Choosing the right rod seals for excavator parts plays a vital role in maintaining the efficiency of your hydraulic system. These seals prevent fluid leaks and ensure smooth operation, even under harsh conditions. Poor-quality seals can lead to friction-related issues, causing leaks and costly downtime. YNF Machinery offers high-quality hydraulic cylinder oil seals designed to meet OEM standards. These seals provide durability, precision, and long-lasting performance, protecting your excavator’s critical components from leaks and contamination. With YNF Machinery, you can enhance your equipment’s reliability and reduce maintenance costs.

Key Takeaways

Choosing high-quality rod seals is crucial for preventing hydraulic fluid leaks and ensuring the efficient operation of excavators.

Different types of rod seals, such as single-acting and double-acting, cater to specific hydraulic system needs; selecting the right type enhances performance. Materials like polyurethane and PTFE offer durability and resistance to harsh conditions, making them ideal for excavator applications.

Regular inspections and timely replacement of worn seals can prevent costly repairs and extend the lifespan of your hydraulic system.

Investing in YNF Machinery’s hydraulic seal kits ensures compatibility, reliability, and ease of installation, reducing maintenance downtime.

Understanding the environmental challenges your excavator faces helps in selecting seals that protect against dust, water, and extreme temperatures.

Understanding Rod Seals for Excavator Parts

What Are Rod Seals and Their Function in Hydraulic Systems?

Rod seals are essential components in hydraulic systems. They create a barrier that prevents hydraulic fluid from leaking out of the cylinder while allowing the piston rod to move smoothly. This sealing action ensures that the hydraulic pressure remains consistent, which is vital for the system’s performance. Without proper rod seals, fluid leakage can occur, leading to reduced efficiency and potential damage to the equipment.

In excavators, rod seals play a critical role in maintaining the functionality of hydraulic cylinders. These cylinders power various movements, such as lifting, digging, and rotating. By preventing fluid leaks, rod seals help maintain the hydraulic pressure needed for these operations. Additionally, they keep contaminants like dust and debris from entering the system, which could otherwise cause wear and tear on internal components.

Modern advancements in rod seal design have further enhanced their performance. Manufacturers now use durable materials like polyurethane and rubber to improve resistance to wear and extreme conditions. These innovations ensure that rod seals can withstand the high pressures and temperatures often encountered in excavator applications.

Why Rod Seals Are Critical for Excavator Performance

Rod seals directly impact the efficiency and reliability of excavators. They prevent hydraulic fluid from escaping, which is crucial for maintaining the power needed to operate heavy machinery. A well-functioning rod seal ensures that your excavator performs at its best, even under demanding conditions.

When rod seals fail, the consequences can be severe. Fluid leaks not only reduce hydraulic pressure but also increase the risk of contamination. Contaminants entering the system can damage sensitive components, leading to costly repairs and downtime. Moreover, a loss of hydraulic pressure can result in sluggish or incomplete movements, affecting the excavator’s overall productivity.

High-quality rod seals for excavator parts are designed to handle these challenges. They provide a tight seal that minimizes friction and wear, extending the lifespan of the hydraulic system. By investing in reliable rod seals, you can enhance your excavator’s performance and reduce maintenance costs.

“Rod seals are the unsung heroes of hydraulic systems, ensuring smooth operation and preventing costly failures.”

Types of Rod Seals for Excavator Parts

Choosing the right type of rod seal is essential for maintaining the efficiency and reliability of your excavator’s hydraulic system. Each type of seal serves a specific purpose, ensuring optimal performance under various operating conditions. Below, you will find an overview of the most common types of rod seals for excavator parts.

Single-Acting Rod Seals

Single-acting rod seals are designed to seal in one direction. These seals are ideal for applications where hydraulic pressure acts from only one side of the cylinder. By creating a tight barrier, they prevent fluid from escaping while allowing the piston rod to move smoothly.

These seals are commonly used in excavators that operate under consistent pressure conditions. Their simple design makes them highly durable and easy to maintain. Materials like polyurethane are often used in single-acting seals due to their excellent wear resistance and ability to withstand high pressures. If your excavator requires a straightforward sealing solution, single-acting rod seals provide an effective and reliable option.

Double-Acting Rod Seals

Double-acting rod seals are engineered to seal in both directions. This makes them suitable for hydraulic systems where pressure is applied alternately on either side of the piston. These seals ensure that hydraulic fluid remains contained, regardless of the direction of force.

Excavators with complex hydraulic systems often rely on double-acting seals for their versatility. These seals are crafted from materials like nitrile rubber or Viton, which offer flexibility and chemical resistance. By choosing double-acting rod seals, you can enhance the performance of your excavator in demanding environments. Their ability to handle fluctuating pressures ensures consistent operation and reduces the risk of leaks.

Specialty Rod Seals for Unique Hydraulic Applications

Specialty rod seals are designed for unique hydraulic applications that require advanced sealing solutions. These seals are tailored to meet specific operational needs, such as extreme temperatures, high-speed movements, or exposure to abrasive contaminants.

For example, some specialty seals incorporate PTFE for high-temperature resistance or advanced elastomers for superior flexibility. These seals are often used in excavators operating in harsh environments, such as mining or heavy construction. By investing in specialty rod seals, you can address unique challenges and extend the lifespan of your hydraulic cylinder components.

“The right rod seal type ensures your excavator operates efficiently, even in the most demanding conditions.”

Material Considerations for Hydraulic Rod Seals

Common Materials Used in Rod Seals

Selecting the right material for rod seals is crucial for ensuring optimal performance in your excavator’s hydraulic system. Each material offers unique properties that cater to specific operational needs. Below are the most commonly used materials and their benefits:

Polyurethane for Durability

Polyurethane stands out for its exceptional wear resistance and mechanical strength. This material performs well in high-pressure environments, making it ideal for heavy-duty applications like excavators. Its ability to resist abrasion ensures a tight seal, even under harsh conditions. Polyurethane seals also maintain their integrity when exposed to hydraulic fluids, providing long-lasting performance in demanding scenarios.

Rubber (Nitrile, Viton, etc.) for Flexibility

Rubber seals, including those made from nitrile and Viton, offer excellent flexibility and resilience. These seals adapt to varying pressures and temperatures, ensuring reliable performance across different conditions. Rubber materials also resist many chemicals, making them suitable for hydraulic systems that use diverse fluids. Their long service life and adaptability make them a popular choice for excavator applications.

PTFE for High-Temperature Resistance

PTFE excels in environments where high temperatures and chemical exposure are common. This material provides the highest chemical resistance among seal options and features a low coefficient of friction. PTFE seals reduce wear on moving parts, ensuring smooth operation and extending the lifespan of hydraulic components. Their non-stick properties make them particularly effective in preventing contamination buildup.

“Choosing the right material for your rod seals ensures durability, efficiency, and reduced maintenance costs.”

Matching Material to Excavator Hydraulic System Requirements

Your excavator’s hydraulic system has specific requirements that dictate the best material for rod seals. Consider factors like operating pressure, temperature, and the type of hydraulic fluid used. For high-pressure systems, polyurethane seals provide unmatched durability. If your excavator operates in chemically aggressive environments, PTFE seals offer superior resistance. Rubber seals work well in systems requiring flexibility and adaptability to fluctuating conditions.

Matching the material to your system’s needs ensures optimal performance and minimizes the risk of leaks or failures. Always evaluate the working environment and operational demands before selecting a seal material.

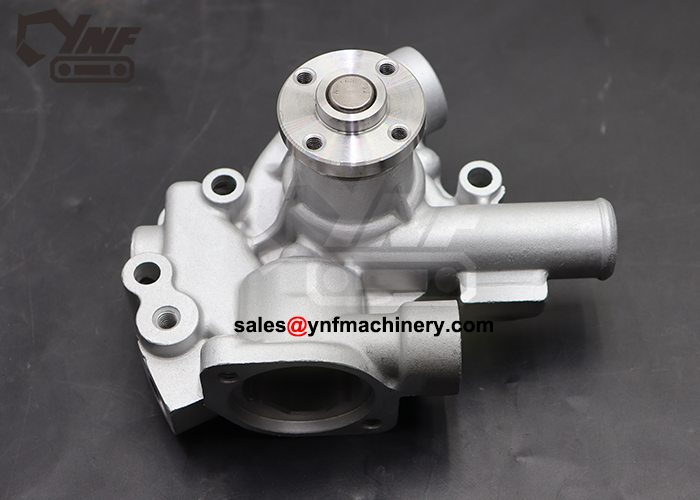

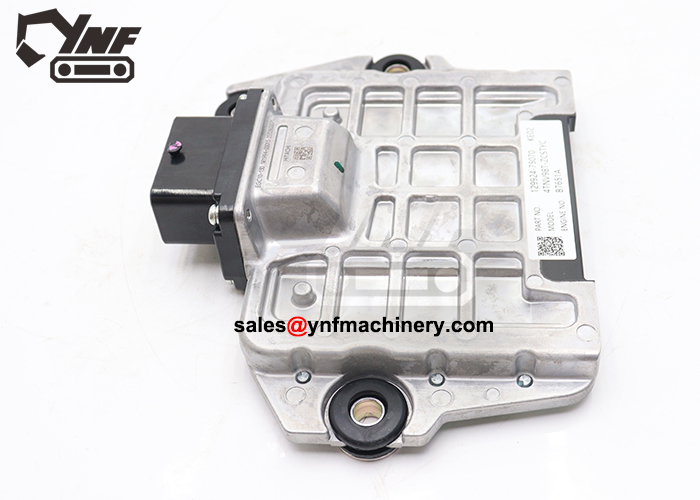

Advantages of YNF Machinery’s Hydraulic Oil Seals

YNF Machinery’s hydraulic oil seals deliver exceptional quality and reliability. These seals are crafted from premium materials like polyurethane, rubber, and PTFE, ensuring they meet the diverse needs of excavator hydraulic systems. Their design focuses on durability, providing long-lasting performance even in challenging conditions. YNF’s seals resist wear, maintain a tight seal, and prevent contamination, safeguarding your equipment’s efficiency.

By choosing YNF Machinery’s hydraulic oil seals, you gain access to products that enhance your excavator’s reliability. These seals reduce maintenance costs and downtime, allowing you to focus on maximizing productivity. With YNF’s commitment to quality, you can trust their seals to protect your hydraulic system and extend its lifespan.

“Investing in high-quality seals from YNF Machinery ensures your excavator operates at peak efficiency, saving you time and money.”

Key Factors for Selecting the Best Rod Seals for Excavator Parts

Pressure and Temperature Ratings

When selecting rod seals for excavator parts, you must evaluate their ability to handle pressure and temperature variations. Excavators operate under demanding conditions, often requiring seals that can withstand high pressure without compromising performance. High-pressure oil seals are specifically designed to maintain a tight seal even in extreme hydraulic environments. These seals prevent fluid leaks and ensure consistent operation.

Temperature fluctuations also play a significant role in seal performance. Hydraulic systems in excavators generate heat during operation, and external environmental conditions can further impact temperature levels. A high-quality seal must resist both high and low temperatures to maintain its integrity. Materials like polyurethane and PTFE excel in these conditions, offering durability and reliability. Always check the pressure and temperature ratings of the seal to ensure it matches your excavator’s operating requirements.

“Choosing seals with the right pressure and temperature ratings ensures your hydraulic system operates efficiently and avoids costly failures.”

Compatibility with Hydraulic Fluids

The compatibility of rod seals with hydraulic fluids is another critical factor. Hydraulic systems use various types of fluids, including mineral oils, synthetic oils, and water-based solutions. Each fluid has unique chemical properties that can affect the seal material. For instance, some fluids may cause swelling or degradation in certain materials, leading to premature failure.

High-pressure oil seals crafted from materials like nitrile rubber or Viton offer excellent compatibility with a wide range of hydraulic fluids. These materials resist chemical reactions, ensuring the seal remains effective over time. Before making a selection, confirm that the seal material aligns with the type of hydraulic fluid used in your excavator. This step minimizes the risk of leaks and extends the lifespan of your hydraulic cylinder components.

“Ensuring compatibility between seals and hydraulic fluids protects your system from damage and enhances its longevity.”

Environmental Considerations (e.g., Dust, Water, Extreme Temperatures)

Excavators often operate in harsh environments filled with dust, water, and extreme temperatures. These conditions can challenge the performance of rod seals. Dust and debris can enter the hydraulic system if the seal fails, causing wear and contamination. Similarly, exposure to water can lead to corrosion and fluid dilution, reducing the efficiency of the hydraulic system.

High-pressure oil seals designed for rugged environments provide a reliable solution. These seals feature advanced designs that block contaminants and resist water intrusion. Materials like polyurethane offer excellent abrasion resistance, making them ideal for dusty or abrasive conditions. For extreme temperatures, PTFE seals provide superior performance, maintaining their properties even in freezing or scorching environments.

By considering environmental factors, you can select seals that protect your hydraulic systems from external threats. This proactive approach ensures smooth operation and reduces maintenance costs.

“Environmental challenges demand robust seals that safeguard your excavator’s hydraulic system from external damage.”

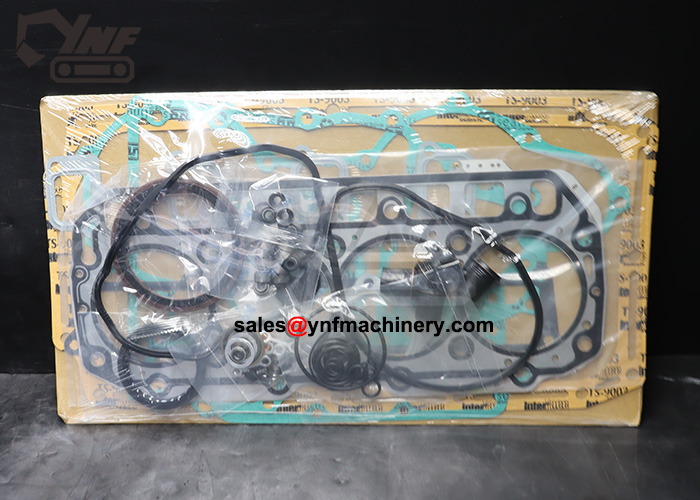

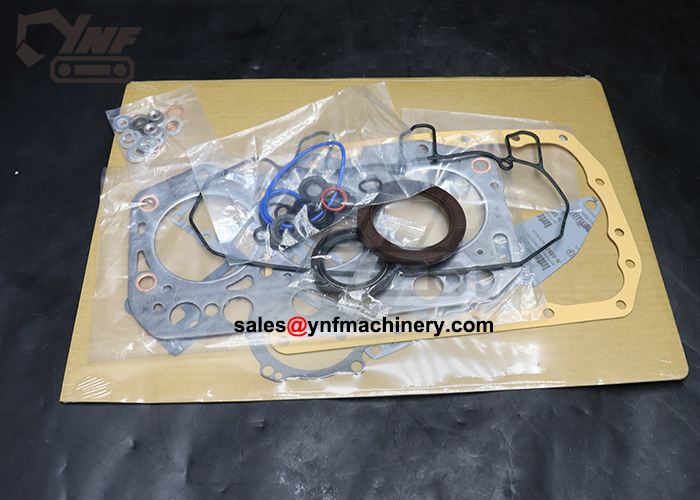

How YNF Machinery’s Cylinder Seal Kits Meet These Requirements

YNF Machinery’s cylinder seal kits provide a comprehensive solution for maintaining the efficiency and reliability of your excavator’s hydraulic system. These seal kits are meticulously designed to meet the demanding requirements of modern excavators, ensuring optimal performance under various operating conditions.

1. Precision Engineering for High Pressure and Temperature

YNF Machinery manufactures cylinder seal kits with materials that excel in high-pressure environments. The kits include seals made from durable materials like polyurethane, nitrile rubber, and PTFE. These materials withstand extreme hydraulic pressures without compromising their sealing capabilities. They also resist temperature fluctuations, ensuring consistent performance in both hot and cold conditions. This precision engineering guarantees that your excavator operates smoothly, even in the most challenging scenarios.

2. Compatibility with Diverse Hydraulic Fluids

The seal kits from YNF Machinery are compatible with a wide range of hydraulic fluids, including mineral oils, synthetic oils, and water-based solutions. This compatibility ensures that the seals maintain their integrity and effectiveness, regardless of the fluid type used in your excavator. By choosing YNF Machinery’s cylinder seal kits, you eliminate the risk of chemical reactions that could degrade the seals and lead to leaks or failures.

3. Protection Against Environmental Challenges

Excavators often work in harsh environments filled with dust, water, and abrasive particles. YNF Machinery’s seal kits are designed to protect your hydraulic system from these external threats. The seals create a robust barrier that prevents contaminants from entering the system. This protection reduces wear and tear on internal components, extending the lifespan of your hydraulic cylinders. Whether your excavator operates in muddy construction sites or dusty mining areas, these seal kits ensure reliable performance.

4. Easy Installation and Maintenance

YNF Machinery’s cylinder seal kits are crafted for easy installation. The precise dimensions and high-quality materials ensure a perfect fit, reducing the time and effort required for replacement. This ease of installation minimizes downtime, allowing you to get your excavator back to work quickly. Additionally, the durability of these seal kits reduces the frequency of maintenance, saving you time and resources in the long run.

5. Proven Reliability and Longevity

Every cylinder seal kit from YNF Machinery undergoes rigorous quality checks to meet international standards. These tests ensure that the kits deliver consistent performance and long-lasting reliability. By investing in these seal kits, you enhance the efficiency of your excavator while reducing the risk of unexpected failures. This reliability translates to lower maintenance costs and increased productivity for your operations.

“YNF Machinery’s cylinder seal kits are engineered to tackle the toughest challenges, ensuring your excavator performs at its peak.”

By selecting YNF Machinery’s cylinder seal kits, you gain access to a trusted solution that addresses all critical factors for hydraulic system performance. These kits combine durability, compatibility, and ease of use, making them an essential choice for excavator maintenance.

Installation and Maintenance Tips for Hydraulic Rod Seals

Proper installation and regular maintenance of hydraulic rod seals are essential to ensure the efficiency and longevity of your excavator’s hydraulic system. Following best practices can help you avoid common issues, reduce downtime, and extend the lifespan of your equipment.

Steps for Proper Installation of Rod Seals

Installing rod seals correctly is crucial for maintaining a leak-free hydraulic system. Follow these steps to ensure a successful installation:

Prepare the Work Area

Clean the workspace thoroughly to prevent dust or debris from contaminating the seals. Contaminants can compromise the seal’s performance and lead to premature wear.Inspect the Components

Examine the cylinder and rod for any signs of damage, such as scratches or dents. Damaged components can cause the seal to fail, so repair or replace them before proceeding.Lubricate the Seal

Apply a thin layer of compatible hydraulic fluid to the seal. Lubrication reduces friction during installation and ensures a proper fit.Use the Right Tools

Utilize specialized tools designed for seal installation. These tools help you avoid stretching or damaging the seal during the process.Install the Seal Carefully

Position the seal in its designated groove, ensuring it sits evenly without twisting. A misaligned seal can lead to leaks and reduced efficiency.Reassemble the Cylinder

Once the seal is in place, reassemble the hydraulic cylinder. Tighten all components securely to maintain system integrity.

“A precise installation process ensures your rod seals perform effectively, safeguarding your hydraulic system from leaks.”

Common Installation Mistakes to Avoid

Avoiding mistakes during installation can save you time and prevent costly repairs. Here are some common errors to watch out for:

Skipping Component Inspection

Failing to inspect the cylinder and rod for damage can lead to seal failure. Always check for imperfections before installation.Using Improper Tools

Using makeshift tools can damage the seal or cause improper alignment. Invest in the right tools for the job.Overlooking Lubrication

Installing a dry seal increases friction, which can result in tears or deformation. Always lubricate the seal before installation.Forcing the Seal into Place

Forcing the seal can stretch or damage it, compromising its effectiveness. Handle the seal gently and ensure it fits naturally.

By avoiding these mistakes, you can ensure a smooth installation process and enhance the performance of your hydraulic system.

Maintenance Practices to Extend Seal Life

Regular maintenance is key to extending the life of your hydraulic rod seals and ensuring optimal system performance. Implement these practices to keep your seals in top condition:

Perform Regular Inspections

Check the seals periodically for signs of wear, such as cracks, tears, or deformation. Early detection of issues allows you to address them before they escalate.Clean the Hydraulic System

Keep the system free of contaminants like dirt and debris. Contaminants can cause abrasion and reduce the seal’s effectiveness.Monitor Hydraulic Fluid Levels

Maintain proper fluid levels to prevent excessive pressure on the seals. Low fluid levels can lead to overheating and increased wear.Replace Worn Seals Promptly

Replace seals at the first sign of damage or wear. Delaying replacement can result in leaks and further damage to the hydraulic system.Use Quality Seal Kits

Invest in high-quality seal kits, such as those offered by YNF Machinery. These kits provide reliable performance and are designed to withstand harsh conditions.

“Regular maintenance not only extends the life of your seals but also enhances the overall efficiency of your hydraulic system.”

By following these installation and maintenance tips, you can maximize the performance and durability of your hydraulic rod seals. Proper care ensures your excavator operates efficiently, reducing downtime and maintenance costs.

Signs of Wear and When to Replace Rod Seals

Recognizing the signs of wear in rod seals is essential for maintaining the efficiency of your excavator’s hydraulic system. Worn seals can lead to fluid leaks, reduced performance, and costly repairs. By identifying these signs early, you can take timely action and avoid further damage to your equipment.

Common Signs of Wear in Rod Seals

Hydraulic Fluid Leaks

One of the most noticeable signs of worn rod seals is fluid leakage around the cylinder. If you observe oil pooling near the rod or dripping from the cylinder, it indicates that the seal has lost its ability to maintain a tight barrier.Reduced Hydraulic Pressure

A drop in hydraulic pressure often points to a failing seal. When the seal wears out, it allows fluid to escape, reducing the pressure needed for efficient operation. This can result in sluggish or incomplete movements of the excavator.Contamination in the Hydraulic System

Worn seals may allow dust, dirt, or water to enter the hydraulic system. Contaminants can cause abrasion and damage to internal components, leading to decreased performance and increased maintenance needs.Visible Damage to the Seal

Inspect the rod seals for cracks, tears, or deformation. Physical damage to the seal compromises its ability to function effectively, making replacement necessary.Unusual Noises or Vibrations

If you notice unusual noises or vibrations during operation, it could be due to a damaged seal. These issues often arise when the seal fails to provide proper lubrication or alignment.

“Ignoring the early signs of wear can lead to severe damage and costly downtime. Regular inspections are key to preventing these issues.”

When to Replace Rod Seals

Timely replacement of rod seals is crucial for maintaining the performance and longevity of your excavator. Here are some scenarios where replacement becomes necessary:

Frequent Fluid Leaks

Persistent leaks indicate that the seal has reached the end of its lifespan. Immediate replacement prevents further loss of hydraulic fluid and protects the system from contamination.Scheduled Maintenance

Incorporate seal replacement into your regular maintenance schedule. Proactive replacement ensures that your hydraulic system operates efficiently and reduces the risk of unexpected failures.After Detecting Wear or Damage

Replace the seal as soon as you identify visible wear or damage. Delaying the seal replacement process can lead to more extensive repairs and higher costs.Performance Decline

If your excavator shows signs of reduced performance, such as slower movements or inconsistent pressure, inspect the seals. Replacing worn seals restores the system’s efficiency and reliability.

Benefits of Timely Replacement

Replacing worn rod seals offers several advantages. It prevents hydraulic fluid leaks, ensuring consistent pressure and smooth operation. Properly functioning seals also block contaminants, protecting internal components from damage. Additionally, timely replacement reduces downtime and maintenance costs, allowing you to maximize productivity.

Using high-quality seal kits, such as those from YNF Machinery, simplifies the replacement process. These kits include durable seals designed to withstand harsh conditions, ensuring long-lasting performance. Regular maintenance with reliable seal kits enhances the overall functionality of your excavator and safeguards your investment.

“Investing in timely seal replacement not only extends the life of your hydraulic system but also boosts the efficiency of your machinery.”

Common Issues and Troubleshooting for Rod Seals

Identifying Common Problems (e.g., Leaks, Wear, Contamination)

Rod seals in hydraulic systems often face challenges that can compromise their performance. Identifying these issues early helps you maintain the efficiency of your excavator and avoid costly repairs. Below are some common problems you may encounter:

Leaks: Hydraulic fluid leaks are one of the most noticeable issues. A damaged or worn rod seal can fail to maintain a proper barrier, allowing fluid to escape. This reduces system pressure and affects the performance of your excavator.

Wear: Over time, rod seals experience wear due to friction, high pressure, and exposure to harsh conditions. Signs of wear include cracks, tears, or deformation, which can lead to reduced sealing efficiency.

Contamination: Dust, dirt, and water can infiltrate the hydraulic system when the rod seal fails. Contamination accelerates wear on internal components and reduces the overall lifespan of the system. It also increases the risk of corrosion and operational inefficiencies.

Pro Tip: Regular inspections can help you detect these problems early. Look for visible damage, fluid leaks, or unusual noises during operation.

Causes of Rod Seal Failures in Excavators

Understanding the causes of rod seal failures allows you to take preventive measures and extend the life of your hydraulic system. Here are some common reasons why rod seals fail:

Improper Installation

Incorrect installation techniques can damage the seal or cause misalignment. Using the wrong tools or skipping lubrication during installation increases the risk of failure.Material Incompatibility

Using a rod seal made from materials that are not compatible with the hydraulic fluid or operating environment can lead to swelling, hardening, or degradation.Excessive Pressure or Temperature

Hydraulic systems in excavators operate under high pressure and temperature. If the rod seal is not designed to handle these conditions, it may fail prematurely.Contaminants in the System

Dust, debris, and water entering the hydraulic cylinder can damage the rod seal. Contaminants cause abrasion and reduce the seal’s ability to maintain a tight barrier.Aging and Wear

Over time, even high-quality rod seals degrade due to constant exposure to friction and harsh conditions. Aging seals lose their flexibility and effectiveness, leading to leaks and contamination.

Key Insight: Addressing these causes during maintenance and replacement ensures your rod seals perform reliably and last longer.

Solutions to Address Common Issues with YNF Machinery’s Hydraulic Cylinder Seal Kits

YNF Machinery offers high-quality hydraulic cylinder seal kits designed to tackle common issues and enhance the performance of your excavator. Here’s how these kits provide effective solutions:

Durable Materials for Longevity

YNF Machinery’s seal kits use premium materials like polyurethane, nitrile rubber, and PTFE. These materials resist wear, high pressure, and extreme temperatures, ensuring long-lasting performance.Precision Engineering for a Perfect Fit

Each seal kit is crafted to match the exact specifications of your hydraulic cylinder. This precision reduces the risk of improper installation and ensures a tight seal, preventing leaks and contamination.Enhanced Resistance to Contaminants

The seals in YNF Machinery’s kits create a robust barrier that blocks dust, dirt, and water from entering the system. This protection minimizes wear on internal components and extends the lifespan of your hydraulic system.Compatibility with Hydraulic Fluids

YNF Machinery’s seal kits are compatible with a wide range of hydraulic fluids. This compatibility prevents chemical reactions that could degrade the seal, ensuring reliable performance over time.Ease of Installation and Maintenance

The seal kits are designed for easy installation, reducing downtime and maintenance efforts. With clear instructions and high-quality components, you can replace worn seals quickly and efficiently.

Why Choose YNF Machinery? By investing in YNF Machinery’s hydraulic cylinder seal kits, you gain access to reliable solutions that address common issues and enhance the efficiency of your excavator.

Choosing high-quality rod seals for excavator parts is essential for maintaining hydraulic system efficiency and extending the lifespan of your equipment. Poor-quality seals can lead to leaks, reduced performance, and costly downtime. YNF Machinery’s Hydraulic Oil Seals and Hydraulic Cylinder Seal Kits offer reliable solutions tailored to meet the demands of modern excavators. By prioritizing quality, compatibility, and regular maintenance, you ensure your equipment maintenance remains efficient and cost-effective. Protect your investment by selecting durable seals that enhance performance and reduce the risk of failures.

FAQ

What are hydraulic cylinder packing kits, and why are they important?

Hydraulic cylinder packing kits consist of seals and components designed to prevent hydraulic fluid leakage in cylinders. These kits maintain consistent pressure, ensuring your excavator operates efficiently. Without proper packing kits, fluid leaks can reduce power delivery, leading to equipment downtime and increased maintenance costs. By using high-quality packing kits, you enhance the reliability and lifespan of your hydraulic cylinder packing kits.

How do I know when to replace rod seals in my excavator?

You should replace rod seals when you notice hydraulic fluid leaks, reduced pressure, or unusual noises during operation. Visible damage, such as cracks or deformation, also indicates the need for replacement. Regular inspections help you identify these signs early, preventing further damage to your hydraulic system.

Can I install rod seals on my own, or should I hire a professional?

You can install rod seals yourself if you have the right tools and follow proper installation steps. Clean the workspace, inspect components, and lubricate the seal before installation. However, if you lack experience or encounter complex issues, hiring a professional ensures the job is done correctly.

What materials are best for rod seals in harsh environments?

For harsh environments, materials like polyurethane and PTFE work best. Polyurethane offers excellent wear resistance and durability, while PTFE provides high-temperature resistance and chemical stability. These materials ensure reliable performance even in extreme conditions, such as construction or mining sites.

How do I choose the right rod seal for my excavator?

To choose the right rod seal, consider factors like operating pressure, temperature, and hydraulic fluid compatibility. Match the seal material to your excavator’s specific requirements. For example, use polyurethane for high-pressure systems or PTFE for chemically aggressive environments. Consulting with a trusted supplier like YNF Machinery simplifies this process.

What causes rod seal failures, and how can I prevent them?

Rod seal failures often result from improper installation, material incompatibility, or exposure to contaminants. Prevent failures by using high-quality seals, following correct installation procedures, and maintaining a clean hydraulic system. Regular inspections and timely replacements also reduce the risk of failure.

Are YNF Machinery’s hydraulic cylinder packing kits compatible with all excavators?

Yes, YNF Machinery’s hydraulic cylinder packing kits are designed to fit a wide range of excavator models. These kits meet international standards and include seals made from durable materials, ensuring compatibility and reliable performance across various brands and applications.

How can I extend the lifespan of my rod seals?

To extend the lifespan of your rod seals, perform regular maintenance. Keep the hydraulic system clean, monitor fluid levels, and replace worn seals promptly. Using high-quality seals from YNF Machinery also ensures durability and reduces the frequency of replacements.

What benefits do high-quality rod seals provide for excavators?

High-quality rod seals prevent hydraulic fluid leaks, maintain consistent pressure, and block contaminants. These benefits enhance your excavator’s performance, reduce downtime, and lower maintenance costs. Investing in reliable seals improves the overall efficiency and longevity of your equipment.

Why should I choose YNF Machinery for my hydraulic seal needs?

YNF Machinery offers premium hydraulic seals crafted from durable materials like polyurethane, nitrile rubber, and PTFE. These seals meet OEM standards, ensuring reliability and long-lasting performance. With YNF Machinery, you gain access to high-quality products that protect your excavator’s hydraulic system and reduce maintenance costs.