Excavator internal parts are the cab, arm assembly (boom, stick, bucket), hydraulic system, engine, undercarriage, counterweight, swing drive, slewing ring, pins, and linkages. The cab has the main controls. The operator sits in the cab. The arm assembly moves dirt and rocks. The hydraulic system makes things move. The engine gives power to the machine. The undercarriage holds up the weight. It also helps the excavator move. The counterweight keeps the machine balanced. The swing drive and slewing ring help the top part turn. Pins and linkages join moving parts together. Knowing each part and what it does helps you use the machine safely and with better control.

Key Takeaways

Excavators have important parts like the cab, arm assembly, hydraulic system, engine, undercarriage, and counterweight. These parts work together to dig, lift, and move things.

The cab is where the operator sits and uses the controls. It is made to be comfortable and safe. This helps people work longer and do a better job.

The hydraulic system uses fluid power to move the boom, arm, and bucket. It makes these parts strong and able to move with care.

Taking care of pins, linkages, and the undercarriage is important. This keeps the excavator safe and helps it last longer.

Picking the right boom, stick, and bucket for each job is smart. It helps the machine work better and stay steady.

Main Components of an Excavator

Excavator Internal Parts Overview

Excavators have many important parts. These parts help the machine work well and safely. The main parts are the cab, arm assembly, hydraulic system, engine, undercarriage, counterweight, swing drive, slewing ring, pins, and linkages. Each part does something special. The cab is where the operator sits and uses the controls. The arm assembly has the boom, stick, and bucket. It is used for digging and lifting. The hydraulic system uses pumps and cylinders. It helps move the arm and other tools. The engine is usually diesel. It gives power to the whole excavator. The undercarriage holds up the machine’s weight. It lets the excavator move with tracks or wheels. The counterweight keeps the machine steady when lifting heavy things. The swing drive and slewing ring help the top part turn. Pins and linkages connect moving parts. They let these parts move and turn.

Top brands say the main parts are the chassis or undercarriage, house, operator cab, hydraulic system, excavator arm, and engine. These parts work together. They help the excavator dig, lift, and move things.

Here is a quick look at how the main parts of an excavator work together:

Part | Role and Interaction |

|---|---|

Boom | Sticks out from the body. It helps the arm and bucket reach out to dig, lift, and move things. |

Arm (Stick) | Connects the boom to the bucket. It moves in and out. This helps dig deeper or reach farther. |

Bucket | Attaches to the end of the arm. It digs, scoops, and carries dirt or rocks. You can change it for other tools. |

Hydraulic System | Uses strong fluid to move the boom, arm, and bucket. The operator controls it for power and accuracy. |

Engine | Gives energy to the hydraulic system and other parts. It helps the excavator move and work. |

Swing Gear | Lets the top part turn all the way around. This helps the operator move the arm without moving the tracks. |

Undercarriage | Holds up the excavator. It keeps it steady and helps it move with tracks or wheels. |

Counterweight | Makes sure the excavator does not tip over when lifting heavy loads. |

Cab | The operator sits here. This is where all the controls are to run the excavator. |

Excavator Parts Diagram

A normal excavator parts diagram shows how the parts fit together. It helps people see where each part is. Operators and technicians use the diagram to learn about the machine. Here is a simple table that lists the main parts and where they are:

Part Number | Part Name |

|---|---|

1 | Excavator Boom |

2 | Excavator Boom Cylinder |

3 | Excavator Track Rollers |

4 | Bucket |

5 | Bucket Cylinder |

6 | Excavator Cab |

7 | Excavator Arm |

8 | Excavator Arm Cylinder |

9 | Excavator Final Drive |

10 | Excavator H Link |

11 | Excavator Main Control Valve |

12 | Excavator Hydraulic Pump |

13 | Excavator Side Link |

14 | Excavator Fuel Tank |

15 | Excavator Hydraulic Fluid Tank |

16 | Excavator Slew Ring |

17 | Excavator Sprocket |

18 | Excavator Swing Motor |

19 | Excavator Track Adjuster |

20 | Excavator Track Chains and Rails |

21 | Excavator Track Pad |

22 | Excavator Rock Guards |

23 | Excavator Counterweight |

24 | Excavator Driver Seat |

25 | Excavator Cab Controls |

This diagram shows how the big and small parts connect. It helps people learn the names and places of each part. This makes it easier to know how the excavator works.

Key Parts of an Excavator

Cab

The excavator cab is where the operator works. It sits high on the machine and lets the operator see the job site well. The cab has all the controls, like joysticks, pedals, and screens. Newer cabs have many things to help the operator feel safe and comfortable:

Big LCD touchscreens show live data and let you change settings.

Heating and air conditioning keep the cab nice in any weather.

Special seats warm up or cool down and help stop shaking.

Joystick controls are easy to use and help you work better.

CAN bus technology in the joysticks helps controls work well.

Large windows, mirrors, and cameras help you see all around.

Materials in the cab make it quieter and less shaky.

Some cabs have wireless phone charging and places to store things.

These new cab features help operators work longer and safer. The cab’s design helps the operator feel less tired and pay attention. This makes the cab one of the most important parts of an excavator.

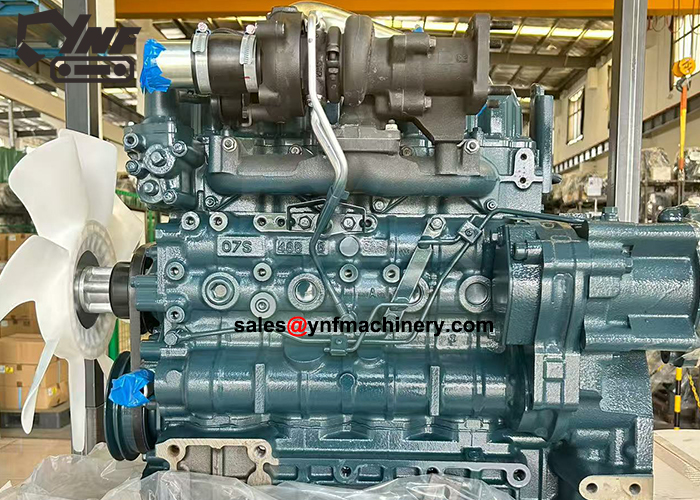

Engine

The engine gives power to the whole excavator. Most excavators use diesel engines because they are strong and save fuel. The engine sends power to the hydraulic pump. This pump moves the boom, arm, and bucket. There are different engines for excavators, and each has its own good points:

Engine Type | Cylinder Count | Power Output Range | Main Features |

|---|---|---|---|

V-Twin (2-cylinder) | 2 | ~20 HP | Fast throttle, strong power at low speeds |

3-Cylinder | 3 | Up to ~60 HP | Smooth power, saves fuel, good for heavy work |

Mini excavators often use engines from Yanmar, Kubota, Perkins, Cummins, and Caterpillar. These engines have about 20 to 60 horsepower. New engines have turbocharging and direct injection. These help the engine meet rules for clean air and work better.

How much fuel the engine uses changes how much it costs to run. Fuel use depends on how hard the machine works, the ground, and the weather. Good operators and regular care can use up to 15% less fuel. Picking the right size machine and not letting it idle too long also saves fuel and money. Watching fuel use helps companies plan and avoid surprise costs.

Hydraulic System

The hydraulic system is like the excavator’s muscles. It uses fluid under pressure to move the boom, arm, and bucket. The main parts are the hydraulic pump, cylinders, valves, and hoses. In a medium excavator, the hydraulic system works at about 4,500 psi.

Hydraulic cylinders use fluid to move the boom, arm, and bucket. This gives the machine its digging and lifting strength.

The system lets the operator do many things at once. This makes work faster and easier.

The operator can change speed and force for different jobs.

The hydraulic system is simple, so it is reliable and easy to fix.

Safety features stop the machine from using too much force.

The hydraulic system lets you change tools quickly, so the excavator can do more jobs.

Some systems have boom priority and arm priority. These send fluid where it is needed most. This helps the excavator work better and safer.

Undercarriage

The undercarriage holds up the excavator and helps it move. It has many track frame parts that work together to keep the machine steady and moving. The main undercarriage parts are:

Sprockets: These toothed wheels move the track forward and backward.

Rollers: Track rollers hold up the machine and keep the track in place.

Idlers: These keep the track tight and guide it around the sprockets.

Tracks: The tracks spread out the machine’s weight and help it move over rough ground.

Final Drive: This gearbox sends power from the engine to the sprockets.

Pins and Bushings: These connect the track links and let them bend.

Track Adjusters: These keep the track tight enough.

The undercarriage spreads the weight and keeps the track tight. Track excavators need these parts to move well and stay balanced. How long the undercarriage lasts depends on the ground, speed, and how the operator uses the machine. Cleaning, keeping the track tight, and changing worn parts can make the undercarriage last 4,000–6,000 hours. Bad care or rough ground can make it wear out faster and cost more to fix.

Counterweight

The counterweight is a heavy block on the back of the excavator. Its job is to balance the machine when it lifts or digs. The counterweight stops the excavator from tipping over by balancing the load and the arm.

Counterweights are made to match the machine’s center of gravity and how much it can lift.

Sometimes, the engine or hydraulic system is inside the counterweight to save space and help balance.

The counterweight turns with the top part of the excavator, so it keeps balance no matter which way the machine turns.

Safety rules say the counterweight must be checked and put on right.

Operators should always check the counterweight before lifting heavy things to stay safe.

The counterweight is very important for safe and steady work. It works with the undercarriage and tracks to keep the excavator steady during hard jobs.

Arm Assembly and Movement

The arm assembly gives the excavator its digging and lifting strength. It has the boom, stick, and bucket. These parts work together with cylinders and linkages. They help move dirt, rocks, and other things. The swing drive and slewing ring let the top part turn. This makes the excavator flexible and useful on any job.

Boom

The boom is the biggest part of the arm. It connects to the house and can pivot there. The boom lifts and lowers the arm assembly. This helps the operator reach up or down. Hydraulic cylinders, called boom cylinders, attach to the boom. These cylinders control how the boom moves. They give the boom power to lift heavy things and dig deep.

The boom holds the arm and bucket while working.

It pivots at the house to move the arm in and out.

The boom cylinder helps the boom move with power and control.

The boom’s shape helps balance digging, lifting, and flexibility.

Strong steel keeps the boom steady and safe.

A longer boom lets the excavator reach farther and dig deeper. But a longer boom can make lifting heavy things harder. Operators pick the right boom length for each job.

Boom Length Increase (meters) | Horizontal Reach Gain (meters) | Digging Depth Gain (meters) |

|---|---|---|

1 | 0.8 – 0.9 | 0.6 – 0.7 |

A longer boom helps cover more ground without moving the machine. This saves time and helps get more work done. But it can make the excavator less steady when lifting big loads.

Stick (Arm/Dipper)

The stick, also called the arm or dipper, links the boom to the bucket. It holds the bucket and works with the boom to dig or lift. A hydraulic cylinder, called the arm cylinder, connects the boom and stick. This cylinder moves the stick. The stick then moves the bucket closer or farther from the machine.

The stick sits between the boom and the bucket.

It has a system to attach different tools.

The arm cylinder lets the stick pivot.

Moving the cylinder brings the bucket in or out.

The stick can be longer or shorter for different jobs.

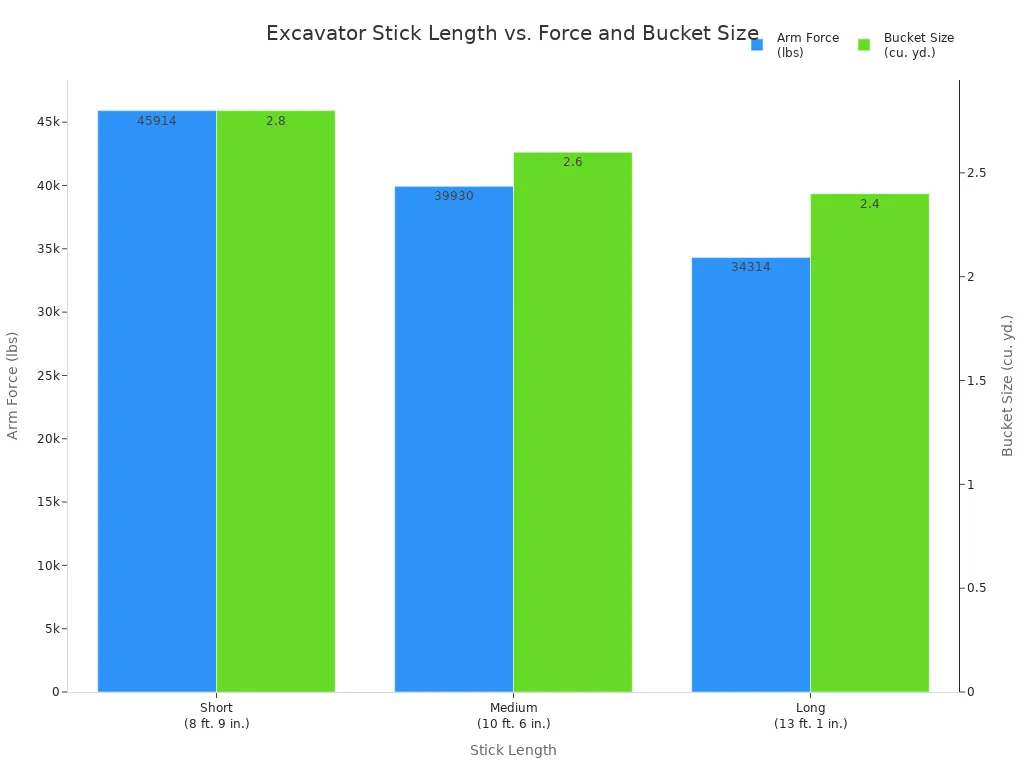

Shorter sticks give more digging power and can use bigger buckets. But they do not reach as far or as deep. Longer sticks reach farther and dig deeper. But they cannot lift as much and need smaller buckets.

Stick Length | Arm Force (lbs) | Recommended Bucket Size (cu. yd.) | Key Performance Impact |

|---|---|---|---|

Short (8 ft. 9 in.) | 45,914 | 2.8 | Most digging power, bigger bucket, good for hard ground, less reach and depth |

Medium (10 ft. 6 in.) | 39,930 | 2.6 | Balanced reach and power, medium bucket size |

Long (13 ft. 1 in.) | 34,314 | 2.4 | More reach and depth, less lifting power, smaller bucket, less steady |

Operators pick stick length for each job. Long sticks are good for trenching or finishing. Short sticks are best for tough digging.

Bucket

The bucket is the tool that digs, scoops, and carries things. It attaches to the end of the arm. There are many types of buckets for different jobs. A hydraulic cylinder helps the bucket move. The operator can tilt, curl, or dump the bucket.

Bucket Type | Specific Function |

|---|---|

Digging Bucket | Used for digging with teeth to break hard ground; common in building and landscaping. |

Rock Bucket | Has sharp teeth for breaking hard things like stone and rock. |

Utility Bucket | Rounded edge to dig near utility lines without breaking cables or pipes. |

Grading Bucket | Wide, shallow bucket for smoothing dirt and sand. |

Tilt Ditch Cleaning Bucket | Like a grading bucket but can tilt to work on slopes or uneven ground. |

V Bucket | Makes narrow V-shaped trenches for pipes, cables, or drains. |

Frost Bucket | Extra teeth to dig through frozen or very hard ground. |

Micro Trenching Bucket | Small, claw-like bucket for very narrow, deep trenches, often for cables. |

Skeleton Bucket | Has slots to sift small stuff from bigger pieces, good for sorting rocks and dirt. |

Rake Riddle Bucket | Long teeth rake out roots and plants, letting dirt fall through. |

Clean-up Bucket | Big bucket for finishing, grading, and moving loose dirt. |

The right bucket helps get work done faster. Bigger buckets move more dirt each time. But a bucket that is too big can hurt the arm and slow things down. A bucket that is too small wastes time. Operators must pick the right bucket for the job and machine.

Bucket size depends on the excavator, the job, and the material. For example, a grading bucket is best for smoothing dirt. A rock bucket is best for breaking hard ground. Picking the right bucket keeps the machine safe and working well.

Pins and Linkages

Pins and linkages join the parts of the arm assembly. Pins act as pivots so the boom, stick, and bucket can move. Linkages are strong connectors. They help move power from the cylinders to the bucket and other tools.

Part Description | Location | Function |

|---|---|---|

Left-side link between dipper stick and bucket linkage | Left side | Moves power from stick to bucket linkage |

Right-side link between dipper stick and bucket linkage | Right side | Moves power from stick to bucket linkage |

Pin connecting dipper arm to bucket linkage | Central pivot | Lets the parts pivot in the middle |

Link connecting bucket linkage to dipper arm | Mid-size CAT excavators | Joins bucket linkage to dipper arm, lets it move |

Link connecting bucket linkage to hydraulic cylinder | N/A | Helps the bucket move by joining to the cylinder |

Pins hold the boom, stick, and bucket linkage together so they can pivot.

Linkages join the stick to the bucket and other tools for smooth movement.

Pins and linkages let the operator dig, lift, and dump with control.

It is important to take care of pins and linkages. Operators should grease and check them often. Good care stops friction, keeps parts from wearing out, and makes the arm last longer. Not taking care of them can cause expensive repairs and unsafe work.

Tip: Grease all moving parts and check for wear every week, or every day if the job is tough. This keeps the arm working well and safely.

Swing Drive and Slewing Ring

The swing drive and slewing ring let the top of the excavator turn all the way around. The swing drive uses a hydraulic motor and gears. This system turns power into torque. It moves the top part around its center. The operator uses joysticks to control the swing drive. They can change speed and direction for smooth turning.

The slewing ring sits at the bottom of the top part. It holds heavy loads and lets the excavator turn without moving the tracks. The slewing ring’s design cuts down on friction and wear. This makes turning smooth and easy. It has holes for mounting, places for grease, and seals for easy care.

The slewing ring handles big loads and keeps the excavator steady.

It lets the top part turn freely, making the machine easy to move.

The small design fits in tight spots and keeps weight balanced.

The slewing ring is strong and simple to care for, even in tough places.

The swing drive and slewing ring let the excavator swing the house and tools in any direction. This helps the operator dig, load, and dump faster and easier.

Knowing how each excavator part works helps people keep machines safe. It also helps them work better. Training and checking the machine every day help find problems early. They can see leaks, worn pins, or loose tracks before they get worse.

Operators who know about the hydraulic system, undercarriage, and controls make fewer mistakes. They do not forget to check for leaks or add grease.

Reading the Operation and Maintenance Manual and using the right tools helps the machine last longer. It also stops big repairs from costing a lot.

A team that learns and checks the machine often keeps downtime short. This makes sure every job goes well.

FAQ

What does the hydraulic system do in an excavator?

The hydraulic system helps move the boom, stick, and bucket. It uses fluid under pressure to make strong force. This lets the operator dig, lift, and move heavy things easily.

How often should operators check the pins and linkages?

Operators need to check pins and linkages every day before work. Greasing these parts often stops them from wearing out. Regular checks help keep the arm safe and working right.

Why is the counterweight important?

The counterweight helps keep the excavator balanced. It stops the machine from tipping when lifting heavy things. A good counterweight helps the operator stay safe.

Can operators change the bucket on an excavator?

Yes! Operators can change buckets to fit the job. Different buckets help with digging, grading, or trenching. Quick couplers let you switch buckets fast and easily.