To choose the right china excavator final drive parts, start by identifying your excavator’s exact model, serial number, and key measurements. Always verify compatibility with your supplier and compare OEM with aftermarket options. Check certifications to ensure quality and review supplier reputation. Consider price and installation support before making a decision. Accurate selection of excavator parts reduces equipment failure rates and can lower maintenance costs by up to 20%. These steps help you avoid costly mistakes and keep your excavator running at peak performance.

Key Takeaways

Always identify your excavator’s exact model, serial number, and measurements before buying final drive parts to ensure a perfect fit.

Match part numbers and confirm all details with your supplier to avoid ordering wrong or incompatible parts.

Compare OEM and aftermarket parts carefully; OEM offers higher reliability, while aftermarket can save money if chosen wisely.

Check for ISO and CE certifications and research supplier reputation to guarantee quality and trustworthy service.

Consider price, value, and installation support together to get durable parts and smooth repairs that keep your excavator running strong.

Identify Excavator Specs

Model & Serial Number

You should always start by recording your excavator’s model and serial number. These two details help you find the correct excavator final drive and avoid costly errors.

Tip: Double-check the numbers on the machine’s data plate before you contact a supplier.

Here are five reasons why you must verify the accuracy of your model and serial number:

You need the exact equipment model and serial number to complete EPA form 3520-21.

Customs clearance and regulatory compliance depend on these details.

Accurate numbers help you avoid delays during customs processing.

You can prevent fraud by confirming the excavator’s identity.

Matching documentation with your actual equipment ensures proper due diligence.

When you provide the right information, you make it easier to match your excavator final drive components and final drive motors to your machine.

Weight & Track Type

You must also know your excavator’s operating weight and track type. These factors affect the size and power of the excavator final drive and travel motors you need.

Lighter excavators use smaller travel motors and final drive motors.

Heavier machines require stronger excavator final drive units for reliable travel.

Track type matters, too. Steel tracks and rubber tracks put different demands on your travel motor and final drive. You should always tell your supplier if your excavator uses steel or rubber tracks. This information helps you get the right excavator final drive for your travel needs.

Final Drive Measurements

Precise measurements make a big difference when you order a new excavator final drive. You should measure the mounting holes, shaft diameter, and flange size.

Note: Use a caliper or tape measure for accuracy.

If you give your supplier the correct measurements, you reduce the risk of fit issues with your travel motor or final drive. This step ensures your new excavator final drive and travel motors will install smoothly and work with your machine’s travel system.

You should always check these details before you buy, so your excavator final drive and travel motor deliver the best performance.

Compatibility for China Excavator Final Drive Parts

Choosing the right china excavator final drive parts requires you to focus on compatibility. You must match the correct excavator final drive to your machine. This step prevents costly downtime and avoids common excavator final drive problems. When you work with Chinese suppliers, you need to provide exact details. These include your excavator’s model, serial number, and precise measurements. Accurate information helps you avoid mistakes and ensures your new parts fit perfectly.

Match Part Numbers

You should always start by matching part numbers. Every excavator final drive and travel motor has a unique part number. This number links to your machine’s specifications.

Check your equipment manual for the correct part number.

Compare the number on your old final drive motor or travel motor with the supplier’s listing.

If you cannot find the number, ask your supplier for help.

Tip: Matching part numbers reduces the risk of ordering the wrong excavator final drive components. It also helps you avoid delays in your travel system repairs.

Confirm with Supplier

After you match the part numbers, confirm all details with your supplier. Chinese suppliers often request extra information to ensure compatibility.

Provide your excavator’s model, serial number, and measurements.

Share photos of your current final drive motors and travel motors.

Ask the supplier to double-check the fit for your machine.

A reliable supplier will review your information and confirm if the china excavator final drive parts will work. This step protects you from receiving incorrect parts and saves you time during installation.

Address Fit Issues

Sometimes, even with careful checks, fit issues can happen. You should prepare for this by discussing possible solutions with your supplier before you order.

Ask about the supplier’s return or exchange policy for excavator final drive parts.

Request detailed installation guides or diagrams for your travel motor and final drive.

If you notice any differences in mounting holes or shaft sizes, contact the supplier immediately.

Note: Addressing fit issues early helps you avoid extra costs and keeps your excavator running smoothly. Quick action also prevents long delays in your travel system repairs.

You can avoid most compatibility problems by following these steps. Always provide full details, match part numbers, and confirm everything with your supplier. This approach ensures your excavator final drive, travel motors, and other parts will fit and perform as expected.

OEM vs. Aftermarket Excavator Final Drive

OEM Pros & Cons

When you select an OEM excavator final drive, you choose a part made by the original manufacturer. This option offers several advantages:

OEM parts guarantee a perfect fit and full compatibility with your excavator final drive system.

Research shows that OEM parts extend the life of your equipment and reduce the risk of major repairs.

You receive a warranty and reliable performance, which helps prevent unexpected breakdowns.

Although OEM parts cost more upfront, they lower your total operating expenses by reducing downtime and repair frequency.

Following the recommended maintenance schedule with OEM parts can help your engine and hydraulic pump last longer.

Note: Cheaper aftermarket parts may seem attractive, but they often lead to more frequent failures and higher long-term costs.

However, you should also consider the drawbacks. OEM excavator final drive parts usually cost more and may have longer lead times, especially if you order from overseas.

Aftermarket Pros & Cons

Aftermarket excavator final drive parts offer a different set of benefits. You can often find these parts at a lower price, which helps you save money, especially for non-critical components. Many aftermarket suppliers provide quality parts that meet industry standards. If you need a quick replacement, aftermarket options are often more readily available.

Still, you must weigh the risks. Aftermarket parts may not always match the exact specifications of your original excavator final drive. This mismatch can lead to fit issues or reduced performance. While you might save money at first, you could face higher ownership costs if the part fails sooner than expected.

Choosing the Best Excavator Final Drives

You need a clear decision-making process when choosing the best excavator final drives. Consider the following comparison:

Criteria / Aspect | OEM Model Characteristics | ODM (Aftermarket) Model Characteristics |

|---|---|---|

Design Participation | Follows purchaser’s exact specifications | Manufacturer designs based on your requirements |

Intellectual Property | Owned by purchaser | Shared or divided as per contract |

Cost and Budget | Higher upfront, predictable from past data | Lower upfront, but includes design and testing costs |

Project Cycle | Faster mass production | Requires more stages: design, testing, verification |

Quality Control | Stable process, strict inspection | Combined design and production checks |

Performance Verification | Consistent monitoring (SPC, Cpk/PPK) | Simulation, prototyping, third-party testing |

Risk Factors | Drawing errors, supply delays, quality fluctuations | Design feasibility, verification gaps, IP disputes |

Response Strategies | Technical reviews, confidentiality agreements | Simulation, prototype testing, milestone controls |

Tip: Always review your project needs, budget, and risk tolerance before making a choice. OEM parts deliver the highest reliability for your excavator final drive, but aftermarket options can offer value if you select a reputable supplier.

By understanding these differences, you can make an informed decision and ensure your excavator final drive delivers the performance and durability you expect.

Quality & Supplier Check

Certifications (ISO, CE)

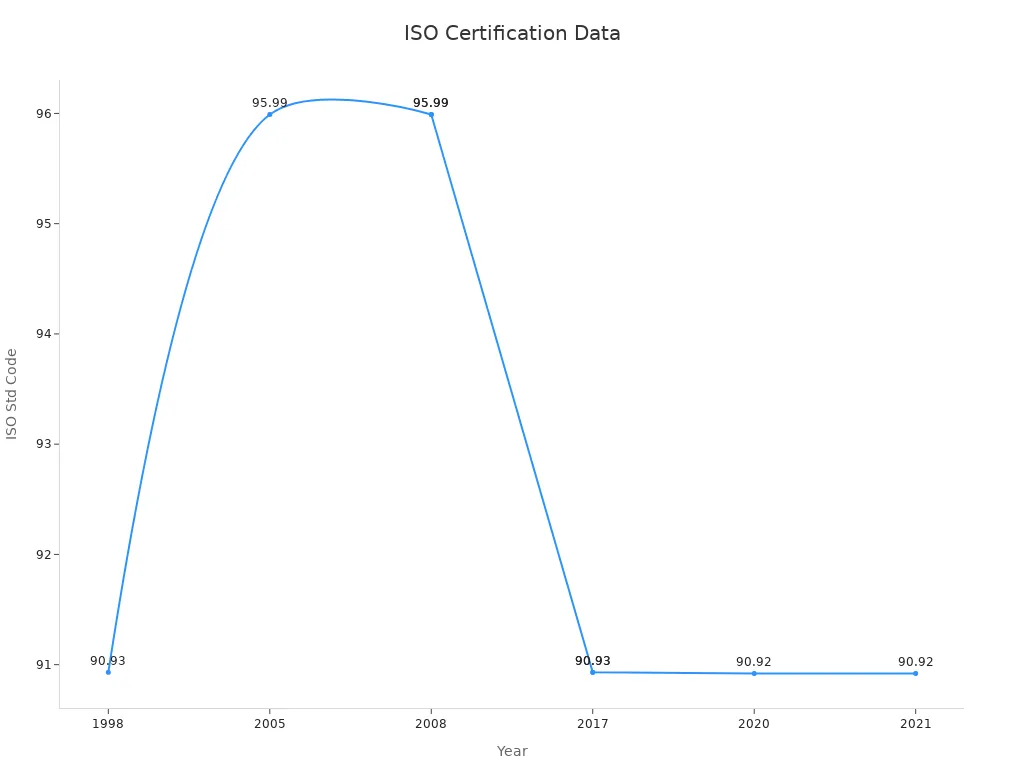

You should always check for ISO and CE certifications before you buy excavator final drive parts. These certifications show that the parts meet strict safety and performance standards. ISO standards cover many areas, such as operator safety, machine control, and hydraulic system performance. The table below lists some important ISO standards for excavator parts:

ISO Standard Code | Year | Focus Area | Description |

|---|---|---|---|

95.99 | 2005 | Safety requirements for remote operator control | ISO 15817:2005 – Earth-moving machinery safety |

90.92 | 2020 | Worksite data exchange – Telematics data | ISO/TS 15143-3:2020 |

90.93 | 2017 | Lifting and tying-down attachment points – Performance requirements | ISO 15818:2017 |

95.99 | 2008 | Machine-control systems – Performance criteria and tests for functional safety | ISO 15998:2008 |

90.92 | 2021 | Functional safety – Tables of performance levels | ISO/TS 19014-5:2021 |

90.93 | 1998 | Hydraulic excavators – Laboratory tests and performance requirements for operator protective guards | ISO 10262:1998 |

95.99 | 2008 | Safety – General requirements for earth-moving machinery | ISO 20474-1:2008 |

90.93 | 2017 | Safety – General requirements for earth-moving machinery | ISO 20474-1:2017 |

You can see how these standards have changed over time in the chart below:

When you choose parts with ISO and CE marks, you help protect your equipment and your team. These certifications also show that the manufacturer cares about quality.

Supplier Reputation

You should always research the reputation of any supplier before you place an order. A reliable supplier will have a strong track record of delivering quality parts and quality travel motors. Look for suppliers who have been in business for several years and who can provide proof of their certifications. You can also check if the supplier works with well-known brands or has industry awards.

Tip: Ask the supplier for references or case studies. This step helps you see how they handle orders and solve problems.

Customer Feedback

Customer feedback gives you real-world insight into the supplier’s service and product quality. Read online reviews and ratings on trusted platforms. Pay attention to comments about delivery times, part fit, and after-sales support. If you see repeated complaints about the same issue, you should consider another supplier. Positive feedback about quality and support means you can trust the supplier with your excavator final drive needs.

Price, Value & Installation

Market Price Range

You need to understand the typical price range for China excavator final drive parts before you buy. Prices can vary based on your excavator’s size, the brand, and whether you choose OEM or aftermarket. For small to mid-size excavators, you often see prices between $800 and $2,500 per final drive. Larger machines may require parts that cost $3,000 or more. Shipping costs and import duties can also affect your total price. Always ask your supplier for a detailed quote that includes all fees. This step helps you avoid surprises and plan your budget with confidence.

Value for Money

Getting the best value means more than just picking the lowest price. You should compare the part’s quality, warranty, and expected lifespan. A cheaper final drive may save you money now, but it could lead to more frequent repairs and higher long-term costs. Reliable suppliers offer parts that last longer and come with strong support. You should also consider the supplier’s ability to provide fast replacements and technical help. When you invest in quality, you reduce the risk of breakdowns and keep your excavator working longer. Good value comes from balancing cost, durability, and support.

Installation Support

Proper installation support makes a big difference in your project’s success. Many suppliers offer guides, videos, or even on-site help. When you use professional installation services, you benefit in several ways:

Certified technicians use advanced tools and receive ongoing training, which leads to faster and more accurate repairs.

Mobile repair units and strong supplier networks help you get replacement parts quickly, reducing downtime.

Preventive maintenance by trusted services extends your equipment’s lifespan and lowers the chance of unexpected failures.

Regular inspections and scheduled maintenance tasks, such as cleaning and lubrication, help you spot small issues before they become big problems.

Tip: Keep detailed maintenance records. This habit supports compliance and helps your projects run smoothly.

You should always choose suppliers who offer strong installation and maintenance support. This approach keeps your excavator safe, reliable, and ready for work.

You can choose the right China excavator final drive parts by following these steps:

Identify your machine’s specs and measurements.

Check part compatibility with your supplier.

Compare OEM and aftermarket options.

Review certifications and supplier reputation.

Evaluate price, value, and installation support.

Take these steps to avoid costly mistakes and keep your excavator running strong. Make your next purchase with confidence and protect your investment.

FAQ

What information should you give your supplier to ensure the right final drive part?

You should provide your excavator’s model, serial number, and accurate measurements.

Tip: Share clear photos of your current final drive to help your supplier confirm compatibility.

How do you know if a China supplier is trustworthy?

Check for ISO or CE certifications. Read customer reviews and ask for references.

Reliable suppliers respond quickly

They provide detailed product information

They offer clear warranty terms

Can you install a final drive yourself, or do you need a professional?

You can install a final drive if you have mechanical experience and the right tools.

For best results, use a certified technician. This reduces installation errors and protects your equipment warranty.

What should you do if the new final drive does not fit your excavator?

Contact your supplier immediately.

Provide photos and measurements

Ask about return or exchange options

Review the supplier’s installation guide for troubleshooting steps