Choosing the right Mitsubishi excavator parts ensures optimal performance and extends your equipment’s lifespan. Incompatible or low-quality parts can cause serious issues. These include costly downtime, reduced excavator efficiency, and potential safety hazards for both operators and machinery. You must prioritize finding the right parts to avoid these risks. Start by understanding your equipment’s specific requirements and verifying compatibility. This buyer’s guide will help you make informed decisions, ensuring your excavator operates at its best.

Key Takeaways

Know your excavator’s brand and model to pick the right parts. This avoids expensive errors and delays.

Check your equipment manual for part numbers. It helps you find the exact parts your excavator needs.

Use real Mitsubishi parts for better quality and long-lasting use. Genuine parts improve performance and lower the chance of problems.

Make sure suppliers are certified and read reviews. This helps you avoid fake parts.

Inspect your excavator often and replace old parts quickly. Regular care keeps it working well and lasting longer.

Understand Your Mitsubishi Excavator

Identify Your Excavator’s Make and Model

Start by identifying the make and model of your excavator. This step is crucial because different brands and models have unique specifications for their components. For example, the size, shape, and design of parts can vary significantly between models. Knowing your excavator’s exact make and model ensures you select parts that fit perfectly and perform as expected. You can usually find this information on the identification plate attached to the machine. If the plate is missing or damaged, check your purchase documents or contact the manufacturer for assistance.

Use the Equipment Manual for Part Numbers

Your equipment manual is an invaluable resource when searching for Mitsubishi excavator parts. It contains detailed diagrams and part numbers for every component of your machine. These part numbers act as a unique identifier, helping you locate the exact parts you need. Using the manual eliminates guesswork and reduces the risk of ordering incompatible parts. If you’ve misplaced the manual, many manufacturers offer digital copies on their websites. Always refer to the manual before making a purchase to ensure accuracy.

Verify Compatibility with Serial Numbers

Part compatibility is another critical factor to consider. Even if two excavators share the same model, their parts may differ due to production updates or regional variations. To avoid issues, verify part compatibility using your excavator’s serial number. The serial number provides specific details about your machine, such as its production year and configuration. Share this number with your supplier when ordering parts to confirm they match your equipment. This step prevents costly mistakes and ensures your excavator operates smoothly.

Benefits of Genuine Mitsubishi Spare Parts

Quality and Durability of OEM Parts

Using genuine Mitsubishi spare parts ensures your excavator operates at peak efficiency. These parts are specifically engineered to match the exact specifications of your equipment. Authentic Mitsubishi spare parts undergo rigorous testing to meet industrial standards, guaranteeing both durability and reliability. This means they can withstand the demanding conditions of excavation work, reducing the likelihood of unexpected failures.

When you choose genuine Mitsubishi parts, you also benefit from easier installation. These parts fit perfectly, saving you time and effort during maintenance. Additionally, they come with a manufacturer’s warranty, offering peace of mind and coverage for replacements if needed. Over time, the superior quality and performance of these parts help maintain your excavator’s value, making them a smart investment.

Risks of Counterfeit or Generic Excavator Parts

Counterfeit or generic excavator parts may seem like a cost-effective option, but they often lead to more problems than solutions. These parts lack the precision engineering of genuine Mitsubishi parts, which can result in poor performance and inefficiencies. For example, a poorly fitting hydraulic component could cause leaks, reducing your excavator’s productivity and increasing downtime.

Generic parts also tend to wear out faster, leading to frequent replacements and higher maintenance costs. Without the rigorous testing that genuine parts undergo, these alternatives may fail under pressure, causing costly breakdowns. Furthermore, counterfeit parts rarely come with warranties, leaving you unprotected if something goes wrong. By avoiding these risks and choosing authentic Mitsubishi spare parts, you ensure your equipment remains reliable and efficient for years to come.

Key Factors When Choosing Excavator Parts

Ensuring Compatibility with Your Machine

Ensuring compatibility between your excavator and its parts is essential for smooth operation. Start by confirming the make and model of your machine. This ensures the parts you choose fit correctly and function as intended. Always opt for OEM (Original Equipment Manufacturer) parts. These are specifically designed for your equipment and provide better compatibility and performance.

Check the quality and durability of the parts before purchasing. High-quality components last longer and reduce the risk of breakdowns. Use your equipment manual or consult a trusted supplier to verify part numbers. This step eliminates guesswork and helps in finding the right parts for your excavator.

Tip: Always double-check the serial number of your excavator when ordering parts. This ensures you avoid mismatched components caused by production variations.

Balancing Quality and Cost

Balancing quality and cost is a critical aspect of choosing excavator parts. While it may be tempting to go for cheaper options, low-cost parts often compromise on quality. These parts wear out quickly, leading to frequent replacements and higher long-term expenses.

Investing in authentic Mitsubishi spare parts ensures durability and reliability. Though they may cost more upfront, their superior performance reduces maintenance costs over time. Compare prices from multiple suppliers to find competitive rates without sacrificing quality. Prioritize value over short-term savings to keep your excavator running efficiently.

Long-Term Value of High-Quality Parts

High-quality parts offer significant long-term value for your excavator. They enhance the machine’s performance and reduce the likelihood of unexpected failures. For example, durable hydraulic components improve efficiency in gearbox and motor applications, ensuring consistent operation.

Using authentic Mitsubishi spare parts also protects your investment. These parts maintain the resale value of your equipment by ensuring it remains in excellent condition. Replacing excavator parts with high-quality options minimizes downtime and maximizes productivity. Over time, this approach saves you money and extends the lifespan of your machine.

Note: Consider high-quality filters and wear items like tracks and buckets. These components experience heavy use and directly impact your excavator’s performance.

Finding Reliable Suppliers for Mitsubishi Excavator Parts

Check Supplier Certifications and Reviews

A reliable supplier ensures you receive high-quality excavator parts that meet industry standards. Always check for certifications that demonstrate their commitment to quality, safety, and environmental responsibility. Certifications like ISO 9001 and ISO 14001 indicate adherence to strict quality and environmental management practices. OHSAS 18001 ensures the supplier prioritizes occupational health and safety. For automotive-related parts, IATF 16949 certification is essential. The table below highlights key certifications to look for:

Certification/Standard | Description |

|---|---|

ISO 9001 | Quality management standard |

ISO 14001 | Environmental management standard |

OHSAS 18001 | Occupational health and safety management |

IATF 16949 | Automotive quality management standard |

BSCI | Business Social Compliance Initiative |

In addition to certifications, read customer reviews. Reviews provide insights into the supplier’s reliability, product quality, and customer service. A trusted supplier will have positive feedback and a proven track record of delivering genuine Mitsubishi excavator parts.

Look for Warranties and Return Policies

Warranties and return policies are essential when purchasing excavator parts. They offer several benefits:

Cost Savings: Warranties protect you from unexpected repair costs.

Increased Productivity: Prompt servicing under warranty minimizes downtime.

Peace of Mind: Knowing your investment is covered reduces stress.

A reputable supplier will provide clear warranty terms and flexible return policies. These features demonstrate their confidence in the quality of their products and their commitment to customer satisfaction.

Avoid Unverified or Unreliable Sellers

Unverified sellers often lack the certifications and reviews that indicate trustworthiness. Purchasing from such sources increases the risk of receiving counterfeit or low-quality parts. These parts may not fit your excavator properly, leading to inefficiencies and potential damage. Stick to suppliers with verified credentials and a strong reputation. This ensures you get authentic parts that enhance your excavator’s performance and longevity.

Tip: Always verify the supplier’s contact details and business address to confirm their legitimacy.

Essential Mitsubishi Excavator Parts to Consider

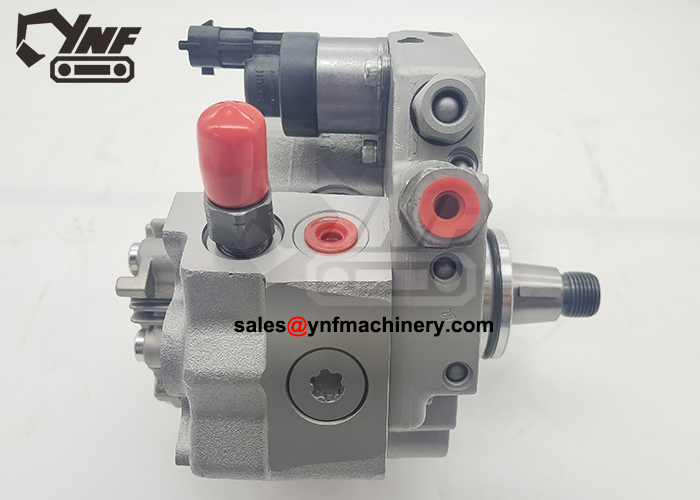

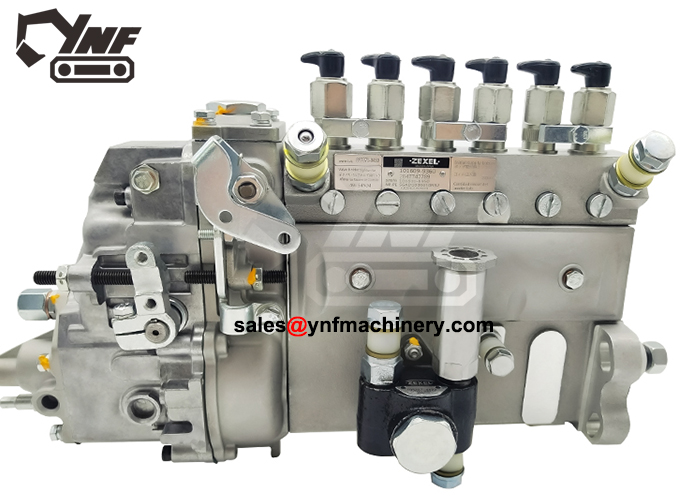

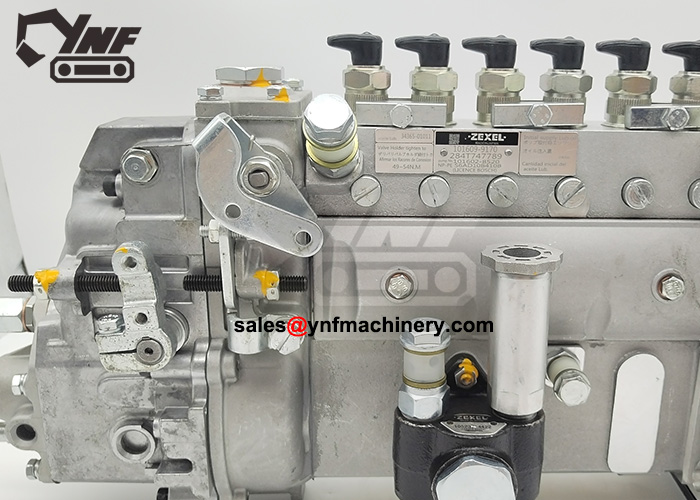

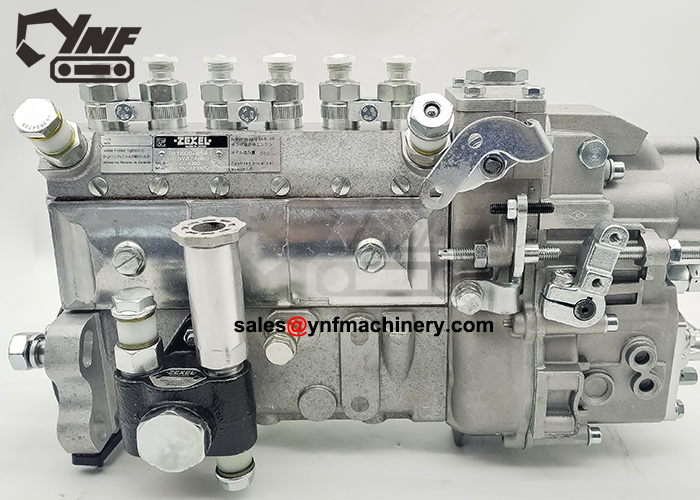

Hydraulic Components and Their Role

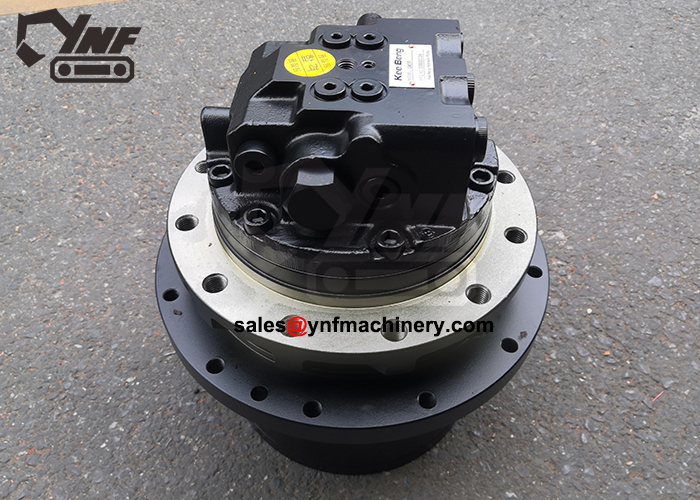

Hydraulic components are the backbone of your excavator’s performance. These parts power the machine’s movements and ensure precise control over its attachments. Hydraulic pumps, for instance, convert mechanical energy into hydraulic energy, enabling smooth operation. Their efficiency directly impacts the productivity of your excavator.

Other critical hydraulic components include hoses and cylinders. Hydraulic hoses transport fluid under high pressure, connecting various parts of the system. Over time, these hoses may wear out due to constant use, making them one of the most commonly replaced excavator parts. Regularly inspecting and replacing worn hoses prevents leaks and ensures uninterrupted operation.

By maintaining high-quality hydraulic components, you enhance your excavator’s efficiency and extend its lifespan. These parts play a vital role in gearbox and motor applications, ensuring the machine operates seamlessly in demanding conditions.

Filters for Optimal Performance

Filters are essential for protecting your excavator’s engine and hydraulic systems from contaminants. Air filters prevent dust and debris from entering the engine, while fuel and oil filters ensure clean fuel and proper lubrication. High-quality filters improve efficiency and reduce the risk of damage to critical components.

Clean fluids reduce friction and wear, ensuring smooth operation. Regularly replacing filters not only protects your investment but also enhances the machine’s overall performance. Proper filtration extends the life of your excavator, keeping it in peak condition for longer periods.

Neglecting filters can lead to clogged systems, reduced efficiency, and costly repairs. Make filter maintenance a priority to achieve optimal performance and avoid unnecessary downtime.

Wear Items (Tracks, Buckets, and Teeth)

Wear items like tracks, buckets, and teeth endure the most stress during excavation work. Tracks provide stability and mobility, making them crucial for your excavator’s functionality. Over time, they wear down due to constant contact with rough surfaces. Replacing worn tracks ensures smooth movement and prevents damage to other components.

Bucket teeth are another common wear item. These teeth handle heavy loads and abrasive materials, which causes them to wear out quickly. Replacing them regularly maintains digging efficiency and reduces strain on the bucket.

Buckets themselves also experience wear, especially when used in tough conditions. Inspecting and replacing worn buckets ensures your excavator continues to perform at its best. By addressing these wear items promptly, you minimize downtime and maximize productivity.

Maintenance Tips for Mitsubishi Spare Parts

Routine Inspections to Prevent Downtime

Routine inspections are essential for keeping your excavator in top condition. Regularly checking your excavator parts helps you identify wear and tear before it leads to costly breakdowns. Start by inspecting hydraulic components, filters, and wear items like tracks and bucket teeth. Look for signs of leaks, cracks, or unusual wear. Pay attention to any changes in your excavator’s performance, such as reduced efficiency or strange noises. These could indicate underlying issues.

Create a maintenance schedule and stick to it. Daily visual checks and weekly detailed inspections can prevent unexpected failures. Use your equipment manual as a guide to ensure you don’t miss critical areas. By catching problems early, you minimize downtime and keep your excavator running smoothly.

Tip: Keep a log of your inspections. This helps you track the condition of your parts and plan replacements proactively.

Timely Replacement of Worn Parts

Replacing excavator parts at the right time is crucial for maintaining optimal performance. Worn parts, such as hydraulic hoses or bucket teeth, can strain other components and reduce efficiency. Delaying replacements increases the risk of sudden failures, which can halt your operations.

Monitor the condition of high-wear items and replace them as needed. For example, swap out filters regularly to protect your engine and hydraulic systems from contaminants. Use genuine Mitsubishi spare parts to ensure compatibility and durability. Timely replacements not only extend the life of your excavator but also save you money in the long run.

Note: Always have spare parts on hand to avoid delays when replacements are needed.

Proper Storage of Spare Parts

Proper maintenance includes storing your spare parts correctly. Poor storage conditions can damage parts, making them unusable when you need them most. Keep your spare parts in a clean, dry, and organized space. Avoid exposing them to moisture, extreme temperatures, or direct sunlight, as these can cause corrosion or degradation.

Label your parts clearly and store them in a way that makes them easy to access. Use shelves or bins to keep everything organized. This reduces the time spent searching for parts during repairs. Proper storage ensures your spare parts remain in excellent condition, ready for use when needed.

Reminder: Rotate your stock to use older parts first. This prevents them from becoming obsolete or deteriorating over time.

Choosing the right Mitsubishi excavator parts is essential for maintaining your equipment’s performance and longevity. High-quality parts ensure reliable operations and reduce the risk of costly downtime. Regular maintenance, including timely replacement of worn components like hydraulic hoses and filters, further extends your excavator’s lifespan.

Prioritize quality and compatibility over cost when selecting excavator parts. Durable, OEM components enhance functionality and minimize long-term expenses. Avoid low-quality or incompatible parts, as they can lead to inefficiencies and damage.

Work with reputable suppliers to guarantee authentic parts. Research online platforms, check reviews, and verify credentials to find reliable sources. By making informed decisions, you protect your investment and keep your excavator running smoothly in demanding conditions.

FAQ

What are the signs that my excavator parts need replacement?

Look for reduced performance, unusual noises, or visible wear on components like tracks, bucket teeth, or hydraulic hoses. Leaks in the hydraulic system or clogged filters also indicate the need for replacements. Regular inspections help you catch these issues early.

Can I use generic parts for my excavator?

Using generic parts may save money initially, but they often lack the durability and precision of genuine parts. This can lead to inefficiencies, frequent breakdowns, and higher long-term costs. Always prioritize authentic parts for optimal performance and reliability.

How do I find the right parts for my excavator?

Start by identifying your excavator’s make, model, and serial number. Use the equipment manual to locate part numbers. Share this information with a trusted supplier to ensure compatibility. Avoid guessing, as incorrect parts can damage your machine.

How often should I replace filters in my excavator?

Replace filters based on the manufacturer’s recommendations or when you notice reduced efficiency. Regular filter changes protect your engine and hydraulic systems from contaminants, ensuring smooth operation. Neglecting this can lead to costly repairs and downtime.

Why is it important to store spare excavator parts properly?

Proper storage prevents damage from moisture, extreme temperatures, or sunlight. Organizing parts in a clean, dry space ensures they remain in good condition. This saves time during repairs and avoids unnecessary expenses caused by degraded components.