Choosing the right parts of a mini excavator plays a vital role in ensuring your machine operates efficiently and lasts longer. High-quality components enhance performance, reduce downtime, and save costs over time. A right-sized excavator equipped with durable parts can handle heavy tasks while maintaining optimal capacity. YNF Machinery offers reliable solutions for mini excavators, including Excavator Engine Parts, excavator couplings, and Hydraulic Cylinder Seal Kits. With over 35 years of expertise, YNF ensures you get dependable parts that keep your excavator running smoothly in demanding conditions.

Key Takeaways

Always verify compatibility by checking your mini excavator’s model and serial number before purchasing parts to avoid costly mistakes.

Consider the difference between OEM and aftermarket parts; while OEM parts offer guaranteed quality, aftermarket options can provide cost-effective alternatives if they meet required standards.

Invest in high-quality materials for parts to ensure durability and performance, especially for critical components like hydraulic pumps and engine parts.

Choose suppliers with a strong reputation and positive customer reviews, as this ensures you receive reliable parts and excellent service.

Look for parts with ISO and CE certifications to guarantee they meet international safety and performance standards.

Prioritize suppliers like YNF Machinery that offer transparent pricing and comprehensive warranty policies to protect your investment.

Regularly inspect and maintain your excavator’s undercarriage and attachments to enhance performance and extend the machine’s lifespan.

Key Factors to Consider When Choosing Parts of a Mini Excavator

Ensuring Compatibility with Your Mini Excavator

Checking model and serial number requirements

Choosing the right parts of a mini excavator starts with ensuring compatibility. Each excavator model has unique specifications, and using incompatible parts can lead to performance issues or even damage. Always check the model and serial number of your machine before purchasing replacement components. These details help you identify the exact parts that fit your excavator. Manufacturers often provide an excavator size guide to simplify this process. By matching the part number with your machine’s requirements, you avoid costly mistakes and ensure smooth operation.

Understanding OEM vs. aftermarket parts

When selecting parts, you often face a choice between OEM (Original Equipment Manufacturer) and aftermarket options. OEM parts are designed by the original manufacturer, ensuring precise compatibility and high quality. They typically last longer and maintain the excavator’s performance. However, they come with higher upfront costs and may not always be readily available.

Aftermarket parts, on the other hand, offer a cost-effective alternative. These parts are manufactured by third-party companies and are designed to match or exceed OEM standards. While they may lack the brand recognition of OEM components, many aftermarket parts deliver reliable performance at a lower price. Consider factors like cost, availability, and the critical nature of the part when deciding between these options. For essential components like excavator undercarriage parts, OEM parts might be a safer choice due to their durability and precision.

Evaluating Durability and Material Quality

Importance of high-quality materials for heavy-duty use

Excavators operate in demanding environments, making durability a top priority. High-quality materials ensure that parts can withstand heavy loads, extreme temperatures, and constant wear. For example, components like hydraulic pumps and cylinders must handle intense pressure without failing. Investing in durable parts reduces the risk of breakdowns and extends the lifespan of your machine. This is especially important for maintaining the capacity of a right-sized excavator, as durable parts ensure consistent performance over time.

How YNF Machinery ensures durability in Excavator Engine Parts

YNF Machinery prioritizes durability in its products, particularly in Excavator Engine Parts. These components are crafted from premium materials designed to endure harsh conditions. Rigorous quality inspections ensure that every part meets high standards. YNF’s engine parts, such as pistons and crankshafts, are built to handle heavy-duty use, reducing the need for frequent replacements. By choosing YNF Machinery, you gain access to reliable parts that enhance your excavator’s efficiency and longevity.

Balancing Cost and Budget

Finding affordable yet reliable parts

Balancing cost and quality is crucial when selecting parts of a mini excavator. While cheaper options may seem appealing, they often compromise on durability and performance. Look for parts that offer a balance between affordability and reliability. Aftermarket parts can be a great option if they meet the required standards. Researching and comparing prices helps you find components that fit your budget without sacrificing quality.

Avoiding hidden costs with YNF Machinery’s transparent pricing

Hidden costs can quickly inflate your expenses when purchasing excavator parts. YNF Machinery eliminates this concern with its transparent pricing policy. The company provides clear information about the cost of each component, ensuring you know exactly what you’re paying for. This approach helps you plan your budget effectively and avoid unexpected expenses. With YNF Machinery, you get high-quality parts at competitive prices, making it easier to maintain your mini excavator without overspending.

Supplier Reputation and Reliability

Why YNF Machinery is a trusted name in the industry

When choosing parts of a mini excavator, the reputation of the supplier plays a critical role. A trusted supplier ensures you receive high-quality components that enhance your machine’s performance and longevity. YNF Machinery has built a strong reputation over its 35 years of service by consistently delivering reliable excavator parts to customers worldwide. Their commitment to quality and customer satisfaction sets them apart in the industry.

YNF Machinery excels in maintaining efficient communication with its clients. This ensures you get the right parts promptly, minimizing downtime. One customer shared, “Working with YNF Machinery has made my job easier. They help me find exactly what I need with just the part numbers, and the quality has always been reliable.” This level of service makes YNF a dependable partner for excavator owners and operators.

The company’s focus on durability and precision further strengthens its reputation. YNF Machinery’s products, such as Excavator Engine Parts and Hydraulic Cylinder Seal Kits, undergo rigorous quality checks to meet international standards. This attention to detail ensures that your excavator operates at its full capacity, even in demanding conditions. By choosing YNF, you invest in parts that deliver long-term value and performance.

Researching customer reviews and testimonials

Customer reviews and testimonials provide valuable insights into a supplier’s reliability. Positive feedback from other users helps you make informed decisions when selecting a supplier for your excavator parts. YNF Machinery has garnered praise for its exceptional service and product quality. One satisfied customer noted, “It’s a great one-stop shop for excavator parts.” Such testimonials highlight the convenience and reliability YNF offers.

When researching reviews, look for comments about product durability, delivery speed, and customer support. YNF Machinery consistently receives high marks in these areas. Their transparent pricing and efficient problem resolution further enhance their appeal. Effective communication ensures you avoid costly mistakes and receive the right-sized excavator parts for your specific needs.

By prioritizing suppliers with strong reputations and positive customer feedback, you reduce risks and ensure your excavator remains in top condition. YNF Machinery’s proven track record makes them a trusted choice for professionals seeking reliable parts and excellent service.

Evaluating the Quality of Mini Excavator Parts

Material Standards and Certifications

Importance of ISO and CE certifications

When selecting parts of a mini excavator, certifications like ISO and CE serve as essential indicators of quality. These certifications ensure that the components meet strict international safety and performance standards. For instance, ISO 9001 certification guarantees that the manufacturing process follows consistent quality control measures. This minimizes defects and ensures the parts perform efficiently under demanding conditions.

CE certification, on the other hand, confirms that the parts comply with European safety regulations. This is particularly important for ensuring the safe operation of critical components like hydraulic pumps and excavator undercarriage parts. By choosing certified parts, you reduce the risk of equipment failure and enhance the overall capacity of your excavator.

“Certifications like ISO and CE guarantee safety and performance standards for parts, ensuring efficient and safe equipment operation.”

How YNF Machinery meets international quality standards

YNF Machinery takes pride in adhering to international quality standards. The company’s products, including Excavator Engine Parts and Hydraulic Cylinder Seal Kits, undergo rigorous testing to meet ISO and CE requirements. This commitment to quality ensures that every part delivers reliable performance, even in harsh environments. By maintaining these certifications, YNF Machinery not only stands out in the competitive market but also provides you with peace of mind when purchasing parts for your mini excavator.

Warranty and Return Policies

Why warranties indicate confidence in product quality

A warranty reflects the manufacturer’s confidence in their product. When you purchase parts of a mini excavator with a warranty, you gain assurance about their durability and performance. Warranties protect you from unexpected costs by covering defects or failures within a specified period. This is especially valuable for high-stress components like hydraulic cylinders and quality undercarriage parts, which are critical to maintaining the excavator’s capacity.

A clear return policy further enhances your purchasing experience. It allows you to replace or return parts that do not meet your expectations, ensuring you get the best value for your investment.

YNF Machinery’s warranty and return policies

YNF Machinery offers comprehensive warranty and return policies to support its customers. The company provides detailed information about warranty coverage for each part, ensuring transparency. If you encounter any issues, YNF’s efficient return process allows you to resolve them quickly. This customer-focused approach demonstrates the company’s commitment to quality and reliability, making it a trusted choice for excavator owners worldwide.

Identifying High-Quality Parts

Signs of well-made parts, such as precise dimensions

High-quality parts exhibit specific characteristics that set them apart. Precise dimensions ensure a perfect fit, reducing the risk of misalignment and wear. Durable materials withstand heavy loads and extreme conditions, extending the lifespan of your excavator. Smooth finishes and consistent construction indicate meticulous manufacturing processes. By examining these features, you can identify parts that will enhance your machine’s performance and reliability.

How YNF Machinery ensures quality in Hydraulic Cylinder Seal Kits

YNF Machinery excels in producing Hydraulic Cylinder Seal Kits that meet the highest standards. These kits are crafted from premium materials like NBR and FKM, ensuring flexibility and durability. Each kit undergoes stringent quality checks to guarantee precise dimensions and a perfect fit. This attention to detail prevents oil leaks and ensures smooth operation, even under challenging conditions. By choosing YNF’s seal kits, you invest in parts that maintain your excavator’s efficiency and reduce downtime.

Understanding Specific Mini Excavator Parts and Their Functions

Undercarriage Components

Tracks, rollers, and sprockets

The undercarriage forms the foundation of your mini excavator, directly influencing its mobility and stability. Key components like tracks, rollers, and sprockets work together to ensure smooth operation across various terrains. Tracks bear the machine’s weight and provide traction, enabling it to move efficiently on surfaces like mud or gravel. Rollers guide the tracks and maintain proper alignment, while sprockets drive the tracks by engaging with the chain links.

High-quality undercarriage parts are essential for maintaining performance and reducing downtime. For example, durable tracks and sprockets can withstand extreme pressure during operation, ensuring your excavator operates reliably in rugged environments. Regular inspection and timely replacement of these components help prevent costly repairs and extend the lifespan of your machine.

How undercarriage health impacts performance

The health of your undercarriage directly affects your excavator’s performance and efficiency. A well-maintained undercarriage ensures stability, smooth movement, and optimal digging power. Worn-out tracks or misaligned rollers can lead to uneven wear, reduced traction, and increased fuel consumption. Neglecting undercarriage maintenance may also compromise the machine’s capacity to handle heavy loads.

To keep your excavator in top condition, follow a proactive maintenance routine. Clean the undercarriage regularly to remove debris, inspect components for wear, and replace damaged parts promptly. By prioritizing undercarriage health, you enhance your machine’s reliability and productivity.

Attachments and Accessories

Common attachments like buckets, augers, and breakers

Attachments expand the versatility of small excavators, allowing them to perform a wide range of tasks. Common options include buckets, augers, and breakers. Buckets are ideal for digging and material handling, with various sizes available to suit different project needs. Augers are used for drilling holes in soil, making them perfect for landscaping or construction projects. Breakers, on the other hand, are designed for demolishing concrete or rock, providing powerful impact force.

Understanding the types of excavator attachments available helps you select the right tools for your projects. Each attachment serves a specific purpose, so choosing the appropriate one ensures efficiency and precision in your work.

Choosing attachments based on your project needs

Selecting the right attachments depends on the nature of your project and the excavator’s specifications. Consider factors like the material you’ll be working with, the required digging depth, and the machine’s lifting capacity. For example, a trenching bucket is ideal for narrow excavations, while a grading bucket works best for leveling surfaces.

Refer to an excavator size guide to ensure compatibility between the attachment and your machine. This step prevents operational issues and maximizes productivity. Investing in high-quality attachments not only improves performance but also reduces wear on your excavator.

Engine and Hydraulic System Parts

Key engine components, including YNF Machinery’s Excavator Engine Parts

The engine serves as the heart of your mini excavator, converting fuel into mechanical energy to power the machine. Key components include pistons, crankshafts, and fuel injectors. These parts work together to deliver the necessary torque and horsepower for heavy-duty tasks. High-quality engine components ensure efficient combustion, reducing fuel consumption and emissions.

YNF Machinery offers reliable Excavator Engine Parts designed for durability and performance. Their products undergo rigorous quality checks to meet international standards, ensuring your excavator operates smoothly even in demanding conditions. By choosing YNF’s engine parts, you enhance your machine’s efficiency and longevity.

Importance of hydraulic pumps, hoses, and seals, including YNF Machinery’s Hydraulic Cylinder Seal Kits

The hydraulic system powers essential functions like digging, lifting, and swinging. Critical components include hydraulic pumps, hoses, and seals. Pumps generate the pressure needed to move hydraulic fluid, while hoses transport the fluid to various parts of the machine. Seals prevent leaks and maintain system integrity, ensuring smooth operation.

YNF Machinery’s Hydraulic Cylinder Seal Kits are crafted from premium materials to withstand high pressure and extreme conditions. These kits provide a perfect fit, preventing oil leaks and reducing maintenance downtime. By investing in quality hydraulic components, you ensure your excavator delivers consistent performance and handles tough tasks with ease.

Tips for Choosing Reliable Suppliers for Mini Excavator Parts

Evaluating Customer Support and Service

Availability of technical support and advice

Reliable customer support is a cornerstone of a trustworthy supplier. When sourcing parts for your excavator, you need a supplier who provides prompt and knowledgeable assistance. Technical support becomes essential when you face challenges in identifying the right parts or understanding their installation. A supplier with a dedicated team ensures you receive accurate advice tailored to your machine’s specifications.

Suppliers like YNF Machinery excel in offering expert guidance. With over 35 years of experience, they help you navigate complex decisions, such as selecting the correct hydraulic components or understanding the compatibility of attachments. Their team remains available to answer questions, ensuring you make informed choices that enhance your excavator’s performance.

“Look for suppliers who respond quickly and offer practical solutions,” advises Aline, an industry expert with over a decade of experience. This responsiveness minimizes downtime and keeps your operations running smoothly.

How YNF Machinery provides exceptional customer service

YNF Machinery stands out for its exceptional customer service. Their team prioritizes clear communication, ensuring you receive the right parts without delays. Whether you need assistance with an excavator size guide or advice on specific excavator parts and functions, YNF’s experts provide reliable solutions. Customers frequently praise their ability to simplify the purchasing process, making it easier to maintain small excavators efficiently.

One satisfied customer shared, “YNF Machinery has made my job easier. Their team helps me find exactly what I need with just the part numbers.” This level of support reflects their commitment to customer satisfaction and reliability.

Comparing Pricing and Value

Identifying fair pricing for quality parts

Fair pricing is crucial when selecting a supplier. While low-cost options may seem appealing, they often compromise on quality and durability. High-quality parts ensure your excavator operates efficiently and maintains its capacity over time. To identify fair pricing, compare costs across multiple suppliers and evaluate the materials and certifications of the parts offered.

Reputable suppliers provide transparent pricing, helping you avoid hidden costs. They also offer a balance between affordability and reliability, ensuring you get value for your investment. For example, when choosing types of excavator attachments, prioritize suppliers who provide durable options at competitive prices.

Why YNF Machinery offers competitive pricing without compromising quality

YNF Machinery combines competitive pricing with uncompromising quality. Their transparent pricing policy ensures you know exactly what you’re paying for, eliminating unexpected expenses. By sourcing high-grade materials and adhering to international standards, YNF delivers parts that enhance the longevity and efficiency of your excavator.

Their commitment to affordability extends to a wide range of products, from engine components to attachments. This approach allows you to maintain your machine without exceeding your budget. Customers appreciate YNF’s ability to provide cost-effective solutions without sacrificing performance or reliability.

After-Sales Services and Support

Importance of maintenance and repair services

After-sales services play a vital role in maintaining your excavator’s performance. Regular maintenance and timely repairs prevent costly breakdowns and extend the lifespan of your machine. A reliable supplier offers comprehensive after-sales support, including access to replacement parts, technical assistance, and repair services.

Suppliers who prioritize after-sales support help you address issues quickly, minimizing downtime. This is especially important for small excavators, which often operate in demanding environments. By partnering with a supplier who values long-term customer relationships, you ensure your machine remains in optimal condition.

YNF Machinery’s commitment to after-sales support

YNF Machinery demonstrates a strong commitment to after-sales support. Their team provides ongoing assistance, ensuring you have access to the parts and services needed to keep your excavator running smoothly. From troubleshooting technical issues to facilitating returns, YNF prioritizes customer satisfaction at every stage.

Their warranty policies further enhance their reliability. By offering coverage for defects and failures, YNF gives you peace of mind when investing in their products. This dedication to quality and support makes them a trusted partner for professionals seeking dependable excavator parts.

Choosing the right parts for your mini excavator requires careful consideration of compatibility, quality, and supplier reliability. Ensuring that parts match your machine’s specifications prevents costly errors and enhances performance. High-quality components, such as engine parts and attachments, improve durability and reduce downtime. Partnering with a trusted supplier like YNF Machinery guarantees access to reliable products and exceptional customer support. Always verify part details, prioritize quality over cost, and select suppliers with a proven track record. These steps ensure your excavator operates efficiently and meets the demands of your projects.

FAQ

What does maintenance for mini excavators include?

Maintenance for mini excavators involves several key tasks to ensure optimal performance and longevity. Regular inspections and servicing of the engine, hydraulics, and attachments are essential. You should check and replace fluids like engine oil, hydraulic oil, and coolant. Cleaning or replacing filters also helps maintain efficiency. Additionally, inspect tracks, undercarriage components, and electrical systems to identify wear or damage. Routine maintenance keeps your excavator running smoothly and reduces the risk of costly repairs.

How can you operate a mini excavator safely?

Operating a mini excavator safely requires preparation and attention to detail. Start by reading the operator’s manual to understand the controls and safety features. Conduct a pre-operation inspection to check for visible damage, fluid levels, and wear on attachments. Wear proper personal protective equipment (PPE), including a hard hat, safety glasses, gloves, high-visibility clothing, and steel-toed boots. Secure the work area with barriers or warning signs to keep bystanders safe. Always operate at a controlled speed and avoid sudden movements to maintain stability. Following these steps ensures a safe and efficient operation.

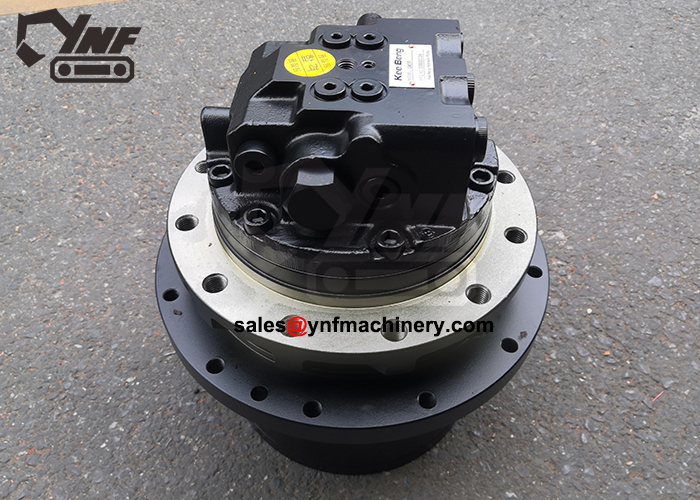

What are final drives for excavators, and why are they important?

Final drives for excavators are critical components that transfer power from the hydraulic motor to the tracks, enabling movement. These parts play a vital role in ensuring smooth and efficient operation. High-quality final drives enhance the machine’s mobility and stability, especially on challenging terrains. Regular inspection and maintenance of final drives prevent wear and extend their lifespan, keeping your excavator in top condition.

How do you choose the right hydraulic components for your excavator?

Choosing the right hydraulic components involves understanding your excavator’s specifications and operational needs. Check the compatibility of hydraulic pumps, hoses, and seals with your machine. Look for high-quality materials that can withstand pressure and extreme conditions. Certified components, such as those meeting ISO standards, ensure reliability and safety. Investing in durable hydraulic parts minimizes downtime and enhances your excavator’s performance.

Why is regular inspection of tracks and undercarriage important?

Tracks and the undercarriage form the foundation of your excavator, directly affecting its stability and performance. Regular inspection helps identify wear or damage early, preventing costly repairs. Clean the undercarriage frequently to remove debris that can cause uneven wear. Replace worn-out tracks or rollers promptly to maintain traction and reduce fuel consumption. Proper care of these components ensures your excavator operates efficiently across various terrains.

What should you consider when selecting attachments for a mini excavator?

When choosing attachments, consider the type of work you plan to perform and your excavator’s specifications. Common attachments include buckets for digging, augers for drilling, and breakers for demolition. Ensure the attachment matches your machine’s lifting capacity and size. High-quality attachments improve efficiency and reduce wear on your excavator. Refer to the manufacturer’s guide to confirm compatibility and maximize productivity.

How can you extend the lifespan of your excavator?

Extending the lifespan of your excavator requires consistent maintenance and proper operation. Perform regular inspections to identify and address issues early. Use high-quality replacement parts, such as durable hydraulics and final drives, to maintain performance. Operate the machine within its capacity and avoid overloading. Follow the manufacturer’s maintenance schedule to keep all components in optimal condition. These practices reduce wear and ensure long-term reliability.

What are the signs of wear in hydraulic systems?

Signs of wear in hydraulic systems include reduced performance, unusual noises, and visible leaks. Slow or inconsistent movement of attachments may indicate pressure loss. Inspect hoses and seals for cracks or damage. Addressing these issues promptly prevents further damage and ensures the hydraulic system operates efficiently. Regular maintenance and high-quality components help avoid common hydraulic problems.

How do you ensure compatibility when purchasing excavator parts?

To ensure compatibility, always check your excavator’s model and serial number before purchasing parts. Match these details with the part specifications provided by the supplier. Refer to the operator’s manual or consult with the supplier for guidance. Choosing compatible parts prevents performance issues and ensures a perfect fit, reducing the risk of damage to your machine.

What role does supplier reputation play in purchasing excavator parts?

A supplier’s reputation reflects the quality and reliability of their products. Trusted suppliers provide high-quality parts that enhance your excavator’s performance. Look for customer reviews and testimonials to evaluate their service and product durability. Reliable suppliers, like YNF Machinery, offer transparent pricing, excellent customer support, and certified components. Partnering with a reputable supplier ensures you receive dependable parts and long-term value.