Excavator parts explained for 2026 reveal many exciting new changes. Companies are now producing special booms, improved hydraulics, and smarter attachments that enhance performance. The table below highlights some of the latest innovations:

|

Excavator Part / Innovation |

Description |

Significance |

|---|---|---|

|

Volvo EC300E Straight Boom Demolition Excavator |

23-foot straight boom for demolition, enhanced safety features |

Improved reach and operator safety |

|

Kubota 8.5-ton Mini-Excavator with Two-Piece Boom Option |

Expanded working range, advanced hydraulic controls |

Greater versatility in tight spaces |

|

Epiroc AB Acquisition of STANLEY Infrastructure |

Integration of new attachments and hydraulic tools |

Broader selection of parts and tools |

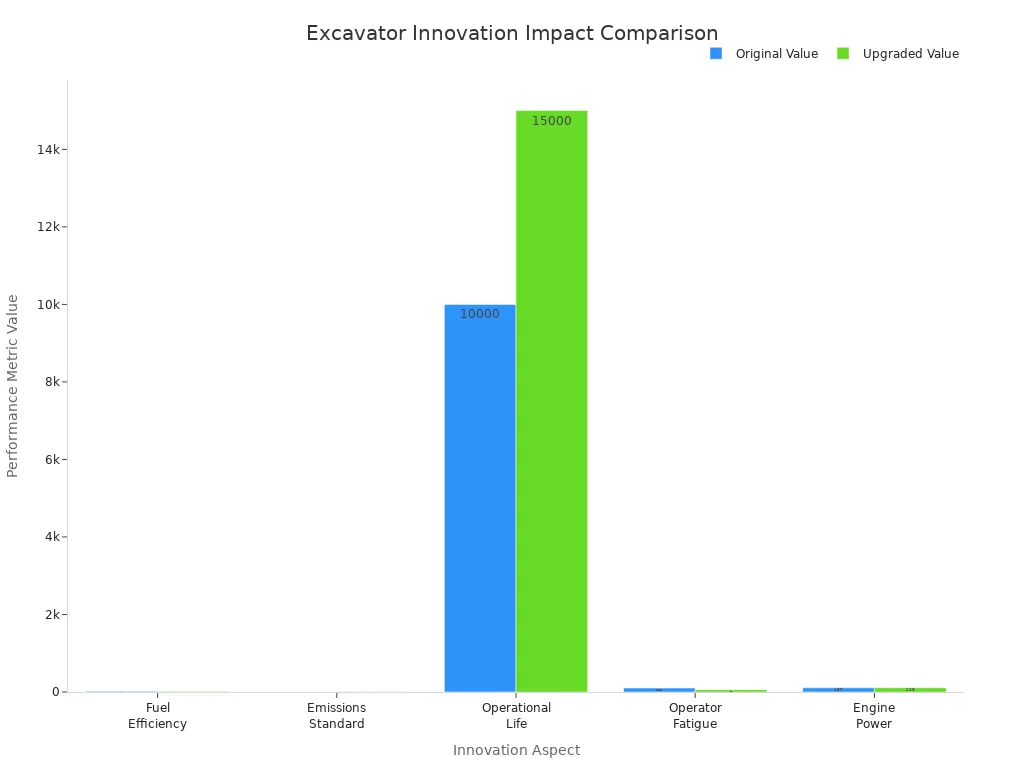

When excavator parts explained include hybrid power and advanced hydraulics, it’s clear these upgrades help machines use less fuel, reduce emissions, and extend lifespan. The chart below demonstrates how much more efficient these machines have become, proving that investing in new technology is a smart move:

Thanks to these advancements, people feel more confident choosing upgrades. The newest excavator parts explained here show how innovative features help you work faster and save money over time.

Key Takeaways

-

New excavator parts like electric powertrains and smart controls help save fuel. They also make machines safer and work better.

-

Advanced hydraulics and digital systems help workers finish jobs faster. They let workers dig with more accuracy. These parts also help machines last longer.

-

Telematics and predictive maintenance warn owners about problems early. This helps stop long breaks and saves money on repairs.

-

Eco-friendly parts and electric models make less pollution. They help companies follow environmental rules.

-

Digital dashboards and online parts platforms make machines easier to use. They also help people buy parts faster and for less money.

Excavator Parts Explained

Key Components

Excavator parts explained means knowing the main pieces of these big machines. Each part has a job that helps the excavator work well. The house sits on a turntable, so it can spin all the way around. This part holds the cab, engine, and controls. The cab is where the operator sits. It lets the operator see, stay safe, and use the controls. The engine gives power to the hydraulic pumps and other systems. Most engines use diesel because it lasts a long time.

The arm has three main parts: the boom, stick, and bucket. The boom is the biggest part and connects to the house. It lifts and lowers the arm with hydraulic cylinders. The stick links the boom to the bucket. It helps the arm reach out and dig carefully. The bucket is at the end. It scoops, digs, grades, or breaks things. Operators can change the bucket for other tools. This makes the machine useful for many jobs.

The undercarriage holds up the whole machine and helps it move. Tracks or wheels let the excavator go over different ground. The swing drive and motor help the top part turn. This lets operators move the machine easily. Counterweights keep the excavator from tipping when lifting heavy things. The hydraulic system moves the boom, stick, bucket, and tools by using pressurized fluid. The control system lets the operator move everything with joysticks, pedals, and buttons.

Tip: Picking the right parts can make work safer and faster.

|

Component |

Specific Function |

|---|---|

|

Boom |

Biggest arm part; helps dig and lift with hydraulics. |

|

Stick (Dipper Arm) |

Connects boom to bucket; makes digging and moving things easier. |

|

Bucket |

Scoops, digs, grades, or breaks things; can be swapped for other jobs. |

|

Cab |

Where the operator sits; has controls, screens, and keeps the operator safe. |

|

Hydraulic System |

Moves the boom, stick, bucket, and tools with pressurized fluid. |

|

Undercarriage |

Holds up the machine and lets it move; uses tracks or wheels. |

|

Swing Drive & Motor |

Lets the top part spin all the way around for easy moving. |

|

Counterweight |

Stops the machine from tipping when lifting heavy things. |

|

Engine |

Gives power to the pumps and other parts; usually runs on diesel. |

|

Control System |

Lets the operator move the machine with joysticks, pedals, and buttons. |

|

Attachments |

Extra tools like hammers or augers to do more jobs. |

|

Fuel Tank |

Holds diesel fuel for the engine, which affects how long it can run. |

|

Cooling System |

Keeps the engine and hydraulics from getting too hot by moving coolant and air. |

Explaining excavator parts like this helps buyers and operators see how each part affects how well the machine works, how safe it is, and how much it can do.

Recent Upgrades

In the last few years, excavator parts explained by new tech have changed a lot. Now, companies use GPS and 3D controls to guide the bucket and arm. This makes digging and grading more exact. Operators can follow digital plans, so they make fewer mistakes and finish faster. Remote control tech lets workers run machines from far away. This keeps them safe in dangerous places.

Hydraulic systems are now better, with more joints and cylinders for strong and smooth moves. New control valves help operators control speed, direction, and force more easily. These changes make the machines work better and do more jobs.

|

Excavator Part/System |

Recent Upgrades and Features |

Differences from Previous Generations |

|---|---|---|

|

Electro-Hydraulic Systems |

Smarter system with engine speed control and better cooling. |

Uses less fuel, moves smoother, and saves up to 15% more fuel. |

|

Hydraulic Components |

Hydraulic oil lasts longer and needs less service. |

Less time and money spent on fixing things. |

|

Machine Control Systems |

Boom and bucket move by themselves, better joysticks, and more work modes. |

Easier to use, safer, and less mess. |

|

Operator Cab |

Better seats, bigger heated mirrors, no-key start, and smarter controls. |

More comfort, better work, and more ways to set it up. |

|

Safety and Productivity Tech |

3D grade help, finds obstacles, weighs loads, and levels things digitally. |

More exact work, safer, and digital help built in. |

|

Specific Model Technologies |

Electronic hydraulic pump, three cameras, digital level, and Active Control system. |

Lets you change flow, see better, and watch how things work. |

Companies like Caterpillar now have systems that let operators set how deep or sloped they want to dig. They use joysticks, screens, or dials. Screens show the right grade, height, and depth. This makes it easier to get the job just right. Cat Grade with 3D uses satellites and RTK to dig exactly as the plan says. These features make the machines more accurate, easier to use, and tougher than old ones.

-

GPS and 3D controls help operators grade perfectly with less work.

-

Remote controls keep workers safe in risky places.

-

Hydraulic systems with more joints and cylinders can move gently or with lots of power.

-

Better control valves make the machine work faster and do more jobs.

-

Augmented reality shows real-time info on screens, so operators feel sure and work better.

Explaining excavator parts with these upgrades shows how technology turns simple machines into smart, strong helpers. These changes help companies finish jobs faster, safer, and with better results.

Smart Tech & Automation

Telematics

Telematics is now very important in new excavators. Companies put sensors and AI in the undercarriage, engine, and hydraulics. These watch the machine all the time. Operators and managers get alerts when something needs fixing. This stops the machine from breaking down. Telematics also adds cool things like weighing loads, lift-assist, and some automation. These make work safer and faster.

-

Machines check themselves and show how they are working.

-

You get alerts when it is time for repairs.

-

Weighing and lift-assist help you control the machine.

-

Augmented reality shows digging depth and warns about obstacles.

Telematics lets managers see where machines are and how they work. They can do this from anywhere. This saves time looking for equipment. It also helps stop theft by using geofencing. Remote checks find problems fast. This means repairs can happen before things get worse.

|

Benefit Area |

Description and Impact |

|---|---|

|

Equipment Tracking |

GPS finds machines right away and saves time. |

|

Theft Prevention |

Geofencing warns if a machine moves without permission. |

|

Utilization |

Watching engine hours helps plan how to use the fleet. |

|

Preventive Maintenance |

Using data for repairs means less downtime and lower costs. |

Predictive Maintenance

Predictive maintenance uses telematics and sensors to check machines every day. Operators can spot problems early and fix them before a breakdown. This keeps machines working longer and saves money on repairs. For example, one big company kept machines running 95% of the time. They had 83% less surprise breakdowns. Repairs went from two days to just a few hours. This saved over a million dollars each year.

Note: Predictive maintenance means fewer surprises and more time working.

Autonomous Features

Excavators now have smart and semi-smart features that help people work better and safer. AI helps guide digging and lifting. It changes how the machine works based on the ground and bucket load. Machines can follow set paths for jobs that repeat or are dangerous. This keeps work steady and cuts down on waiting. Radar and sensors watch for people and things. They stop the machine if something gets too close.

-

Fully smart excavators help finish work faster.

-

Sensors and cameras spot danger and stop crashes.

-

Remote controls let people run machines from safe places.

-

AI helps dig better and waste less.

These smart tools help people work faster, safer, and with fewer mistakes. This makes every job site better.

Electrification

Electric Powertrains

Electric powertrains are changing how excavators work. These systems use electric motors instead of diesel engines. This means there is no exhaust and less noise. Electric excavators give instant torque, so they are smooth and easy to control. They also work well with sensors and automation.

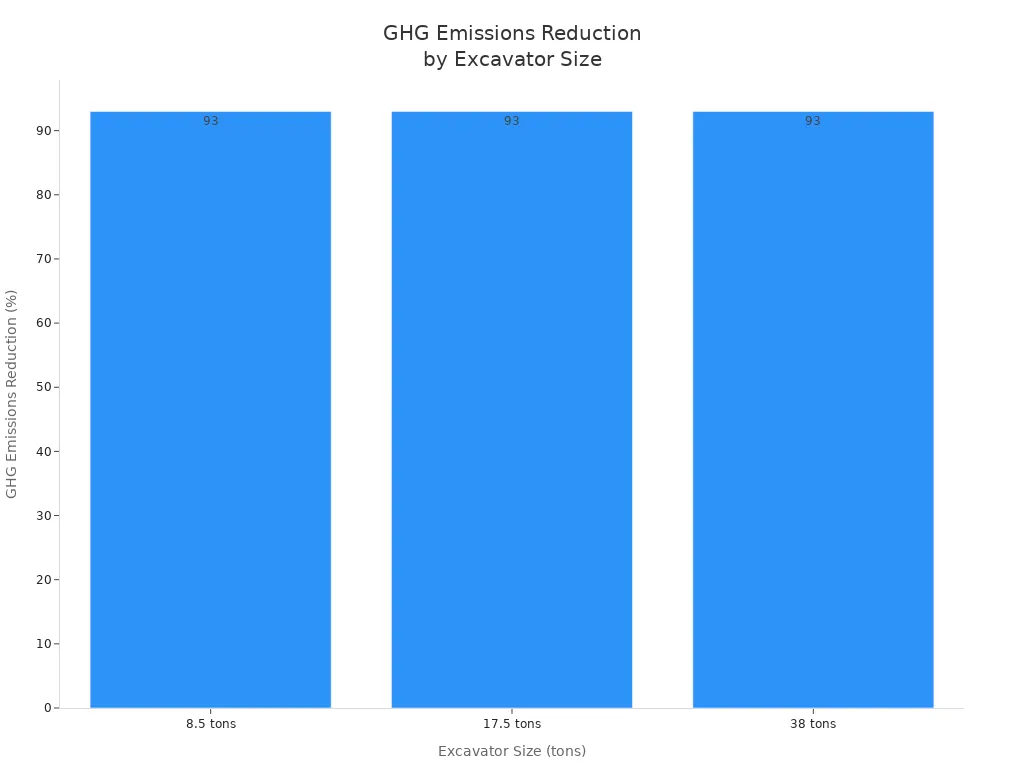

The biggest benefit is less greenhouse gas emissions. Over ten years, electric excavators can lower emissions by up to 96% compared to diesel ones. The table below shows how much emissions drop for different sizes and power sources:

|

Excavator Size (tons) |

GHG Emissions Reduction Over 10 Years |

Main Emission Source for Diesel Excavators |

Main Emission Source for Electric Excavators (EU Mix) |

Main Emission Source for Electric Excavators (Norwegian Mix) |

|---|---|---|---|---|

|

8.5 |

90%-96% reduction |

Operation (96%-97%) |

Operation (45%), Production (38%) |

Production (62%), Operation (22%) |

|

17.5 |

90%-96% reduction |

Operation (96%-97%) |

Operation (49%), Production (39%) |

Production (69%), Operation (11%) |

|

38 |

90%-96% reduction |

Operation (96%-97%) |

Operation (64%), Production (31%) |

Production (71%), Operation (19%) |

-

Electric excavators use batteries, so they do not need diesel.

-

They make no exhaust, which helps the air and workers.

-

They are quieter, so job sites are safer and more comfortable.

-

Operators feel smoother and more exact control.

-

Some problems still exist, like needing good charging stations.

Hybrid Systems

Hybrid excavators use both a regular engine and hydraulic or electric parts. These machines save and reuse energy, which helps them use less fuel and make less pollution. There are two main types: hydraulic hybrids and electric hybrids. Hydraulic hybrids use accumulators to save energy from the boom moving. Electric hybrids use batteries and electric motors.

|

Hybrid System Type |

Description |

Configuration Types |

Performance Improvements |

Best Configuration for Excavators |

|---|---|---|---|---|

|

Hydraulic Hybrid |

Combines ICE with hydraulic accumulators and components acting as pump/motor |

Series, Parallel, Mixed |

Energy recovery, improved fuel economy, better powertrain efficiency |

Parallel system offers best balance of fuel economy and cost |

|

Electric Hybrid |

Combines ICE with electric motor (EM) and energy storage unit |

Series, Parallel |

Fuel economy enhancement, drivability improvements |

Parallel system preferred due to cost and efficiency |

The Volvo EC300 Hybrid uses a hydraulic hybrid system. It saves energy when the boom goes down and uses it to help the pump motor. This makes the machine use up to 17% less fuel when digging and dumping. It still has the same power as a normal excavator.

Battery Advances

New battery technology helps electric excavators work longer and charge faster. Most new machines use lithium-ion batteries. These batteries hold more energy and last longer than old ones. They also make the machines lighter and more efficient.

-

Lithium-ion batteries store lots of energy and last a long time.

-

Bigger battery packs let machines work longer before charging.

-

Good motors and drivetrains help batteries last longer.

-

Fast charging and regenerative braking save time.

-

New models, like Komatsu’s electric mini excavators, show these changes help machines work longer and weigh less.

-

Scientists are working to make batteries even better and stronger.

Note: Better batteries mean operators can work longer without stopping, which helps keep job sites cleaner and more efficient.

Hydraulics & Eco Materials

Hydraulic Innovations

Excavator hydraulic systems have gotten much better lately. Companies use new technology to make them stronger and easier to control. These changes help operators do hard jobs with less work and more accuracy.

-

New hydraulic systems use power in a smarter way. Operators can move the machine smoothly and exactly, even when the job is hard.

-

Machine learning and AI look at how the machine works. They can tell when it needs fixing, so there are fewer breakdowns and repairs cost less.

-

Joystick controls and touchscreens are now easier to use. Operators can react quickly and feel more comfortable while working.

-

Hybrid and electric machines use engines that save fuel. These machines make less pollution and help the environment.

-

IoT lets machines send data all the time. This helps find problems early and keeps machines working longer.

-

Automation, like closed cabins and better views, keeps operators safe and helps them get more done.

-

Electro-hydraulic systems from companies like Volvo and Danfoss use digital controls. This makes the machines work better and need less fixing.

Tip: Better hydraulic systems help machines dig deeper, stay steady, and work better overall.

Many new excavators can use tiltrotators and smart controls. These tools let operators do more jobs and work more carefully.

Eco-Friendly Parts

Being good to the environment is very important now. Eco-friendly excavator parts help companies protect nature and work better.

-

Hydraulic pumps and motors that save energy use less fuel and make less pollution.

-

Biodegradable and fake hydraulic fluids are safer for dirt and water.

-

Strong hydraulic parts last longer. This means less trash from broken parts and fewer repairs.

-

Smart controls help operators use just the right amount of material. This means less waste and fewer mistakes.

-

Eco-friendly parts help finish jobs faster. Quicker work uses fewer resources and costs less money.

-

Safer hydraulic controls help keep workers safe and support green work habits.

|

Eco-Friendly Feature |

Benefit |

|---|---|

|

Energy-efficient hydraulics |

Lower fuel use and emissions |

|

Biodegradable fluids |

Reduced environmental impact |

|

Durable components |

Less waste, longer machine life |

|

Smart controls |

Less material waste, higher productivity |

In the future, smart automation and plant-based fluids will help excavators be even better for the planet.

Digitalization & Supply Chain

Digital Dashboards

Modern excavators now have digital dashboards that help operators. Big touchscreen monitors show live data like fuel use and machine status. Operators can use systems like Volvo Dig Assist for help with digging. These systems move the boom and bucket by themselves. This makes work easier and more exact. Operators can save up to 20 settings for attachments and joysticks. Cameras and radar watch around the machine and warn about danger. Controls are close by, so they are easy to reach. Wireless charging and heated seats help operators stay comfortable and focused.

|

Technology / Feature |

Description / Functionality |

|---|---|

|

Touchscreen Monitors |

Show real-time machine data and settings |

|

Machine Control Systems |

Guide digging and automate movements |

|

Custom Operator Settings |

Store profiles and attachment configurations |

|

Safety Integration |

Monitor surroundings and provide alerts |

|

Comfort Features |

Wireless charging, Bluetooth, heated/cooled seats |

Online Parts Platforms

Online parts platforms make it easier to buy excavator parts. These sites have many parts like bucket teeth and sensors. Contractors can see what is in stock from all over the world. This helps them avoid waiting for local parts. Prices online are much lower than at dealers, even with shipping. Many repair shops let customers bring their own parts. This helps buyers skip dealer markups. Digital tools help match part numbers and check if parts fit. This makes ordering faster and more correct. Experts say online part sales grew by 19% because of more choices, quick shipping, and saving money.

-

Many easy-to-install parts to pick from

-

Live stock updates and worldwide options

-

Lower prices and quicker delivery

-

Tools to check if parts will fit

Supply Chain Trends

In 2026, getting excavator parts can take longer. Trade problems and tariffs make parts cost more and slow things down. Fewer workers mean slower making and moving of parts. New rules raise the price of materials. Companies try to fix this by using more suppliers and buying parts from the U.S. Some companies make deals to get better service. Digital tools connect everyone on one platform and cut down on paperwork. Mobile apps and live data help teams make fast choices. This keeps jobs moving and helps finish projects on time.

Digital supply chains help contractors work faster, save money, and avoid costly delays.

Cab Design

Ergonomics

Excavator cabs in 2026 are made for comfort and easy use. Companies want operators to feel good and work well, even on long days. Heated seats with air suspension help support the back and keep people warm or cool. There is lots of space for legs, so anyone can fit. The seat and controls move together, so everything stays close. This helps short and tall people reach the controls easily.

-

Heated seats with air suspension keep you comfy in any weather

-

Big legroom fits all sizes of operators

-

Moving seat and controls make it easy to reach everything

-

Controls can be set to feel just right for each person

-

A big 10-inch screen helps manage attachments

-

Cameras let you see almost all around the machine

These changes help operators feel less tired and get more done. Bigger windows and more glass mean you do not have to twist your neck as much. Special mounts filled with silicon cut down on shaking and noise. Many cabs now have seats that can be adjusted, plus air and heat for comfort. Wide doors and low steps make it easy to get in and out, which keeps people safe and happy.

Operators in comfy cabs say they hurt less and can pay attention better, so they work faster and make fewer mistakes.

Advanced Controls

New excavator cabs have smart controls that help keep people safe and working well. The switches and joysticks are close by, so hands do not get tired. Air seats with armrests can be changed to fit each person, so they can work all day. Bluetooth lets operators talk without using their hands, and screens show important info.

-

Easy-to-use controls help you work fast

-

Cameras show all around the cab, so there are no blind spots

-

Thick glass and tight seals keep out noise and shaking

-

Safety features like quick exits, seat belts, and strong frames protect people

-

Some controls can move the boom and bucket by themselves, so operators do not get as tired

Touchscreens in the cab show live info and help with repairs. Operators can change settings, check the machine, and use attachments with just a few taps. Smart hydraulics use only the power needed, which saves fuel and helps the machine last longer. With climate control and places to store things, the cab is a nice place to work all day.

New ideas in excavator parts are changing construction machines. Electric powertrains help machines work better and save money. Smart controls make it easier to use the equipment. Predictive maintenance finds problems early and keeps machines running. Contractors should think about material costs, how many workers they need, and if new technology will help them.

|

Practical Takeaway |

Why It Matters |

|---|---|

|

Smart tech and automation |

Less downtime and safer job sites |

|

Eco-friendly parts |

Follow rules and lower pollution |

|

Digital dashboards |

Make work easier and more accurate |

Learning about new trends helps you get better results and do well for a long time.

FAQ

What are the most important new excavator parts for 2026?

Manufacturers are now making electric powertrains, better hydraulics, and smart control systems. These new parts help machines last longer and use less fuel. They also make the machines safer to use. Operators find it easier to work and see better results with these upgrades.

How does predictive maintenance help excavator owners?

Predictive maintenance uses sensors and telematics to watch the machine’s health. Owners get alerts before something breaks. This helps stop long waits for repairs and saves money. It also helps the equipment last longer.

Can older excavators use new smart technology?

Many smart features, like telematics and digital dashboards, can be added to older machines. Owners need to check if these parts fit their model. Sometimes, a professional must help with the upgrade.

Why choose eco-friendly excavator parts?

Eco-friendly parts help lower pollution and waste. They use less fuel and last longer than regular parts. Companies can follow environmental rules and save money over time. Operators also work in cleaner and safer places.

Where can contractors find reliable excavator parts online?

Contractors can shop on trusted websites with live stock, part-matching tools, and worldwide shipping. These sites often have lower prices and faster shipping than local stores.

Tip: Always check if the part fits your machine before you order online to avoid problems.