Choosing the right swing motor excavator parts is essential for maintaining your machine’s performance and durability. High-quality components ensure smooth operation, reduce downtime, and minimize costly repairs. Using incompatible or low-quality parts can lead to inefficiencies, frequent breakdowns, and increased expenses. By making informed decisions when sourcing excavator spare parts, you not only enhance operational efficiency but also extend the lifespan of your equipment. Investing in reliable parts supports better fuel efficiency and aligns with modern construction demands, saving you money in the long run.

Key Takeaways

Choose high-quality swing motor parts to enhance your excavator’s performance and reduce downtime.

Always verify compatibility by checking part numbers and specifications against your excavator’s manual.

Prioritize OEM parts for guaranteed fit and reliability, as they meet the exact specifications of your machine.

Research suppliers thoroughly; look for positive reviews and industry certifications to ensure quality.

Balance cost and quality by avoiding overly cheap parts that may lead to hidden expenses in repairs.

Consult experts or trusted suppliers when in doubt to avoid costly mistakes and ensure optimal performance.

Regularly maintain and inspect swing motor parts to extend the lifespan of your excavator and improve operational efficiency.

Understanding Swing Motor Excavator Parts

What Are Swing Motor Excavator Parts?

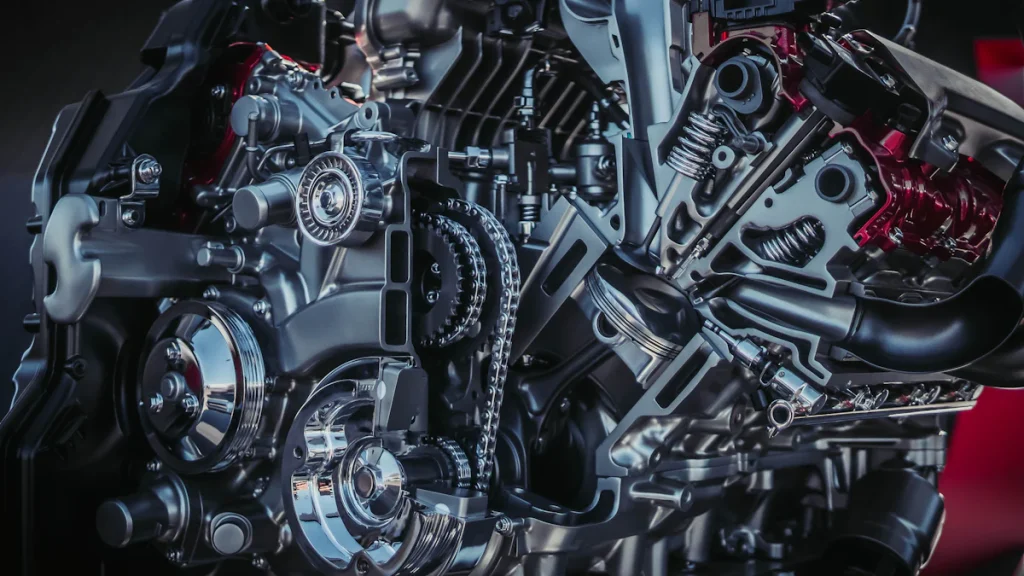

Overview of the swing motor’s role in excavator operation.

The swing motor plays a vital role in the operation of an excavator. It enables the machine’s upper structure to rotate horizontally, allowing you to position the boom and bucket assembly with precision. This rotation is essential for tasks like digging, loading, and dumping materials efficiently. The swing motor operates using hydraulic pressure, which drives its internal mechanisms to create the rotational movement. By facilitating smooth and controlled rotation, the swing motor enhances the excavator’s versatility and performance across various applications.

Key components of swing motor excavator parts and their functions.

Swing motor excavator parts consist of several key components that work together to ensure optimal functionality:

Hydraulic Pump: Supplies pressurized hydraulic fluid to power the swing motor.

Motor Mechanism: Converts hydraulic pressure into rotational motion, enabling the excavator’s superstructure to pivot.

Control Valves: Regulate the flow of hydraulic fluid, ensuring precise and smooth operation.

Bearings and Gears: Support the motor’s rotation and transfer torque effectively.

Seals and O-rings: Prevent hydraulic fluid leaks, maintaining system efficiency.

Each component plays a specific role in ensuring the swing motor operates reliably. Understanding these parts helps you maintain your excavator and address potential issues effectively.

Why Are Swing Motor Excavator Parts Important?

Impact on excavator performance and efficiency.

Swing motor excavator parts directly influence the machine’s performance and efficiency. High-quality components ensure smooth and precise rotation, which is critical for completing tasks accurately. A well-functioning swing motor reduces operational delays, minimizes fuel consumption, and enhances overall productivity. By maintaining these parts in excellent condition, you can maximize the efficiency of your excavator and achieve better results on construction sites.

Consequences of using incorrect or low-quality parts.

Using incorrect or low-quality swing motor parts can lead to significant problems. Incompatible components may cause operational inefficiencies, such as jerky movements or reduced rotation speed. Low-quality parts often wear out quickly, resulting in frequent breakdowns and costly repairs. Additionally, these issues can compromise the safety of your equipment and delay project timelines. To avoid these risks, always choose reliable and compatible swing motor excavator parts that meet your machine’s specifications.

Key Factors to Consider When Choosing Swing Motor Excavator Parts

Compatibility

Importance of matching parts to your excavator model.

Choosing swing motor excavator parts that match your machine’s model is critical for seamless operation. Each excavator is designed with specific dimensions, hydraulic systems, and performance requirements. Using parts that align with these specifications ensures smooth integration and optimal functionality. For example, a mismatch in size or hydraulic pressure capacity can lead to inefficiencies or even damage to the swing motor. Always verify the part numbers and specifications provided by the manufacturer to avoid compatibility issues.

Common compatibility issues and how to avoid them.

Compatibility issues often arise when parts are sourced without proper verification. Common problems include incorrect dimensions, mismatched hydraulic flow rates, or incompatible mounting configurations. To avoid these pitfalls:

Consult your excavator manual: It provides detailed information about compatible parts.

Check part numbers: Match the numbers on your existing components with those of the replacement parts.

Seek expert advice: Reach out to a trusted supplier or mechanic for guidance.

Taking these steps minimizes the risk of operational disruptions and ensures your excavator performs at its best.

Quality

Benefits of durable materials and high-quality manufacturing.

High-quality parts made from durable materials significantly enhance the performance and lifespan of your excavator. Components crafted with precision and robust materials resist wear and tear, even under demanding conditions. For instance, seals and gears made from premium alloys or reinforced polymers maintain their integrity longer, reducing the need for frequent replacements. Investing in high-quality parts also improves fuel efficiency and reduces downtime, saving you money over time.

Why OEM parts are often the best choice for excavator spare parts.

OEM (Original Equipment Manufacturer) parts are specifically designed to meet the exact specifications of your excavator. They ensure a perfect fit and reliable performance. Unlike some aftermarket alternatives, OEM parts undergo rigorous testing to guarantee quality and compatibility. While aftermarket parts can sometimes offer cost savings, their quality varies widely. OEM parts provide peace of mind, as they are built to the same standards as the original components. When in doubt, prioritize OEM parts to maintain your machine’s reliability and efficiency.

Supplier Reputation

How to assess a supplier’s reliability and trustworthiness.

A reliable supplier plays a crucial role in ensuring you receive high-quality parts. To evaluate a supplier’s reputation:

Research online reviews: Look for feedback from other customers to gauge their experiences.

Check certifications: Reputable suppliers often hold industry certifications that reflect their commitment to quality.

Ask about warranties: A supplier offering warranties demonstrates confidence in their products.

These steps help you identify trustworthy suppliers who prioritize customer satisfaction.

Importance of customer reviews and testimonials.

Customer reviews and testimonials provide valuable insights into a supplier’s reliability. Positive reviews highlight consistent product quality and excellent service. Pay attention to feedback about delivery times, product durability, and after-sales support. Testimonials from industry professionals or long-term customers carry extra weight, as they reflect real-world experiences. By considering these reviews, you can make informed decisions and choose a supplier that meets your expectations.

Cost

Balancing affordability with quality.

When selecting swing motor excavator parts, balancing cost and quality is crucial. High-quality parts may come with a higher price tag, but they offer long-term value by reducing the frequency of replacements and minimizing downtime. Investing in durable components ensures your excavator operates efficiently, saving you money on repairs and fuel consumption over time.

To strike the right balance, consider the following:

Evaluate the part’s material and build: Durable materials, such as reinforced alloys or high-grade polymers, often justify their cost through extended lifespan and reliability.

Compare OEM and aftermarket options: OEM parts guarantee compatibility and performance, while reputable aftermarket parts can provide cost-effective alternatives without compromising quality.

Assess warranties and support: Parts with warranties and reliable customer support offer added assurance, making them worth the investment.

By focusing on quality, you safeguard your excavator’s performance and avoid unnecessary expenses in the future.

Avoiding the pitfalls of overly cheap parts.

Choosing the cheapest option might seem appealing, but it often leads to hidden costs. Overly cheap parts are typically made from inferior materials, which wear out quickly and compromise your excavator’s efficiency. These parts may also lack precise compatibility, causing operational issues or even damage to your machine.

To avoid these pitfalls:

Research the supplier’s reputation: Trustworthy suppliers prioritize quality and provide detailed product information.

Inspect product specifications: Ensure the parts meet your excavator’s requirements to prevent performance issues.

Seek expert advice: Consult with professionals or experienced suppliers to identify reliable yet affordable options.

Investing in well-made swing motor excavator parts protects your equipment and ensures smooth operation, making it a smarter choice than opting for the cheapest alternatives.

Steps to Ensure Compatibility of Swing Motor Excavator Parts

Check Part Numbers and Specifications

How to locate part numbers on your excavator.

Finding the correct part numbers is the first step in ensuring compatibility. You can locate these numbers on the swing motor itself or in the excavator’s maintenance manual. Manufacturers often engrave part numbers on the surface of the component or attach a label for easy identification. If the part number is unclear, inspect the swing motor closely for any markings or consult the machine’s documentation. Keeping these numbers handy simplifies the process of sourcing the right swing motor excavator parts.

Verifying specifications with the manufacturer or manual.

Once you have the part number, verify the specifications to ensure they match your excavator’s requirements. Cross-check the details with the manufacturer’s catalog or website. Specifications such as size, hydraulic pressure capacity, and material composition must align with your machine’s design. If you are unsure, reach out to the manufacturer or supplier for confirmation. This step prevents costly mistakes and ensures the new part integrates seamlessly with your equipment.

Consult the Excavator Manual

Using the manual to identify compatible parts.

Your excavator manual is an invaluable resource for identifying compatible parts. It provides detailed information about the swing motor and its components, including part numbers, dimensions, and performance requirements. Refer to the manual when selecting replacement parts to avoid mismatches. The manual also includes diagrams and instructions that help you understand how the swing motor fits into the overall system, making it easier to choose the right components.

Importance of following manufacturer recommendations.

Following the manufacturer’s recommendations ensures optimal performance and longevity for your excavator. These guidelines are based on extensive testing and engineering expertise. Using parts that deviate from these recommendations can lead to inefficiencies, premature wear, or even damage to the swing motor. Always prioritize parts that meet the manufacturer’s standards to maintain the reliability and safety of your equipment.

Seek Expert Advice

When to consult a mechanic or supplier for guidance.

If you encounter challenges in identifying or sourcing the correct parts, consulting a professional can save you time and effort. Mechanics and suppliers have the expertise to guide you through the selection process. They can assess your excavator’s condition, recommend suitable swing motor excavator parts, and provide insights into installation. Seeking expert advice is particularly helpful when dealing with complex compatibility issues or when the required part is unavailable.

Benefits of professional input in avoiding costly mistakes.

Professional input minimizes the risk of errors that could lead to operational disruptions or additional expenses. Experts can identify potential compatibility issues, recommend high-quality parts, and ensure the new components integrate smoothly with your excavator. Their guidance helps you avoid the pitfalls of using incorrect or substandard parts, ultimately saving you money and extending the lifespan of your equipment.

Evaluating Quality and Materials of Swing Motor Excavator Parts

Importance of Durable Materials

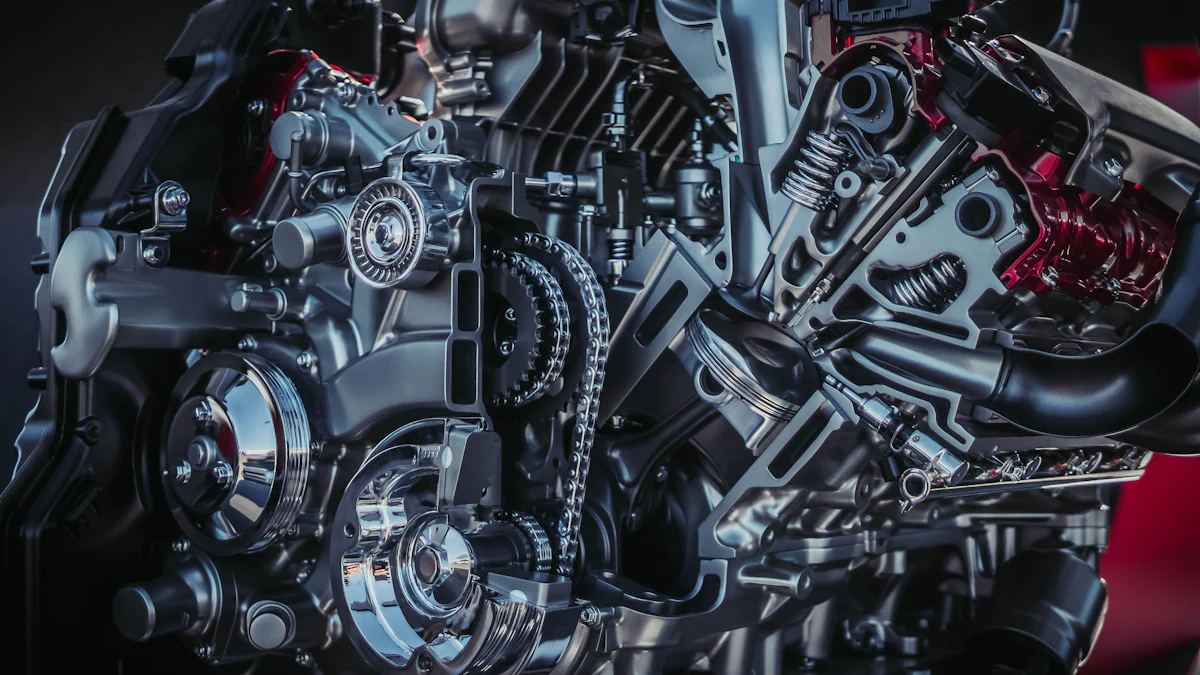

How material quality affects part longevity and performance.

The quality of materials used in swing motor parts directly impacts their durability and performance. High-quality materials resist wear and tear, even under extreme working conditions. For example, components made from reinforced alloys or hardened steel can withstand heavy loads and high pressure without deforming. This durability reduces the frequency of replacements, saving you time and money.

Using substandard materials, on the other hand, can lead to premature failures. Weak seals may cause hydraulic fluid leaks, while poorly constructed gears can break under stress. These issues not only disrupt operations but also increase repair costs. By prioritizing quality materials, you ensure that your excavator operates efficiently and reliably over time.

Common materials used in high-quality swing motor parts.

Manufacturers of high-quality parts often use materials specifically chosen for their strength and resilience. Some common materials include:

Hardened Steel: Ideal for gears and bearings due to its ability to handle high stress and resist wear.

Reinforced Polymers: Frequently used for seals and O-rings, offering flexibility and resistance to hydraulic fluid.

Alloy Composites: Provide a balance of strength and lightweight properties, making them suitable for various components.

These materials undergo rigorous testing to ensure they meet industry standards. Choosing parts made from such materials guarantees better performance and a longer lifespan for your excavator.

OEM vs. Aftermarket Parts

Pros and cons of OEM parts.

OEM (Original Equipment Manufacturer) parts are designed to match the exact specifications of your excavator. They offer several advantages:

Perfect Fit: OEM parts integrate seamlessly with your machine, ensuring smooth operation.

Reliable Performance: These parts undergo extensive testing to meet the manufacturer’s quality standards.

Warranty Coverage: Many OEM parts come with warranties, providing added peace of mind.

However, OEM parts can be more expensive than aftermarket alternatives. While the higher cost reflects their quality and compatibility, it may not always fit within every budget.

When aftermarket parts might be a viable option.

Aftermarket parts can serve as a cost-effective alternative to OEM components. Reputable suppliers produce aftermarket parts that meet or exceed OEM standards. These parts often provide similar performance at a lower price, making them an attractive option for budget-conscious buyers.

To ensure you choose reliable aftermarket parts, follow these tips:

Research the Supplier: Look for reviews and certifications to verify the supplier’s credibility.

Compare Specifications: Match the part’s dimensions and materials with your excavator’s requirements.

Seek Expert Advice: Consult a trusted mechanic or supplier to confirm the part’s suitability.

While aftermarket parts can save money, always prioritize quality to avoid compromising your excavator’s performance. YNF Machinery offers both OEM and high-quality aftermarket options, ensuring you find the right balance between cost and reliability.

Choosing a Reliable Supplier for Swing Motor Excavator Parts

Researching Supplier Reputation

Checking online reviews and ratings.

When selecting a supplier for swing motor parts, online reviews and ratings provide valuable insights. These reviews reflect the experiences of other customers, helping you gauge the supplier’s reliability. Look for consistent positive feedback about product quality, delivery times, and customer service. Avoid suppliers with frequent complaints about defective parts or delayed shipments. Platforms like Google Reviews or industry-specific forums often host detailed evaluations from professionals who have used the supplier’s products.

Importance of industry certifications and accreditations.

Certifications and accreditations indicate a supplier’s commitment to quality and industry standards. Reputable suppliers often hold certifications such as ISO 9001, which ensures adherence to strict manufacturing and quality control processes. These credentials demonstrate that the supplier prioritizes excellence and reliability. Always verify if the supplier has certifications relevant to the excavator industry. This step ensures you receive parts that meet high-performance standards and align with your equipment’s requirements.

Evaluating Customer Support

How responsive and knowledgeable customer service can help.

Responsive and knowledgeable customer service simplifies the process of sourcing swing motor parts. A reliable supplier provides prompt answers to your questions, helping you identify the right components for your excavator. Their team should have a deep understanding of swing motor systems and be able to guide you through compatibility checks. Quick responses to inquiries about part specifications, availability, and shipping timelines reflect a supplier’s dedication to customer satisfaction.

Signs of a trustworthy supplier.

Trustworthy suppliers exhibit several key traits. They maintain clear communication, ensuring transparency about pricing, warranties, and return policies. Their website or catalog should provide detailed product descriptions, including part numbers and specifications. Additionally, they often offer technical support to assist with installation or troubleshooting. Suppliers who prioritize these aspects demonstrate their commitment to building long-term relationships with customers.

Warranty and Return Policies

Why a good warranty is essential.

A strong warranty protects your investment in swing motor parts. It guarantees that the supplier stands behind the quality of their products. Warranties provide assurance that you can replace or repair defective parts without incurring additional costs. This is especially important for critical components like swing motors, where failures can disrupt operations. Always review the warranty terms to understand the coverage period and conditions.

Understanding return policies to avoid issues.

Clear return policies ensure a hassle-free resolution if you receive incorrect or damaged parts. A reliable supplier outlines the steps for returning items, including timelines and required documentation. Familiarize yourself with these policies before making a purchase. This preparation helps you avoid unexpected challenges and ensures a smooth process if you need to exchange or return parts.

Pro Tip: YNF Machinery excels as a trusted supplier for swing motor excavator parts. With over 35 years of experience, they offer high-quality components backed by rigorous quality inspections, competitive pricing, and exceptional customer support. Their commitment to reliability makes them an excellent choice for your excavator needs.

Comparing Prices for Swing Motor Excavator Parts

Tips for Balancing Cost and Quality

How to avoid overly cheap parts that compromise quality.

When comparing prices for swing motor parts, you might feel tempted to choose the cheapest option. However, overly cheap parts often come with hidden risks. These parts are usually made from inferior materials, which can wear out quickly or fail under pressure. This not only disrupts your excavator’s operation but also leads to higher repair costs in the long run. To avoid this, always prioritize parts made from quality materials that meet industry standards. Look for suppliers who provide detailed product descriptions and certifications to ensure the parts are reliable.

Pro Tip: Established dealers often offer better support and warranties than individual sellers. A reliable warranty can save you significant costs if a part fails unexpectedly.

Identifying fair pricing for swing motor parts.

Fair pricing reflects a balance between cost and quality. To identify reasonable prices, research the market and compare rates from multiple suppliers. Pay attention to the material quality, manufacturing process, and compatibility of the parts. High-quality parts may cost more upfront, but they reduce downtime and maintenance expenses over time. Avoid deals that seem too good to be true, as they often compromise on durability and performance.

Remember: Trusted suppliers often provide transparent pricing and detailed specifications. This transparency helps you make informed decisions without compromising your excavator’s efficiency.

Shopping Around

Benefits of comparing prices from multiple suppliers.

Shopping around allows you to explore a variety of options and find the best value for your money. Different suppliers may offer varying prices for the same part, depending on their sourcing and overhead costs. By comparing prices, you can identify competitive deals without sacrificing quality. Additionally, reading customer reviews and testimonials helps you assess the reliability of each supplier.

For example, a supplier with consistently positive feedback on product durability and delivery times is more likely to meet your expectations. This step ensures you invest in parts that enhance your excavator’s performance.

When to negotiate for better deals.

Negotiation can be a valuable tool when purchasing swing motor parts, especially if you’re buying in bulk. Many suppliers are open to offering discounts or flexible terms to secure your business. Before negotiating, research the average market price for the part you need. Use this information to justify your request for a better deal. Highlight your long-term purchasing potential to strengthen your position.

Tip: Suppliers like YNF Machinery often provide competitive pricing and low minimum order quantities. Their customer-centric approach ensures you receive high-quality parts at fair prices, making them an excellent choice for your excavator needs.

Why Choose YNF Machinery for Excavator Spare Parts

YNF Machinery’s Expertise in Swing Motor Excavator Parts

Over 35 years of experience in providing high-quality excavator spare parts.

With over 35 years of industry experience, YNF Machinery has established itself as a trusted name in the excavator spare parts market. This extensive expertise ensures that you receive parts designed to meet the highest standards of performance and durability. YNF Machinery understands the unique demands of excavators and delivers solutions tailored to enhance their efficiency and reliability. Their long-standing presence in the industry reflects their commitment to quality and customer satisfaction.

Rigorous quality inspections to ensure reliable performance.

YNF Machinery prioritizes quality at every step. Each part undergoes rigorous inspections to ensure it meets strict performance criteria. These inspections focus on material strength, precision, and compatibility, guaranteeing that the parts perform reliably under demanding conditions. By choosing YNF Machinery, you can trust that the parts you receive will maintain your excavator’s performance and reduce the risk of unexpected failures.

Comprehensive Product Range

Availability of excavator couplings, Excavator Engine Parts, and Hydraulic Cylinder Seal Kits.

YNF Machinery offers a wide range of products to meet your excavator’s needs. Their inventory includes essential components such as excavator couplings, engine parts, and hydraulic cylinder seal kits. These parts are crafted to address common maintenance and repair challenges, ensuring your machine operates smoothly. Whether you need to replace worn-out seals or upgrade your engine components, YNF Machinery provides reliable solutions to keep your excavator running efficiently.

Compatibility with over 26 excavator brands.

Finding compatible parts for your excavator can be challenging, but YNF Machinery simplifies the process. Their products are designed to fit over 26 excavator brands, ensuring seamless integration with your machine. This compatibility reduces the risk of operational issues and ensures that the parts work harmoniously with your equipment. By offering such a diverse range, YNF Machinery makes it easier for you to find the right parts without compromising on quality.

Customer-Centric Services

Competitive pricing and low minimum order quantities.

YNF Machinery understands the importance of balancing cost and quality. They offer competitive pricing, making high-quality parts accessible without straining your budget. Additionally, their low minimum order quantities allow you to purchase only what you need, reducing unnecessary expenses. This flexibility ensures that businesses of all sizes can benefit from their products and services.

Comprehensive support, including documentation and logistics assistance.

Purchasing excavator spare parts involves more than just selecting the right components. YNF Machinery provides comprehensive support to streamline the process. Their team assists with documentation, ensuring you have all the necessary information for installation and maintenance. They also offer logistics support, helping you receive your parts promptly and efficiently. This customer-focused approach ensures a hassle-free experience, allowing you to focus on maintaining your excavator’s performance.

Pro Tip: Choosing YNF Machinery means partnering with a supplier that values quality, compatibility, and customer satisfaction. Their expertise, product range, and support services make them an ideal choice for your excavator spare parts needs.

Understanding swing motor parts is essential for maintaining your excavator’s performance and longevity. By ensuring compatibility, prioritizing quality, and selecting a reliable supplier, you can avoid costly mistakes and keep your machine running efficiently. YNF Machinery stands out as a trusted partner with over 35 years of expertise, offering high-quality parts that meet OEM standards. Take your time, consult experts, and make informed decisions to protect your investment and enhance your excavator’s operational efficiency.

FAQ

What are the key factors to consider when choosing swing motor parts for your excavator?

When selecting swing motor parts, focus on compatibility, quality, supplier reputation, and price. Ensure the parts match your excavator model to avoid operational issues. Opt for high-quality materials that enhance durability and performance. Choose a reputable supplier with positive reviews and industry certifications. Balancing cost and quality is essential to ensure long-term reliability.

How can you verify the compatibility of swing motor parts?

To verify compatibility, check the part numbers and specifications in your excavator’s manual. Cross-reference these details with the supplier’s catalog or website. If you’re unsure, consult the manufacturer or a trusted mechanic. This ensures the parts fit seamlessly and function correctly with your machine.

Why should you prioritize OEM parts over aftermarket options?

OEM (Original Equipment Manufacturer) parts are designed to meet the exact specifications of your excavator. They offer a perfect fit, reliable performance, and often come with warranties. While aftermarket parts can be cost-effective, their quality varies. Reputable aftermarket options may meet or exceed OEM standards, but always research the supplier before purchasing.

How do high-quality materials impact the performance of swing motor parts?

High-quality materials, such as hardened steel and reinforced polymers, resist wear and tear under demanding conditions. These materials ensure durability, reduce the frequency of replacements, and maintain efficient operation. Poor-quality materials can lead to premature failures, increasing downtime and repair costs.

What steps can you take to avoid purchasing low-quality parts?

To avoid low-quality parts, research the supplier’s reputation and read customer reviews. Verify product specifications and ensure they meet your excavator’s requirements. Avoid overly cheap options, as they often compromise on material quality and durability. Consulting experts can also help you identify reliable parts.

How can you find a trustworthy supplier for swing motor parts?

Look for suppliers with positive online reviews, industry certifications, and transparent policies. A reliable supplier provides detailed product descriptions, responsive customer support, and clear warranty terms. YNF Machinery, for instance, has over 35 years of experience and a strong reputation for quality and reliability.

Why is it important to follow the manufacturer’s recommendations?

Manufacturer recommendations ensure the parts you choose align with your excavator’s design and performance standards. Using recommended parts prevents inefficiencies, reduces wear, and avoids potential damage to your machine. Always refer to the manual or consult the manufacturer for guidance.

What are the benefits of consulting experts when selecting swing motor parts?

Experts, such as mechanics or suppliers, provide valuable insights into part compatibility and quality. They help you avoid costly mistakes by recommending suitable components. Their guidance ensures the parts integrate smoothly with your excavator, enhancing its performance and longevity.

How does YNF Machinery stand out as a supplier of swing motor parts?

YNF Machinery offers over 35 years of expertise in providing high-quality excavator parts. Their products undergo rigorous quality inspections to ensure reliability. They provide a comprehensive range of parts compatible with over 26 excavator brands. Competitive pricing, low minimum order quantities, and excellent customer support make them a trusted choice.

What should you consider when comparing prices for swing motor parts?

When comparing prices, focus on the balance between cost and quality. Research market rates and avoid overly cheap options that compromise durability. Look for suppliers offering transparent pricing and warranties. Shopping around and negotiating, especially for bulk purchases, can help you secure better deals.