You can make your chinese excavator hydraulic pump better if you follow the right steps. Many owners notice their machines move faster and get stronger after they change the pump. You do not have to be an expert to make your machine work better. If you take your time and are careful, you will see your machine work smoother and stronger.

Key Takeaways

Upgrade your hydraulic pump if movement is slow or controls are hard. These signs show the pump is worn out and works less well.

A new hydraulic pump gives better pressure and flow. This makes your excavator move faster and saves fuel.

Pick a pump that fits your excavator’s needs. Check the flow rate and make sure it matches your machine. This helps your excavator work its best.

Always use good tools and wear safety gear when you upgrade. This keeps you safe and helps the job go smoothly.

Take care of your pump by changing fluids and checking it often. This helps your new pump work well and last longer.

When to Upgrade

Signs of Pump Wear

Sometimes your excavator does not work as well as before. The handles can feel hard to move. The machine might not have enough strength. These things often mean your hydraulic pump is getting old. When the pump gets worn, more fluid can leak inside. This makes the pressure go down. Low pressure makes your excavator weaker.

More leaking inside the pump lowers the pressure.

Low pressure means your excavator cannot lift or move well.

You may see the machine slow down or have trouble with easy jobs.

Hard handles and weak power usually mean pump trouble.

If you notice these problems, it is smart to think about upgrading your chinese excavator hydraulic pump.

Performance Benefits

Getting a new hydraulic pump can really help. A new pump brings back the right pressure and flow. Your excavator will work better. You will see it move faster and run smoother. The machine will answer quickly when you use the controls.

Tip: A new pump can help you finish work faster. It can also save fuel because the system works better.

Here are some good things you might see:

More lifting and digging strength

Smoother and quicker control

Less stress on the engine and other parts

If you upgrade your chinese excavator hydraulic pump at the right time, your machine will keep working its best.

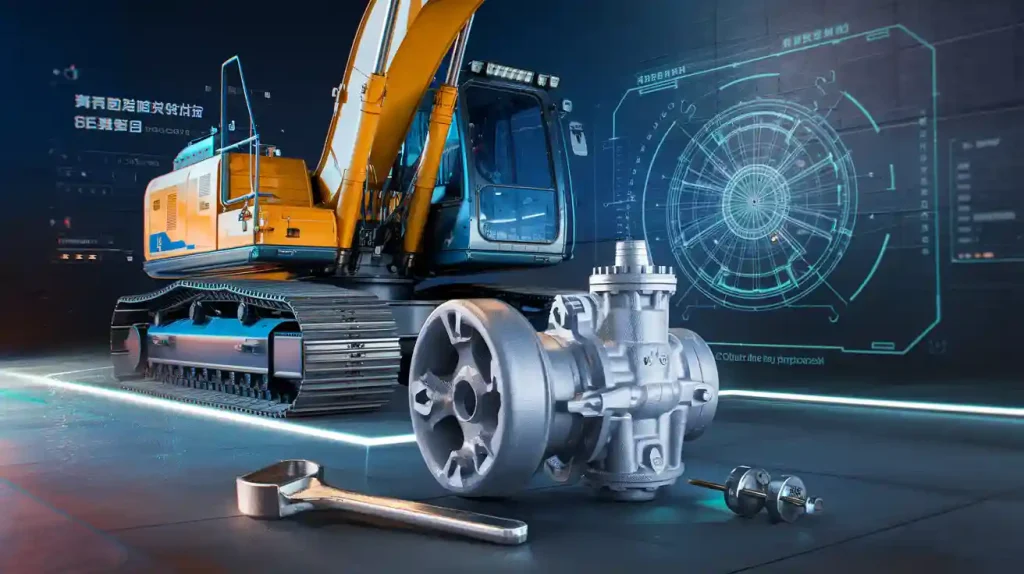

Choosing a Chinese Excavator Hydraulic Pump

Flow Rate and Compatibility

When you pick a chinese excavator hydraulic pump, check the flow rate. The flow rate shows how much hydraulic fluid moves each turn. A pump with a 20ml flow rate moves more fluid than a 14ml pump. If you choose a pump with more flow, your excavator will move faster. It will also feel smoother. You will see the arm move quicker. Digging will be stronger.

You must make sure the pump fits your machine. Not every pump works with every excavator. Look at your pump’s size and shape. Check how it connects to the hoses. Make sure the new pump fits in the same place. It should line up with the other parts. If you use the wrong pump, your excavator may not work well. It could even get damaged.

Mini excavators use two main pump types: gear pumps and piston pumps. Piston pumps work better and handle higher pressure. They give smoother operation and last longer. Gear pumps cost less but may not work as well. Think about what matters most to you. Do you want speed, strength, or to save money?

Note: A strong hydraulic system helps your excavator dig, lift, and turn easily. Picking the right pump size and type keeps your machine working well.

Here are some things to look for in a good pump:

High efficiency uses less energy

Compact design fits easily

Long service life for tough jobs

High-pressure ability for heavy work

Low noise for quiet use

Easy maintenance for quick fixes

Versatility for different jobs

You should know if your excavator uses an open loop or closed loop hydraulic system. Most mini excavators use open loop systems. These are simple and easy to fix. Closed loop systems cost more but control fluid temperature and pressure better.

Sourcing Reliable Pumps

You want a pump that works well and lasts long. Always buy your chinese excavator hydraulic pump from a trusted seller. YNF Machinery is a good choice for hydraulic pumps. They have pumps for many Chinese mini excavators. They are known for quality and support.

Before you buy, check if you need to change your system. Sometimes you must upgrade the filtration system or add new parts for the new pump. Here is a table with common system changes:

Modification Type | Description |

|---|---|

Return Filtration System | Upgrade to a 10-micron filter with a bypass valve for better oil control. |

New Bung Hole in Tank | Add a new hole for easier filter access and faster maintenance. |

Suction Filtration Replacement | Replace the old suction filter to stop cavitation and protect the new pump. |

Tip: Always know your current setup before you order a new pump. This helps you avoid mistakes and makes upgrading easier.

When you pick the right chinese excavator hydraulic pump and a trusted seller like YNF Machinery, your machine will work better and last longer.

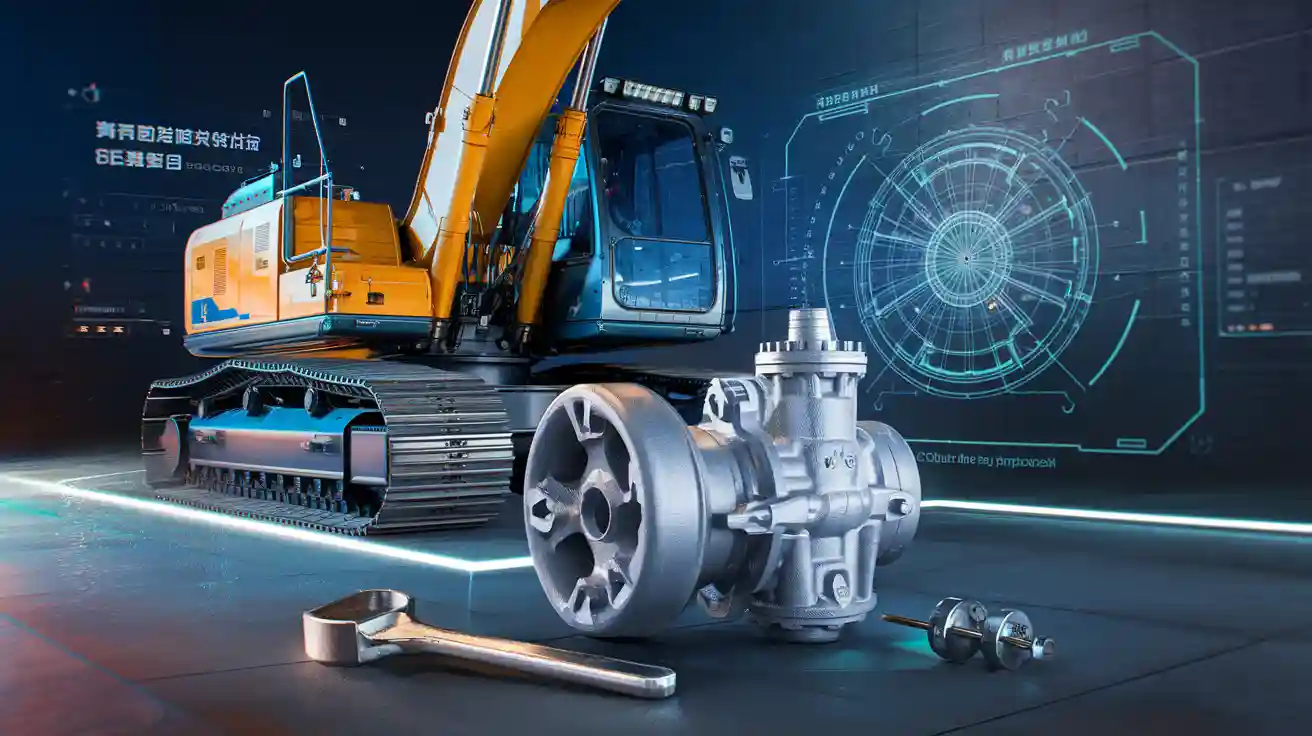

Tools, Parts, and Safety

Tools Checklist

You need the right tools to upgrade your hydraulic pump. Good tools help you work faster and safer. Here is a checklist to guide you:

Wrenches (metric and standard sizes)

Socket set

Screwdrivers (flathead and Phillips)

Pliers and adjustable wrench

Torque wrench

Oil drain pan

Clean rags or towels

Hydraulic hose crimper (if you need to replace hoses)

Flashlight or work light

Small brush for cleaning parts

Tip: Organize your tools before you start. This saves time and helps you avoid mistakes.

A torque wrench helps you tighten bolts to the correct level. You protect the pump and other parts from damage. Clean rags keep dirt out of the system. A flashlight lets you see inside tight spaces.

Parts and Safety Gear

You need more than tools for a safe upgrade. You must gather the right parts and safety gear. Here is a table to help you prepare:

Item | Purpose |

|---|---|

Main part for the upgrade | |

Hydraulic hoses | Replace old or damaged hoses |

Seals and gaskets | Prevent leaks and keep system tight |

Hydraulic fluid | Fill the system after installation |

Filter system | Protect the new pump from dirt |

Safety gloves | Protect your hands from oil and sharp edges |

Safety glasses | Shield your eyes from splashes |

Work boots | Keep your feet safe around heavy parts |

You should always wear gloves and safety glasses. Oil can hurt your skin and eyes. Work boots protect your feet if you drop a part. Never skip safety gear.

Note: YNF Machinery offers quality parts for your chinese excavator hydraulic pump upgrade. You get reliable products and support.

Check your parts before you begin. Make sure everything fits your machine. You avoid delays and keep your upgrade smooth.

Upgrade Process

Remove Old Pump

You need to remove the old hydraulic pump before you can install a new one. Follow these steps to do it safely and correctly:

Turn off your excavator and disconnect the battery. This keeps you safe from electric shock.

Release any pressure in the hydraulic system. Open the bleed valve or loosen a hose slowly to let out trapped pressure.

Place an oil drain pan under the pump. Hydraulic fluid may spill when you remove hoses.

Use wrenches to disconnect all hydraulic hoses from the pump. Mark each hose with tape so you remember where it goes.

Remove the bolts that hold the pump in place. Keep these bolts in a safe spot for later.

Gently pull the pump away from the mounting area. If it feels stuck, tap it lightly with a rubber mallet.

Clean the pump area. Remove old gasket material and dirt. Make sure the pump shaft and gear hole are clean.

Check the pump shaft key. Do not disturb it. Make sure no parts are loose or missing.

Tip: Take photos before you remove anything. These photos help you remember how to put everything back together.

Install New Pump

Now you can install your new chinese excavator hydraulic pump. Take your time and follow these steps:

Place the new gasket on the mounting surface first.

Align the key way on the gear with the pump shaft. You can use the crankshaft to help line it up.

Hold the gear in place and gently tap the pump shaft into the gear. You can also tap the gear onto the pump shaft if that feels easier.

Slide the pump housing onto the shaft. Tap it gently until it sits fully in place.

Insert the bolts and tighten them by hand first. Then use a torque wrench to tighten them to the correct level.

Reconnect all hydraulic hoses. Use your tape marks or photos to match each hose to the right spot.

Double-check all connections. Make sure every hose and bolt is tight.

Note: YNF Machinery supplies pumps that fit many Chinese mini excavators. Their pumps come with clear instructions and support.

System Checks

After you install the new pump, you need to check the system before you use your excavator. This step helps you avoid leaks and damage.

Fill the hydraulic tank with fresh fluid. Use the type recommended by your machine’s manual.

Start the engine and let it idle. Watch for leaks around the pump and hoses.

Move the controls slowly. Check if the excavator responds smoothly.

Use a flashlight to look for drips or wet spots. Tighten any loose fittings if you see leaks.

Check the hydraulic temperature with a gauge. The system should not get too hot. If it does, turn off the engine and let it cool.

Listen for strange noises. Squealing or grinding sounds may mean a problem with the installation.

Checkpoint | What to Look For | What to Do If You Find a Problem |

|---|---|---|

Fluid Level | Should be at the correct mark | Add more fluid if needed |

Leaks | No drips or wet spots | Tighten fittings or replace seals |

Temperature | Should stay in safe range | Let system cool, check for blockages |

System Response | Smooth and quick | Recheck hose connections and pump mount |

Callout: Always monitor the hydraulic temperature during the first few hours of use. Overheating can damage your new pump.

You have now completed the upgrade process. Your excavator should feel stronger and smoother. If you notice any issues, stop and check your work. Careful installation and testing keep your machine running well.

Maintenance and Troubleshooting

Regular Maintenance

You need to take care of your excavator after you upgrade the hydraulic pump. Regular checks help your new pump last longer and work better. Always change fluids and add a hydraulic filter system after you upgrade. Clean oil and strong filters keep dirt out and protect the pump.

Here is a table to help you remember what to do and how often:

Maintenance Task | Frequency |

|---|---|

Checking and changing oil and filters | Regularly |

Greasing all pin joints and moving parts | Regularly |

Inspecting the undercarriage for wear | Regularly |

Checking hydraulic hoses for leaks | Regularly |

Monitoring the engine for unusual noises | Regularly |

Keeping track of all service performed | Ongoing |

Check engine oil, hydraulic oil, and coolant every day. Look at air filters for dust. Watch hoses and connections for leaks. Check tracks or tires for wear. Grease all pivot points so parts move smoothly.

Most makers say to change hydraulic fluid every 2,000 to 4,000 hours. If you work in dirty places, change fluid more often. Fluid tests help you know when to change it.

Tip: Write down each time you do service. This helps you find problems early and keeps your excavator working well.

Common Issues

After you upgrade your chinese excavator hydraulic pump, some problems may show up. Leaks, overheating, and system issues can happen. You can fix most problems with easy checks.

If you see leaks, follow these steps:

Step | Description |

|---|---|

1 | Look for air leaks in the hydraulic system. |

2 | Make sure the hydraulic fluid tank is full. |

3 | Check the pump and parts for damage or wear. |

4 | Check the hydraulic filter and change it if needed. |

5 | Look for leaks inside the pump from worn parts. |

To stop overheating, check oil levels every day before you work. Clean the cooler every week to get rid of dirt. Change hydraulic oil on time to keep things cool.

Sometimes, the pump does not get enough fluid. This happens if the hydraulic inlet is too high, especially when the excavator tilts. A small oil tank can also cause overflow or pump problems. Watch for these signs and change your setup if needed.

YNF Machinery gives good help and quality parts for your maintenance needs. Good care and quick fixes keep your excavator safe and working well.

Upgrading your Chinese excavator hydraulic pump is easy if you get ready and follow each step. If you work slowly and pay attention, you can stop problems like parts not lining up or dirt getting inside. Here are some important things to remember for taking care of your machine:

Check your machine often to keep out dirt and stop seals from breaking.

Cleaning your machine helps it stay cool.

Look at hoses often so they do not break suddenly.

Change the oil when you should so your pump lasts longer.

When you upgrade the right way, your machine works better and lasts longer. Be proud of your work and enjoy how well your machine runs!

FAQ

How do you know if your hydraulic pump needs an upgrade?

You may notice slow movement, weak digging, or hard controls. These signs mean your pump may not work well. If you see leaks or hear strange noises, check your pump soon.

Can you install a new hydraulic pump by yourself?

Yes, you can install a new pump if you follow the steps and use the right tools. Take your time and use safety gear. If you feel unsure, ask a mechanic for help.

What type of hydraulic pump should you choose?

Pick a pump that matches your excavator’s size and system. Check the flow rate and pressure. YNF Machinery offers pumps that fit many Chinese mini excavators and provide good support.

How often should you change hydraulic fluid after upgrading?

Change the hydraulic fluid every 2,000 to 4,000 hours. If you work in dusty or dirty places, change it more often. Clean fluid helps your new pump last longer.

Where can you buy a reliable hydraulic pump for your Chinese excavator?

You can buy a reliable pump from YNF Machinery. They offer quality pumps and helpful support for Chinese mini excavators. Always choose trusted suppliers for the best results.