Choosing the right china excavator hydraulic parts for your project means you need to focus on quality, compatibility, and trusted supplier options. You want accessories that match your excavator’s brand and model, ensuring each hydraulic part fits perfectly. Many construction experts stress that high-quality, OEM-standard china excavator parts last longer under tough conditions. When you select accessories from a reliable supplier, you get warranties, expert support, and quick delivery. Your guide to finding the right parts should include checking brand, comparing accessories, and making sure each purchase meets your needs. This buyer’s guide helps you make a confident selection by reviewing china excavator parts, hydraulic accessories, supplier reputation, and brand quality. Always confirm the compatibility of accessories before you purchase, and choose a supplier who offers a wide range of china excavator hydraulic accessories and supports every purchase.

Tip: Prioritize accessories that meet strict quality standards and come from a supplier with a proven track record. This selection improves your excavator’s performance and reduces downtime.

Key Takeaways

Always check your excavator’s model and serial number to find parts that fit perfectly and avoid costly mistakes.

Choose hydraulic parts from trusted suppliers with ISO or CE certifications to ensure quality and reliable support.

Match each part carefully to your excavator’s specifications to prevent leaks, failures, and downtime.

Invest in high-quality materials and certified parts to boost durability and reduce maintenance costs.

Look for suppliers who offer strong after-sales service, fast delivery, and clear communication to keep your project on track.

Identify Excavator Parts

Confirm Model and Serial Number

You need to start by checking your excavator’s model and serial number. These numbers are usually stamped on the frame near the cab door. They help you match the right excavator parts and accessories to your machine. Serial numbers tell you the year, make, and model. This information helps you avoid mistakes when ordering excavator accessories. For example, John Deere part numbers give you details that make it easier to find the correct excavator parts for repairs or upgrades. Always look for unique numbers on the packaging and the parts themselves. You can scan QR codes or barcodes to confirm if the excavator accessories are genuine. If you have doubts, contact the dealer or check the numbers in official catalogs.

Tip: Only buy excavator accessories from trusted dealers. This step helps you avoid fake parts and keeps your excavator running smoothly.

Specify Hydraulic Part Needed

Next, you must know which hydraulic part you need. Excavator accessories include many hydraulic components, such as pumps, cylinders, hoses, and valves. You might also need a bucket or a breaker, depending on your project. Industry standards like PCSA Std. No. 3 and ISO 20474-5:2017 give clear rules for hydraulic excavator parts. These standards help you choose safe and reliable accessories. When you specify the hydraulic part, use the exact name and part number. This step makes sure you get the right excavator accessories for your machine.

Gather Technical Specs

You should collect all technical specs before you order excavator parts. Important details include the model, engine type, horsepower, bucket capacity, and operating weight. Serial numbers help you match the right excavator accessories to your machine’s year and version. Use the service manual to find diagrams and torque specs for each part. Many companies use ISO 9001 standards to check the quality of excavator accessories. They also use advanced tools like 3D printing and computer simulations to test new parts. Trusted labs, such as TÜV Rheinland and SGS, test excavator parts for strength and safety. Keeping good records of your excavator accessories helps you track changes and avoid mistakes.

Note: Always double-check technical specs before you buy new excavator parts. This habit saves you time and money.

Research China Excavator Parts Suppliers

Check Certifications (ISO, CE)

When you start your search for china excavator parts, always check if the supplier holds ISO or CE certifications. These certifications show that the supplier follows strict quality management systems. ISO 9001 certification is known worldwide for helping companies improve their focus on clients and meet high standards. CE certification means the products meet safety and quality rules for the European market. While these certifications do not guarantee perfect hydraulic parts, they do show that the supplier cares about quality and reliability. You should always prioritize a reputable supplier with these certifications. This step helps you avoid problems with low-quality excavator parts and ensures your selection meets industry standards.

Tip: A trusted supplier with ISO or CE certifications often provides better after-sales support and more reliable excavator parts.

Review Product Range

You need to look at the full product range when choosing china excavator hydraulic parts. A wide selection means the supplier can meet many needs for different excavator models and brands. For example, some suppliers like SPARKLING MACHINERY offer a large variety of excavator and engine components. They cover systems such as rubber, sealing, oil coolers, radiators, hydraulic, and engine parts. This broad selection shows the supplier has experience and can handle different requests. Top brands like XCMG Group, John Deere, Caterpillar, Komatsu, and Volvo also offer many types of excavator parts. These brands keep launching new products and forming partnerships, which proves their strength and reliability in the market.

Suppliers with a wide selection often:

Combine research, manufacturing, and training.

Maintain strong supply chains for fast delivery.

Provide after-sales support and training.

Serve customers in many countries.

Offer both OEM and aftermarket excavator parts.

When you see a supplier with a large selection, you know they can help with many types of excavator projects. This makes your selection easier and more reliable.

Compare Prices

Price matters when you buy china excavator parts, but you should not focus only on the lowest cost. The price of hydraulic parts depends on size, power, pump type, control system, and material quality. Gear pumps cost less, while piston pumps cost more but give better efficiency. Advanced control systems and custom features can raise the price, but they may lower your long-term costs by improving performance and reducing downtime.

When comparing prices, you should:

Look at the full cost, including shipping and any extra fees.

Ask for quotes from several suppliers.

Check if the supplier offers bulk discounts.

Think about installation, maintenance, and future repairs.

Choose mid-range options for the best balance between cost and quality.

You should always consider the long-term value, not just the first price you see. A reputable supplier will help you understand the full pricing structure. This approach helps you make a smart selection and avoid problems with low-quality excavator parts.

Note: Choosing a chinese supplier with a proven track record and a wide selection of china excavator parts helps you get the best value for your project.

Evaluate Part Compatibility and Quality

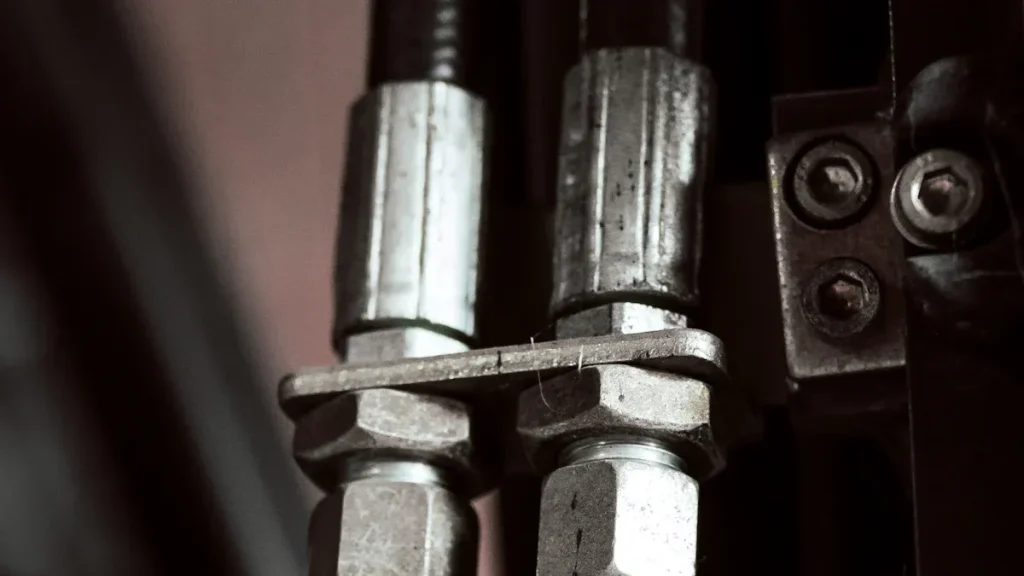

Match to Excavator Model

You need to make sure every hydraulic part matches your excavator model. Start by checking the model and serial number on your machine. These numbers help you find the right excavator parts and avoid costly mistakes. Always use official manuals or ask a professional technician if you feel unsure. Many experts use digital tools, like a vernier caliper, to measure parts and confirm the fit. You can also use accessory matching apps or number query systems to double-check compatibility before you buy.

Here are some steps to help you with finding the perfect fit:

Compare the new part with your old one using professional tools.

Check the hydraulic oil circuit pressure to see if it stays within the standard range.

Monitor the working pressure and temperature of your hydraulic system.

Inspect hydraulic cylinders for leaks and smooth piston movement.

Look for ISO9001 or third-party testing data to confirm quality and stable operation.

Tip: Always match the part to your excavator’s exact model and serial number. This step helps you avoid downtime and keeps your machine running at optimal performance.

Assess Material Quality

Material quality plays a big role in the durability and performance of your excavator. High-strength steel with special alloying elements makes hydraulic parts last longer. Many manufacturers use hard chrome plating on piston rods to stop corrosion and wear. Quality seals prevent leaks and keep your hydraulic system working smoothly. You should ask for material certificates to check if the parts meet industry standards and OEM requirements.

Durability testing is important. Manufacturers use fatigue tests, hydraulic pressure tests, and non-destructive methods like ultrasonic or magnetic particle inspections. These tests make sure the parts can handle heavy loads and tough jobs. High-quality excavator parts from trusted brands often pass these tests and come with proof of quality.

Key points to check for material quality:

High-quality materials increase the lifespan of excavator parts.

Certifications and OEM testing show the part meets strict standards.

Real-world data shows that using poor-quality parts can cause downtime, costing companies up to $260,000 per hour.

Investing in certified, high-quality excavator parts reduces maintenance costs and boosts performance.

Reputable suppliers, like Five Star Equipment, offer durable components that lower the risk of failure.

Note: Always choose parts with strong material quality and proven durability. This choice protects your investment and ensures optimal performance.

Avoid Low-Quality Options

Low-quality options may look cheaper at first, but they often lead to bigger problems. Poor materials can cause leaks, cracks, or even total failure of your hydraulic system. You might see issues with the bucket or breaker if the parts do not meet the right standards. Always check for detailed product information, including dimensions and adapter sizes. This information helps you avoid mismatches and ensures the part will fit your excavator.

You should always prioritize OEM or high-quality aftermarket parts. These parts go through strict quality checks and meet industry standards. They last longer and keep your excavator working at its best. Avoid parts that do not have clear certifications or come from unknown suppliers.

Signs of low-quality parts:

No material certificates or unclear product details.

Lack of ISO or CE certifications.

Poor reviews or no track record from the supplier.

Parts that do not match your excavator’s technical specs.

Alert: Using low-quality parts can lead to equipment failure, lost time, and high repair costs. Always invest in quality to keep your project on track.

Purchase and Supplier Support

Confirm After-Sales Service

When you make a purchase of excavator hydraulic parts, you should always check the after-sales service your supplier offers. Good after-sales support helps you with installation, troubleshooting, and regular maintenance. Companies that excel in after-sales service keep almost 70% more customers. This shows a strong link between support and customer loyalty. Timely maintenance after your purchase can lower costs over the life of your equipment. For heavy machinery, maintenance costs can reach over 20% of the original investment. Quick support and scheduled maintenance reduce these expenses and improve your satisfaction. Many companies use new technology like IoT and AI to monitor equipment and predict when maintenance is needed. This makes your purchase safer and more reliable.

Benefits of strong after-sales service:

Reduces maintenance costs

Increases customer loyalty

Boosts satisfaction and repeat purchase rates

Supports product innovation through feedback

Tip: Always ask your supplier about their maintenance plans and after-sales support before you make a purchase.

Check Delivery and Logistics

Prompt delivery is a key part of a successful purchase. You want your hydraulic parts to arrive on time, complete, and in good condition. Delivery performance is a main benchmark for supplier support. It measures if your order arrives when promised, with all parts included and undamaged. Delays or missing parts can cause problems with your maintenance schedule and slow down your project. Top suppliers use real-time shipment tracking and advanced planning tools. These help them avoid delays and keep your purchase on track. When you compare suppliers, look at their delivery accuracy and speed. Fast and reliable delivery means you can start maintenance right away and avoid costly downtime.

Note: Always review the supplier’s delivery record before you make a purchase. This step helps you avoid future maintenance issues.

Ensure Clear Communication

Clear communication with your supplier makes every purchase smoother. When you share your goals and needs, your supplier can help you choose the right parts and plan for maintenance. Case studies show that strong communication leads to better procurement results. For example, companies like Apple and Walmart use regular meetings and feedback to improve supplier relationships. This approach leads to fewer mistakes and better maintenance planning.

Ways to improve communication with your supplier:

Set clear requirements and share them early

Use regular updates to track your purchase and maintenance progress

Respect your supplier’s time with concise messages

Give feedback after each purchase to help improve future maintenance

Callout: Good communication helps you avoid errors, keeps your maintenance on schedule, and builds trust with your supplier.

Key Tips for China Excavator Hydraulic Parts

Double-Check Compatibility

You should always double-check the compatibility of your excavator accessories before making a purchase. This step in your guide helps you avoid costly mistakes and keeps your excavator running at optimal performance. When you match hydraulic parts to your machine, you reduce the risk of leaks, pressure loss, and equipment malfunctions. The CNTOPA article explains that damaged or leaking hydraulic lines often cause pressure loss and equipment failures. Regular inspections and timely replacements prevent these issues. Using high-quality, compatible accessories ensures your hydraulic system works as designed. The Louisiana CAT source also points out that human error, such as using incompatible parts, leads to hydraulic system failures. Double-checking compatibility helps you avoid installation errors and keeps your excavator accessories working smoothly.

Regular inspections help you spot early signs of wear.

High-quality, compatible accessories improve durability and performance.

Double-checking fit prevents operational failures.

Tip: Always use your buyer’s guide to confirm part numbers and technical specs. This habit supports finding the perfect fit for your excavator.

Verify Supplier Reliability

You need to choose a supplier with a strong reputation for quality and support. A reliable supplier offers a wide range of excavator accessories, including both OEM and aftermarket options. Look for suppliers who provide clear product details, certifications, and after-sales service. This guide recommends checking reviews and asking about maintenance support. A trusted supplier helps you with installation, troubleshooting, and regular maintenance. They also offer guidance on finding the right parts for your brand and model. Reliable suppliers help you maintain optimal performance and reduce downtime.

Callout: A good supplier stands behind their accessories and supports your maintenance needs.

Consider Working Conditions

You should always consider the working conditions of your excavator when selecting hydraulic accessories. Different job sites require different levels of durability and performance. For example, harsh environments need accessories made from high-quality materials. Your guide suggests checking if the accessories can handle extreme temperatures, heavy loads, or abrasive materials. Proper maintenance extends the life of your excavator accessories and keeps your machine at optimal performance. Always choose accessories that match your brand and meet the demands of your project. This approach ensures your excavator delivers reliable performance and reduces the risk of breakdowns.

Choose accessories designed for your specific working conditions.

Schedule regular maintenance to protect your investment.

Use your guide to compare brands and find the best fit for your needs.

Note: The right hydraulic accessories improve durability, boost performance, and make maintenance easier.

Choosing the right excavator accessories starts with checking model details, confirming part compatibility, and reviewing supplier certifications. Reliable suppliers offer accessories with ISO or CE certifications, which guarantee quality and safety. Always select accessories that match your excavator to avoid costly repairs and performance issues. Regular maintenance with certified accessories extends equipment life and reduces downtime. Consult manuals, use matching apps, and ask technicians for help. Stay updated on new accessories and maintenance tips to keep your excavator running smoothly. Contact suppliers for quotes and support to ensure you get the best quality and service.

Certified accessories:

Reduce equipment failures

Improve maintenance results

Protect your investment

FAQ

What are hydraulic parts, and why are they important for excavators?

Hydraulic parts control the movement and power of your excavator. They include pumps, cylinders, and hoses. These components ensure smooth operation and allow your machine to handle heavy loads efficiently. Without quality hydraulic parts, your excavator may experience performance issues or breakdowns.

How do you ensure the compatibility of excavator accessories?

Check your excavator’s model and serial number. Match these details with the part specifications provided by the supplier. Use official manuals or consult a technician to confirm compatibility. This step prevents mismatches and ensures the accessories fit perfectly.

Should you choose OEM or aftermarket hydraulic parts?

OEM parts guarantee compatibility and quality since they are made by the original manufacturer. Aftermarket parts can be a cost-effective alternative if they meet industry standards. Always prioritize durability and performance when selecting hydraulic accessories for your excavator.

How can you identify a reliable supplier for excavator accessories?

Look for suppliers with ISO or CE certifications. Check customer reviews and ask about after-sales support. A reliable supplier offers a wide range of accessories, clear product details, and timely delivery. This ensures you receive high-quality parts for your hydraulic system.

What maintenance tips help extend the life of hydraulic accessories?

Regularly inspect hydraulic components for leaks, wear, or damage. Replace worn-out parts promptly. Use high-quality hydraulic oil and follow the maintenance schedule in your excavator’s manual. Proper care ensures your accessories last longer and perform efficiently.