Choosing good crawler excavator parts is very important. It helps your machine work well and saves money. Bad or wrong parts can cause more breakdowns and less efficiency. They can also make your machine wear out faster. For example, newer mid-size Caterpillar excavators use 20% less fuel. They also cost less to fix when using good parts. This saves money and increases profits. Using the right parts keeps your excavator running smoothly. It also prevents wasting time on repairs.

Key Takeaways

Pick the correct parts for your excavator to work better and save money.

Check your job type and surroundings to find parts that fit your needs.

Focus on quality and fit instead of cheap prices to prevent breakdowns and extra costs later.

Look up sellers and read reviews to get good parts and helpful support.

Keep a repair log to track fixes and checks, making your excavator last longer and work well.

Identifying Your Needs for Crawler Excavator Parts

Assessing Work Type and Application

To pick the right excavator, know what tasks it will do. Different excavators work best for specific jobs. Mini excavators are great for small spaces and light work. Bigger excavators are better for heavy construction tasks. Think about whether you’ll dig, lift, or demolish. Each job needs certain features, like bucket size or lifting power.

Tip: Match your excavator type to your work needs. This helps it work better and last longer.

Studies show work type affects how well excavators perform. For example, a study found terrain and task difficulty impact efficiency. At one site with blasting work, machines moved 28.18 cubic meters per hour. This shows why picking the right equipment is so important.

Evaluating Terrain and Environmental Conditions

Your worksite affects the parts your excavator needs. Rocky, muddy, or uneven ground needs specific tracks. Strong tracks work well on rough ground, while rubber tracks suit soft areas.

Think about weather and environment too. Heat, humidity, and dust can wear out parts faster. Hot areas may need heat-resistant parts. Dusty places need better filters.

Terrain Type | Recommended Excavator Features |

|---|---|

Rocky | Strong tracks, tough buckets |

Muddy | Wide tracks for balance |

Urban | Small size, quiet operation |

Note: Knowing your worksite saves money on repairs and keeps your machine running well.

Understanding Machine Specifications and Requirements

Before buying, learn your excavator’s details. Sizes range from small ones under 13,000 lbs. to big ones for large jobs. Mini excavators are cheaper and easy to move, good for small tasks. Big ones lift more and handle heavy work.

Important features include:

Bucket capacity: How much material it can carry at once.

Engine power: Helps with tough jobs.

Mobility: Choose wheels or tracks based on your ground.

Operator comfort: Good seats and controls boost work speed.

Fuel efficiency: Saves money over time.

Pro Tip: Make sure parts fit your excavator’s size and type. This avoids problems and keeps it running smoothly.

Knowing these details helps you pick the best equipment. It also makes your work faster and saves money.

Excavator Selection Considerations for Key Parts

Ensuring Compatibility with Your Crawler Excavator

Picking the right parts for your excavator is very important. Each machine has its own design and needs specific parts. Wrong parts can cause damage or make it work poorly. For example, tracks and rollers must fit your excavator’s size and weight. If they don’t match, they wear out faster and work less efficiently.

Check your excavator’s manual or ask the manufacturer for help. Find details like size, weight limits, and other features. If you’re unsure, talk to a trusted supplier for advice.

Tip: Always check part numbers and details before buying. This simple step saves time and money later.

Evaluating Material Quality and Durability

Good materials make your excavator parts last longer and work better. Strong materials help your machine handle tough jobs without breaking often. Undercarriage parts need to be extra durable since they face constant wear.

Here are some brands known for strong materials:

GFM: Makes undercarriage parts that last at least one year or 2,000 hours.

DMC Wear Parts: Offers tough parts that fit many machines and resist wear.

SAIVS: Provides strong, wear-resistant materials and custom options for heavy equipment.

Choose materials based on your work type. For rocky ground, pick wear-resistant alloys. For soft ground, lighter materials might work better.

Pro Tip: Spending more on strong materials now saves money on repairs later.

Considering Brand Reputation and Reliability

The brand you pick matters for how well your parts work. Well-known brands usually have good quality and happy customers. They also offer better warranties and replacement options.

Read reviews to learn about different brands. Look for feedback on parts like tracks, rollers, and sprockets. A good brand will meet or exceed industry standards every time.

Note: Avoid unknown brands, even if they’re cheaper. Poor quality parts cost more in repairs and replacements over time.

By focusing on compatibility, material strength, and trusted brands, you can keep your excavator working well for a long time.

Balancing Cost-Effectiveness and Long-Term Value

Picking parts for crawler excavators needs careful thought. Cheap parts may seem good but cost more later. They wear out fast and need frequent repairs. Spending more on strong parts saves money over time. These parts last longer and work better.

A Cost-Benefit Analysis (CBA) helps you decide wisely. It compares a part’s price to its benefits. This ensures your money is spent well. For example, durable undercarriage parts cost more upfront. But they lower repair costs during their use.

Maintenance costs also affect the total ownership price. Regular care keeps your excavator reliable and working longer. This reduces downtime and improves productivity. Over time, this saves money.

Think about resale value too. Good parts keep your excavator’s worth high. New parts are reliable and may have payment plans. Used parts cost less and lose value slower.

Tip: Don’t just look at the price. Think about how a part affects your machine’s work, care needs, and value over time.

Checking Availability of Replacement Parts and Support

Getting replacement parts quickly is very important. Reliable suppliers help you avoid delays and keep projects moving.

Suppliers offer different parts and services. For example:

Supplier | Parts Offered | Extra Services |

|---|---|---|

Takeuchi | Genuine parts | Dealer locator worldwide |

MacAllister | New, used, remanufactured parts | Cat dealer in Indiana and Michigan |

ConEquip | Many excavator parts | Help from parts specialists |

Pick suppliers with many parts and good support. Takeuchi offers real parts and a global locator to find dealers. ConEquip gives expert help to find the right parts.

Pro Tip: Choose suppliers known for quality and great service. This ensures you get good parts and advice when needed.

By focusing on smart spending, long-term savings, and trusted suppliers, you can keep your excavators working well and avoid extra costs.

Tips for Evaluating Suppliers and Manufacturers

Verifying Certifications and Industry Standards

Certifications show if suppliers are trustworthy for crawler excavators. Look for ISO9001/2015 certification. This proves they follow strict rules and meet quality checks. Suppliers should also follow ASTM, AWS, or EN standards. These ensure parts are safe and work well.

Good suppliers check every step carefully. They test raw materials for size and strength. During production, they check surface quality and how parts work. Before shipping, they inspect to make sure parts meet your needs.

Tip: Pick suppliers who test machines in real conditions. They should check assembly, brakes, and hydraulic systems.

Reviewing Warranties and Return Policies

Warranties protect your money when buying replacement parts. A good warranty covers defects and ensures high-quality parts. Some suppliers offer warranties for up to 2,000 hours or one year.

Return policies should be simple and fair. Good suppliers take back defective or wrong parts without trouble. This saves you time and money if problems happen.

Note: Always read warranty and return policy details. This avoids surprise costs and makes returns easier.

Analyzing Customer Reviews and Testimonials

Customer reviews help you learn about a supplier’s reliability. Positive reviews often mention fast delivery, good parts, and helpful service. Look for reviews about less downtime and lower maintenance costs.

Trusted suppliers can cut maintenance costs by 20% and downtime by 30%. This makes your crawler excavator work better and saves money.

Metric/Benchmark | Description |

|---|---|

Technical Expertise | Suppliers need ISO9001/2015 certification and follow ASTM, AWS, or EN standards. |

Parts Inventory Range | Managing inventory well is key; 70% of operations lack proper timing for maintenance. |

Cost of Unplanned Downtime | Unplanned downtime costs $250,000 per hour, showing why parts availability matters. |

Maintenance Cost Reduction | Reliable suppliers lower maintenance costs by 20%. |

Equipment Downtime Reduction | Quality suppliers reduce equipment downtime by 30%. |

Pro Tip: Check reviews on different websites for a full picture of a supplier’s performance.

Comparing Pricing and Delivery Options

When buying crawler excavator parts, compare prices and delivery times. Good suppliers offer fair prices and quick shipping. This keeps your projects running smoothly.

Things to Check When Comparing Prices

Prices depend on the part type, material, and supplier. To save money:

Watch for extra fees: Some suppliers charge for shipping or handling.

Look for bulk deals: Buying many parts together can lower costs.

Ask about payment plans: Some suppliers let you pay over time.

Tip: Don’t pick the cheapest parts without checking their quality. Cheap parts break faster and cost more to fix.

Delivery Speed and Trustworthiness

Fast shipping keeps your machine working. Delays can stop work and waste time. Choose suppliers who:

Let you track your order easily.

Offer same-day or next-day shipping for urgent needs.

Have a good record of delivering on time.

Supplier Name | Delivery Speed | Tracking Available |

|---|---|---|

ConEquip | Same-day shipping | Yes |

MacAllister | Next-day delivery | Yes |

Takeuchi | Standard shipping | No |

Note: Fast and reliable shipping avoids delays and saves money.

Balancing Cost and Delivery

It’s important to balance price and delivery speed. Paying a bit more for faster shipping can reduce downtime and save money.

Pro Tip: Ask suppliers if they guarantee delivery times. A supplier with delivery promises shows they care about customers.

By comparing prices and delivery options, you can get parts quickly without spending too much.

Maintenance Tips for Crawler Excavator Parts

Doing Regular Checks and Preventive Care

Regular checks keep your crawler excavator in good shape. These checks help find problems early and avoid costly repairs. Focus on important parts like the engine, hydraulic system, and undercarriage. For example:

Check engine oil, hydraulic fluid, coolant, and fuel daily.

Do maintenance every 250, 500, or 1,000 hours for reliability.

Look for damage, check key parts, and test safety devices.

Keep records of all checks and repairs. This helps track your machine’s condition and plan fixes. Regular care can make excavators last longer. Many work up to 9,800 hours before needing big repairs. Mini-excavators can last about 10,000 hours with good care.

Tip: Teach operators and staff the best ways to maintain machines. This improves safety and saves time.

Storing and Handling Parts the Right Way

Store and handle excavator parts properly to keep them in good condition. Follow these tips:

Take care of fluids: Use stabilizers to keep fuel fresh in storage.

Maintain batteries: Remove batteries and use chargers to avoid draining.

Protect from weather: Store parts in clean, dry places to avoid damage.

Keep records: Write down all repairs and maintenance for better planning.

Inspect before storing: Check parts for problems before putting them away.

Pro Tip: Keep parts safe from moisture and heat to stop rust and wear.

Picking Genuine Parts Instead of Cheaper Options

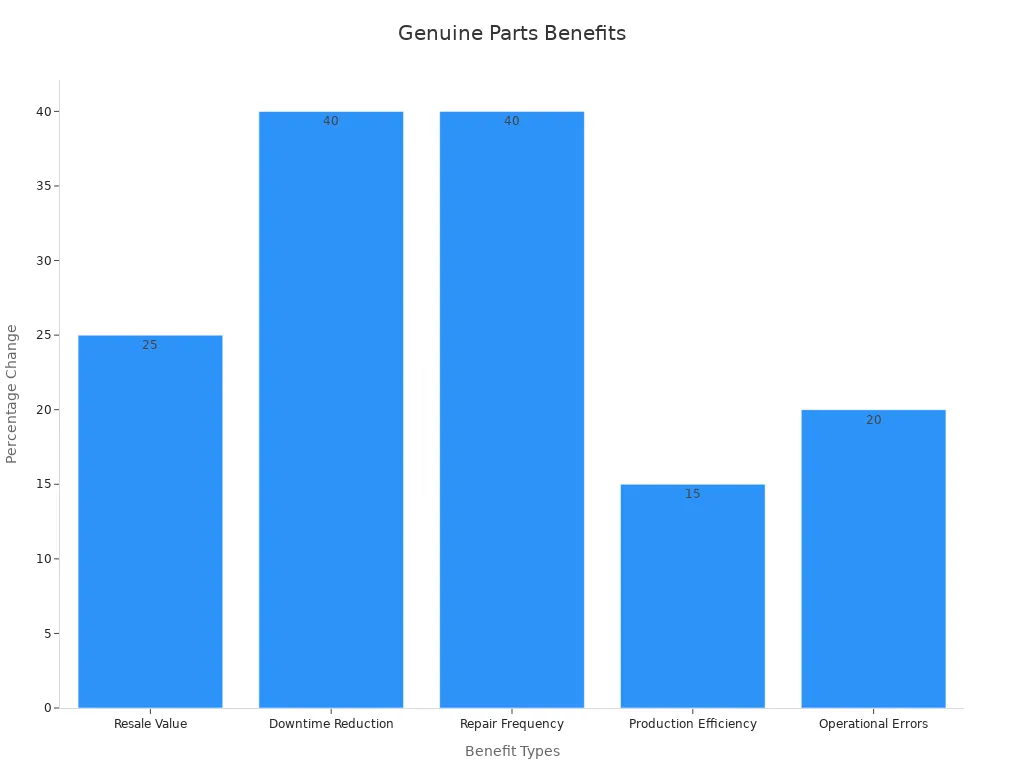

Genuine parts work better and last longer than aftermarket ones. They meet strict ISO rules and pass tough quality tests. Here’s why genuine parts are worth it:

Benefit | Proof |

|---|---|

Higher Resale Value | Machines with genuine parts sell for 25% more. |

Less Downtime | Genuine parts cut downtime by 40%. |

Fewer Repairs | Repairs happen 40% less often with genuine parts. |

Better Efficiency | Mining jobs see 15% more efficiency using genuine parts. |

Fewer Errors | Companies report 20% fewer mistakes with genuine parts. |

Note: Spending on genuine parts saves money over time and boosts machine performance.

Keeping a Maintenance Log for Performance Tracking

A maintenance log helps your crawler excavator work better. It keeps track of repairs, part changes, and inspections. This makes sure nothing is missed. Logs show patterns and help predict problems early. They also make planning care easier.

Benefits of a Maintenance Log

Longer Equipment Life: Fix small issues before they get worse.

Save Money: Catch problems early to avoid big repair costs.

Better Productivity: A cared-for machine works smoothly with less downtime.

Tip: Use apps or digital tools to update logs easily.

What to Include in Your Maintenance Log

Write down key details about your excavator’s care and use. Include these:

Inspection Dates: Record when you check the engine, tracks, and hydraulics.

Parts Changed: Note the part name, date, and where you bought it.

Service History: Add oil changes, filter swaps, and other routine tasks.

Performance Notes: Write down strange sounds or lower efficiency.

Maintenance Task | How Often | Important Notes |

|---|---|---|

Engine Oil Check | Daily | Watch for leaks or low levels. |

Hydraulic Fluid Change | Every 500 hours | Use the right fluid for your machine. |

Undercarriage Inspection | Weekly | Look for damage or worn parts. |

How to Use the Log Effectively

Check your log often to find patterns. If one part breaks a lot, it might not fit well or be low quality. Share the log with your team so everyone follows the same care steps.

Pro Tip: Save a backup copy of your log to protect your data.

Keeping a detailed log helps your excavator last longer, saves money, and boosts performance.

Common Mistakes to Avoid When Choosing Excavator Parts

Ignoring Compatibility with Your Machine

Using parts that don’t fit your excavator causes big problems. Each machine has specific needs like size and weight. Wrong parts can make it work poorly or wear out faster. For example, tracks that don’t fit can increase repair costs.

Always check your manual for the right part details. If unsure, ask a trusted supplier or manufacturer for help. They can recommend parts that match your machine perfectly.

Tip: Check part numbers and sizes before buying. This avoids costly mistakes.

Prioritizing Low Cost Over Quality

Cheap parts may seem like a good deal at first. But they often break quickly and need replacing often. This adds up to higher costs over time. For example, weak undercarriage parts can fail during tough jobs, causing delays and repairs.

Spending more on strong parts helps your machine last longer. Durable parts work better and reduce breakdowns. A cost-benefit analysis can show how quality saves money in the long run.

Pro Tip: Paying more for good parts now avoids expensive repairs later.

Overlooking Supplier Reputation and Reliability

Not all suppliers sell good parts or offer helpful service. Picking a bad supplier can mean getting poor-quality products. Reliable suppliers follow rules and give warranties for their parts.

Choose suppliers with good reviews and proven experience. They should help you find the right parts and offer great support. Avoid suppliers with bad return policies or poor customer service.

Note: Trusted suppliers give you better parts and expert advice.

Avoiding these mistakes keeps your excavator working well and saves money.

Neglecting Long-Term Operational Costs

Looking only at upfront costs can cost more later. When picking parts, think about how they affect long-term expenses. Cheap parts might save money now but wear out quickly. This leads to more replacements, downtime, and higher repair bills.

Strong parts cost more but need fewer repairs. For example, good undercarriage parts last longer and work better. This means less downtime and more work hours. Reliable parts also prevent sudden breakdowns that delay projects and raise labor costs.

Fuel use is another thing to check. Some parts, like hydraulic systems, affect fuel use. Efficient parts save fuel and lower costs over time. They also help the environment, which matters more in construction today.

Think about resale value too. Excavators with good parts keep their value longer. This makes selling or trading them easier. Keeping maintenance records shows buyers the machine was cared for well.

Tip: Don’t just look at the price. Think about how a part’s quality and efficiency affect total costs. This saves money and keeps your excavator running smoothly.

Picking the right parts helps your excavator work better and last longer. First, figure out what you need and check things like quality, fit, and supplier trust. These steps stop expensive mistakes and keep your machine working well.

Good suppliers and strong parts lower repair costs and downtime. Use the table below to remember what matters most when choosing parts:

Factor | Why It Matters |

|---|---|

Quality Check | Makes sure parts are tough and work well in hard jobs. |

Fit and Size | Ensures parts match your machine for smooth operation. |

Reading customer feedback helps you pick trusted sellers. |

Follow these tips to keep your excavator running smoothly and in great shape for a long time.

FAQ

What should I think about when picking crawler excavator parts?

Make sure the parts fit your machine and are strong. Check your machine’s details to find the right match. Using tough materials and trusted brands helps avoid breakdowns and saves money.

Tip: Check part numbers and read your machine’s manual before buying.

How do I know if a supplier is reliable?

Look for certifications like ISO9001/2015 and industry rules like ASTM. Read reviews from other buyers and check their warranties. Good suppliers sell quality parts and give great support.

Note: Stay away from suppliers with unclear return rules or bad service.

Are aftermarket parts as good as genuine ones?

Aftermarket parts cost less but don’t last as long. Genuine parts follow strict rules and work better. They help your machine run smoothly and need fewer repairs.

Comparison | Genuine Parts | Aftermarket Parts |

|---|---|---|

Durability | Very High | Medium |

Cost | Higher | Lower |

Efficiency | Excellent | Average |

How often should I check my crawler excavator parts?

Look at your parts every day for damage or wear. Do bigger maintenance checks every 250, 500, or 1,000 hours. Regular care keeps your machine working longer and avoids big repair bills.

Pro Tip: Write down all checks and fixes in a log to stay organized.

What if I can’t find the parts I need?

Ask your supplier or the company that made your machine. Many suppliers have tools to help you find parts or offer advice. You can also use remanufactured parts for a short time.

Tip: Pick suppliers with lots of parts and fast shipping to avoid delays.