You should know the excavator body parts name to keep your machine running smoothly and reduce breakdowns. Understanding each excavator body parts name helps you identify issues early on. Training teaches you how to perform daily maintenance and care. It also helps prevent your machine from being out of service. Proper training keeps your excavator operating efficiently and gives you the skills to work more effectively. Knowing the excavator body parts name allows you to spot worn components before they cause problems. Training helps you plan maintenance to extend your machine’s lifespan, minimize downtime, and keep your excavator working at its best. With this knowledge, you gain the confidence to troubleshoot and maintain your machine successfully.

Key Takeaways

Know the names and jobs of main excavator parts. This helps you find problems early and take care of your machine with confidence.

Use a checklist to look over your excavator every day. Check for leaks, broken parts, and safety problems before you start work.

Clean your excavator often and add oil to moving parts. This stops damage and helps everything work well.

Look at fluids and filters a lot, and change old parts fast. This stops big problems and helps your machine last longer.

Write down all the work you do on your excavator and follow a set plan. This helps you fix things on time, have less waiting, and keep your machine safe.

Excavator Body Parts Name

When you know the excavator body parts name, you understand how the machine works. The main parts are the cab, boom, arm, bucket, engine, hydraulic system, undercarriage, and counterweight. You can split the machine into three big sections: the undercarriage, the cab, and the arm/boom assembly. Knowing these parts helps you check and fix your excavator with confidence.

Cab and Controls

The cab is where you sit to use the excavator. All the controls and safety features are inside the cab. New cabs are made for comfort and safety.

Tip: Always look for safety features in the cab before you start.

Some features you find in the cab and controls are:

Seat belts to keep you safe.

Backup alarms and systems to stop accidents.

Safety glass and guards to protect you.

Good visibility and comfy design to help you work longer.

Emergency stop switches you can reach fast.

Walkways that do not slip and ladders that are safe.

New technology like GPS, monitors, and controls you can change.

Seats that heat up or cool down.

Touchscreen monitors and joystick buttons you can set.

More than one emergency exit and switches to lock the battery.

These features help you stay safe and comfortable when you use the excavator. The cab lets you see the boom, arm, and bucket clearly, so you can work better.

Boom, Arm, and Bucket

The boom, arm, and bucket are the parts that do the digging. You use them to dig, lift, and move things. The boom is attached to the top part and gives lifting power. The arm is connected to the boom and helps you reach farther. The bucket is at the end of the arm and does the digging.

The bucket is made from strong materials to last in tough places. Its design makes it strong and easy to fix if the edge wears out. You can pick different ground engaging tools (GET) to make the bucket last longer and easier to care for. The bucket’s weight and balance help the boom and arm last longer.

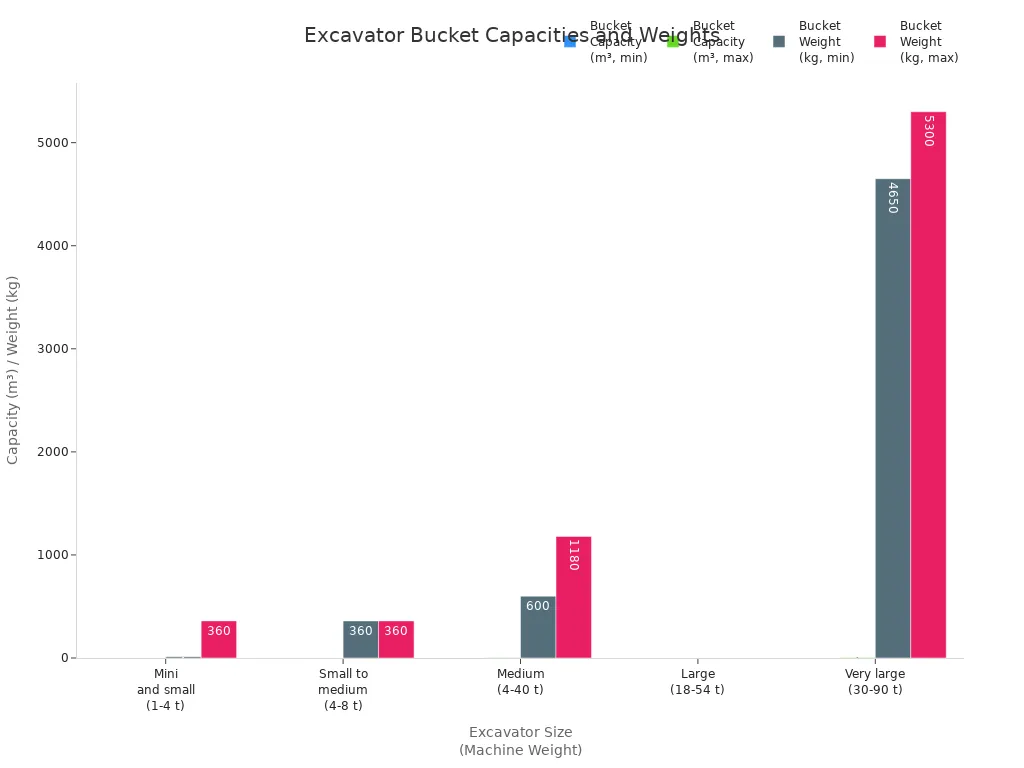

Excavator Size (Machine Weight) | Bucket Capacity (m³ or liters) | Bucket Weight (kg) |

|---|---|---|

Mini and small excavators (approx. 1 t to 4 t) | 0.05 m³ to 0.4 m³ (50 to 400 liters) | 13 kg to 360 kg |

Small to medium excavators (4 t to 8 t) | Around 0.2 m³ | 360 kg |

Medium excavators (4 t to 40 t) | 0.3 m³ to 1.5 m³ (300 to 1500 liters) | 600 kg to 1180 kg |

Large excavators (18 t to 54 t) | 0.5 m³ to 1.2 m³ | Not specified |

Very large excavators (30 t to 90 t) | 1 m³ to 5 m³ (up to 5000 liters) | 4650 kg to 5300 kg |

You need to pick the right bucket size and weight for your excavator. The boom and arm must be strong enough for the bucket. Check the boom, arm, and bucket often to find cracks or worn edges early.

Engine and Hydraulic System

The engine gives power to the excavator and runs the hydraulic system. Most excavators use diesel engines that control pollution. The engine is in the back, covered by panels. The engine’s health is important, so check for leaks, strange sounds, or warning lights.

Manufacturer | Engine Model | Engine Type | Cylinders | Displacement | Emission Standard |

|---|---|---|---|---|---|

Volvo | ISUZU 6HK1 | 4-stroke, turbocharged diesel with intercooler, water-cooled | 6 | 7.79 L | EU Stage V |

Manufacturer | Engine Model | Power Output | Displacement | Fuel Compatibility | Emission Standards | Hydraulic System Features |

|---|---|---|---|---|---|---|

Caterpillar | Cat C7.1 TTA | ~223-306 hp | 7.01 L | Biodiesel up to B20, renewable fuels | EPA Tier 4 Final, EU Stage V, Japan 2014 | Pressure-compensated proportional priority (PPPC), Load anticipation enhanced control (LEAC), Engine torque load control (ETLC) |

The hydraulic system uses fluid under pressure to move the boom, arm, and bucket. You use joysticks in the cab to control these parts. If there are hydraulic problems, the arm may not lift as much, or you might see leaks or slow movement. To stop problems, you should:

Look at hoses and connections for leaks.

Change oil filters when needed.

Keep hydraulic fluid clean and filled.

Watch the fluid temperature so it does not get too hot.

Change seals and gaskets if they wear out.

Taking care of the engine and hydraulic system keeps your excavator working well.

Undercarriage and Excavator Tracks

The undercarriage holds up the excavator and lets it move. There are two types: tracked and wheeled. Tracked excavators use chains for good grip and balance on rough ground. Wheeled excavators move faster and work best on hard surfaces.

Tracked undercarriages spread the weight, so the ride is smoother and more comfortable. The tracks are made from strong steel. The undercarriage has rollers, guide wheels, and a drive sprocket to move the tracks.

Signs of wear in the undercarriage and tracks are:

Tracks wearing unevenly.

Rollers and guide wheels getting worn.

Loose parts.

Cracks or bent pieces.

Mud and dirt making extra friction.

Note: Clean and check the undercarriage often to stop big repairs and save time.

If you see the tracks getting loose, cracks, or slipping, fix these problems right away. Keeping the undercarriage in good shape helps your excavator last longer.

Counterweight and Superstructure

The counterweight is at the back of the superstructure. It balances the boom, arm, and bucket when you work. For example, a wheel excavator’s counterweight can weigh about 3,500 kg. The superstructure holds the engine, hydraulic system, and cab. It turns on the undercarriage, so you can swing the boom and arm any way you want.

Check the counterweight to make sure it is tight and not damaged. The superstructure should turn smoothly and not leak or make strange noises. Keeping these parts in good shape keeps your excavator safe and working well.

When you learn the excavator body parts name and what they do, you can keep your machine safe and working right. Checking and caring for the boom, arm, bucket, engine, hydraulic system, undercarriage, and counterweight helps you stop breakdowns and make your equipment last longer.

Parts of an Excavator: Visual Inspection

What to Check Daily

You need to follow daily inspection protocols to keep your excavator safe and ready for work. Start your day by walking around the machine. Look for leaks, loose bolts, or anything that seems out of place. Use a checklist to make sure you do not miss any steps.

Here is a simple daily inspection checklist:

Check fluid levels (engine oil, hydraulic fluid, coolant, fuel).

Look for leaks under the excavator.

Inspect the tracks or tires for damage.

Make sure all lights and alarms work.

Test the horn and backup alarm.

Check the cab for clean windows and working seat belts.

Inspect the boom, arm, and bucket for cracks or dents.

Make sure all safety devices are in place.

Confirm that all attachments are secure.

Tip: Good training helps you spot problems early. Always follow daily inspection protocols before you start the engine.

Signs of Wear or Damage

During each inspection, you must look for signs of wear or damage. You might see worn bucket teeth, cracked hoses, or loose bolts. If you find any of these, you need to fix them right away.

Common signs to watch for include:

Oil or hydraulic fluid leaks.

Worn or missing bucket teeth.

Cracks in the boom, arm, or undercarriage.

Loose or missing bolts.

Damaged tracks or tires.

Unusual noises during operation.

Proper training teaches you how to spot these issues. You should also check all safety devices and attachments. Attachment maintenance is important for safe operation. If you see a problem during your inspection, report it and do not use the excavator until it is fixed.

Remember, regular inspection and good training keep your excavator running longer and safer.

Excavator Maintenance Essentials

Cleaning and Lubrication

It is important to keep your excavator clean. This helps it work well and stops breakdowns. Dirt and mud can build up on moving parts. This makes them wear out faster. Clean the machine every day to find leaks or damage early. Use a pressure washer or brush to get mud off the undercarriage and tracks. Pay close attention to the bucket, rollers, and joints.

Lubrication is just as important as cleaning. Moving parts like pins, bushings, and rollers need grease. Grease helps them move smoothly. If you do not use grease, parts will wear out quickly. You will need more repairs. Always follow the manufacturer’s schedule for lubrication. Use good lubricants that fit your excavator. Check oil and grease levels often. Add more if they are low.

Tip: Clean and grease all moving parts often. This easy habit helps your excavator last longer and work better.

Fluid and Filter Checks

Fluids and filters are very important for excavator care. You must check engine oil, hydraulic fluid, coolant, and fuel every day. If fluids are low or dirty, the machine will not work well. It could even break down. Change fluids when the manufacturer says to. Clean hydraulic fluid and filtered oil are needed for hard jobs.

Filters keep dirt out of the engine and hydraulic system. Check filters every 250 hours. Replace them every 500 hours or as the manual says. Use filters that fit your excavator. Here are the main filters you should check:

Oil filter: Takes dirt out of engine oil.

Air filter: Stops dust from getting in the engine.

Fuel filter: Keeps bad stuff out of the engine.

Hydraulic filter: Protects the hydraulic system.

Cabin air filter: Keeps the air clean for the operator.

High-pressure and low-pressure oil filters: Used in different excavators.

Magnetic and cartridge oil filters: Give extra protection and are easy to change.

Note: Always use the right filters and fluids for your excavator’s brand and model. This keeps your warranty safe and helps your machine work its best.

Track and Undercarriage Care

Taking care of the tracks and undercarriage is very important. The undercarriage holds up the whole machine and lets it move. Check track tension often. If tracks are too loose or tight, they will wear out fast. Adjust the tension to match what the manufacturer says.

Clean the tracks every day. Take off mud, rocks, and debris that can cause extra wear. Grease the rollers and moving parts to help them work well. Try not to make sharp turns on hard ground. This can hurt the tracks and undercarriage.

Here are some tips for undercarriage care:

Look for cracks, loose bolts, or worn parts.

Use the right grease for heavy machines.

Change worn rollers, sprockets, and track pads when needed.

Use strong replacement parts to make them last longer.

Callout: Good undercarriage care stops big repairs and helps your excavator last longer.

When to Repair or Replace

You need to know when to fix or change parts. This helps you avoid surprise breakdowns. Some parts wear out faster than others. Bucket teeth, hoses, filters, and seals need to be checked often. If you see cracks, leaks, or worn edges, act fast. Change broken parts before they stop working.

Here is a list of parts that need regular checks:

Part | Check Frequency | Signs You Need Repair or Replacement |

|---|---|---|

Bucket teeth | Daily | Worn, broken, or missing teeth |

Hydraulic hoses | Weekly | Cracks, leaks, or bulges |

Filters | 250-500 hours | Clogged, dirty, or damaged |

Undercarriage parts | Weekly | Excessive wear, cracks, or loose bolts |

Engine belts | Monthly | Fraying, cracks, or slipping |

Seals and gaskets | Monthly | Leaks or visible damage |

If you see any of these problems, fix them right away. Do not wait for a breakdown. Acting fast saves money and keeps your excavator working well.

Reminder: Doing regular care and quick repairs helps you avoid long downtime and keeps your excavator safe.

Daily, Monthly, and Quarterly Maintenance Tasks

You should follow a schedule to keep your excavator in good shape. Here is a simple guide:

Daily: Clean the machine, add fuel, grease moving parts, and fix urgent problems.

Monthly and Quarterly: Check the excavator, make small fixes, and look for issues.

Higher-level maintenance: Plan for big repairs, major part changes, and overhauls with skilled workers.

Following this schedule helps you find problems early. Your excavator will work better, break down less, and last longer.

Attachment maintenance is also important. Check all attachments for wear and damage before you use them.

Keep up with excavator care to protect your investment, work better, and avoid expensive downtime.

Maintenance Schedule and Records

Creating a Maintenance Plan

You need a good plan to keep your excavator working well. Start by making clear goals for your maintenance. You might want your machine to work more or break down less. Look at your old repair records to see what broke before. This helps you find problems and plan better.

Here are steps to make your plan:

Write down all your excavators and keep a record for each.

Make a budget for maintenance. Experts say spend most of your money on preventing problems, not just fixing them.

Use your manuals to know when to do maintenance and how to stay safe.

Give jobs to trained workers. Keep track of what they do and how much it costs.

Pick the type of schedule that works for you. You can use time or how much the machine is used.

Try digital tools like ERP software to track jobs, costs, and parts. These tools help you stay organized and use less paper.

Plan regular checks and set reminders for future tasks.

Check your plan often and change it if you need to do better.

A strong plan helps you stop surprise breakdowns and keeps your excavator running well. Digital tools make it easy to manage your work and keep your records up to date.

Tracking Inspections and Repairs

You must keep track of every check and repair to keep your excavator in good shape. Use checklists for daily, weekly, and monthly checks. Write down what you see and what you fix. This helps you find problems early and fix them before they get worse.

Try using a logbook or a digital app. These tools let you write down every job, check, and repair. You can see when you last checked the undercarriage or changed a filter. This helps you follow a good plan and keep your maintenance on time.

Tip: Keep all your records in one place. This makes it easy to look back at your history and show you did the right things if you need to.

Keeping good records helps your excavator work better, break down less, and last longer. When you track your work, you make better choices and keep your machine running strong.

If you know the name of each excavator body part, you can keep your machine safe and working right. Check your machine often and fix any problems as soon as you find them. Doing this helps you stay safe and makes your machine last longer.

For the best help, use pictures, serial numbers, or talk to a professional if you are not sure about a part’s name.

Always check your machine before using it.

Write down what you find and fix.

Get help from an expert if you need it.

FAQ

What are the most important excavator parts to check every day?

You should check the boom, arm, bucket, tracks, and hydraulic hoses every day. Look for leaks, cracks, or loose bolts. Make sure all safety devices work.

Tip: Use a checklist to help you remember each step.

How do you know when to replace bucket teeth?

You need to replace bucket teeth when you see them worn down, cracked, or missing. Worn teeth make digging harder and can damage the bucket.

Always check the teeth before you start work.

Can you use any type of oil or filter in your excavator?

No, you must use the oil and filters listed in your excavator’s manual. Using the wrong type can damage the engine or hydraulic system.

Note: The right parts help your machine last longer.

Why does track tension matter on an excavator?

Track tension keeps your excavator moving smoothly. If tracks are too loose, they can slip off. If too tight, they wear out fast.

Check tension often.

Adjust as needed for safe operation.

How often should you clean your excavator?

You should clean your excavator every day after use. Dirt and mud can hide damage and cause parts to wear out faster.

Clean machines last longer and work better.