the operator works safely from different sides.

Excavators can sort and load stuff after demolition.

They help recycle concrete and metal, so there is less waste.

Strong arms and buckets lift heavy things during cleanup.

New excavators, like the HEAP, show how tech makes work safer and faster. Some machines can even work with little help from people. This makes building safer and quicker.

Excavator shovels are now a must for building, earthmoving, and road jobs. Their speed, strength, and smart features help finish work on time and save money.

Excavator Shovel in Mining

Mining shovels are very important in surface and strip mining. These machines help start mines and remove hard layers of dirt or rock. They also move a lot of material at once. Operators use mining shovels to dig up overburden and ore. This makes mining faster and easier. The cab can turn all the way around. This lets operators dig and load from any side.

Overburden Removal

Overburden is dirt and rock on top of minerals. Mining shovels, like cable shovel excavators and hydraulic excavators, take off this layer. These machines dig into hard ground and lift it away. The dipper and teeth can get worn out from this tough job. This can cause the machine to stop working for repairs. Many mines use smart excavation systems to help. These systems have sensors and cameras to watch for stress and hard spots. Operators can change how they dig or break up tough areas. This helps mining shovels last longer and work better.

Mining shovels in overburden removal:

Dig through hard ground.

Lift and move heavy rocks and dirt.

Use live data to dig better and protect the machine.

Ore Loading

After removing overburden, mining shovels load ore into haul trucks. Hydraulic excavators and rope shovels both do this job. Hydraulic excavators use diesel engines and hydraulic systems to dig and move ore. Rope shovels use electric motors and a rope-and-pulley system. Rope shovels last longer and use less energy for each ton of ore. Both types help mines load ore quickly and safely.

Best ways to load ore:

Blast rocks to make loose piles for easy digging.

Break big rocks to speed up loading.

Fill each bucket as much as possible.

Use smart systems to match trucks with shovels.

Good blasting and careful loading help mining shovels work faster and cost less to fix.

Working with Haul Trucks

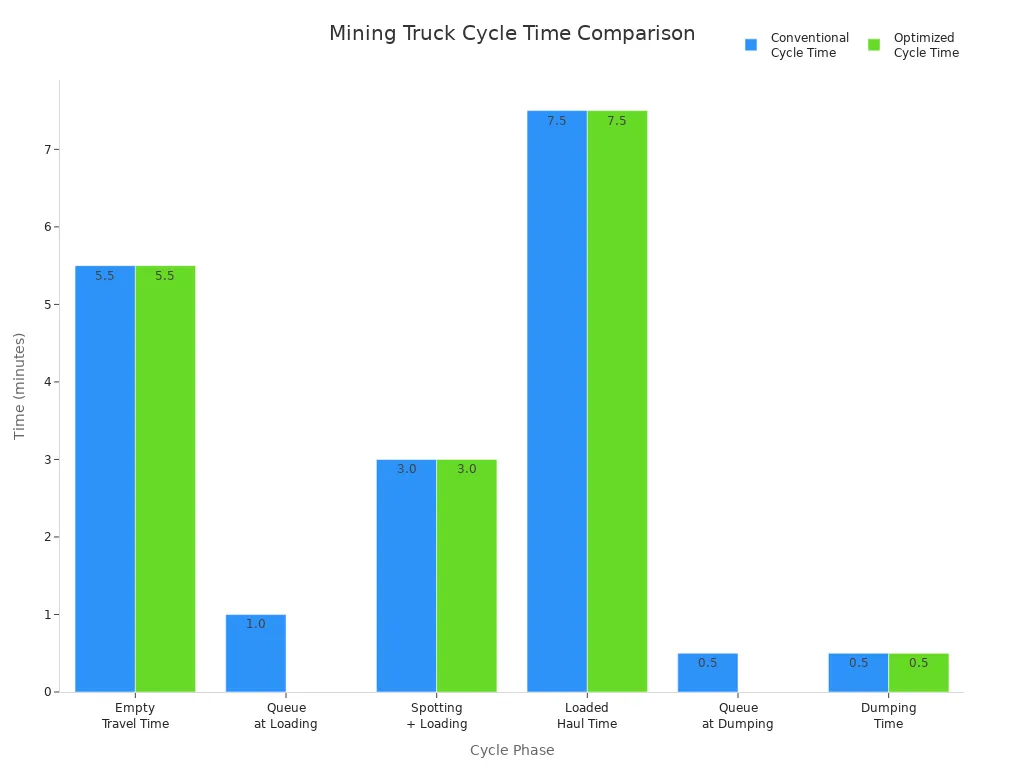

Mining shovels and haul trucks must work well together. Good teamwork keeps both machines busy and saves time. Mines use live dispatch systems to send trucks to shovels based on travel and loading times. This stops long lines and keeps mining shovels moving material.

Parameter | Conventional Cycle Time (min) | Optimized Cycle Time (min) |

|---|---|---|

Empty Travel Time | 5.5 | 5.5 |

Queue Time at Loading Point | 1.0 | 0 |

Spotting + Loading Time | 3.0 | 3.0 |

Loaded Haul Time | 7.5 | 7.5 |

Queue Time at Dumping Point | 0.5 | 0 |

Dumping Time | 0.5 | 0.5 |

Total Truck Cycle Time (T) | 18.0 | 16.5 |

Excavator Cycle Time (E) | 3.0 | 3.0 |

Number of Trucks per Excavator (N) | 6.0 | 5.5 |

Key points for mining shovels and haul trucks:

Live systems help cut waiting and idle time.

Fewer trucks are needed for each mining shovel when cycles are better.

Watching the system helps change routes and jobs for better results.

Mining shovels, like hydraulic excavators and rope shovels, now use electric drives and automation. These upgrades make mining safer, save energy, and help mines get more done.

Excavator shovels are very important in mining and other jobs. They can dig, load, and move lots of material fast. Operators use them for grading, sampling, and leveling the ground.

Shovels and trucks must work together well. Good planning means less waiting and more work gets done.

New technology, like real-time monitoring, helps stop breakdowns. It also keeps projects moving on time.

Knowing how excavator shovels work helps people stay safe. It also saves money and helps finish jobs faster.

FAQ

What is the main difference between an excavator shovel and a backhoe?

An excavator shovel’s bucket points away from the machine. It digs things that are above the ground. A backhoe’s bucket points toward the machine. It digs things that are below the ground. Each one is best for certain digging jobs.

How often should operators check the hydraulic system?

Operators need to check the hydraulic system every day before work. They look for leaks, low fluid, or broken hoses. Checking often helps stop problems and keeps the machine safe.

Can one excavator shovel use different buckets?

Yes, most excavator shovels can use different buckets. Operators use quick couplers or pins to change buckets. This helps the machine do many jobs like digging, grading, or lifting.

What safety steps should operators follow?

Operators must wear safety gear and check for dangers nearby. They need to look over the machine before using it. They should follow all site rules and wear seat belts in the cab. These steps help stop accidents.

Why do mining sites use both hydraulic and rope shovels?

Mining sites use hydraulic shovels because they dig fast and can do many jobs. Rope shovels are good for hard, heavy work and last a long time. Each kind is best for different mining jobs.