When you pick the right excavator parts, your machine works better. It will also last longer. Using parts that fit your excavator’s model and job helps a lot. You get better results, fewer problems, and spend less money. Always check if each part is good quality and fits well. You should also decide if you want genuine, OEM, or aftermarket parts. Look for suppliers you can trust who have the parts in stock.

Picking the right parts can:

Help you finish work faster and save on labor.

Make your excavator do more jobs with special attachments.

Let you change attachments quickly, so you waste less time.

Getting the best construction machinery parts for excavator sale keeps your investment safe. It also helps your projects stay on schedule.

Key Takeaways

Pick excavator parts that fit your machine’s model and job needs. This helps your machine work better and saves money.

Think about the kind of parts you need: genuine, OEM, or aftermarket. Each type has good and bad points. Choose the one that fits well and is good quality.

Check and take care of your excavator parts often. This stops your machine from breaking and helps it last longer.

Buy from trusted suppliers who sell good parts and help customers. This makes sure you get your parts on time and get help when needed.

Always make sure attachments fit your machine. This keeps your machine working well and keeps everyone safe.

Identify Your Excavator and Job Needs

Before you buy excavator parts, know your machine. You also need to know what you want it to do. This helps you avoid mistakes that cost money. It keeps your equipment working well.

Find Model and Specs

First, check your excavator’s model and main specs. These details help you pick the right parts. They also help you choose the best attachments. Here is a table that compares different excavator types:

Specification | Mini Excavator | Mid-Size Excavator | Large Excavator |

|---|---|---|---|

Engine Power | 13 to 50 hp | 50 to 120 hp | 120 hp and above |

Operating Weight | 0-6 tons | 6-15 tons | 25-50 tons |

Digging Depth | Up to 3 meters | Up to 6 meters | Up to 8 meters |

Bucket Capacity | 0.025 m³ to 0.15 m³ | 0.15 m³ to 1 m³ | 1 m³ to 5 m³ |

Always match new parts to your machine’s model and specs. Even small changes can affect how parts fit and work.

Assess Job Requirements

Think about what jobs your excavator will do. Will you dig deep holes, move heavy things, or work in small spaces? Each job may need different parts or attachments. Make a list of your main jobs. This helps you pick the right equipment. It also stops you from buying things you do not need.

Tip: See if your job needs special features. You might need more digging depth or a bigger bucket. This can change which parts you should get.

Note Attachment Compatibility

Using the wrong attachment can cause problems. You might work slower, break parts faster, or have safety issues. Here are some common risks:

Risk Type | Description |

|---|---|

Operational Inefficiencies | Attachments that do not fit can slow you down. |

Increased Wear and Tear | Bad fit can hurt the attachment and the excavator. |

Safety Hazards | If things do not line up, accidents can happen. |

To stop these problems, always check if parts and attachments fit your machine. Follow these steps:

Make sure the part fits your model.

Ask about how the manufacturer checks quality.

Think about the total cost, not just the price.

Picking the right parts and attachments keeps your projects safe and helps you work better.

Types of Excavator Parts and Options

Genuine, OEM, and Aftermarket Parts

You can pick from three kinds of excavator parts. These are genuine, OEM, and aftermarket. Each one has good and bad points. You need to know how they are different to choose the best one.

Type | Performance Characteristics | Lifespan Characteristics |

|---|---|---|

OEM | High durability, engineered for optimal performance, less vibration-induced wear | Typically outlasts aftermarket by 40%, with longer warranty coverage (6-24 months) |

Aftermarket | Variable quality, some high-end options match OEM but lower-grade parts may fail under load | Shorter lifespan, with reports of up to 20% higher failure rates in demanding environments |

Genuine parts are made by the original company. OEM parts come from the same maker but may have a new brand name. Aftermarket parts are made by other companies. Some aftermarket parts work well, but some do not last or fit right. Always check if the part is good before you buy it.

High-Quality Excavator Parts for Sale

When you want good excavator parts, look for special certifications. These show the parts are safe and high quality. Here are some important certifications:

Certification | Description |

|---|---|

ISO 9001 | Ensures a well-defined quality management system for consistent product quality. |

CE | Indicates compliance with EU health and safety requirements for products sold in the EEA. |

API | Relevant for parts used in the oil and gas industry, ensuring performance under harsh conditions. |

Parts with these marks usually last longer and work better. This helps protect your money and keeps your excavator working well.

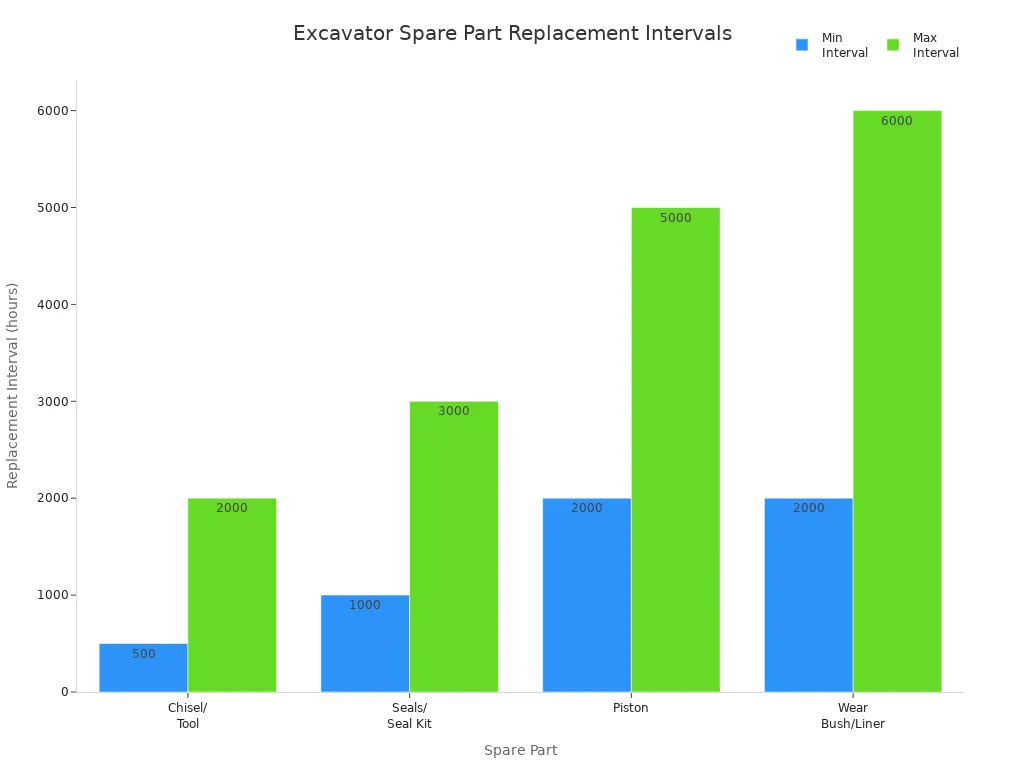

Excavator Spare Parts Selection

Some excavator spare parts need to be changed often. This keeps your machine working its best. Here are some common parts and when to change them:

Air filters: Change when the gauge says so.

Hydraulic filters: Change every 1,000 hours.

Oil filters: Change every 250-500 hours or once a year.

Fuel filters: Change at least once a year.

Belts: Check them during each service.

Seals: Price and how often you change them can be different.

Hoses: Last 1-4 years, depending on use.

Bucket teeth: Cost and how often you change them can be different.

Today, picking the right equipment is very important. The right choice can help your project finish on time and on budget. Excavators do many jobs like digging, lifting, and breaking things. If a part breaks, your project can slow down and cost more.

You should always pick the right excavator spare parts for your job. This helps you avoid mistakes that cost a lot. It also keeps your excavator buckets and other tools working well. Good excavator parts help you finish work faster and keep your machine ready for anything.

Check Quality and Compatibility

When you pick excavator parts, focus on quality and fit. If you skip this, your machine might break down. You could have safety problems and spend more money. You can keep your machine safe by following some easy steps.

Match Parts to Machine

Always use parts made for your excavator model. Even small changes can cause big trouble. The right parts help your machine work better and safer. Look at the table below to see why matching parts matters:

Evidence Type | Details |

|---|---|

Equipment Failures | Almost 40% of failures come from wrong parts. |

Service Life Increase | A good idler cap can make parts last 20% longer. |

Cost Implications | Wrong parts cost more to fix and cause delays. |

Using the right parts helps your machine last longer. You also save money and avoid waiting for repairs.

Review Manufacturer Guidelines

Manufacturers give rules to help you pick parts. Always follow these steps:

Find your excavator’s model and serial number. This helps you get the right part.

Learn about genuine, OEM, and aftermarket parts. This helps you pick the right quality.

Buy from trusted sellers with good reviews and a warranty.

Pick parts that fit your job. This keeps your machine strong.

Make sure parts and attachments fit together. This stops problems at work.

Check if the part is in stock. This helps you avoid waiting.

If you follow these rules, your machine will work better. You will also have fewer problems with parts.

Tip: Keep your machine’s manual close. It gives the best advice for picking and caring for parts.

Avoid Compatibility Issues

Many people have problems when they do not check fit. You can stop these problems by doing these things:

Know your machine’s make, model, and serial number. This is the first step to getting the right parts.

Different serial numbers may need different parts. This helps you avoid mistakes.

Learn about OEM and aftermarket parts. Each has good and bad sides.

Use a trusted seller. This makes buying parts safer and easier.

If you do these things, you will avoid most problems. Your excavator will work well on every job.

Note: Good excavator parts last longer and work better. They also help you finish jobs on time.

When you check quality and fit, you protect your machine and money. You also keep your team safe and your projects running well.

Supplier Evaluation and Part Availability

Reliable Suppliers for Construction Machinery Parts

You need a supplier you can trust for excavator equipment parts. YNF Machinery is known for good quality and service. When picking a supplier, check if they can make enough parts. This shows if you will get your parts on time. If they cannot keep up, your project may be late and cost more. The material used is also important. Good materials help parts last longer and work well in hard jobs.

Here is a table to help you know what to check in a supplier:

Criteria | Description |

|---|---|

Maintenance Support | Helps your equipment last longer and stops big breakdowns. |

Competitive Pricing | Gives good prices for all businesses, with payment plans if needed. |

Customer Satisfaction | Listens to customers and uses clear contracts. |

Production Capacity | Can make enough parts fast, so you meet your project deadlines. |

Material Quality | Good materials make parts safe, strong, and last longer. |

YNF Machinery meets these needs, so it is a great choice for excavator equipment parts.

Warranties and Support

A good warranty helps you feel safe when buying parts. Always check what the warranty covers and how to make a claim.

A warranty is a promise. You should check if the company keeps its promises.

If something breaks, the best suppliers want to fix your machine fast.

Even the best warranty may not pay for every cost if something fails.

YNF Machinery gives strong support after you buy. Their team helps you fix problems fast, so your excavator works again soon.

Lead Time and Availability

You want your parts ready when you need them. Lead time is how long you wait after you order. Most parts take 7 to 14 days to arrive. Custom parts may take longer. YNF Machinery uses smart shipping to make wait times short.

To always have the right parts, try these tips:

Keep your parts list up to date.

Order parts you use a lot before you run out.

Store spare parts in a clean, safe spot.

Use technology to watch your machines and manage your parts.

If you plan ahead, you will not have delays. Your excavator will keep working well.

Installation, Maintenance, and Mistakes to Avoid

Installation Tips

You want your excavator attachments to work well and last. Clean all surfaces before you put on new excavator spare parts. Take off old gasket pieces, rust, and dirt. Only use the lubricants the maker says to use. Line up each part with care. Use a guiding sleeve or tap gently so you do not break anything. Always use a torque wrench and follow the right numbers. When you finish, turn the part by hand to see if it moves smoothly. Here is a table with best ways to do things:

Best Practice Category | Description |

|---|---|

Cleaning | Clean surfaces to get rid of dirt and rust. |

Lubrication | Use only grease or oil the maker says to use. |

Alignment | Line up parts carefully so they do not break. |

Fastening | Use a torque wrench and follow the right numbers. |

Testing | Turn by hand to check for smooth movement. |

Maintenance | Plan to check all excavator attachments often. |

Tip: Change worn pins and bushings in buckets, grapples, and breakers right away. This stops bigger problems from happening.

Maintenance for Longevity

Check your construction machinery every day to keep it strong. Look at your excavator spare parts daily. Watch for cracks, leaks, or loose bolts on buckets, hydraulic breakers, and grapples. Clean attachments after you use them. Store them in a dry place. Put rust blockers on metal that shows. Doing these things helps your construction machinery last longer and saves money on repairs. Here are some steps:

Check all excavator attachments for damage or wear.

Grease moving parts to stop friction.

Change broken replacement parts fast.

Do not put too much weight in buckets, grapples, or breakers.

Use good excavator spare parts for better work.

Taking care of your machine early stops small problems from getting big. You save money and do not have delays.

Common Mistakes

Many people make mistakes when buying excavator accessories or picking excavator spare parts. These mistakes can stop your machine, cost a lot to fix, and make work slower. Here is a table that shows what can go wrong:

Consequence | Impact |

|---|---|

Increased Downtime | Problems in the final drive can stop your machine and slow your project. |

Costly Repairs | Dirty oil can hurt hydraulic circuits and cost a lot to fix. |

Accelerated Wear | Bad lubrication and wrong track tension wear out parts faster. |

Reduced Efficiency | Wrong track tension uses more fuel and lowers power. |

Hydraulic Pressure Loss | Leaks in cylinders make your machine weaker and slower. |

Always check if parts fit before you buy. Read what other users and experts say. Picking the right bucket, breaker, and excavator grapples keeps your equipment safe and working well.

Picking the right excavator parts starts with knowing your machine and what jobs you need to do. You should look at different part choices, check if they are good quality, and make sure they fit your model. The table below shows how making smart choices can help your project:

Factor | Benefit |

|---|---|

Structural Optimization | Your machine works better and breaks down less. |

Material Selection | Parts last longer and work better. |

Operator Training | Work is safer and gets done faster. |

You get the best excavator attachments when you work well with your supplier and take care of your machine before problems happen. This way, you can stop delays and keep your machine working for a long time.

FAQ

What should you check before buying construction machinery parts for excavator sale?

Check your machine’s model before you buy parts. Think about the job you want to do. Make sure the part fits your machine. Ask if the construction machinery parts for excavator sale match what you need. This helps you not make mistakes. It also keeps your machine working well.

How often should you replace excavator spare parts?

Follow the schedule in your manual. Most excavator spare parts need checking every few months. Air filters, oil filters, and hoses wear out faster than other parts. Regular checks help you find problems early. This keeps your excavator safe.

Can you use aftermarket parts for construction machinery parts for excavator sale?

You can use aftermarket parts for your machine. Some aftermarket construction machinery parts for excavator sale work well. Always check the quality and fit before you buy. Ask your supplier if the part is safe. This helps you avoid problems and keeps your machine strong.

Why do excavator spare parts fail early?

Excavator spare parts fail early for a few reasons. You might pick the wrong type or skip maintenance. Low-quality parts can break faster. Dirt, rust, and bad fit also cause problems. Clean parts and follow the maker’s advice to help them last longer.

Where can you find reliable construction machinery parts for excavator sale and excavator spare parts?

You can find good construction machinery parts for excavator sale and excavator spare parts from trusted suppliers. Look for companies with good reviews and fast shipping. Ask about warranties and see if they have the parts you need in stock.