Selecting the right excavator parts factory plays a critical role in keeping your heavy equipment running efficiently. You face challenges like ensuring part quality, evaluating supplier reputation, and balancing costs with long-term value. Timely delivery and reliable customer support also impact your operations. A dependable supplier, such as YNF Machinery, simplifies these concerns by offering high-quality, compatible parts that meet your needs. This ensures your excavator performs optimally, reducing downtime and operational disruptions.

Key Takeaways

Focus on quality when picking excavator parts. Good parts last longer and break less often.

Make sure the parts fit your excavator. Check part numbers and your manual to prevent problems.

Look at customer reviews to check the supplier’s reputation. A trusted supplier makes your work easier and safer.

Think about clear pricing when picking a supplier. Knowing costs helps you get good parts within your budget.

Work well with your parts supplier. A good relationship can mean lower prices, faster help, and useful tips.

Key Factors to Consider When Choosing an Excavator Parts Factory

Quality Standards in Heavy Equipment Parts

When buying heavy equipment parts, quality should always be your top priority. High-quality parts ensure durability, efficiency, and safety for your excavator. They withstand the rigorous demands of construction projects, reducing unexpected breakdowns and costly repairs. For example, superior-grade hydraulic couplings prevent leakages and maintain optimal hydraulic pressure, which enhances operational efficiency. Regular maintenance with high-quality parts also prevents premature engine wear and extends the lifespan of your equipment. Neglecting this can lead to frequent failures and increased downtime, which disrupts your project requirements. Always choose an excavator parts factory that prioritizes quality and compatibility in its products.

Compatibility with Your Excavator Models

Ensuring compatibility between your excavator and replacement parts is crucial for optimal performance. Parts that do not fit correctly can cause operational inefficiencies and even damage your equipment. To avoid this, verify part numbers and specifications before making a purchase. Consulting your excavator’s manual or the manufacturer’s recommendations can also help you choose the right excavator parts. Whether you are working with different excavator size classes or a specific model, selecting compatible parts ensures smooth operations. A reliable excavator parts supplier will guide you in finding the right-sized excavator components for your project.

Cost Transparency and Affordability

Cost transparency plays a significant role when choosing an excavator parts factory. A trustworthy supplier provides clear pricing details, helping you balance cost and quality effectively. The table below highlights key factors influencing cost transparency:

Factor | Description |

|---|---|

Quality | The quality of parts affects their performance and longevity, influencing overall costs. |

Compatibility | Parts must be compatible with the machinery to ensure efficient operation, impacting costs. |

Supplier Reputation | A supplier’s reputation reflects their reliability and quality, which can affect pricing. |

Price vs. Quality | Balancing cost and quality is crucial; lower prices may lead to higher long-term maintenance costs. |

When you buy from a reputable supplier, you gain access to high-quality parts at competitive prices. This ensures your excavator needs are met without compromising your budget. Always evaluate the supplier’s reputation and pricing structure to make informed decisions for your project.

Reputation of the Excavator Parts Supplier

The reputation of an excavator parts supplier plays a pivotal role in determining the success of your operations. A supplier with a strong reputation ensures you receive high-quality parts and dependable service, minimizing risks and downtime. Evaluating a supplier’s reputation involves considering several key indicators.

Reliability: A reputable supplier consistently delivers high-quality parts on time, ensuring your projects stay on schedule.

Customer Reviews: Feedback from other businesses provides valuable insights into the supplier’s service quality and reliability.

Warranty and Return Policies: These policies protect your investment, offering peace of mind in case of defective or incompatible parts.

Timely Delivery: Prompt delivery reduces equipment downtime, keeping your operations running smoothly.

Support Services: Expert assistance for technical issues demonstrates the supplier’s commitment to customer satisfaction.

Online reviews and ratings are excellent tools for assessing a supplier’s reputation. They reveal patterns in product quality and service reliability. Reviews often highlight how suppliers handle customer inquiries and resolve issues, giving you a clear picture of their professionalism. Additionally, mentions of timely deliveries in reviews reflect the supplier’s adherence to deadlines. Comparing reviews across multiple suppliers helps you benchmark their performance and make informed decisions.

Choosing a reputable excavator parts supplier ensures you receive reliable products and services. This not only enhances your equipment’s performance but also builds a long-term partnership that supports your business growth. Always prioritize suppliers with a proven track record of excellence and customer satisfaction.

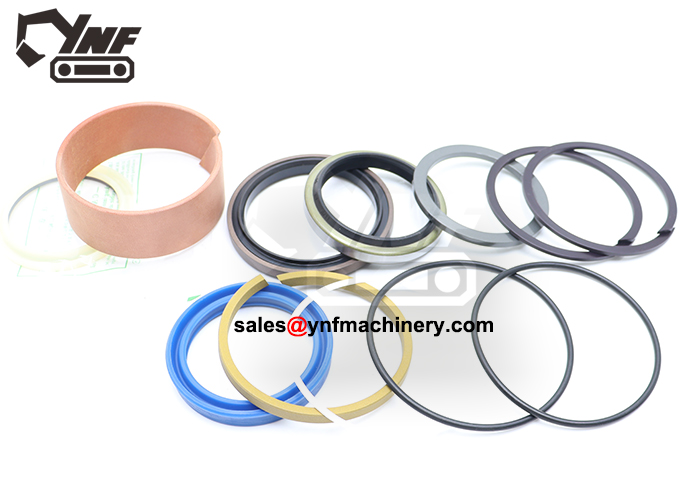

Types of Excavator Parts and Their Specific Requirements

Excavator Engine Parts and Their Importance

Excavator engine parts form the backbone of your machine’s performance. These components power the excavator, enabling it to handle demanding tasks like digging and lifting. High-quality replacement parts, such as pistons, crankshafts, and turbochargers, ensure the engine operates efficiently under tough conditions. Regular maintenance and timely replacement of these parts prevent engine wear and extend the lifespan of your equipment.

When selecting replacement parts, focus on compatibility with your excavator model. For instance, an engine overhaul kit tailored to your machine ensures seamless integration and optimal performance. Reliable suppliers like YNF Machinery offer a wide range of excavator spare parts, including both OEM and aftermarket options, to meet your specific needs. Investing in durable engine components reduces downtime and enhances productivity, making them a critical aspect of heavy equipment parts management.

Excavator Couplings for Power Transmission

Excavator couplings play a vital role in transmitting power from the engine to the hydraulic pump system. These replacement parts ensure smooth and efficient operation by compensating for misalignments and absorbing vibrations. High-quality couplings, such as Centaflex-A or Bowex models, enhance the reliability of your excavator, minimizing the risk of mechanical failures.

When choosing replacement parts for couplings, prioritize durability and ease of installation. Materials like high-grade elastomers and metals withstand the stresses of heavy equipment parts usage. Properly maintained couplings not only improve operational efficiency but also reduce wear on other components. By selecting the right excavator spare parts, you ensure consistent performance and lower maintenance costs.

Hydraulic Components for Precision and Reliability

Hydraulic components are essential for the precision and reliability of your excavator. These parts enable smooth and powerful movements, making them indispensable for tasks requiring accuracy. High-quality hydraulic replacement parts, such as pumps, hoses, and valves, directly impact the efficiency and safety of your machine.

Using superior-grade hydraulic couplings prevents leakages and maintains optimal pressure, enhancing operational efficiency.

The table below outlines specific requirements for hydraulic components:

Component | Description |

|---|---|

Oil Reservoir | Stores hydraulic fluid and cools it, reducing contaminants. |

Hydraulic Pump | Pumps fluid; gear and piston pumps are common, with piston pumps being more efficient. |

Excavator Engine | Powers the hydraulic pump; diesel engines are preferred for efficiency. |

Safety Release Valve | Releases excess pressure to prevent damage; must be rated for the correct pressure. |

Main Control Valve | Controls fluid flow to actuators, enabling movement. |

Filters | Keep hydraulic fluid clean to prevent system failure; placed in multiple locations. |

Hydraulic Fluid | Transmits power and lubricates components. |

Hydraulic Hoses | Must withstand high pressure; made of durable materials. |

Oil Cooler | Helps manage heat in the system, prolonging component life. |

Linear Actuators | Enable linear motion; typically hydraulic cylinders. |

Rotary Actuators | Enable rotary motion; typically hydraulic motors. |

By maintaining these hydraulic replacement parts, you ensure your excavator performs with precision and reliability. This attention to detail reduces downtime and maximizes the lifespan of your heavy equipment parts.

Attachments and Accessories for Versatility

Attachments and accessories transform your excavator into a multi-functional tool, enabling you to tackle a wide range of tasks with ease. These components act as extensions of the machine, allowing operators to perform jobs that would otherwise require additional equipment. Whether you need to dig trenches, break concrete, or lift heavy materials, the right attachment can significantly enhance your excavator’s capabilities.

Here are some of the most versatile attachments and accessories you can consider:

Rippers: These attachments excel at breaking through tough ground conditions, such as compacted soil or frozen terrain. They operate quickly and quietly, making them ideal for challenging environments.

Hydraulic Thumbs: Perfect for handling irregularly shaped materials, hydraulic thumbs provide secure clamping and improved control. They are indispensable for tasks like moving debris or loading logs.

By using these attachments, you can increase your excavator’s versatility and efficiency. For example, a hydraulic breaker allows you to demolish concrete structures, while a grapple simplifies material handling. Each attachment is designed to optimize performance for specific tasks, reducing the need for multiple machines on-site. This not only saves time but also lowers labor and operational costs.

Tip: Regularly inspect and maintain your attachments to ensure they perform at their best. Proper care extends their lifespan and keeps your operations running smoothly.

Attachments also improve productivity by streamlining workflows. Instead of switching between machines, you can rely on a single excavator equipped with the right tools. This adaptability makes your equipment more valuable, especially in industries like construction, mining, and landscaping. By investing in high-quality accessories, you maximize your excavator’s potential and achieve better results on every project.

Evaluating a Reliable Parts Supplier Like YNF Machinery

Customer Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into the reliability of a supplier. They highlight key aspects such as product quality, compatibility, and service efficiency. When evaluating a reliable parts supplier, pay attention to recurring themes in customer feedback. These themes often reflect the supplier’s strengths and areas of expertise.

Theme | Description |

|---|---|

Quality | Customers emphasize the importance of high-quality parts that meet their expectations. |

Compatibility | Reviews often mention the need for parts that are compatible with specific excavator models. |

Supplier Reputation | A strong reputation is frequently highlighted as a key factor in choosing a reliable supplier. |

Timely Delivery | Customers stress the necessity of prompt delivery to avoid equipment downtime. |

Customer Support | Access to knowledgeable support is valued for resolving issues and ensuring proper part selection. |

Positive reviews about YNF Machinery often highlight its commitment to delivering high-quality parts and excellent customer service. Testimonials also praise the company’s ability to provide compatible components for various excavator models. By considering customer feedback, you can gauge whether a supplier aligns with your business needs.

Warranty and Return Policies

Warranty and return policies significantly impact your trust in a supplier. A comprehensive warranty program not only protects your investment but also reflects the supplier’s confidence in their products. Suppliers offering warranties often justify higher price points by providing peace of mind against defects. This assurance encourages repeat purchases and fosters long-term relationships.

Evidence | Explanation |

|---|---|

Warranties can justify higher price points | Customers feel more secure making a purchase when they know they have protection against defects, which enhances trust. |

Warranties boost repeat purchases | Satisfied customers are more likely to return for future purchases, indicating increased trust in the supplier. |

Comprehensive warranty programs create a competitive edge | Suppliers that offer better warranties can attract more customers, enhancing their reputation and trustworthiness. |

YNF Machinery offers warranties on all its products, ensuring you receive reliable parts. Their return policies are straightforward, making it easier to address any issues with defective or incompatible components. These policies demonstrate the company’s dedication to customer satisfaction.

Delivery and Logistics Support

Efficient delivery and logistics support are essential for minimizing downtime and maintaining smooth operations. A reliable parts supplier ensures timely delivery, reducing the risk of project delays. YNF Machinery excels in this area by offering fast shipping and comprehensive logistics assistance. Their global reach ensures you receive the parts you need, regardless of your location.

Timely delivery not only keeps your equipment running but also enhances your overall experience with the supplier. YNF Machinery’s logistics team provides detailed tracking information, allowing you to plan your operations effectively. This level of support underscores the company’s commitment to reliability and customer satisfaction.

Comparing OEM vs. Aftermarket Excavator Parts

Why Choose OEM Parts for Your Excavator

OEM (Original Equipment Manufacturer) parts are designed specifically for your excavator by the original manufacturer. These parts ensure a perfect fit and maintain the machine’s original performance. By using OEM parts, you benefit from their durability and efficiency, which are essential for modern construction needs. For example, high-quality hydraulic couplings prevent leakages and maintain hydraulic pressure, enhancing operational safety and efficiency.

OEM parts undergo rigorous testing to meet strict quality standards. This guarantees reliability and reduces the risk of breakdowns, saving you from costly repairs. Additionally, they often come with warranties, offering peace of mind and protecting your investment. While OEM parts may have higher upfront costs, their long-term value makes them a preferred choice for critical components.

Benefits of Aftermarket Parts from Reliable Suppliers

Aftermarket parts provide a cost-effective alternative to OEM parts. These parts are manufactured by third-party companies and often cost up to 60% less than OEM options. Reliable suppliers ensure that aftermarket parts meet or exceed industry standards, offering comparable performance. In some cases, aftermarket parts can even outperform OEM parts, depending on the manufacturer.

One of the biggest advantages of aftermarket parts is the variety of options available. You can choose from a wide range of manufacturers, giving you flexibility in terms of price and quality. However, it’s crucial to source these parts from reputable suppliers to avoid quality inconsistencies. Trusted suppliers like YNF Machinery ensure you receive high-quality aftermarket parts that enhance your excavator’s performance without breaking your budget.

Deciding Between OEM and Aftermarket Based on Needs

When deciding between OEM and aftermarket parts, consider your excavator’s specific requirements. For critical components, such as engine parts or hydraulic systems, OEM parts guarantee quality and compatibility. On the other hand, aftermarket parts are ideal for less critical components, offering significant cost savings.

Evaluate factors like budget, quality, and warranty coverage. While OEM parts provide assurance and long-term reliability, aftermarket parts offer affordability and variety. If you buy or rent an excavator for short-term use, aftermarket parts may be a practical choice. Balancing these factors ensures you make the best decision for your equipment and operational needs.

Tips for Long-term Value and Cost Management

Building Strong Relationships with Your Excavator Parts Supplier

Establishing a strong relationship with your excavator parts supplier is essential for ensuring consistent access to high-quality heavy equipment parts. A reliable supplier becomes a valuable partner in your supply chain, helping you maintain smooth operations and reduce downtime. Building this partnership requires mutual trust and collaboration.

Reliable suppliers deliver parts promptly, ensuring your equipment remains operational.

Customer reviews and testimonials provide insights into a supplier’s reliability and service quality.

By fostering a long-term relationship, you gain access to better pricing, priority service, and expert advice. This collaboration also allows you to plan your projects more effectively, knowing that your supplier will meet your needs without delays.

Regular Maintenance and Inventory Planning

Effective maintenance and inventory planning are critical for minimizing downtime and extending the lifespan of your heavy equipment parts. Following best practices ensures your excavator operates efficiently throughout its lifecycle.

Conduct daily inspections to check engine oil, hydraulic fluid, coolant, and fuel levels.

Follow the manufacturer’s maintenance schedule for periodic checks at specified intervals.

Use maintenance management software to log activities and findings for better tracking.

Report significant issues immediately to prioritize repairs and avoid costly breakdowns.

Additionally, maintaining an organized inventory prevents delays during critical projects. Keep a log of frequently replaced parts and store them in a climate-controlled environment to avoid damage. Using a first-in, first-out method ensures older parts are used first, reducing waste and maintaining quality.

Tip: Clean the undercarriage weekly to prevent buildup that could lead to repairs. Regularly inspect high-wear areas like bucket teeth and tracks to address issues early.

Staying Updated on Market Trends in Heavy Equipment Parts

Staying informed about emerging trends in the heavy equipment parts market helps you make strategic decisions for your projects. Manufacturers are constantly innovating to improve efficiency, safety, and environmental impact.

Compact excavators, such as Hitachi’s ZAXIS-7, are designed for urban work sites, offering better task efficiency.

Mini excavators now feature advanced hydraulic systems and electrification to reduce emissions.

New models, like Caterpillar’s Cat® 320 Next Gen, include computerized features and built-in telematics for enhanced performance.

Date | Company | Product Name | Key Features |

|---|---|---|---|

April 2023 | Caterpillar Inc. | Cat® 320 Next Gen | New computerized features, built-in telematics for improved performance. |

September 2022 | Doosan Infracore | DX225LC-7 | Operator visibility and control improvements. |

October 2022 | Hyundai Construction | HX210AL | Enhanced safety measures, increased visibility with cameras and alarms. |

By keeping up with these advancements, you can invest in parts and equipment that align with modern standards, ensuring your projects remain competitive and efficient.

Selecting the right excavator parts factory is essential for maintaining operational efficiency and reducing costs. Focus on quality and compatibility to ensure your excavator performs optimally. Research supplier reputation through reviews and certifications to guarantee reliability. A dependable supplier provides timely delivery and robust customer support, minimizing downtime. High-quality parts, whether OEM or aftermarket, offer durability and safety, meeting the demands of modern construction. By balancing cost with long-term value, you can save on maintenance and enhance productivity. Prioritize these factors to make informed decisions that align with your business goals.

Quality parts ensure durability and efficiency, reducing the risk of breakdowns and costly repairs.

FAQ

1. How do I ensure compatibility when purchasing excavator parts?

You should verify the part numbers and specifications against your excavator’s manual. Consult the supplier for guidance if needed. Reliable suppliers like YNF Machinery provide expert support to help you select compatible parts for your specific excavator model.

2. What is the difference between OEM and aftermarket parts?

OEM parts are made by the original manufacturer, ensuring a perfect fit and high quality. Aftermarket parts, produced by third-party companies, offer cost-effective alternatives. Both options can meet your needs, but you should choose based on your budget and the criticality of the part.

3. Why is supplier reputation important when buying excavator parts?

A reputable supplier ensures you receive high-quality parts and dependable service. This reduces downtime and operational risks. Look for customer reviews, testimonials, and warranty policies to evaluate a supplier’s reliability before making a purchase.

4. How can I reduce downtime when waiting for replacement parts?

Maintain an inventory of frequently replaced parts to avoid delays. Partner with a supplier like YNF Machinery that offers fast shipping and logistics support. Planning ahead ensures you have the necessary components when needed.

5. What should I consider when choosing hydraulic components?

Focus on durability, pressure ratings, and compatibility with your excavator. High-quality hydraulic parts, such as pumps and hoses, ensure precision and reliability. Regular maintenance and proper installation also extend the lifespan of these components.

Tip: Always use hydraulic fluid recommended by the manufacturer to maintain system efficiency.