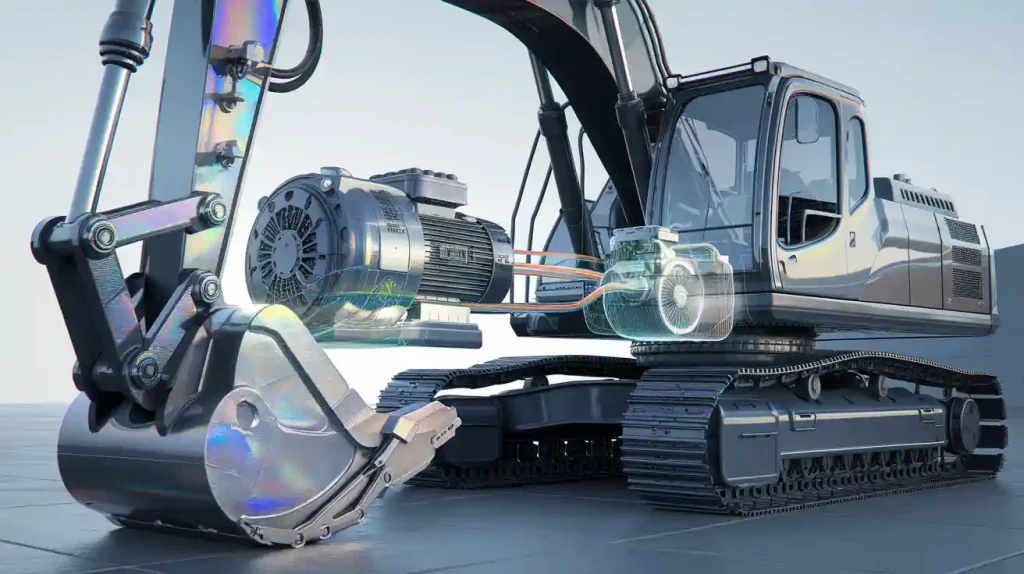

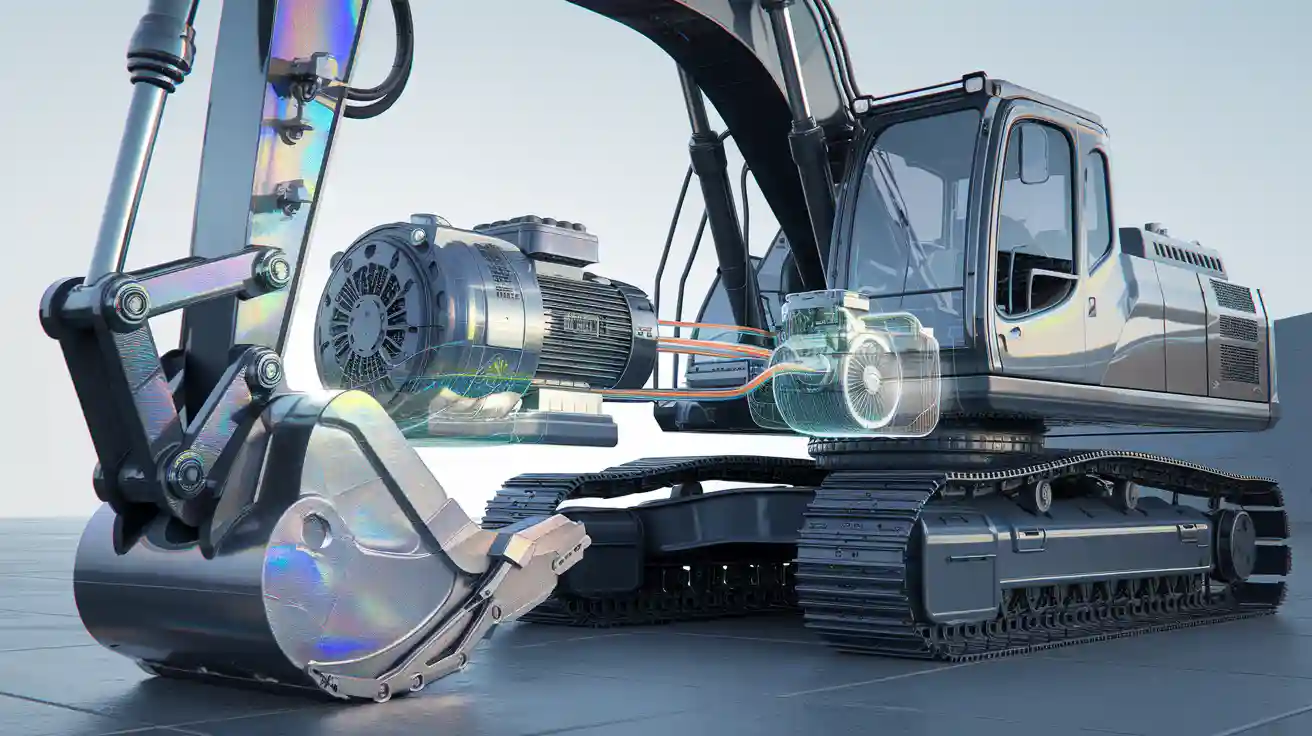

You can see how electrical motors excavator hydraulic pump systems work together in modern excavators. Electrical motors excavator hydraulic pump combinations provide strong and steady power. The electrical motors excavator hydraulic pump setup uses this power to move hydraulic fluid, which helps control the arm and bucket. When electrical motors excavator hydraulic pump systems operate in sync, you get impressive results:

Fuel use and carbon dioxide emissions can drop by 15%.

You can save up to 30% energy by adjusting the pump flow to match what is needed.

Some electrical motors excavator hydraulic pump systems can save energy, reducing total consumption by up to 50%.

Electrical motors excavator hydraulic pump setups can reach about 90% efficiency when operating properly.

These improvements give you better control, higher efficiency, and smarter performance from your excavator.

Key Takeaways

Electric motors and hydraulic pumps work together in excavators. This teamwork helps excavators use less fuel. It also lowers emissions by up to 30%.

Electric motors can save energy. They help cut waste and make the excavator work better.

Smart Power Control is an advanced system. It helps excavators use energy in a smart way. This makes them work better and smarter.

Hydraulic systems give strong power and control. They are needed for digging and lifting. They work well even in tough places.

Taking care of electric and hydraulic systems is important. Regular maintenance helps your excavator last longer. It also keeps it working well.

Electrical Motors Excavator Hydraulic Pump Basics

Electric Motors in Excavators

Electric motors help run many parts of an excavator. They work with the electrical motors excavator hydraulic pump system. This system sends energy to where it is needed most. Electric motors can save energy by using power from braking or when the arm goes down. This helps stop waste and makes the machine work better. Electric motors also lower metering losses compared to only using hydraulic motors. Hybrid excavators use batteries or capacitors to store extra energy. This gives strong power when needed. Companies like Kobelco and Hitachi are making electric hybrid prototypes to make machines more efficient.

Here is a table that shows how electric motors affect energy use in excavators:

Aspect | Description |

|---|---|

Energy Recovery | Electric motors let the machine use braking and gravity energy, so less is wasted. |

Elimination of Metering Losses | Using electric motors instead of hydraulic motors cuts out metering losses. |

Improved Efficiency | Adding electric motors makes the machine use less fuel and work better. |

Hybrid Technology | Hybrid excavators use batteries or capacitors to save energy and give steady power. |

Manufacturer Innovations | Companies like Kobelco and Hitachi are making new electric hybrid machines for better results. |

Tip: Electric motors in your electrical motors excavator hydraulic pump system can help you use less fuel and work better. 🚜

Hydraulic Pump Function

The hydraulic pump is the main part of the excavator’s hydraulic system. When you use the controls, the pump moves hydraulic fluid through hoses and valves. This fluid makes the boom, arm, and bucket move. Good hydraulic pumps and motors help the excavator lift heavy things and move fast. If the hydraulic pump is not working well, the machine will be slower and weaker. A good hydraulic pump gives smooth, quick, and strong movements every time.

Hydraulic systems are very important for how the excavator works. The hydraulic pump and hydraulic motor help you control attachments and move the machine exactly how you want. You need hydraulic power for almost every job, like digging or lifting. Picking a good hydraulic pump helps your excavator do its best work.

System Integration

Power Transfer

You need a strong way to move energy in excavators. The electric motor connects to the hydraulic pump. The motor uses a speed variable inverter. This drives a pump that can change how much fluid it moves. It also changes how much force it makes. You can control the flow rate and pressure. This matches what the boom, arm, or bucket needs.

Sensors watch movement, speed, and pressure. The controller uses this data to change how the motor and pump work. You get the right amount of power for each job. This saves energy and gives better performance. The hydraulic pump and hydraulic motor work together. They move fluid and create force for digging, lifting, or swinging.

Here is a table showing a common way to connect electric motors with hydraulic pumps in excavators:

Method | Benefits |

|---|---|

Electric motor and hydraulic pump fusion | Makes the system smaller and quieter. It improves efficiency and allows advanced hydraulics. It also reduces losses from many actuators. |

You may see some problems when you join electric motors and hydraulic pumps. Sometimes, you must change the frame to fit the motor and gearbox. This can make the frame up to 30% bigger. The motor’s position can make the back swing out more. This is hard in small spaces. Electric actuators are stiffer than hydraulic ones. You need shock-absorbing parts to protect from sudden jolts.

When you use the electrical motors excavator hydraulic pump system, think about efficiency. Every time you change energy, you lose some as heat. Leaks inside the hydraulic pump and hydraulic motor can lower power. When the system gets hotter and pressure rises, leaks get worse. For example, a hydraulic pump with 80 cm³/rev at 250 bar and 0.85 efficiency can lose 8.8 kW at the shaft. The electric motor and inverter might have 0.92 efficiency. This means a power loss of 9.5 kW at the electrical supply. Over 1,000 hours, you can lose 9,500 kWh of energy and over 5,000 kg of CO2.

Note: Picking the right size and using each part smartly helps your hydraulic system work best and save energy.

Control and Automation

You need advanced controls to make the electric motor, hydraulic pump, and hydraulic motor work well together. Modern excavators use systems like Smart Power Control (SPC) and Hi-POSS. SPC lets you change motor speed and pump torque. This helps you use less fuel and get more work done. Hi-POSS uses special accumulators with nitrogen. These store and reuse hydraulic energy. This makes the system more efficient.

Hyundai uses poppet valves controlled by electronics instead of old spool valves. These new valves let you control fluid flow and pressure very precisely. You get better efficiency and smoother operation. Advanced vehicle controls are now needed for smooth operation of hydraulic pumps and motors with electric motors. Old hydraulic controls may not give you the precision you want in electric systems.

“Hydraulics are going digital: Valves are controlled by computer programs. Sensors watch actuators. Pressure changes based on data from the environment. This change allows for semi- and full-autonomous operation. It creates smarter systems needed for automated features on excavators.”

You can use automation to make your excavator smarter. Sensors and controllers work together to adjust the hydraulic pump and hydraulic motor in real time. Variable displacement pumps, load-sensing controls, and electro-hydraulic systems help you use less energy and get more accurate movements. These systems also help you save fuel, lower battery costs, and waste less energy. You get high power density and precise control. This means your excavator works better and safer.

Here are some benefits of electro-hydraulic systems:

Better energy efficiency lowers fuel costs.

On-demand operation means you only use energy when needed.

High power density and precise control make your excavator work better.

Closed loop systems make your machine safer and more reliable.

Less maintenance means more uptime and lower costs.

Tip: Using electro-hydraulic systems gives you better control, saves money, and helps the environment.

Real-World Operation

Movement and Attachments

When you use an excavator, electric motors and hydraulic pumps work together. The motor gives power to the hydraulic pump. The pump sends fluid through the system. This fluid moves the boom, arm, and bucket. You can control each part very well. These systems respond much faster than old ones. They can be up to 10 times quicker. You also use less fuel, sometimes saving 20%. Productivity can go up by almost 30%.

Many new excavators use these systems. For example:

The Komatsu PC200-8E0 hybrid excavator uses an electric swing motor and hydraulic systems. It can lower fuel use by 25%.

Volvo’s newest excavators use electric-over-hydraulic systems. These let you change flow when you need it and pick work modes for different jobs.

The hydraulic pump and motor help with many attachments. When you switch from a bucket to a breaker or grapple, the system changes flow and pressure. You get the right power for each tool. The pump and motor work together to lift heavy things and handle tough jobs. How well they work depends on the material. Sticky soils make work harder, but the hydraulic system helps you stay in control. The energy-saving system can use about 17.6% less power than older machines.

Tip: If you want electric motors and hydraulic pumps that last, YNF Machinery has good parts to keep your excavator working well.

Underwater and Specialized Uses

Sometimes you need to use your excavator underwater or in rough places. Hydraulic motors are great for these jobs. They have high torque density and are very strong. This makes them better than electric or diesel engines for underwater work. Hydraulic pumps and motors give you the power and control you need, even when things get tough.

Underwater excavators use new materials and smart controls. This makes them last longer and work better. The hydraulic pump and motor do not rust and can handle high pressure. Electric motors need to be waterproof. Makers use brushless underwater DC motors with titanium and plastic parts. These stop rust and work in saltwater. The motors can handle pressure up to 600 bar. This design keeps your equipment safe and working.

Special excavators use strong wires and covers for protection. Hydraulic parts have better seals and filters to keep out dirt. Electronics help control cooling so your machine works in hot or cold weather.

Note: If you pick the right hydraulic pump, motor, and waterproof electric motor, your excavator can do any job, anywhere.

You can see electric motors and hydraulic pumps working together in excavators. These systems help the machine use less fuel. They also make the excavator quieter. This helps you follow tough environmental rules. You will find it easier to fix problems. The parts last longer, so you do not need to replace them often.

These systems are up to 70% more efficient than older ones.

They lower emissions and use less fuel.

It is easier to find problems and the machine is quieter.

New smart controls will make your excavator work even better. These machines are becoming more popular every year. If you need good parts and help, YNF Machinery can keep your excavator working well.

FAQ

How do electric motors and hydraulic pumps work together in an excavator?

The electric motor gives power to the hydraulic pump. The pump sends fluid to the parts that move. This teamwork lets you control the arm, boom, and bucket easily and smoothly.

What are the main benefits of using electric motors in excavators?

You use less fuel and save energy. Electric motors make the excavator quieter. You can move the parts more exactly. These things help you spend less money and help the planet.

Can you use an excavator underwater with these systems?

Yes, you can use hydraulic systems underwater. You need electric motors that are waterproof and strong seals. These things keep your machine safe and working in water.

How do you maintain electric and hydraulic systems in excavators?

Check the fluid often and look for leaks. Clean the filters and check the electric connections and seals. Taking care of these things helps your excavator last longer and work better.

Where can you find reliable parts for your excavator’s electric and hydraulic systems?

YNF Machinery has good parts and support for your excavator. They give you strong and reliable electric motors and hydraulic pumps.