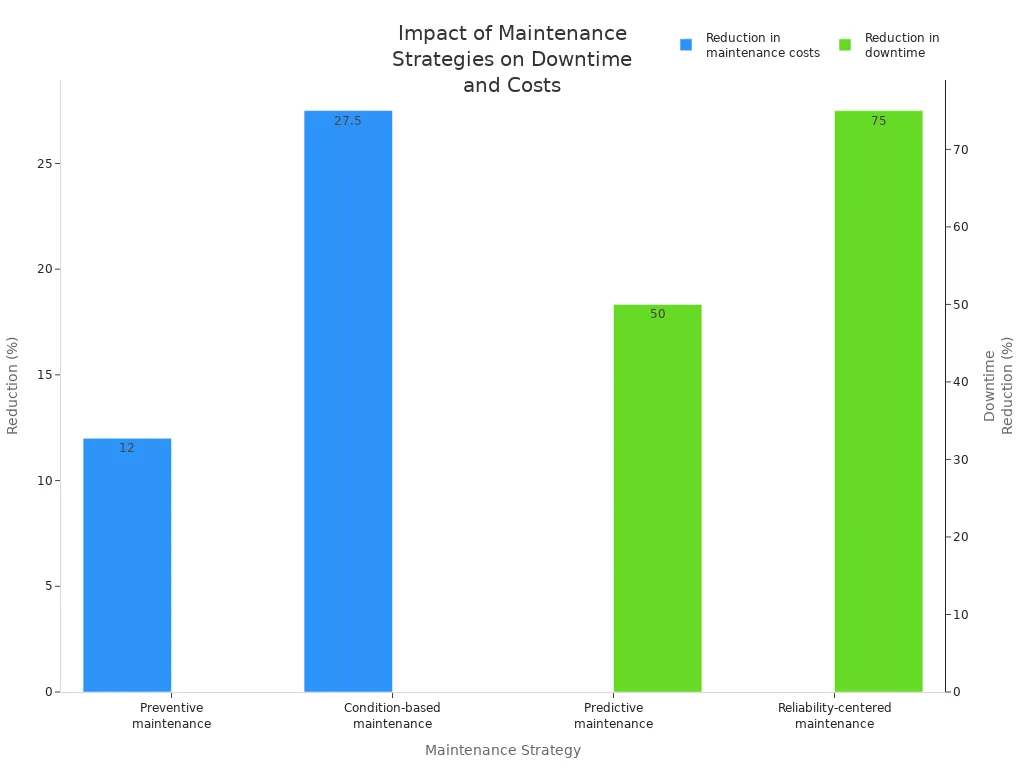

When you choose the right, durable excavator part, your machine works better and lasts longer. You also save money. Bad parts break more often. This means you pay more for repairs and your machine does not last as long. Look at how much downtime and costs matter in this field:

Evidence Description | Impact |

|---|---|

Unplanned downtime costs manufacturers every year | $50 billion |

Equipment failure causes unplanned downtime costs | 42% |

Average cost of equipment downtime each hour | $260,000 |

Think about how you replace and fix parts now. Small changes can help a lot.

Key Takeaways

Pick strong materials for excavator parts. Materials like high manganese steel and tungsten carbide-tipped parts last longer. They help you spend less on repairs.

Check your excavator often to find problems early. Looking at important parts often stops big breakdowns. This keeps your machine working well.

Use parts that fit your excavator just right. Good fitting parts help your machine work better. They also make your equipment last longer.

Buy parts from trusted suppliers like YNF Machinery. Good suppliers give you strong parts and good help. This helps you stop your machine from breaking down.

Take care of your excavator on a set schedule. Regular care and changing old parts on time keep your machine working well. This also saves you money.

Durable Excavator Part Essentials

Material Quality

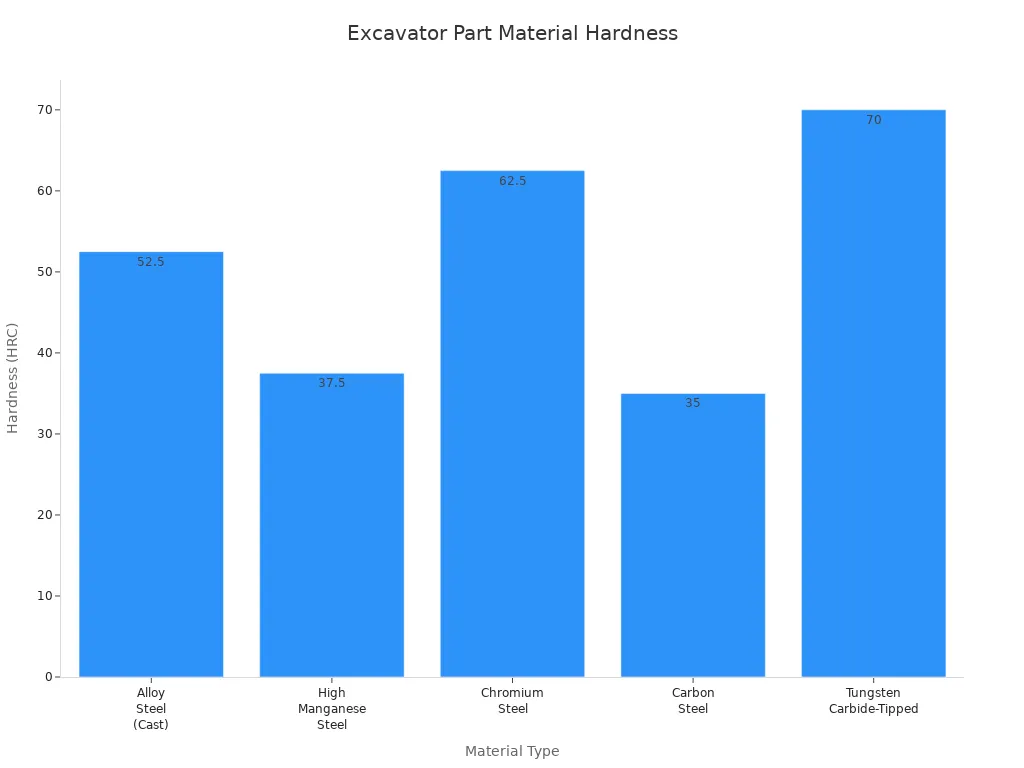

When you want a strong excavator part, check the material first. The right material helps your machine work better and last longer. Some materials are much stronger than others. Look at this table to see how materials are different:

Material Type | Hardness (HRC) | Toughness | Wear Resistance | Best Used For |

|---|---|---|---|---|

Alloy Steel (Cast) | 50-55 | High | High | General digging, sand, gravel |

High Manganese Steel | 35-40 | Very High | Moderate | Rock excavation, mining |

Chromium Steel | 60-65 | Low | Very High | Hard and abrasive materials |

Carbon Steel | 30-40 | Moderate | Low | Light-duty applications |

Tungsten Carbide-Tipped | 70+ | Low | Extremely High | Heavy-duty rock or demolition work |

For tough jobs, pick high manganese steel or tungsten carbide-tipped parts. These materials are strong and last a long time. You can do more work before you need new parts.

Manufacturing Standards

Always check how the part is made. Good parts follow strict rules and tests. This means fewer problems and better use. If you pick high-quality parts, they break less often. You save money because you do not replace them as much. Look for signs like certifications or product details to know the part is good.

Design Fit

A strong excavator part needs to fit your machine well. If it fits right, your machine works better and lasts longer. Here is what a good fit does for you:

Your machine feels steady because weight is spread out.

You get better traction on rough ground.

Vibrations and shocks are absorbed, so the ride is smoother.

Parts last longer when carrying heavy loads.

If you focus on quality, material, and fit, your excavator parts will work hard for you.

Choosing the Right Excavator Parts

OEM vs. Aftermarket

When you need excavator parts, you have two choices. You can pick OEM parts or aftermarket parts. OEM stands for “Original Equipment Manufacturer.” These parts come from the company that made your excavator. They fit perfectly and last a long time. You can trust their quality and reliability.

Aftermarket parts are another option. Many people buy them because they cost less at first. You can find many types, even custom ones. Some aftermarket parts work as well as OEM parts. Trusted brands make good aftermarket parts. You often get them faster, so your excavator keeps working.

Here’s a table to help you compare:

Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

Reliability | Superior durability and performance | May not guarantee the same level of quality |

Lifespan | Longer lifespan due to exact specifications | Potentially shorter lifespan due to fit issues |

Cost | Higher upfront cost but lower total cost of ownership | Lower initial cost but may incur higher long-term costs |

You want your excavator to last and work well. OEM parts give you confidence. Aftermarket parts can save money if you choose carefully. Many aftermarket parts are tested and use strong materials. You get good value and can trust their performance.

Tip: Always check if aftermarket parts meet OEM standards. This helps you avoid problems and keeps your excavator running well.

Supplier Reputation

You need a supplier you can trust. The right supplier gives you high-quality excavator parts every time. YNF Machinery is a top choice for strong excavator parts. They deliver on time and their parts fit your machine.

When you pick a supplier, look for these things:

Client references: Ask for three past customers. Find out if they got their parts on time and if the parts fit.

Certifications: Look for ISO 9001 or CE compliance. These show the supplier cares about quality.

Digital footprint: Read online reviews. If most reviews are good, the supplier is reliable.

YNF Machinery meets these standards. You get parts that last and help your excavator work better. Their aftermarket parts are tested and use strong materials. You save money and avoid downtime.

Compatibility

Every part should fit your excavator. If a part does not match, your machine can break down. You pay more for repairs and your project slows down. That’s why you must check quality and compatibility before you buy.

Parts made for your excavator model work best. They help your machine run smoothly and avoid problems. Always match the part number and specs to your excavator. This keeps your equipment strong and your work on track.

Note: Picking parts with the right quality and compatibility means less downtime and lower costs. Your excavator keeps working and you finish jobs faster.

Evaluating and Replacing Excavator Components

Inspection Tips

You want your excavator to work well every day. Checking it often helps you find problems early. Look at the main parts like sprockets, engines, undercarriage, and rubber tracks. Watch for these signs of wear:

Rubber track damage, such as cracks or missing lugs.

Sprockets that look hooked or make the track come off.

Track tension that is too loose or too tight.

Tread depth that is not safe, which can make your excavator slip.

If you see these problems, plan to replace the parts soon. Broken tracks or sprockets slow down your work and cost more to fix. You can stop bigger problems by finding these signs early.

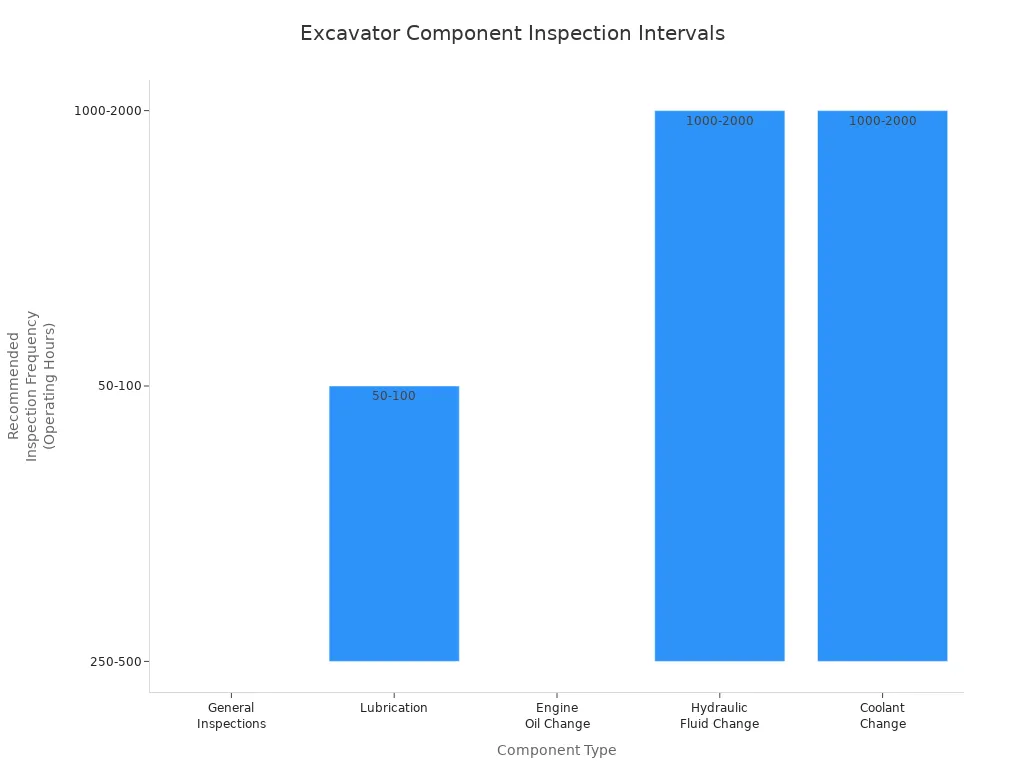

How often should you check your excavator? Use this table to help keep your machine working well:

Component Type | Recommended Inspection Frequency |

|---|---|

General Inspections | Every 250 to 500 operating hours |

Lubrication | Every 50 to 100 operating hours |

Fluid Changes | Engine oil: every 250 to 500 hours |

Hydraulic fluid: every 1,000 to 2,000 hours | |

Coolant: every 1,000 to 2,000 hours |

If you do these checks, you lower the chance of surprise breakdowns. Your excavator will stay strong for every job.

Replacement Timing

You may wonder when to change old parts for new ones. It is smart to replace them early. Waiting too long can hurt other parts. For example, a bad sprocket can damage your rubber tracks. Slow hydraulic response or leaks can mean bigger problems if you ignore them.

Here are some things you can do:

Check your excavator’s filters often. Dirty filters can block your system and cause damage.

Follow a filter replacement schedule. This helps your machine run well and saves money on repairs.

Keep track of every part’s condition. Use a logbook, spreadsheet, or software to guess when you need new parts.

Change filters on time. This keeps dirt out and helps your excavator last longer.

Tip: If you replace worn parts early, you stop more damage and keep your excavator working longer. You also save money by avoiding big repairs.

When you buy new parts, make sure they fit your machine’s specs. OEM filters work best, but good aftermarket parts from YNF Machinery also work well. Always check that your new part fits your excavator model.

Warranty and Support

Warranties are important when you buy excavator parts. They protect you from big repair bills and help your machine keep running. Here is what a good warranty does for you:

No huge repair costs. You avoid surprise bills.

Less downtime. Fast repairs help you get back to work.

Good parts and service. Skilled workers use OEM or trusted aftermarket parts, so your excavator is safe.

Higher re-sale value. Well-kept equipment with a warranty sells for more.

Doing regular maintenance keeps your warranty good. If you skip care, you might lose coverage. Then you pay for repairs yourself.

Note: If you ignore maintenance, your equipment can break down more. You could also lose your warranty. This means you pay for repairs that could be covered.

Support from your supplier helps a lot. YNF Machinery gives after-sale help, like advice and troubleshooting. They handle returns and exchanges if you have problems. You can trust their reputation and customer reviews. Dealers like YNF Machinery give better support than single sellers.

If you pick the right parts, check your excavator often, and do regular maintenance, your machine will last longer. You will spend less on repairs and keep your projects moving.

Maintenance for Long-Lasting Parts

Preventive Care

You want your excavator to last as long as possible. Preventive care makes a big difference. When you act quickly on parts that show signs of wear, you keep your machine running and avoid costly downtime. Staying proactive helps your excavator work better and longer.

Here are some simple habits you can follow:

Do routine check-ups and preventive maintenance.

Inspect parts often and fix any problems right away.

Keep track tension just right to stop extra wear.

Lubricate pins and bushings so they move smoothly.

Check hydraulic oil often to protect moving parts from rust.

You can also follow these steps:

Clean the cooling system every day with compressed air. This stops overheating.

Keep the fuel tank full. This helps you avoid problems from condensation.

Adjust tracks to the right tension. This prevents track failures.

If you stick to these habits, your excavator will stay strong and ready for work.

Proper Installation

Installing parts the right way matters a lot. If you use the wrong part or skip steps, you can cause damage and shorten the life of your machine. Here’s what you need to watch out for:

Make sure every part fits your machine. Incompatible parts can cause vibration and damage.

Always check adapters for wear. Ignoring them leads to uneven wear.

Install locking mechanisms correctly. If not, you might lose parts during work.

Clean all mounting surfaces before you start. Dirt can create gaps and loosen parts.

Use the right amount of force. Too much can crack or bend parts.

Don’t mix old and new parts. This puts extra strain on your excavator.

Keep up with regular maintenance. Skipping it can damage adapters and waste fuel.

Choose high-quality parts from trusted suppliers like YNF Machinery. Low-quality parts wear out faster.

Tip: Take your time with installation. Careful work now saves you trouble later.

Upgrade Strategies

You can make your excavator even tougher by upgrading key parts. Try these strategies:

Use high-efficiency hydraulic valves, wear-resistant buckets, and smart control units for your work conditions.

Pick bucket teeth with better designs and high-hardness alloy materials. These last longer.

Change filters often to keep dirt out and protect important parts.

Choose advanced materials that resist wear, rust, and fatigue. This helps your machine work better and longer.

When you upgrade, you get more work done and spend less on repairs. Your excavator stays ready for any job.

Operator Impact on Excavator Part Lifespan

Training

You play a big role in how long your excavator parts last. Training helps you understand what your machine can and cannot do. When you know your equipment well, you make fewer mistakes. Good training covers more than just driving. You learn how to check your machine before each shift and how to read load charts. This helps you use your excavator safely and keeps it in good shape.

Here are some ways training helps you and your machine:

You learn the limits of your equipment, so you avoid pushing it too hard.

You make fewer errors, which means less damage to parts.

You know how to spot problems early during pre-shift checks.

You understand how to use the right loads for each job.

When you get full training, you do not just operate the machine. You also learn how to care for it. This means you help your excavator last longer and save money on repairs.

Tip: Keep learning about your machine. The more you know, the better you protect your equipment.

Usage Habits

How you use your excavator every day matters a lot. Some habits can wear out parts faster. For example, driving on hard surfaces like concrete or asphalt makes rubber tracks wear down quickly. Turning the machine by spinning the tracks in place puts extra stress on the undercarriage. If you always turn in the same direction, one side of the track wears out faster.

Try these habits to help your machine last:

Avoid spinning the tracks when you turn.

Drive straight up and down slopes, not sideways.

Do not drive too fast or use reverse more than needed.

Slow down before stopping or turning.

Do not overload your machine. Heavy loads can break parts.

When you use good habits, your excavator parts last longer. You spend less time fixing your machine and more time getting work done.

Professional Support for Excavator Maintenance

Certified Technicians

You want your excavator to work well every day. Certified technicians help you reach this goal. These experts know how to find problems before they get worse. They check your machine and spot parts that are almost worn out. If you change these parts early, you stop breakdowns and keep your work going.

Here’s what certified technicians do for you:

Find parts that might fail soon, so you can change them first.

Help you avoid losing time by fixing problems early.

Make your job site safer by keeping your machine in good shape.

Help your work go faster because your machine runs well.

Keep your excavator strong, so it works at full power.

When you trust certified technicians, you protect your money and keep your team safe. You also make sure your excavator is ready for any job.

Dealer Resources

You do not have to solve everything alone. Trusted dealers like YNF Machinery give you help to pick and care for tough excavator parts. They offer new, used, and remanufactured parts to keep your machine working. Their team knows about different work sites, like dusty or wet places, and can suggest parts with special features for extra strength.

Before you buy, always check if the parts are real OEM or good aftermarket choices. Using the right parts keeps your excavator running well and stops problems. Dealers with a good name, like YNF Machinery, make it easy to find what fits your machine. You can ask their experts for help and compare part details with your equipment manual.

Tip: Work with a supplier who knows your machine and job site. This way, you get the right parts and keep your excavator working hard.

Quick Checklist for Durable Excavator Parts

You want your excavator to work well every day. A checklist helps you choose the best parts. It also helps you avoid expensive mistakes. Use this guide when you buy or fix excavator parts.

🛠️ What to Check Before You Buy

Material Composition: Pick parts made with strong metals. These last longer and do tough jobs.

Load Capacity: Make sure the part can hold your excavator’s weight. Always check the specs before you buy.

Dimensional Accuracy: Look for parts with exact measurements. A good fit means less damage and smoother work.

Wear Resistance: Choose parts that do not scratch or rust easily. These keep working in hard places.

Warranty: Ask about the warranty every time. Good parts have coverage to protect your money.

Manufacturing Reputation: Learn about the maker. YNF Machinery is known for strong and reliable parts.

Expert Tip: Ask about how the part works, the warranty, and if it fits your machine. Good suppliers answer your questions and help you feel sure about your choice.

🔍 Daily and Regular Maintenance Checks

Check important parts like tracks, sprockets, and engines often. Early checks stop big problems from happening.

Watch dashboard lights every day. They tell you if something is wrong.

Write down all maintenance in a log. This helps you know your excavator’s condition.

Check coolant and hydraulic fluid levels. Low fluids can make your machine overheat or slow down.

Fill the fuel tank before each shift. This stops surprise breakdowns.

🏷️ OEM vs. Aftermarket Parts

OEM Parts Advantages | Aftermarket Parts Advantages |

|---|---|

Guaranteed compatibility | Cost-effective |

Premium materials | Wide availability |

Manufacturer warranty coverage | Suitable for non-critical components |

If you use this checklist, you make smart choices. Your excavator stays strong and you save money. Always trust suppliers like YNF Machinery for the toughest parts.

You can keep your excavator running strong by following a few simple steps. Check out this table for a quick recap:

Step | What You Should Do |

|---|---|

Know Your Parts | Learn what each part does and why it matters. |

Pick Quality Materials | Choose tough, heat-treated steel for longer life. |

Trust Reliable Suppliers | Go with YNF Machinery for proven, certified parts. |

Stick to Maintenance | Inspect, adjust, and grease parts on a regular schedule. |

When you focus on quality and replace parts on time, you save money, avoid downtime, and keep your team safe. Use the checklist, talk to experts, and review your daily routines to make your excavator last even longer!

FAQ

What makes heavy equipment parts last longer?

You get longer life from parts when you choose durable components. Clean your machine often. Use the right parts for your heavy equipment. Follow the manual for care. Good habits help you avoid early wear and keep your machine strong.

How do I know if a part fits my heavy equipment?

Check your heavy equipment’s manual for the right part number. Match the specs before you buy. YNF Machinery can help you find the best fit. If you use the wrong part, your machine may break down or work poorly.

Why should I pick YNF Machinery for heavy equipment parts?

YNF Machinery offers strong, tested parts for heavy equipment. You get fast delivery and good support. Their team knows what works best for your machine. You can trust their advice and products for all your heavy equipment needs.

How often should I do excavator maintenance on my heavy equipment?

You should check your heavy equipment every day. Look for leaks, loose bolts, and worn parts. Do a full service after every 250 to 500 hours. Regular excavator maintenance keeps your machine safe and ready for work.

Can I upgrade my heavy equipment with new durable components?

Yes! You can upgrade your heavy equipment with new durable components. These parts help your machine work better and last longer. Ask YNF Machinery for advice on the best upgrades for your heavy equipment.